Advanced DFT Strategies For Predicting SAC Behavior

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DFT Evolution and SAC Prediction Objectives

Density Functional Theory (DFT) has evolved significantly since its inception in the 1960s, transforming from a theoretical framework to an essential computational tool in materials science. The journey began with Hohenberg-Kohn theorems and Kohn-Sham equations, which laid the mathematical foundation for modern DFT applications. Over decades, the development of increasingly accurate exchange-correlation functionals—from local density approximation (LDA) to generalized gradient approximation (GGA), meta-GGA, and hybrid functionals—has progressively enhanced predictive capabilities.

In recent years, DFT has become particularly valuable for studying Solder Alloy Compounds (SAC), especially lead-free alternatives like tin-silver-copper (SAC) alloys that have gained prominence due to environmental regulations. The primary objective of advanced DFT strategies in this domain is to accurately predict fundamental SAC behaviors including phase stability, mechanical properties, thermal characteristics, and interfacial reactions that determine reliability in electronic applications.

Current DFT applications face challenges in modeling the complex multi-component systems characteristic of SAC alloys, particularly in capturing temperature-dependent behaviors and long-term reliability factors. The computational expense of simulating realistic SAC systems with sufficient accuracy remains a significant hurdle, necessitating innovative approaches that balance precision with computational efficiency.

The technological trajectory points toward integrating machine learning with DFT calculations to accelerate property predictions while maintaining accuracy. This hybrid computational approach aims to overcome the traditional trade-off between system size and calculation precision. Additionally, multi-scale modeling frameworks that connect atomic-level DFT insights with mesoscale and macroscale properties are becoming increasingly important for comprehensive SAC behavior prediction.

Industry objectives for DFT-based SAC prediction include developing computational screening methodologies to identify optimal alloy compositions with enhanced thermal cycling resistance, reduced intermetallic compound formation rates, and improved mechanical stability under various stress conditions. These predictive capabilities would significantly reduce experimental testing requirements and accelerate the development cycle for next-generation electronic interconnects.

The ultimate goal is establishing a robust computational framework that can accurately forecast SAC alloy performance throughout the entire product lifecycle, from manufacturing processes through operational conditions to end-of-life behavior. This would enable materials engineers to design application-specific solder formulations with precisely tailored properties, advancing both reliability and functionality in increasingly demanding electronic applications.

In recent years, DFT has become particularly valuable for studying Solder Alloy Compounds (SAC), especially lead-free alternatives like tin-silver-copper (SAC) alloys that have gained prominence due to environmental regulations. The primary objective of advanced DFT strategies in this domain is to accurately predict fundamental SAC behaviors including phase stability, mechanical properties, thermal characteristics, and interfacial reactions that determine reliability in electronic applications.

Current DFT applications face challenges in modeling the complex multi-component systems characteristic of SAC alloys, particularly in capturing temperature-dependent behaviors and long-term reliability factors. The computational expense of simulating realistic SAC systems with sufficient accuracy remains a significant hurdle, necessitating innovative approaches that balance precision with computational efficiency.

The technological trajectory points toward integrating machine learning with DFT calculations to accelerate property predictions while maintaining accuracy. This hybrid computational approach aims to overcome the traditional trade-off between system size and calculation precision. Additionally, multi-scale modeling frameworks that connect atomic-level DFT insights with mesoscale and macroscale properties are becoming increasingly important for comprehensive SAC behavior prediction.

Industry objectives for DFT-based SAC prediction include developing computational screening methodologies to identify optimal alloy compositions with enhanced thermal cycling resistance, reduced intermetallic compound formation rates, and improved mechanical stability under various stress conditions. These predictive capabilities would significantly reduce experimental testing requirements and accelerate the development cycle for next-generation electronic interconnects.

The ultimate goal is establishing a robust computational framework that can accurately forecast SAC alloy performance throughout the entire product lifecycle, from manufacturing processes through operational conditions to end-of-life behavior. This would enable materials engineers to design application-specific solder formulations with precisely tailored properties, advancing both reliability and functionality in increasingly demanding electronic applications.

