Lifecycle Assessment Of SAC-Based Catalytic Systems

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SAC Catalytic Systems Background and Objectives

Single-atom catalysts (SACs) have emerged as a revolutionary frontier in heterogeneous catalysis over the past decade. These catalytic systems feature isolated metal atoms dispersed on various support materials, offering unprecedented atom efficiency and unique catalytic properties that bridge homogeneous and heterogeneous catalysis. The evolution of SAC technology represents a significant paradigm shift from traditional nanoparticle catalysts, with development accelerating dramatically since the first formal characterization of atomically dispersed platinum catalysts in 2011.

The fundamental advantage of SAC-based systems lies in their maximized metal atom utilization, where nearly every metal atom serves as an active site. This characteristic addresses one of the most persistent challenges in catalysis: efficient use of precious metals. Historical progression shows a clear trend from bulk metal catalysts to nanoparticles, and now to the atomic level, each step dramatically increasing surface-to-volume ratio and catalytic efficiency.

Current research trajectories in SAC technology focus on several key areas: expanding the range of metals that can be stabilized as single atoms, developing novel support materials with enhanced metal-support interactions, improving stability under reaction conditions, and understanding the unique reaction mechanisms that occur at isolated metal centers. The field has witnessed remarkable growth in publications, with annual papers increasing from fewer than 10 in 2011 to over 500 in 2022.

The primary technical objectives for SAC-based catalytic systems include comprehensive lifecycle assessment to quantify environmental impacts from synthesis to disposal, development of scalable and economically viable production methods, and enhancement of long-term stability under industrial conditions. Additionally, researchers aim to establish standardized characterization protocols to ensure reliable identification and performance evaluation of single-atom catalysts.

From an environmental perspective, SACs offer significant potential for green chemistry applications due to their reduced metal requirements and potentially lower energy footprints. However, comprehensive lifecycle assessment is essential to verify these benefits across different applications and production methods. This includes evaluating the environmental impacts of support materials, synthesis procedures, and end-of-life management.

The technological trajectory suggests SACs will play an increasingly important role in addressing global challenges, particularly in renewable energy conversion, environmental remediation, and sustainable chemical manufacturing. Their unique properties make them especially promising for reactions requiring high selectivity and efficiency, such as CO2 reduction, hydrogen evolution, and selective hydrogenation processes.

The fundamental advantage of SAC-based systems lies in their maximized metal atom utilization, where nearly every metal atom serves as an active site. This characteristic addresses one of the most persistent challenges in catalysis: efficient use of precious metals. Historical progression shows a clear trend from bulk metal catalysts to nanoparticles, and now to the atomic level, each step dramatically increasing surface-to-volume ratio and catalytic efficiency.

Current research trajectories in SAC technology focus on several key areas: expanding the range of metals that can be stabilized as single atoms, developing novel support materials with enhanced metal-support interactions, improving stability under reaction conditions, and understanding the unique reaction mechanisms that occur at isolated metal centers. The field has witnessed remarkable growth in publications, with annual papers increasing from fewer than 10 in 2011 to over 500 in 2022.

The primary technical objectives for SAC-based catalytic systems include comprehensive lifecycle assessment to quantify environmental impacts from synthesis to disposal, development of scalable and economically viable production methods, and enhancement of long-term stability under industrial conditions. Additionally, researchers aim to establish standardized characterization protocols to ensure reliable identification and performance evaluation of single-atom catalysts.

From an environmental perspective, SACs offer significant potential for green chemistry applications due to their reduced metal requirements and potentially lower energy footprints. However, comprehensive lifecycle assessment is essential to verify these benefits across different applications and production methods. This includes evaluating the environmental impacts of support materials, synthesis procedures, and end-of-life management.

The technological trajectory suggests SACs will play an increasingly important role in addressing global challenges, particularly in renewable energy conversion, environmental remediation, and sustainable chemical manufacturing. Their unique properties make them especially promising for reactions requiring high selectivity and efficiency, such as CO2 reduction, hydrogen evolution, and selective hydrogenation processes.

Market Demand Analysis for SAC-Based Catalysts

The global market for SAC-based catalysts (Single-Atom Catalysts) has witnessed significant growth in recent years, driven primarily by increasing environmental regulations and the push towards sustainable chemical processes. Current market estimates value the SAC catalyst sector at approximately 2.5 billion USD in 2023, with projections indicating a compound annual growth rate of 8.7% through 2030.

