SACs For Biomass Conversion Electrochemistry

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SACs Development History and Research Objectives

Single-atom catalysts (SACs) represent a revolutionary frontier in heterogeneous catalysis, emerging as a distinct field around 2011 when Zhang and colleagues first coined the term. The conceptual foundation of SACs, however, can be traced back to earlier work on supported metal catalysts with extremely low loadings. The development trajectory of SACs has been characterized by significant breakthroughs in synthesis methodologies, from initial wet chemistry approaches to more sophisticated atomic layer deposition techniques and defect engineering strategies.

The evolution of SACs research has been marked by three distinct phases. The initial discovery phase (2011-2015) focused primarily on proving the concept and developing preliminary synthesis routes. The second expansion phase (2016-2019) witnessed rapid growth in applications across various catalytic processes, including CO oxidation, water-gas shift reactions, and hydrogen evolution. The current maturation phase (2020-present) has seen increasing sophistication in both theoretical understanding and practical applications, with biomass conversion emerging as a particularly promising frontier.

In the context of biomass conversion electrochemistry, SACs offer unprecedented advantages due to their unique structural properties. The isolated metal atoms anchored on supports provide maximum atom utilization efficiency and distinct electronic structures that differ significantly from their bulk counterparts. These characteristics enable selective bond activation in complex biomass molecules, potentially overcoming longstanding challenges in biomass valorization.

The research objectives in SACs for biomass conversion electrochemistry encompass several interconnected goals. First, developing robust and scalable synthesis methods specifically tailored for creating SACs with optimal performance in biomass conversion reactions. Second, establishing comprehensive structure-activity relationships to guide rational catalyst design. Third, enhancing catalyst stability under the harsh conditions often encountered in biomass processing, including acidic environments and presence of catalyst poisons.

Additionally, research aims to expand the range of transformations accessible through SAC-catalyzed electrochemical processes, particularly focusing on selective C-O bond cleavage and C-C bond formation reactions relevant to converting biomass-derived platform molecules into value-added chemicals. The ultimate objective is to develop integrated electrochemical systems incorporating SACs that can efficiently convert various biomass feedstocks with minimal energy input and waste generation.

The field is now moving toward multifunctional SAC systems that can catalyze cascade reactions, thereby simplifying process designs and improving overall efficiency in biomass conversion pathways. This represents a critical step toward establishing economically viable and environmentally sustainable alternatives to petroleum-based chemical production.

The evolution of SACs research has been marked by three distinct phases. The initial discovery phase (2011-2015) focused primarily on proving the concept and developing preliminary synthesis routes. The second expansion phase (2016-2019) witnessed rapid growth in applications across various catalytic processes, including CO oxidation, water-gas shift reactions, and hydrogen evolution. The current maturation phase (2020-present) has seen increasing sophistication in both theoretical understanding and practical applications, with biomass conversion emerging as a particularly promising frontier.

In the context of biomass conversion electrochemistry, SACs offer unprecedented advantages due to their unique structural properties. The isolated metal atoms anchored on supports provide maximum atom utilization efficiency and distinct electronic structures that differ significantly from their bulk counterparts. These characteristics enable selective bond activation in complex biomass molecules, potentially overcoming longstanding challenges in biomass valorization.

The research objectives in SACs for biomass conversion electrochemistry encompass several interconnected goals. First, developing robust and scalable synthesis methods specifically tailored for creating SACs with optimal performance in biomass conversion reactions. Second, establishing comprehensive structure-activity relationships to guide rational catalyst design. Third, enhancing catalyst stability under the harsh conditions often encountered in biomass processing, including acidic environments and presence of catalyst poisons.

Additionally, research aims to expand the range of transformations accessible through SAC-catalyzed electrochemical processes, particularly focusing on selective C-O bond cleavage and C-C bond formation reactions relevant to converting biomass-derived platform molecules into value-added chemicals. The ultimate objective is to develop integrated electrochemical systems incorporating SACs that can efficiently convert various biomass feedstocks with minimal energy input and waste generation.