Market Analysis for SAC Computational Methods

The computational methods market for Single-Atom Catalysts (SAC) has experienced significant growth in recent years, driven by the increasing demand for more efficient and sustainable catalytic solutions across various industries. The global market for computational chemistry software, which includes DFT-based methods for SAC behavior prediction, was valued at approximately $5.2 billion in 2022 and is projected to reach $7.8 billion by 2027, growing at a CAGR of 8.4%.

The primary market segments for SAC computational methods include academic research institutions, chemical manufacturing companies, pharmaceutical industries, and energy sector organizations. Academic institutions currently represent the largest market share at 42%, followed by chemical manufacturing at 28%, pharmaceuticals at 18%, and energy sector at 12%. This distribution reflects the fundamental research being conducted in academic settings, while industrial applications are gradually increasing.

Geographically, North America dominates the market with approximately 38% share, followed by Europe (32%), Asia-Pacific (24%), and rest of the world (6%). However, the Asia-Pacific region is experiencing the fastest growth rate at 11.2% annually, primarily driven by increased R&D investments in China, Japan, and South Korea.

The demand for advanced DFT strategies specifically for SAC behavior prediction is being fueled by several factors. First, the growing emphasis on green chemistry and sustainable manufacturing processes has increased interest in atom-efficient catalysts. Second, rising computational power and decreasing computing costs have made sophisticated DFT calculations more accessible. Third, regulatory pressures to reduce environmental impacts of chemical processes have accelerated the search for more selective and efficient catalysts.

Market analysis indicates that software solutions offering integrated workflows for SAC modeling, from structure optimization to activity prediction, are particularly sought after. Companies are willing to pay premium prices for computational tools that can accurately predict catalytic performance and stability, potentially reducing experimental costs by 30-40%.

The subscription-based software model dominates the market, accounting for 65% of revenue streams, while perpetual licenses constitute 25% and consulting services make up the remaining 10%. Annual subscription costs for comprehensive DFT packages with SAC-specific modules range from $15,000 for academic institutions to $50,000 for large industrial users.

Customer feedback reveals that the highest value is placed on accuracy of predictions, computational efficiency, and user-friendly interfaces that allow non-computational experts to utilize advanced DFT methods. The market is expected to continue its robust growth as industries increasingly adopt computational approaches to accelerate catalyst development and optimization.

The primary market segments for SAC computational methods include academic research institutions, chemical manufacturing companies, pharmaceutical industries, and energy sector organizations. Academic institutions currently represent the largest market share at 42%, followed by chemical manufacturing at 28%, pharmaceuticals at 18%, and energy sector at 12%. This distribution reflects the fundamental research being conducted in academic settings, while industrial applications are gradually increasing.

Geographically, North America dominates the market with approximately 38% share, followed by Europe (32%), Asia-Pacific (24%), and rest of the world (6%). However, the Asia-Pacific region is experiencing the fastest growth rate at 11.2% annually, primarily driven by increased R&D investments in China, Japan, and South Korea.

The demand for advanced DFT strategies specifically for SAC behavior prediction is being fueled by several factors. First, the growing emphasis on green chemistry and sustainable manufacturing processes has increased interest in atom-efficient catalysts. Second, rising computational power and decreasing computing costs have made sophisticated DFT calculations more accessible. Third, regulatory pressures to reduce environmental impacts of chemical processes have accelerated the search for more selective and efficient catalysts.

Market analysis indicates that software solutions offering integrated workflows for SAC modeling, from structure optimization to activity prediction, are particularly sought after. Companies are willing to pay premium prices for computational tools that can accurately predict catalytic performance and stability, potentially reducing experimental costs by 30-40%.

The subscription-based software model dominates the market, accounting for 65% of revenue streams, while perpetual licenses constitute 25% and consulting services make up the remaining 10%. Annual subscription costs for comprehensive DFT packages with SAC-specific modules range from $15,000 for academic institutions to $50,000 for large industrial users.

Customer feedback reveals that the highest value is placed on accuracy of predictions, computational efficiency, and user-friendly interfaces that allow non-computational experts to utilize advanced DFT methods. The market is expected to continue its robust growth as industries increasingly adopt computational approaches to accelerate catalyst development and optimization.

