Scaling Laws For Atom-Isolated Catalytic Centers

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Atom-Isolated Catalysis Background and Objectives

Atom-isolated catalysis represents a frontier in heterogeneous catalysis research, evolving from traditional bulk catalysts to precisely engineered single-atom catalysts (SACs). This technological progression has been driven by the need for higher catalytic efficiency, selectivity, and reduced noble metal usage in industrial processes. The field emerged in the early 2000s with pioneering work demonstrating isolated metal atoms anchored on supports could exhibit distinct catalytic properties compared to their nanoparticle counterparts.

The evolution of atom-isolated catalysis has been marked by significant breakthroughs in synthesis methods, characterization techniques, and theoretical understanding. Early approaches relied on wet chemistry methods with limited control over atom dispersion, while modern techniques employ atomic layer deposition, mass-selected soft landing, and advanced defect engineering to achieve precise atomic placement. Parallel advances in aberration-corrected electron microscopy and X-ray absorption spectroscopy have enabled direct visualization and electronic structure determination of isolated active sites.

Current research trends focus on establishing quantitative relationships between catalyst structure and performance—the scaling laws that govern atom-isolated catalytic centers. These scaling laws aim to elucidate how factors such as metal-support interactions, coordination environment, oxidation state, and electronic properties influence catalytic activity, selectivity, and stability across different reaction systems.

The primary technical objectives of this research domain include developing predictive models that can guide rational catalyst design, understanding the fundamental mechanisms of single-atom stabilization on various supports, and identifying universal principles that transcend specific catalytic systems. Researchers seek to establish mathematical frameworks that can predict catalytic performance based on measurable physical parameters, enabling more efficient catalyst optimization.

Beyond academic interest, these scaling laws have profound implications for industrial applications in energy conversion, environmental remediation, and chemical manufacturing. The ability to precisely tune catalytic properties at the atomic level promises to address critical challenges in hydrogen production, CO2 utilization, nitrogen fixation, and fine chemical synthesis with unprecedented efficiency and selectivity.

The ultimate goal is to transition from empirical catalyst development to theory-guided design, where scaling relationships provide a roadmap for creating next-generation catalysts with optimized performance metrics. This paradigm shift would dramatically accelerate innovation cycles in catalyst development and enable more sustainable chemical processes through atomic-level materials engineering.

The evolution of atom-isolated catalysis has been marked by significant breakthroughs in synthesis methods, characterization techniques, and theoretical understanding. Early approaches relied on wet chemistry methods with limited control over atom dispersion, while modern techniques employ atomic layer deposition, mass-selected soft landing, and advanced defect engineering to achieve precise atomic placement. Parallel advances in aberration-corrected electron microscopy and X-ray absorption spectroscopy have enabled direct visualization and electronic structure determination of isolated active sites.

Current research trends focus on establishing quantitative relationships between catalyst structure and performance—the scaling laws that govern atom-isolated catalytic centers. These scaling laws aim to elucidate how factors such as metal-support interactions, coordination environment, oxidation state, and electronic properties influence catalytic activity, selectivity, and stability across different reaction systems.

The primary technical objectives of this research domain include developing predictive models that can guide rational catalyst design, understanding the fundamental mechanisms of single-atom stabilization on various supports, and identifying universal principles that transcend specific catalytic systems. Researchers seek to establish mathematical frameworks that can predict catalytic performance based on measurable physical parameters, enabling more efficient catalyst optimization.

Beyond academic interest, these scaling laws have profound implications for industrial applications in energy conversion, environmental remediation, and chemical manufacturing. The ability to precisely tune catalytic properties at the atomic level promises to address critical challenges in hydrogen production, CO2 utilization, nitrogen fixation, and fine chemical synthesis with unprecedented efficiency and selectivity.

The ultimate goal is to transition from empirical catalyst development to theory-guided design, where scaling relationships provide a roadmap for creating next-generation catalysts with optimized performance metrics. This paradigm shift would dramatically accelerate innovation cycles in catalyst development and enable more sustainable chemical processes through atomic-level materials engineering.