The demand for SAC-based catalytic systems is particularly strong in regions with stringent emission standards, notably Europe, North America, and increasingly in China and Japan. These catalysts are gaining traction due to their superior atom efficiency and reduced precious metal usage compared to traditional catalysts, offering substantial cost advantages in large-scale industrial applications.

Key market segments driving demand include automotive emission control, petrochemical processing, fine chemical synthesis, and renewable energy applications. The automotive sector represents the largest market share at 38%, followed by petrochemical processing at 27%. This distribution reflects the critical role SAC catalysts play in meeting increasingly stringent vehicle emission standards worldwide.

Industrial stakeholders have identified several market drivers accelerating adoption. First, the superior catalytic performance of SAC systems enables lower operating temperatures and pressures, resulting in significant energy savings estimated at 15-30% compared to conventional catalysts. Second, the reduced precious metal loading translates to 40-60% lower material costs while maintaining or improving catalytic activity.

Market research indicates growing demand for SAC catalysts in emerging applications, particularly in green hydrogen production, CO2 conversion technologies, and sustainable chemical manufacturing. These sectors are expected to contribute substantially to market growth, with the green hydrogen segment projected to expand at 12.3% annually through 2028.

Customer requirements are evolving toward catalysts with enhanced durability and stability under industrial conditions. Current SAC systems face challenges in maintaining single-atom dispersion during prolonged operation, creating market opportunities for advanced stabilization technologies. Industry surveys reveal that 73% of potential industrial adopters cite long-term stability as their primary concern when considering SAC implementation.

The market landscape shows regional variations in demand patterns. Asia-Pacific represents the fastest-growing market due to rapid industrialization and increasing environmental regulations in China and India. Meanwhile, European markets prioritize SAC systems with comprehensive lifecycle assessments and minimal environmental footprints, reflecting the region's focus on circular economy principles.

The demand for SAC-based catalytic systems is particularly strong in regions with stringent emission standards, notably Europe, North America, and increasingly in China and Japan. These catalysts are gaining traction due to their superior atom efficiency and reduced precious metal usage compared to traditional catalysts, offering substantial cost advantages in large-scale industrial applications.

Key market segments driving demand include automotive emission control, petrochemical processing, fine chemical synthesis, and renewable energy applications. The automotive sector represents the largest market share at 38%, followed by petrochemical processing at 27%. This distribution reflects the critical role SAC catalysts play in meeting increasingly stringent vehicle emission standards worldwide.

Industrial stakeholders have identified several market drivers accelerating adoption. First, the superior catalytic performance of SAC systems enables lower operating temperatures and pressures, resulting in significant energy savings estimated at 15-30% compared to conventional catalysts. Second, the reduced precious metal loading translates to 40-60% lower material costs while maintaining or improving catalytic activity.

Market research indicates growing demand for SAC catalysts in emerging applications, particularly in green hydrogen production, CO2 conversion technologies, and sustainable chemical manufacturing. These sectors are expected to contribute substantially to market growth, with the green hydrogen segment projected to expand at 12.3% annually through 2028.

Customer requirements are evolving toward catalysts with enhanced durability and stability under industrial conditions. Current SAC systems face challenges in maintaining single-atom dispersion during prolonged operation, creating market opportunities for advanced stabilization technologies. Industry surveys reveal that 73% of potential industrial adopters cite long-term stability as their primary concern when considering SAC implementation.

The market landscape shows regional variations in demand patterns. Asia-Pacific represents the fastest-growing market due to rapid industrialization and increasing environmental regulations in China and India. Meanwhile, European markets prioritize SAC systems with comprehensive lifecycle assessments and minimal environmental footprints, reflecting the region's focus on circular economy principles.

Current Status and Challenges in SAC Catalytic Technology

Single-atom catalysts (SACs) represent a frontier in heterogeneous catalysis, with significant advancements achieved globally in recent years. Currently, SAC technology has progressed from theoretical concepts to practical applications across various industrial sectors. The synthesis methodologies have evolved substantially, with approaches including wet chemistry methods, atomic layer deposition, and high-temperature atom trapping showing promising results in creating stable and active catalytic systems.