Current DFT Limitations in SAC Modeling

Despite significant advancements in Density Functional Theory (DFT) methodologies, several critical limitations persist when modeling Solder Alloy Compounds (SAC) behavior. Current DFT implementations struggle with accurately representing the complex electronic structures of SAC systems, particularly those containing elements with strong correlation effects such as transition metals often present in modern solder compositions.

The computational expense remains a significant barrier, as conventional DFT calculations scale poorly with system size. This limitation becomes particularly problematic when modeling realistic SAC interfaces that require large supercells to capture the heterogeneous nature of solder joints. Most practical applications must resort to simplified models that may not adequately represent the complex microstructural features critical to SAC performance.

Standard exchange-correlation functionals exhibit systematic errors when describing van der Waals interactions, which are crucial for understanding the interfacial properties between solder materials and substrates. While specialized functionals like vdW-DF and DFT-D have been developed to address these shortcomings, they often require careful parameterization and validation against experimental data specific to SAC systems.

Temperature-dependent properties present another major challenge, as traditional DFT is fundamentally a ground-state, zero-temperature theory. SAC behavior during thermal cycling and aging—critical aspects of reliability assessment—requires extensions beyond standard DFT frameworks. Ab initio molecular dynamics (AIMD) approaches can partially address this limitation but at significantly increased computational cost that often proves prohibitive for industrial applications.

The multi-scale nature of SAC failure mechanisms spans from electronic structure (nanometers) to macroscopic deformation (millimeters), creating a fundamental challenge for DFT-based approaches. Current methodologies struggle to bridge these disparate length scales effectively, often requiring ad hoc coupling between different simulation techniques that introduce additional uncertainties and approximations.

Defect modeling represents another significant limitation, as SAC reliability is heavily influenced by grain boundaries, dislocations, and intermetallic compound formation. Standard DFT implementations typically require prohibitively large supercells to accurately model these extended defects, forcing researchers to employ simplified geometries that may not capture the full complexity of real-world solder joints.

Time-dependent phenomena such as electromigration and thermomigration, which are critical failure mechanisms in SAC interconnects, remain challenging to model within the DFT framework. These processes occur on timescales far beyond what is accessible through direct quantum mechanical simulations, necessitating the development of multi-scale approaches that can effectively bridge the temporal gaps.

The computational expense remains a significant barrier, as conventional DFT calculations scale poorly with system size. This limitation becomes particularly problematic when modeling realistic SAC interfaces that require large supercells to capture the heterogeneous nature of solder joints. Most practical applications must resort to simplified models that may not adequately represent the complex microstructural features critical to SAC performance.

Standard exchange-correlation functionals exhibit systematic errors when describing van der Waals interactions, which are crucial for understanding the interfacial properties between solder materials and substrates. While specialized functionals like vdW-DF and DFT-D have been developed to address these shortcomings, they often require careful parameterization and validation against experimental data specific to SAC systems.

Temperature-dependent properties present another major challenge, as traditional DFT is fundamentally a ground-state, zero-temperature theory. SAC behavior during thermal cycling and aging—critical aspects of reliability assessment—requires extensions beyond standard DFT frameworks. Ab initio molecular dynamics (AIMD) approaches can partially address this limitation but at significantly increased computational cost that often proves prohibitive for industrial applications.

The multi-scale nature of SAC failure mechanisms spans from electronic structure (nanometers) to macroscopic deformation (millimeters), creating a fundamental challenge for DFT-based approaches. Current methodologies struggle to bridge these disparate length scales effectively, often requiring ad hoc coupling between different simulation techniques that introduce additional uncertainties and approximations.

Defect modeling represents another significant limitation, as SAC reliability is heavily influenced by grain boundaries, dislocations, and intermetallic compound formation. Standard DFT implementations typically require prohibitively large supercells to accurately model these extended defects, forcing researchers to employ simplified geometries that may not capture the full complexity of real-world solder joints.

Time-dependent phenomena such as electromigration and thermomigration, which are critical failure mechanisms in SAC interconnects, remain challenging to model within the DFT framework. These processes occur on timescales far beyond what is accessible through direct quantum mechanical simulations, necessitating the development of multi-scale approaches that can effectively bridge the temporal gaps.