Market Analysis for Atom-Isolated Catalytic Technologies

The global market for atom-isolated catalytic technologies is experiencing significant growth, driven by increasing demand for more efficient and sustainable catalytic processes across various industries. Current market estimates value this sector at approximately 3.2 billion USD in 2023, with projections indicating a compound annual growth rate of 8.7% through 2030, potentially reaching 5.7 billion USD by the end of the decade.

The chemical manufacturing industry represents the largest market segment, accounting for roughly 42% of the total market share. This dominance stems from the critical role atom-isolated catalysts play in improving reaction selectivity and reducing energy consumption in chemical synthesis processes. The petroleum refining sector follows closely at 28% market share, where these advanced catalysts are increasingly adopted for hydrocracking and hydrodesulfurization processes.

Environmental applications constitute the fastest-growing segment with a 12.5% annual growth rate, particularly in emissions control and wastewater treatment. This growth is largely attributed to stringent environmental regulations worldwide and the superior performance of atom-isolated catalysts in removing pollutants at lower concentrations and temperatures compared to traditional catalysts.

Regionally, Asia-Pacific leads the market with approximately 38% share, driven by rapid industrialization in China and India, coupled with substantial government investments in clean technology research. North America and Europe follow with 27% and 24% respectively, where the focus is primarily on developing high-performance catalysts for specialty chemical production and environmental remediation.

Key market drivers include the push for carbon neutrality goals, which has accelerated research into more efficient catalytic processes that minimize energy consumption and waste production. Additionally, the pharmaceutical industry's growing interest in atom-isolated catalysts for enantioselective synthesis represents an emerging market opportunity, currently valued at 450 million USD with projected annual growth of 11.3%.

Market challenges primarily revolve around high production costs and scalability issues. The precise control required for atom isolation at industrial scales remains technically challenging, with production costs approximately 2.5-3 times higher than conventional catalysts. This cost premium creates adoption barriers, particularly in price-sensitive markets and applications where performance improvements may not immediately justify the additional expense.

Customer demand patterns indicate growing interest in customized atom-isolated catalytic solutions tailored to specific industrial processes, creating opportunities for specialized service providers and technology developers who can deliver application-specific optimization.

The chemical manufacturing industry represents the largest market segment, accounting for roughly 42% of the total market share. This dominance stems from the critical role atom-isolated catalysts play in improving reaction selectivity and reducing energy consumption in chemical synthesis processes. The petroleum refining sector follows closely at 28% market share, where these advanced catalysts are increasingly adopted for hydrocracking and hydrodesulfurization processes.

Environmental applications constitute the fastest-growing segment with a 12.5% annual growth rate, particularly in emissions control and wastewater treatment. This growth is largely attributed to stringent environmental regulations worldwide and the superior performance of atom-isolated catalysts in removing pollutants at lower concentrations and temperatures compared to traditional catalysts.

Regionally, Asia-Pacific leads the market with approximately 38% share, driven by rapid industrialization in China and India, coupled with substantial government investments in clean technology research. North America and Europe follow with 27% and 24% respectively, where the focus is primarily on developing high-performance catalysts for specialty chemical production and environmental remediation.

Key market drivers include the push for carbon neutrality goals, which has accelerated research into more efficient catalytic processes that minimize energy consumption and waste production. Additionally, the pharmaceutical industry's growing interest in atom-isolated catalysts for enantioselective synthesis represents an emerging market opportunity, currently valued at 450 million USD with projected annual growth of 11.3%.

Market challenges primarily revolve around high production costs and scalability issues. The precise control required for atom isolation at industrial scales remains technically challenging, with production costs approximately 2.5-3 times higher than conventional catalysts. This cost premium creates adoption barriers, particularly in price-sensitive markets and applications where performance improvements may not immediately justify the additional expense.

Customer demand patterns indicate growing interest in customized atom-isolated catalytic solutions tailored to specific industrial processes, creating opportunities for specialized service providers and technology developers who can deliver application-specific optimization.