The field is now moving toward multifunctional SAC systems that can catalyze cascade reactions, thereby simplifying process designs and improving overall efficiency in biomass conversion pathways. This represents a critical step toward establishing economically viable and environmentally sustainable alternatives to petroleum-based chemical production.

Market Analysis for Biomass Electrochemical Conversion

The global market for biomass electrochemical conversion is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable energy solutions. The market size was valued at approximately $2.3 billion in 2022 and is projected to reach $5.7 billion by 2030, representing a compound annual growth rate (CAGR) of 12.1%. This growth trajectory is supported by favorable government policies promoting renewable energy adoption and substantial investments in research and development.

Biomass electrochemical conversion technologies are gaining traction across various sectors, with the highest demand observed in biofuels production, followed by biochemicals and bioenergy. The transportation sector remains the largest end-user, accounting for nearly 45% of the market share, as industries seek to reduce carbon footprints through sustainable fuel alternatives.

Regionally, North America currently dominates the market with approximately 35% share, attributed to advanced technological infrastructure and supportive regulatory frameworks. However, Asia-Pacific is emerging as the fastest-growing region with a projected CAGR of 14.3% through 2030, primarily driven by China and India's aggressive renewable energy targets and abundant biomass resources.

The integration of Single-Atom Catalysts (SACs) in biomass electrochemical conversion represents a high-growth segment within this market. The enhanced catalytic efficiency offered by SACs is expected to reduce operational costs by 20-30% compared to traditional catalysts, potentially expanding market accessibility and adoption rates.

Key market drivers include increasing fossil fuel prices, growing environmental regulations, and the rising demand for carbon-neutral production processes. The European Union's Renewable Energy Directive II and similar policies worldwide are creating favorable market conditions by mandating minimum renewable content in fuels and chemicals.

However, several challenges persist in market expansion. High initial capital requirements for commercial-scale facilities remain a significant barrier, with average setup costs ranging from $50-200 million depending on capacity and technology. Additionally, feedstock supply chain inconsistencies and competition with food production continue to impact market stability.

Consumer awareness and willingness to pay premium prices for bio-based products are gradually improving, with recent surveys indicating that 62% of consumers across developed markets are willing to pay up to 10% more for products with verified environmental benefits. This trend is particularly strong among younger demographics, suggesting long-term market sustainability.

Biomass electrochemical conversion technologies are gaining traction across various sectors, with the highest demand observed in biofuels production, followed by biochemicals and bioenergy. The transportation sector remains the largest end-user, accounting for nearly 45% of the market share, as industries seek to reduce carbon footprints through sustainable fuel alternatives.

Regionally, North America currently dominates the market with approximately 35% share, attributed to advanced technological infrastructure and supportive regulatory frameworks. However, Asia-Pacific is emerging as the fastest-growing region with a projected CAGR of 14.3% through 2030, primarily driven by China and India's aggressive renewable energy targets and abundant biomass resources.

The integration of Single-Atom Catalysts (SACs) in biomass electrochemical conversion represents a high-growth segment within this market. The enhanced catalytic efficiency offered by SACs is expected to reduce operational costs by 20-30% compared to traditional catalysts, potentially expanding market accessibility and adoption rates.

Key market drivers include increasing fossil fuel prices, growing environmental regulations, and the rising demand for carbon-neutral production processes. The European Union's Renewable Energy Directive II and similar policies worldwide are creating favorable market conditions by mandating minimum renewable content in fuels and chemicals.

However, several challenges persist in market expansion. High initial capital requirements for commercial-scale facilities remain a significant barrier, with average setup costs ranging from $50-200 million depending on capacity and technology. Additionally, feedstock supply chain inconsistencies and competition with food production continue to impact market stability.

Consumer awareness and willingness to pay premium prices for bio-based products are gradually improving, with recent surveys indicating that 62% of consumers across developed markets are willing to pay up to 10% more for products with verified environmental benefits. This trend is particularly strong among younger demographics, suggesting long-term market sustainability.