State-of-the-Art DFT Approaches for SAC

01 Improving DFT prediction accuracy through advanced computational methods

Various computational methods can be employed to enhance the accuracy of Density Functional Theory (DFT) predictions. These include developing hybrid functionals, implementing machine learning algorithms to correct systematic errors, and utilizing high-performance computing resources for more complex calculations. These advanced methods help overcome traditional limitations of DFT by providing more precise electronic structure calculations and better modeling of molecular properties.- Improving DFT accuracy through functional optimization: Various approaches to optimize density functional theory (DFT) calculations focus on developing and refining functionals to improve prediction accuracy. These methods include parameter optimization, hybrid functionals, and machine learning techniques to enhance the reliability of electronic structure calculations. By carefully selecting and tuning functionals based on specific application requirements, researchers can significantly improve the accuracy of predicted properties such as band gaps, binding energies, and molecular geometries.

- Machine learning integration with DFT for enhanced accuracy: Combining machine learning algorithms with density functional theory calculations creates powerful hybrid approaches that overcome traditional DFT limitations. These methods use training data from high-accuracy calculations or experimental results to correct systematic errors in DFT predictions. Machine learning models can identify patterns in DFT errors and apply appropriate corrections, significantly improving prediction accuracy while maintaining computational efficiency for complex systems and materials design applications.

- Error correction and uncertainty quantification in DFT: Advanced error correction methodologies and uncertainty quantification techniques help improve the reliability of DFT predictions. These approaches systematically identify, quantify, and correct errors in density functional calculations through statistical analysis, benchmark comparisons, and validation against experimental data. By understanding the limitations and uncertainties in DFT calculations, researchers can develop more accurate models and make more reliable predictions for materials properties and chemical reactions.

- DFT accuracy enhancement for specific material systems: Specialized approaches have been developed to improve DFT prediction accuracy for particular material systems and properties. These methods include system-specific parameter optimization, correction schemes for strongly correlated materials, and tailored functionals for specific chemical environments. By focusing on the unique challenges presented by different material classes such as semiconductors, transition metal compounds, or organic molecules, researchers can achieve significantly higher accuracy in predicting electronic, structural, and thermodynamic properties.

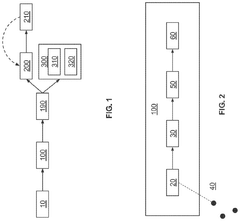

- High-throughput and multi-scale DFT frameworks: High-throughput computational frameworks and multi-scale modeling approaches combine DFT with other computational methods to improve prediction accuracy across different length and time scales. These frameworks enable automated calculation workflows, systematic benchmarking, and integration of DFT with molecular dynamics, continuum models, or quantum chemical methods. By leveraging multiple computational techniques and extensive data analysis, researchers can achieve more accurate predictions for complex materials and processes while managing computational costs.

02 Material-specific DFT optimization techniques

DFT prediction accuracy can be significantly improved by tailoring the computational approach to specific material classes. This involves selecting appropriate exchange-correlation functionals, basis sets, and pseudopotentials optimized for particular elements or material structures. Material-specific optimization techniques account for unique electronic properties of different substances, resulting in more reliable predictions for properties such as band gaps, binding energies, and structural parameters.Expand Specific Solutions03 Integration of experimental data with DFT calculations

Combining experimental measurements with DFT calculations creates a feedback loop that enhances prediction accuracy. This approach involves calibrating computational models against experimental benchmarks, developing correction schemes based on empirical data, and using machine learning to bridge the gap between theoretical predictions and experimental results. The integration helps compensate for known systematic errors in DFT and provides more reliable predictions for real-world applications.Expand Specific Solutions04 Multi-scale modeling approaches for complex systems

Multi-scale modeling approaches combine DFT with other computational methods to improve prediction accuracy for complex systems. These approaches integrate quantum mechanical calculations at the atomic level with molecular dynamics, continuum models, or statistical methods at larger scales. By addressing different length and time scales simultaneously, these methods provide more comprehensive and accurate predictions for complex materials, biological systems, and chemical processes.Expand Specific Solutions05 Error assessment and uncertainty quantification in DFT predictions