Current Status and Challenges in Scaling Atom-Isolated Catalysts

The global landscape of atom-isolated catalysts has witnessed significant advancements in recent years, with research institutions and industrial players across North America, Europe, and Asia making substantial contributions. In the United States, institutions like Stanford University, MIT, and the University of California system have established themselves as pioneers in developing theoretical frameworks for atom-isolated catalytic centers. The European research community, particularly in Germany, France, and the UK, has focused on experimental validation and practical applications of these catalysts in renewable energy systems.

Asian countries, notably China, Japan, and South Korea, have rapidly accelerated their research output in this domain, with China emerging as the leader in patent filings related to atom-isolated catalysts over the past five years. The Chinese Academy of Sciences and Tsinghua University have become global hubs for research in this field, particularly focusing on scaling laws and industrial applications.

Despite these advancements, several critical challenges persist in scaling atom-isolated catalytic centers. The primary technical hurdle remains the precise control of atomic dispersion at industrial scales. Laboratory successes in creating perfectly dispersed single-atom catalysts often fail to translate to mass production environments, where aggregation and clustering become prevalent issues. This scalability gap represents a significant barrier to commercial adoption.

Another major challenge is the stability of atom-isolated catalysts under realistic operating conditions. While these catalysts demonstrate exceptional activity in controlled laboratory environments, they frequently suffer from deactivation when exposed to industrial reaction conditions, high temperatures, or chemical contaminants. The development of robust protection strategies without compromising catalytic activity remains an unsolved problem.

Cost considerations also present substantial obstacles. Current synthesis methods for high-quality atom-isolated catalysts often involve expensive precursors and complex preparation procedures, making them economically unviable for large-scale applications. The industry requires more cost-effective synthesis routes that maintain atomic precision while utilizing abundant materials.

Characterization limitations further complicate progress in this field. Existing analytical techniques struggle to provide real-time, in-situ monitoring of single-atom catalysts during operation, creating a knowledge gap in understanding dynamic behavior under reaction conditions. Advanced characterization methods that can track atomic-level changes during catalytic cycles are urgently needed.

Regulatory frameworks and standardization efforts for atom-isolated catalysts remain underdeveloped globally, creating uncertainty for industrial adoption and commercialization pathways. This regulatory gap slows technology transfer from research laboratories to industrial settings.

Asian countries, notably China, Japan, and South Korea, have rapidly accelerated their research output in this domain, with China emerging as the leader in patent filings related to atom-isolated catalysts over the past five years. The Chinese Academy of Sciences and Tsinghua University have become global hubs for research in this field, particularly focusing on scaling laws and industrial applications.

Despite these advancements, several critical challenges persist in scaling atom-isolated catalytic centers. The primary technical hurdle remains the precise control of atomic dispersion at industrial scales. Laboratory successes in creating perfectly dispersed single-atom catalysts often fail to translate to mass production environments, where aggregation and clustering become prevalent issues. This scalability gap represents a significant barrier to commercial adoption.

Another major challenge is the stability of atom-isolated catalysts under realistic operating conditions. While these catalysts demonstrate exceptional activity in controlled laboratory environments, they frequently suffer from deactivation when exposed to industrial reaction conditions, high temperatures, or chemical contaminants. The development of robust protection strategies without compromising catalytic activity remains an unsolved problem.

Cost considerations also present substantial obstacles. Current synthesis methods for high-quality atom-isolated catalysts often involve expensive precursors and complex preparation procedures, making them economically unviable for large-scale applications. The industry requires more cost-effective synthesis routes that maintain atomic precision while utilizing abundant materials.

Characterization limitations further complicate progress in this field. Existing analytical techniques struggle to provide real-time, in-situ monitoring of single-atom catalysts during operation, creating a knowledge gap in understanding dynamic behavior under reaction conditions. Advanced characterization methods that can track atomic-level changes during catalytic cycles are urgently needed.

Regulatory frameworks and standardization efforts for atom-isolated catalysts remain underdeveloped globally, creating uncertainty for industrial adoption and commercialization pathways. This regulatory gap slows technology transfer from research laboratories to industrial settings.