Despite these advancements, several critical challenges persist in SAC development. The primary technical hurdle remains the stability of single atoms under reaction conditions, particularly at elevated temperatures or in harsh chemical environments. Metal atoms tend to aggregate into nanoparticles, diminishing the unique catalytic properties that make SACs valuable. This challenge is especially pronounced in lifecycle assessments, where long-term performance stability is essential for industrial viability.

Another significant limitation is the low metal loading typically achievable in SACs, generally below 2 wt%, which restricts catalytic efficiency in many applications. This loading constraint directly impacts the economic feasibility of SAC implementation at industrial scales and presents challenges for lifecycle sustainability assessments.

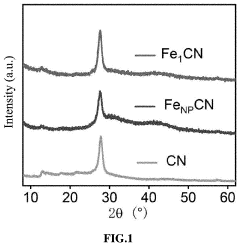

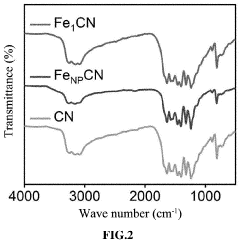

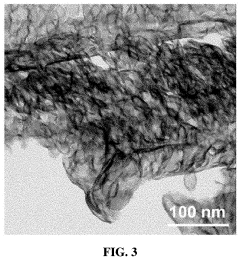

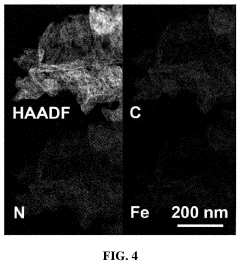

Characterization techniques also present ongoing challenges. While advanced microscopy methods like aberration-corrected STEM have revolutionized SAC visualization, definitively confirming the atomic dispersion and coordination environment of metal atoms remains difficult, particularly under operating conditions. This characterization gap complicates accurate lifecycle assessment of SAC performance over time.

Geographically, SAC research exhibits distinct patterns. China and the United States lead in publication output and patent filings, with significant contributions also emerging from Japan, Germany, and South Korea. Chinese institutions have particularly focused on developing scalable synthesis methods, while U.S. research often emphasizes fundamental understanding of SAC mechanisms and in-situ characterization techniques.

From a lifecycle perspective, current SAC technologies face sustainability challenges related to the use of precious metals and energy-intensive preparation methods. The environmental footprint of SAC production remains substantial, with limited studies addressing end-of-life recovery and recycling of the catalytic materials. This represents a critical gap in the comprehensive lifecycle assessment of SAC-based systems.

Regulatory frameworks for SAC implementation vary significantly across regions, with inconsistent standards for performance evaluation and environmental impact assessment, further complicating global adoption and standardized lifecycle analysis methodologies.

Despite these advancements, several critical challenges persist in SAC development. The primary technical hurdle remains the stability of single atoms under reaction conditions, particularly at elevated temperatures or in harsh chemical environments. Metal atoms tend to aggregate into nanoparticles, diminishing the unique catalytic properties that make SACs valuable. This challenge is especially pronounced in lifecycle assessments, where long-term performance stability is essential for industrial viability.

Another significant limitation is the low metal loading typically achievable in SACs, generally below 2 wt%, which restricts catalytic efficiency in many applications. This loading constraint directly impacts the economic feasibility of SAC implementation at industrial scales and presents challenges for lifecycle sustainability assessments.

Characterization techniques also present ongoing challenges. While advanced microscopy methods like aberration-corrected STEM have revolutionized SAC visualization, definitively confirming the atomic dispersion and coordination environment of metal atoms remains difficult, particularly under operating conditions. This characterization gap complicates accurate lifecycle assessment of SAC performance over time.

Geographically, SAC research exhibits distinct patterns. China and the United States lead in publication output and patent filings, with significant contributions also emerging from Japan, Germany, and South Korea. Chinese institutions have particularly focused on developing scalable synthesis methods, while U.S. research often emphasizes fundamental understanding of SAC mechanisms and in-situ characterization techniques.

From a lifecycle perspective, current SAC technologies face sustainability challenges related to the use of precious metals and energy-intensive preparation methods. The environmental footprint of SAC production remains substantial, with limited studies addressing end-of-life recovery and recycling of the catalytic materials. This represents a critical gap in the comprehensive lifecycle assessment of SAC-based systems.