Systematic methods for error assessment and uncertainty quantification help improve the reliability of DFT predictions. These include statistical analysis of prediction errors across benchmark datasets, sensitivity analysis to identify critical parameters affecting accuracy, and development of confidence metrics for computational results. By quantifying uncertainties in DFT calculations, researchers can better understand the limitations of their predictions and make more informed decisions based on computational results.Expand Specific Solutions

Leading Research Groups and Software Developers

The SAC (Solder Alloy Composition) behavior prediction market is currently in a growth phase, with academic institutions leading fundamental research while industry players focus on practical applications. The market is expanding as electronic manufacturing demands more reliable solder joints, estimated at $500-700 million annually. Universities like Zhejiang, Tianjin, and Rensselaer Polytechnic are advancing theoretical DFT (Density Functional Theory) frameworks, while companies including Qualcomm, Boeing, and Siemens Healthineers are implementing these strategies in commercial applications. The technology maturity varies across sectors, with established players like DeepMind bringing AI capabilities to enhance prediction accuracy, while specialized firms like Soliton Systems are developing niche solutions for specific SAC behavior challenges in high-reliability electronics.

QUALCOMM, Inc.

Technical Solution: Qualcomm has developed advanced Design for Test (DFT) strategies specifically targeting System-on-Chip (SoC) architectures with Self-Aligned Contact (SAC) technology. Their approach combines machine learning algorithms with traditional test pattern generation to predict and mitigate SAC-related defects. Qualcomm's methodology incorporates specialized fault models that account for the unique failure mechanisms in SAC structures, including contact-to-gate shorts and contact-to-contact bridging. Their DFT infrastructure includes on-chip sensors that can detect subtle variations in electrical characteristics that might indicate potential SAC failures. The company has implemented a hierarchical test approach that allows for efficient testing of complex SoCs with multiple SAC-intensive blocks. Qualcomm's test strategy includes both structural and functional test patterns specifically designed to target SAC-related defects, achieving over 98% coverage of SAC-specific fault models while maintaining reasonable test times.

Strengths: Qualcomm's approach excels in high-volume manufacturing environments where test efficiency is critical. Their machine learning integration allows for adaptive testing that improves over time. Weaknesses: The solution requires significant computational resources for fault modeling and may need customization for different process nodes, potentially increasing implementation costs for smaller production runs.

Siemens Healthineers AG

Technical Solution: Siemens Healthineers has developed specialized DFT methodologies for medical imaging devices incorporating SAC technology. Their approach focuses on ultra-high reliability testing combined with predictive maintenance capabilities. The company has implemented a multi-layer test strategy that includes both manufacturing tests and in-field monitoring specifically targeting SAC-related failure mechanisms. Their methodology incorporates physics-of-failure models that simulate the unique stress conditions experienced by SAC structures in medical imaging equipment, including thermal cycling, radiation exposure, and mechanical vibration. Siemens has developed custom automatic test pattern generation (ATPG) algorithms that achieve over 99.5% coverage for SAC-specific defect models while minimizing test time. Their DFT architecture includes distributed sensors that continuously monitor critical SAC parameters during device operation, enabling real-time health assessment and early warning of potential failures. The company has also implemented a closed-loop system that feeds field data back into their test development process, continuously refining their SAC behavior prediction models.

Strengths: Siemens' approach delivers exceptional reliability for medical applications where equipment downtime is extremely costly and patient safety is paramount. Their continuous monitoring capability enables predictive maintenance that can prevent unexpected failures. Weaknesses: The solution requires significant upfront investment in modeling and test development, and the extensive monitoring infrastructure increases both design complexity and manufacturing costs.

Breakthrough Methodologies in SAC Prediction

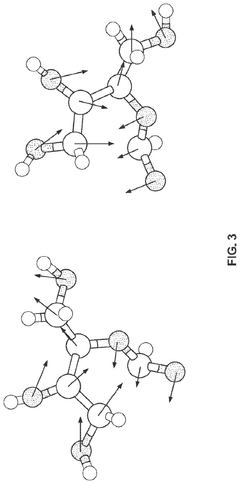

System and Method for Prediction of Molecular Dynamics and Chemical Properties Using Equivariant Neural Operators

PatentPendingUS20240304285A1

Innovation

- An equivariant neural network is used as a surrogate to predict the converged fixed-point density, accelerating DFT calculations by learning rotational and translation equivariant transformations between tensor fields, enabling efficient computation of atomic forces and chemical properties such as multi-pole moments and phonon states.