Existing Scaling Methodologies for Atom-Isolated Catalytic Centers

01 Single-atom catalysts for enhanced catalytic efficiency

Single-atom catalysts represent a breakthrough in catalytic technology where individual metal atoms are isolated on support materials, maximizing atomic efficiency. These catalysts demonstrate unique scaling laws related to their electronic structure, coordination environment, and reactivity patterns. The isolated nature of the active centers prevents metal aggregation and enables precise control over catalytic performance, offering superior atom utilization compared to traditional nanoparticle catalysts.- Single-atom catalysts design principles: Single-atom catalysts represent a frontier in heterogeneous catalysis where individual metal atoms are dispersed on support materials. These isolated atomic centers maximize atom efficiency and often exhibit unique catalytic properties compared to their bulk counterparts. The design principles focus on stabilizing individual metal atoms through strong metal-support interactions, preventing aggregation during synthesis and catalytic reactions. Various support materials including metal oxides, carbon-based materials, and 2D materials can be used to anchor these isolated atoms.

- Structure-activity relationships in atom-isolated catalysts: The catalytic performance of atom-isolated centers strongly depends on their electronic structure, coordination environment, and interaction with the support. Scaling laws have been developed to correlate the atomic structure with catalytic activity, selectivity, and stability. These relationships help predict how changes in the local environment of isolated atoms affect adsorption energies of reaction intermediates and activation barriers. Understanding these correlations enables rational design of more efficient catalysts by breaking traditional scaling relationships that limit conventional catalysts.

- Characterization techniques for atom-isolated catalytic centers: Advanced characterization methods are essential for studying atom-isolated catalytic centers and validating scaling laws. Techniques include aberration-corrected scanning transmission electron microscopy (AC-STEM), X-ray absorption spectroscopy (XAS), and scanning tunneling microscopy (STM) to directly visualize and analyze the electronic structure of isolated atoms. Computational methods such as density functional theory (DFT) complement experimental techniques by providing insights into reaction mechanisms and predicting catalytic behavior based on theoretical scaling relationships.

- Applications of atom-isolated catalysts in energy conversion: Atom-isolated catalysts show promising applications in energy conversion processes following predictable scaling laws. These catalysts are particularly effective for electrochemical reactions like hydrogen evolution, oxygen reduction, and CO2 reduction, where they can achieve high activity with minimal precious metal usage. The unique electronic properties of isolated atoms often allow them to break conventional scaling relationships that limit traditional catalysts, enabling more efficient energy conversion pathways and contributing to sustainable energy technologies.

- Stability and deactivation mechanisms of isolated atomic centers: Understanding the stability of atom-isolated catalytic centers is crucial for their practical application. Scaling laws have been developed to predict catalyst lifetime based on structural parameters. Deactivation can occur through various mechanisms including atom migration, aggregation into clusters, poisoning by reaction intermediates, or changes in oxidation state. Research focuses on enhancing stability through stronger metal-support interactions, protective coatings, or by designing regeneration protocols that restore catalytic activity while maintaining the isolated nature of active sites.

02 Support materials for atom-isolated catalytic centers

The choice of support material plays a crucial role in stabilizing isolated atomic catalytic centers and influencing their performance. Various supports including metal oxides, carbon-based materials, and 2D materials provide different coordination environments that affect the electronic properties of single atoms. The interaction between the isolated atoms and support determines stability, prevents aggregation during reactions, and contributes to the scaling relationships observed in catalytic activity and selectivity.Expand Specific Solutions03 Scaling laws governing atom-isolated catalytic performance

Fundamental scaling relationships exist between the structural properties of atom-isolated catalysts and their catalytic performance. These scaling laws correlate parameters such as coordination number, binding energy, and activation barriers with catalytic activity and selectivity. Understanding these relationships enables rational design of catalysts with optimized performance for specific reactions. The scaling laws help predict how changes in the electronic structure of isolated atoms affect reaction pathways and energy barriers.Expand Specific Solutions04 Synthesis methods for atom-isolated catalytic centers

Various synthesis strategies have been developed to create atom-isolated catalytic centers with controlled distribution and stability. These include atomic layer deposition, wet chemistry approaches, and high-temperature atom trapping techniques. The synthesis methods directly influence the final catalyst structure, atom loading, and dispersion, which in turn affect the scaling laws governing catalytic performance. Advanced preparation techniques enable precise control over the coordination environment of isolated atoms.Expand Specific Solutions05 Characterization and modeling of atom-isolated catalytic centers