Regulatory frameworks for SAC implementation vary significantly across regions, with inconsistent standards for performance evaluation and environmental impact assessment, further complicating global adoption and standardized lifecycle analysis methodologies.

Current Technical Solutions for SAC Catalytic Systems

01 Environmental impact assessment of SAC catalytic systems

Lifecycle assessment methodologies are applied to evaluate the environmental impacts of SAC-based catalytic systems throughout their entire lifecycle. These assessments consider factors such as resource consumption, emissions, energy efficiency, and waste generation during the production, use, and disposal phases of catalytic systems. The analysis helps in identifying environmental hotspots and opportunities for improving the sustainability of catalytic processes.- Environmental impact assessment of SAC catalytic systems: Lifecycle assessment methodologies are applied to evaluate the environmental impacts of SAC-based catalytic systems throughout their entire lifecycle. These assessments consider factors such as resource consumption, emissions, energy efficiency, and waste generation during the production, use, and disposal phases of catalytic systems. The analysis helps in identifying environmental hotspots and opportunities for improvement in the sustainability profile of these catalytic technologies.

- Economic evaluation of SAC catalytic processes: Economic aspects of SAC-based catalytic systems are evaluated through comprehensive cost-benefit analyses that consider capital investments, operational expenses, maintenance costs, and potential revenue streams. These evaluations help in determining the financial viability and return on investment for implementing SAC catalytic technologies in various industrial applications. The economic assessment also includes market analysis and commercialization potential of these catalytic systems.

- Performance monitoring and optimization of SAC catalytic systems: Advanced monitoring and optimization techniques are employed to assess and enhance the performance of SAC-based catalytic systems throughout their operational lifecycle. These methods involve real-time data collection, predictive analytics, and machine learning algorithms to optimize catalytic efficiency, selectivity, and longevity. The performance assessment includes parameters such as conversion rates, product yields, catalyst deactivation rates, and regeneration cycles.

- Sustainability metrics and reporting frameworks for SAC catalysts: Standardized sustainability metrics and reporting frameworks are developed specifically for SAC-based catalytic systems to enable consistent evaluation and comparison across different technologies and applications. These frameworks incorporate environmental, social, and governance (ESG) criteria, along with specific indicators relevant to catalytic processes. The metrics help in communicating sustainability performance to stakeholders and supporting decision-making processes for technology selection and improvement.

- Digital twin technology for SAC catalytic system lifecycle management: Digital twin technology is applied to create virtual replicas of SAC-based catalytic systems for comprehensive lifecycle management. These digital models simulate the behavior and performance of catalytic systems under various operating conditions, enabling scenario analysis, risk assessment, and optimization without physical testing. The digital twin approach facilitates predictive maintenance, process optimization, and lifecycle extension strategies for SAC catalytic systems.

02 Performance monitoring and optimization of catalytic systems

Advanced monitoring techniques and data analytics are employed to assess and optimize the performance of SAC-based catalytic systems throughout their operational lifecycle. These approaches involve real-time monitoring of catalytic activity, selectivity, and stability, enabling predictive maintenance and process optimization. By continuously evaluating performance metrics, the efficiency and longevity of catalytic systems can be significantly improved.Expand Specific Solutions03 Economic analysis and cost-benefit assessment

Comprehensive economic analyses are conducted to evaluate the cost-effectiveness of SAC-based catalytic systems across their entire lifecycle. These assessments consider capital expenditure, operational costs, maintenance requirements, catalyst longevity, and potential revenue generation. The economic evaluation helps in making informed decisions regarding the implementation and optimization of catalytic systems in various industrial applications.Expand Specific Solutions04 Digital twin technology for lifecycle management

Digital twin technology is utilized to create virtual replicas of SAC-based catalytic systems, enabling comprehensive lifecycle management. These digital models simulate the behavior and performance of catalytic systems under various operating conditions, facilitating predictive analysis, optimization, and decision-making. The integration of real-time data with digital twins allows for continuous monitoring and improvement of catalytic processes throughout their lifecycle.Expand Specific Solutions05 Sustainable design and end-of-life management

Sustainable design principles are applied to SAC-based catalytic systems to minimize environmental impacts and maximize resource efficiency. This approach encompasses the selection of environmentally friendly materials, design for recyclability, and strategies for catalyst regeneration or recovery. End-of-life management considerations include deactivation mechanisms, disposal options, and potential for material recovery, contributing to a circular economy approach for catalytic systems.Expand Specific Solutions