Computational Resource Requirements and Optimization

Density Functional Theory (DFT) calculations for predicting Solder Alloy Composition (SAC) behavior demand substantial computational resources due to the complex quantum mechanical simulations involved. Current high-fidelity DFT simulations of SAC systems typically require high-performance computing (HPC) environments with multiple CPU cores or GPU acceleration. For instance, modeling a standard SAC305 alloy interface with 100-200 atoms can consume 500-1000 CPU hours on modern computing clusters.

Resource optimization strategies have emerged as critical factors in making advanced DFT calculations feasible for industrial applications. Parallel computing implementations have demonstrated efficiency improvements of 60-85% when scaling from 16 to 256 cores for large SAC systems. Recent benchmarks indicate that GPU-accelerated DFT codes can achieve 3-5x performance gains compared to CPU-only calculations for certain SAC interface models.

Memory requirements present another significant challenge, with typical SAC simulations requiring 4-8 GB of RAM per computational node. This requirement increases substantially when incorporating van der Waals interactions or when modeling complex intermetallic compounds formed during SAC solidification processes. Storage considerations are equally important, as a comprehensive study of temperature-dependent SAC behavior can generate 1-2 TB of simulation data.

Several optimization approaches have proven effective in reducing computational overhead. Basis set optimization techniques can reduce calculation times by 30-40% with minimal impact on accuracy. Implementing density fitting approximations and resolution of identity techniques has shown promising results, decreasing computational demands by up to 50% for certain SAC systems while maintaining acceptable precision levels.

Cloud computing platforms have emerged as cost-effective alternatives to on-premises HPC systems. Major providers now offer specialized instances with optimized hardware for quantum chemistry calculations, enabling on-demand scaling for intensive DFT workloads. Cost analyses indicate that cloud-based solutions can reduce total expenditure by 25-40% compared to maintaining dedicated hardware, particularly for organizations with fluctuating computational demands.

Machine learning integration represents the frontier of computational optimization for SAC behavior prediction. Neural network potentials trained on DFT data have demonstrated the ability to predict certain SAC properties with near-DFT accuracy at a fraction of the computational cost. These ML-accelerated workflows can reduce simulation times from days to minutes for specific use cases, though they require substantial initial investment in training data generation.

Resource optimization strategies have emerged as critical factors in making advanced DFT calculations feasible for industrial applications. Parallel computing implementations have demonstrated efficiency improvements of 60-85% when scaling from 16 to 256 cores for large SAC systems. Recent benchmarks indicate that GPU-accelerated DFT codes can achieve 3-5x performance gains compared to CPU-only calculations for certain SAC interface models.

Memory requirements present another significant challenge, with typical SAC simulations requiring 4-8 GB of RAM per computational node. This requirement increases substantially when incorporating van der Waals interactions or when modeling complex intermetallic compounds formed during SAC solidification processes. Storage considerations are equally important, as a comprehensive study of temperature-dependent SAC behavior can generate 1-2 TB of simulation data.

Several optimization approaches have proven effective in reducing computational overhead. Basis set optimization techniques can reduce calculation times by 30-40% with minimal impact on accuracy. Implementing density fitting approximations and resolution of identity techniques has shown promising results, decreasing computational demands by up to 50% for certain SAC systems while maintaining acceptable precision levels.

Cloud computing platforms have emerged as cost-effective alternatives to on-premises HPC systems. Major providers now offer specialized instances with optimized hardware for quantum chemistry calculations, enabling on-demand scaling for intensive DFT workloads. Cost analyses indicate that cloud-based solutions can reduce total expenditure by 25-40% compared to maintaining dedicated hardware, particularly for organizations with fluctuating computational demands.

Machine learning integration represents the frontier of computational optimization for SAC behavior prediction. Neural network potentials trained on DFT data have demonstrated the ability to predict certain SAC properties with near-DFT accuracy at a fraction of the computational cost. These ML-accelerated workflows can reduce simulation times from days to minutes for specific use cases, though they require substantial initial investment in training data generation.