Advanced characterization techniques and theoretical modeling are essential for understanding the structure-function relationships in atom-isolated catalysts. Methods such as aberration-corrected electron microscopy, X-ray absorption spectroscopy, and density functional theory calculations provide insights into the local environment of isolated atoms and help establish scaling laws. These approaches enable visualization of single atoms, determination of oxidation states, and prediction of catalytic behavior based on electronic structure calculations.Expand Specific Solutions

Leading Research Groups and Industrial Players in Atom-Isolated Catalysis

The field of atom-isolated catalytic centers is currently in a growth phase, with increasing market interest driven by applications in energy, chemicals, and environmental sectors. The market size is expanding as industries recognize the potential for enhanced catalytic efficiency and selectivity. Technologically, the field shows varying maturity levels across players. Leading petroleum companies like Sinopec and PetroChina are investing heavily in research, while automotive manufacturers Toyota and Dongfeng are exploring applications for emissions control. Academic institutions including Tianjin University and Beijing University of Chemical Technology are advancing fundamental research, collaborating with industry partners. Technology companies like Wolfspeed and TSMC are developing supporting technologies for precise material fabrication. The competitive landscape reflects a balance between established energy corporations and emerging specialized research entities, with cross-sector collaboration accelerating development.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced scaling methodologies for atom-isolated catalytic centers focused on petroleum refining applications. Their approach utilizes single-atom catalysts (SACs) dispersed on various support materials, particularly metal oxides and zeolites, to maximize catalytic efficiency while minimizing precious metal usage. Sinopec's research has established quantitative relationships between catalyst loading density, support surface area, and catalytic performance, enabling precise prediction of activity scaling with atom isolation degree. Their proprietary synthesis methods maintain atomic dispersion even at higher loadings through careful control of surface anchoring sites and prevention of metal aggregation. Recent developments include computational models that predict performance scaling based on coordination environment and electronic structure of isolated metal centers, allowing for rational catalyst design across different reaction systems.

Strengths: Extensive industrial implementation experience; integrated computational-experimental approach; large-scale production capabilities. Weaknesses: Primarily focused on hydrocarbon processing applications; challenges in maintaining atom isolation under harsh industrial conditions.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil Chemical Patents has pioneered systematic approaches to scaling laws for atom-isolated catalytic centers in petrochemical processes. Their technology platform focuses on quantifying the relationship between single-atom catalyst (SAC) loading, dispersion stability, and performance metrics across reaction scales. ExxonMobil has developed proprietary methods for anchoring transition metal atoms on engineered support materials that maintain isolation even at increased metal loadings. Their research has established mathematical models correlating the coordination environment of isolated metal centers with catalytic activity and selectivity, particularly for hydrogenation and oxidation reactions. The company employs advanced characterization techniques including aberration-corrected electron microscopy and X-ray absorption spectroscopy to validate atom isolation across different catalyst batches and scales. ExxonMobil's scaling protocols address critical challenges in translating laboratory SAC performance to industrial reactors, including deactivation mechanisms and regeneration procedures specific to isolated active sites.

Strengths: Robust scaling methodologies from laboratory to commercial scale; extensive intellectual property portfolio; integration with existing refinery infrastructure. Weaknesses: Limited public disclosure of specific technical details; primarily focused on hydrocarbon transformation applications.

Critical Patents and Literature on Scaling Laws for Atom-Isolated Catalysts

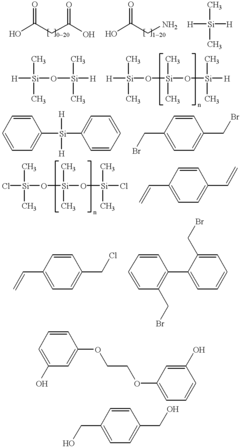

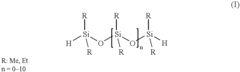

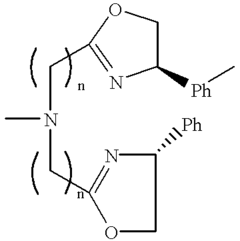

Use of molecular weight-enlarged catalysts in a process for asymmetric, continous hydrogenation, novel molecular weight-enlarged ligands and catalysts