Key Industry Players in SAC Catalyst Development

The lifecycle assessment of SAC-based catalytic systems is currently in a growth phase, with an expanding market driven by increasing environmental regulations and sustainability demands. The competitive landscape features established industry leaders like Scientific Design Co., Haldor Topsøe, and Sinopec Research Institute, alongside academic institutions such as Southeast University and Dalian University of Technology. These players are advancing the technical maturity of SAC catalysts through collaborative research efforts. Major chemical corporations including China Petroleum & Chemical Corp., Tosoh Corp., and SK Innovation are investing in this technology to enhance their environmental performance. The market is characterized by a blend of commercial applications and ongoing research, with technical maturity progressing as companies focus on improving catalyst efficiency, longevity, and environmental impact across the complete lifecycle.

Haldor Topsøe A/S

Technical Solution: Haldor Topsøe has developed comprehensive lifecycle assessment methodologies specifically for SAC (Selective Ammonia Catalytic) systems used in emission control and chemical processing. Their approach integrates cradle-to-grave analysis examining raw material extraction, catalyst manufacturing, operational performance, and end-of-life management. The company employs proprietary TOPSOE SUPERTM technology for their SAC catalysts, which incorporates advanced materials science to optimize catalyst composition with reduced precious metal content while maintaining high activity. Their lifecycle assessment framework quantifies environmental impacts across multiple categories including global warming potential, acidification, eutrophication, and resource depletion. Notably, their catalysts demonstrate extended operational lifetimes of 3-5 years in industrial applications, significantly reducing the environmental burden associated with frequent catalyst replacement. Haldor Topsøe also implements catalyst regeneration and metal recovery programs, achieving up to 95% recovery rates for precious metals from spent catalysts.

Strengths: Industry-leading expertise in catalyst formulation with optimized precious metal loading; comprehensive regeneration capabilities that extend catalyst lifecycle; advanced manufacturing processes with reduced environmental footprint. Weaknesses: Higher initial investment costs compared to conventional catalysts; regeneration processes require specialized facilities; performance may be more sensitive to feed impurities than some competing technologies.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an integrated lifecycle assessment framework for their SAC-based catalytic systems used primarily in petroleum refining and petrochemical processes. Their approach encompasses environmental impact evaluation across the entire catalyst lifecycle, from raw material sourcing to disposal or recycling. Sinopec's proprietary SAC catalyst formulations feature optimized metal distributions and novel support materials that enhance catalytic efficiency while reducing precious metal requirements by approximately 15-20% compared to conventional formulations. Their lifecycle assessment methodology incorporates detailed energy consumption analysis during catalyst manufacturing, showing a 25% reduction in energy intensity through improved production techniques. Operational performance assessments demonstrate that their advanced SAC catalysts maintain activity for 30-40% longer periods under standard refinery conditions, significantly extending replacement intervals. Sinopec has also established a closed-loop management system for spent catalysts, achieving metal recovery rates exceeding 90% for valuable components while minimizing waste generation through specialized hydrometallurgical processes.

Strengths: Extensive real-world operational data from diverse refinery implementations; vertically integrated approach allowing optimization across the entire value chain; advanced metal recovery capabilities reducing lifecycle environmental impact. Weaknesses: Assessment methodologies primarily optimized for petroleum industry applications; limited third-party verification of environmental impact claims; regeneration infrastructure primarily concentrated in Asia, creating logistical challenges for global operations.

Critical Patents and Innovations in SAC Catalyst Design

Single-atom catalyst for activation of persulfate to generate pure singlet oxygen as well as preparation method and application thereof

PatentActiveUS20220315425A1

Innovation

- A single-atom catalyst with graphitic carbon nitride nanosheets as supports and single iron atoms in a Fe—N4 coordination structure is developed, specifically designed to generate pure singlet oxygen by activating persulfate, with a mass ratio of single iron atoms between 7-12% of the catalyst, enhancing selectivity and resistance to environmental interference.