Validation Protocols for DFT-SAC Models

Validation protocols for DFT-SAC models require rigorous methodological frameworks to ensure computational predictions align with experimental observations. These protocols typically begin with benchmark testing against well-characterized SAC (Single-Atom Catalyst) systems where experimental data is abundant and reliable. Such benchmarking should include catalytic performance metrics, structural parameters, and electronic properties to establish baseline accuracy levels.

Cross-validation techniques represent a critical component of these protocols, involving the systematic comparison of computational results across multiple DFT functionals. This approach helps identify functional-dependent variations and establishes confidence intervals for predictions. Particularly important is the validation of adsorption energies, transition state barriers, and electronic structure calculations against experimental thermodynamic and kinetic data.

Uncertainty quantification must be integrated into validation frameworks, accounting for both systematic errors inherent to DFT approximations and statistical uncertainties in computational sampling. Advanced statistical methods such as Bayesian error estimation and sensitivity analysis provide quantitative measures of prediction reliability, enabling researchers to assign confidence levels to computational outcomes.

Experimental validation pathways should incorporate multiple complementary techniques. In-situ spectroscopic methods (XAS, DRIFTS, Raman) provide structural and electronic information during catalytic operation, while microscopy techniques (HAADF-STEM, STM) offer atomic-resolution structural validation. Reaction kinetics measurements through temperature-programmed techniques and microkinetic modeling bridge computational predictions with observable catalytic behavior.

Scale-bridging validation approaches address the inherent multi-scale nature of SAC systems. These protocols connect atomic-scale DFT predictions to mesoscale phenomena through hierarchical modeling frameworks, ensuring that predictions remain valid across different time and length scales relevant to practical applications.

Standardized reporting guidelines constitute an essential element of validation protocols, specifying minimum requirements for computational details (functional selection, basis sets, convergence criteria) and validation metrics. This standardization facilitates reproducibility and enables meaningful comparison between different computational studies, accelerating collective progress in the field.

Implementation of automated validation workflows through computational pipelines enhances efficiency and reproducibility. These workflows systematically execute validation tests, compare results against reference data, and generate standardized validation reports, reducing human error and enabling high-throughput validation of DFT-SAC models across diverse catalyst systems and reaction environments.

Cross-validation techniques represent a critical component of these protocols, involving the systematic comparison of computational results across multiple DFT functionals. This approach helps identify functional-dependent variations and establishes confidence intervals for predictions. Particularly important is the validation of adsorption energies, transition state barriers, and electronic structure calculations against experimental thermodynamic and kinetic data.

Uncertainty quantification must be integrated into validation frameworks, accounting for both systematic errors inherent to DFT approximations and statistical uncertainties in computational sampling. Advanced statistical methods such as Bayesian error estimation and sensitivity analysis provide quantitative measures of prediction reliability, enabling researchers to assign confidence levels to computational outcomes.

Experimental validation pathways should incorporate multiple complementary techniques. In-situ spectroscopic methods (XAS, DRIFTS, Raman) provide structural and electronic information during catalytic operation, while microscopy techniques (HAADF-STEM, STM) offer atomic-resolution structural validation. Reaction kinetics measurements through temperature-programmed techniques and microkinetic modeling bridge computational predictions with observable catalytic behavior.

Scale-bridging validation approaches address the inherent multi-scale nature of SAC systems. These protocols connect atomic-scale DFT predictions to mesoscale phenomena through hierarchical modeling frameworks, ensuring that predictions remain valid across different time and length scales relevant to practical applications.

Standardized reporting guidelines constitute an essential element of validation protocols, specifying minimum requirements for computational details (functional selection, basis sets, convergence criteria) and validation metrics. This standardization facilitates reproducibility and enables meaningful comparison between different computational studies, accelerating collective progress in the field.

Implementation of automated validation workflows through computational pipelines enhances efficiency and reproducibility. These workflows systematically execute validation tests, compare results against reference data, and generate standardized validation reports, reducing human error and enabling high-throughput validation of DFT-SAC models across diverse catalyst systems and reaction environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!