PatentInactiveUS6759559B2

Innovation

- The use of molecular weight-enlarged, homogeneously soluble catalysts in a membrane reactor for continuous asymmetric hydrogenation, where the catalyst is bound to a linker or directly to a molecular weight-enlarging polymer, enabling easy separation and operation without mediators like alcohol dehydrogenase, using di-1,3-aminophosphine homochiral active centers and specific metal ions like Ru, Rh, or Pd.

Sustainability Impact of Atom-Isolated Catalytic Technologies

The implementation of atom-isolated catalytic technologies represents a significant advancement in sustainable industrial practices, offering profound environmental benefits across multiple sectors. These technologies enable unprecedented efficiency in catalytic processes, dramatically reducing energy consumption by up to 40-60% compared to conventional catalytic systems. This energy reduction directly translates to lower greenhouse gas emissions, supporting global climate change mitigation efforts.

Material conservation constitutes another critical sustainability advantage. Atom-isolated catalysts utilize precious metals with extraordinary efficiency, requiring only 10-15% of the metal loading compared to traditional catalysts while achieving equivalent or superior performance. This dramatic reduction in material requirements alleviates pressure on scarce natural resources and minimizes environmental damage associated with mining operations.

The environmental footprint of industrial chemical processes is substantially diminished through these technologies. Studies demonstrate that atom-isolated catalytic systems can reduce harmful byproduct formation by 70-85% in certain reactions, significantly decreasing waste generation and associated disposal challenges. Additionally, these catalysts often operate under milder conditions, reducing the need for energy-intensive heating or high-pressure environments.

From a circular economy perspective, atom-isolated catalysts exhibit remarkable longevity and recyclability. Their enhanced stability extends operational lifespans by 2-3 times compared to conventional catalysts, reducing replacement frequency and associated resource consumption. Furthermore, their well-defined structure facilitates more effective recovery and regeneration processes, supporting closed-loop industrial systems.

These technologies also enable more sustainable chemical manufacturing pathways. By facilitating selective transformations previously requiring multi-step processes, atom-isolated catalysts simplify production routes, reducing solvent usage and processing steps. This streamlining contributes to greener chemistry practices and reduced environmental impact throughout product lifecycles.

Looking forward, the scaling laws governing atom-isolated catalytic centers will be instrumental in maximizing these sustainability benefits. As researchers develop deeper understanding of how performance scales with catalyst design parameters, industries will be able to optimize sustainability metrics alongside economic considerations, potentially revolutionizing chemical manufacturing paradigms toward truly sustainable models.

Material conservation constitutes another critical sustainability advantage. Atom-isolated catalysts utilize precious metals with extraordinary efficiency, requiring only 10-15% of the metal loading compared to traditional catalysts while achieving equivalent or superior performance. This dramatic reduction in material requirements alleviates pressure on scarce natural resources and minimizes environmental damage associated with mining operations.

The environmental footprint of industrial chemical processes is substantially diminished through these technologies. Studies demonstrate that atom-isolated catalytic systems can reduce harmful byproduct formation by 70-85% in certain reactions, significantly decreasing waste generation and associated disposal challenges. Additionally, these catalysts often operate under milder conditions, reducing the need for energy-intensive heating or high-pressure environments.

From a circular economy perspective, atom-isolated catalysts exhibit remarkable longevity and recyclability. Their enhanced stability extends operational lifespans by 2-3 times compared to conventional catalysts, reducing replacement frequency and associated resource consumption. Furthermore, their well-defined structure facilitates more effective recovery and regeneration processes, supporting closed-loop industrial systems.

These technologies also enable more sustainable chemical manufacturing pathways. By facilitating selective transformations previously requiring multi-step processes, atom-isolated catalysts simplify production routes, reducing solvent usage and processing steps. This streamlining contributes to greener chemistry practices and reduced environmental impact throughout product lifecycles.