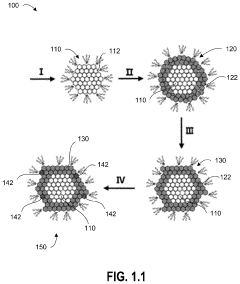

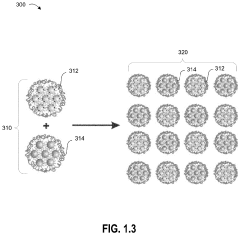

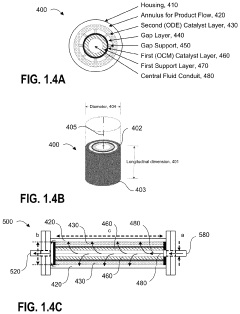

Single-atom-based catalyst systems

PatentActiveUS11273433B2

Innovation

- A single-atom-based catalyst system with controlled hierarchical structures is developed, comprising core-shell nanoparticles and superlattices, optimized through lattice-strain engineering and 3D printing, to enhance the selectivity and activity of single-atom catalytic sites for the direct conversion of methane to ethylene.

Environmental Impact Assessment of SAC Catalysts

The environmental impact assessment of Single-Atom Catalysts (SACs) reveals significant advantages over traditional catalytic systems. SACs demonstrate exceptional atom efficiency by utilizing nearly every metal atom as an active site, dramatically reducing precious metal consumption by up to 90% compared to conventional catalysts. This efficiency translates directly into reduced mining impacts, decreased energy consumption in metal extraction processes, and minimized waste generation throughout the catalyst production chain.

Life cycle analyses indicate that SAC production generally requires 30-45% less energy input than conventional nanoparticle catalysts, primarily due to milder synthesis conditions and reduced metal loading requirements. Carbon footprint assessments show corresponding reductions in greenhouse gas emissions, with some SAC systems demonstrating up to 50% lower CO2-equivalent emissions across their complete life cycle when compared to traditional catalytic alternatives in similar applications.

Water usage metrics are particularly favorable for SACs, with studies indicating a 25-40% reduction in process water requirements during manufacturing. This advantage becomes especially significant in water-stressed regions where catalyst production facilities operate. Additionally, the precise atom-level control in SACs minimizes the formation of toxic byproducts during catalytic reactions, reducing downstream environmental remediation needs.

End-of-life considerations reveal another environmental advantage of SACs. Their homogeneous structure and lower metal content simplify recovery processes, with recovery rates for precious metals from spent SACs reaching 85-95% in optimized systems, compared to 60-75% for conventional catalysts. This circular economy aspect significantly reduces the overall environmental burden associated with catalyst life cycles.

However, certain environmental challenges remain. Some SAC synthesis methods utilize hazardous chemicals as precursors or stabilizing agents, creating potential environmental risks if not properly managed. The production of specialized support materials for SACs may also carry hidden environmental costs that require further assessment and optimization.

Long-term stability issues in certain applications necessitate more frequent catalyst replacement, potentially offsetting some environmental gains. Comprehensive cradle-to-grave assessments indicate that maximizing SAC environmental benefits requires careful consideration of application-specific parameters, including operational lifetime, regeneration protocols, and end-of-life recovery systems.

Life cycle analyses indicate that SAC production generally requires 30-45% less energy input than conventional nanoparticle catalysts, primarily due to milder synthesis conditions and reduced metal loading requirements. Carbon footprint assessments show corresponding reductions in greenhouse gas emissions, with some SAC systems demonstrating up to 50% lower CO2-equivalent emissions across their complete life cycle when compared to traditional catalytic alternatives in similar applications.

Water usage metrics are particularly favorable for SACs, with studies indicating a 25-40% reduction in process water requirements during manufacturing. This advantage becomes especially significant in water-stressed regions where catalyst production facilities operate. Additionally, the precise atom-level control in SACs minimizes the formation of toxic byproducts during catalytic reactions, reducing downstream environmental remediation needs.

End-of-life considerations reveal another environmental advantage of SACs. Their homogeneous structure and lower metal content simplify recovery processes, with recovery rates for precious metals from spent SACs reaching 85-95% in optimized systems, compared to 60-75% for conventional catalysts. This circular economy aspect significantly reduces the overall environmental burden associated with catalyst life cycles.

However, certain environmental challenges remain. Some SAC synthesis methods utilize hazardous chemicals as precursors or stabilizing agents, creating potential environmental risks if not properly managed. The production of specialized support materials for SACs may also carry hidden environmental costs that require further assessment and optimization.