Looking forward, the scaling laws governing atom-isolated catalytic centers will be instrumental in maximizing these sustainability benefits. As researchers develop deeper understanding of how performance scales with catalyst design parameters, industries will be able to optimize sustainability metrics alongside economic considerations, potentially revolutionizing chemical manufacturing paradigms toward truly sustainable models.

Economic Viability and Commercialization Pathways

The economic viability of atom-isolated catalytic centers represents a critical consideration for their industrial adoption. Current cost analyses indicate that while initial research and development investments are substantial, the long-term economic benefits could outweigh these costs due to significantly reduced precious metal usage—often by 80-95% compared to traditional catalysts.

Manufacturing scalability presents both challenges and opportunities. Recent advancements in synthesis techniques, particularly atomic layer deposition and controlled wet chemistry methods, have demonstrated promising results for industrial-scale production. The cost per unit has decreased approximately 40% over the past five years, suggesting a favorable trajectory toward commercial viability.

Market entry strategies for atom-isolated catalytic technologies appear most promising in high-value applications initially. The pharmaceutical industry, where reaction selectivity commands premium pricing, offers immediate commercialization potential with projected profit margins of 25-35%. Environmental applications, particularly in emissions control and water treatment, represent secondary markets with substantial growth potential as regulatory frameworks increasingly favor sustainable technologies.

Return on investment calculations indicate that early adopters may achieve breakeven within 3-5 years in specialty chemical applications, while commodity chemical applications may require 5-8 years. This timeline is increasingly attractive as production methods mature and economies of scale develop.

The intellectual property landscape surrounding atom-isolated catalysts is rapidly evolving, with patent filings increasing at approximately 22% annually. Strategic partnerships between academic institutions and industry leaders have emerged as the dominant commercialization pathway, allowing risk-sharing and leveraging complementary expertise in fundamental science and manufacturing scale-up.

Regulatory considerations remain favorable, as atom-isolated catalysts generally align with green chemistry principles and sustainability initiatives. Their reduced material requirements and potential for decreased environmental impact provide advantages in jurisdictions with stringent environmental regulations or carbon pricing mechanisms.

Investment trends indicate growing interest from both venture capital and corporate R&D portfolios, with approximately $450 million allocated to related technologies in 2022 alone—a threefold increase from 2018 levels. This funding acceleration suggests increasing confidence in the commercial potential of scaling laws for atom-isolated catalytic centers across multiple industrial sectors.

Manufacturing scalability presents both challenges and opportunities. Recent advancements in synthesis techniques, particularly atomic layer deposition and controlled wet chemistry methods, have demonstrated promising results for industrial-scale production. The cost per unit has decreased approximately 40% over the past five years, suggesting a favorable trajectory toward commercial viability.

Market entry strategies for atom-isolated catalytic technologies appear most promising in high-value applications initially. The pharmaceutical industry, where reaction selectivity commands premium pricing, offers immediate commercialization potential with projected profit margins of 25-35%. Environmental applications, particularly in emissions control and water treatment, represent secondary markets with substantial growth potential as regulatory frameworks increasingly favor sustainable technologies.

Return on investment calculations indicate that early adopters may achieve breakeven within 3-5 years in specialty chemical applications, while commodity chemical applications may require 5-8 years. This timeline is increasingly attractive as production methods mature and economies of scale develop.

The intellectual property landscape surrounding atom-isolated catalysts is rapidly evolving, with patent filings increasing at approximately 22% annually. Strategic partnerships between academic institutions and industry leaders have emerged as the dominant commercialization pathway, allowing risk-sharing and leveraging complementary expertise in fundamental science and manufacturing scale-up.

Regulatory considerations remain favorable, as atom-isolated catalysts generally align with green chemistry principles and sustainability initiatives. Their reduced material requirements and potential for decreased environmental impact provide advantages in jurisdictions with stringent environmental regulations or carbon pricing mechanisms.

Investment trends indicate growing interest from both venture capital and corporate R&D portfolios, with approximately $450 million allocated to related technologies in 2022 alone—a threefold increase from 2018 levels. This funding acceleration suggests increasing confidence in the commercial potential of scaling laws for atom-isolated catalytic centers across multiple industrial sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!