Long-term stability issues in certain applications necessitate more frequent catalyst replacement, potentially offsetting some environmental gains. Comprehensive cradle-to-grave assessments indicate that maximizing SAC environmental benefits requires careful consideration of application-specific parameters, including operational lifetime, regeneration protocols, and end-of-life recovery systems.

Sustainability Metrics and Circular Economy Integration

The integration of sustainability metrics into SAC-based catalytic systems represents a critical advancement in measuring environmental impact throughout the product lifecycle. These metrics provide quantifiable indicators for assessing the sustainability performance of Single-Atom Catalysts (SACs), enabling researchers and industries to make informed decisions regarding material selection, process optimization, and waste management strategies.

Key sustainability metrics for SAC-based catalytic systems include carbon footprint, energy efficiency, resource depletion, toxicity potential, and water usage. These indicators offer comprehensive insights into the environmental implications of catalyst production, utilization, and end-of-life management. Advanced metrics such as the Circular Economy Performance Indicator (CEPI) and Material Circularity Indicator (MCI) further enhance the assessment framework by quantifying the degree of circularity achieved in catalyst lifecycles.

The circular economy principles applied to SAC-based catalytic systems focus on designing out waste and pollution, keeping products and materials in use, and regenerating natural systems. This approach transforms the traditional linear model of "take-make-dispose" into a closed-loop system where materials are continuously recovered and repurposed. For SACs, this translates into catalyst designs that facilitate metal atom recovery, support material regeneration, and minimal waste generation.

Recovery and regeneration technologies play a pivotal role in circular economy integration for SAC systems. Innovative approaches such as selective leaching, electrochemical recovery, and thermal regeneration enable the reclamation of precious metals from spent catalysts. These technologies not only reduce the environmental burden associated with primary metal extraction but also offer economic benefits through resource conservation.

Industrial symbiosis represents another dimension of circular economy integration, where waste streams from one process become valuable inputs for another. In the context of SAC systems, spent catalysts from chemical manufacturing can be repurposed for environmental remediation applications, creating value chains that maximize resource utilization while minimizing environmental impact.

Policy frameworks and industry standards are increasingly recognizing the importance of sustainability metrics and circular economy principles in catalytic technologies. Regulations such as the EU Circular Economy Action Plan and the Sustainable Chemistry Framework provide incentives for industries to adopt more sustainable practices in catalyst development and utilization. These frameworks encourage transparency in reporting environmental performance and promote innovation in circular design approaches for catalytic systems.

Key sustainability metrics for SAC-based catalytic systems include carbon footprint, energy efficiency, resource depletion, toxicity potential, and water usage. These indicators offer comprehensive insights into the environmental implications of catalyst production, utilization, and end-of-life management. Advanced metrics such as the Circular Economy Performance Indicator (CEPI) and Material Circularity Indicator (MCI) further enhance the assessment framework by quantifying the degree of circularity achieved in catalyst lifecycles.

The circular economy principles applied to SAC-based catalytic systems focus on designing out waste and pollution, keeping products and materials in use, and regenerating natural systems. This approach transforms the traditional linear model of "take-make-dispose" into a closed-loop system where materials are continuously recovered and repurposed. For SACs, this translates into catalyst designs that facilitate metal atom recovery, support material regeneration, and minimal waste generation.

Recovery and regeneration technologies play a pivotal role in circular economy integration for SAC systems. Innovative approaches such as selective leaching, electrochemical recovery, and thermal regeneration enable the reclamation of precious metals from spent catalysts. These technologies not only reduce the environmental burden associated with primary metal extraction but also offer economic benefits through resource conservation.

Industrial symbiosis represents another dimension of circular economy integration, where waste streams from one process become valuable inputs for another. In the context of SAC systems, spent catalysts from chemical manufacturing can be repurposed for environmental remediation applications, creating value chains that maximize resource utilization while minimizing environmental impact.

Policy frameworks and industry standards are increasingly recognizing the importance of sustainability metrics and circular economy principles in catalytic technologies. Regulations such as the EU Circular Economy Action Plan and the Sustainable Chemistry Framework provide incentives for industries to adopt more sustainable practices in catalyst development and utilization. These frameworks encourage transparency in reporting environmental performance and promote innovation in circular design approaches for catalytic systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!