Current Status and Challenges in SACs Technology

Single-atom catalysts (SACs) represent a frontier in heterogeneous catalysis, with isolated metal atoms dispersed on supports offering maximum atom utilization and unique catalytic properties. In the context of biomass conversion electrochemistry, SACs have demonstrated remarkable potential for transforming renewable biomass resources into value-added chemicals and fuels. Currently, the global research landscape shows significant advancements in SAC synthesis methods, with controlled atomic dispersion techniques evolving from traditional impregnation to more sophisticated approaches like atomic layer deposition and metal-organic framework derivation.

The development of SACs for biomass conversion has reached a critical juncture where laboratory demonstrations have proven their exceptional activity and selectivity. Research groups across North America, Europe, and East Asia have reported SACs capable of catalyzing key biomass conversion reactions with significantly lower overpotentials compared to conventional catalysts. Particularly, single-atom Pt, Ru, and Ni catalysts have shown promising results in electrochemical oxidation of biomass-derived compounds like 5-hydroxymethylfurfural and glycerol.

Despite these advances, several technical challenges persist. The primary limitation remains the stability of single atoms under reaction conditions, with metal atom aggregation frequently occurring during electrochemical processes. This challenge is particularly pronounced in the complex, often acidic environments typical of biomass conversion reactions, where leaching of metal atoms compromises long-term catalyst performance.

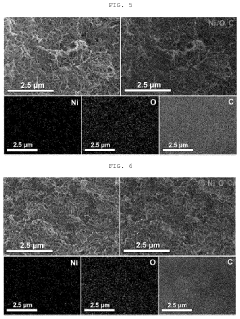

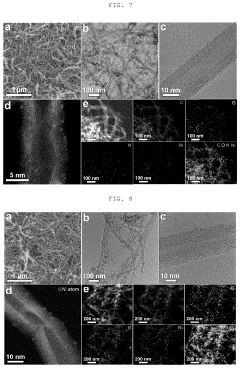

Another significant hurdle is the scalable production of SACs with consistent quality. Current synthesis methods often yield low metal loadings (typically <2 wt%), limiting industrial applicability. Additionally, precise characterization of truly atomic dispersion remains challenging, requiring advanced techniques like aberration-corrected electron microscopy and X-ray absorption spectroscopy, which are not universally accessible.

The mechanistic understanding of SAC-catalyzed biomass conversion reactions presents another frontier challenge. The complex interaction between the single metal atoms, support materials, and biomass-derived molecules creates reaction pathways that differ substantially from conventional catalysts, necessitating sophisticated in-situ characterization techniques and computational modeling.

Geographically, research leadership in SACs for biomass conversion is distributed across several regions. China leads in publication volume, with significant contributions from research institutions focusing on novel synthesis methods. The United States demonstrates strength in fundamental mechanistic studies, while European research clusters excel in advanced characterization techniques. Emerging contributions from South Korea and Japan focus on innovative support materials and industrial applications.

The regulatory landscape adds another layer of complexity, with varying international standards for catalyst materials in sustainable chemical production creating barriers to global technology transfer and commercialization of SAC technologies for biomass valorization.

The development of SACs for biomass conversion has reached a critical juncture where laboratory demonstrations have proven their exceptional activity and selectivity. Research groups across North America, Europe, and East Asia have reported SACs capable of catalyzing key biomass conversion reactions with significantly lower overpotentials compared to conventional catalysts. Particularly, single-atom Pt, Ru, and Ni catalysts have shown promising results in electrochemical oxidation of biomass-derived compounds like 5-hydroxymethylfurfural and glycerol.

Despite these advances, several technical challenges persist. The primary limitation remains the stability of single atoms under reaction conditions, with metal atom aggregation frequently occurring during electrochemical processes. This challenge is particularly pronounced in the complex, often acidic environments typical of biomass conversion reactions, where leaching of metal atoms compromises long-term catalyst performance.

Another significant hurdle is the scalable production of SACs with consistent quality. Current synthesis methods often yield low metal loadings (typically <2 wt%), limiting industrial applicability. Additionally, precise characterization of truly atomic dispersion remains challenging, requiring advanced techniques like aberration-corrected electron microscopy and X-ray absorption spectroscopy, which are not universally accessible.

The mechanistic understanding of SAC-catalyzed biomass conversion reactions presents another frontier challenge. The complex interaction between the single metal atoms, support materials, and biomass-derived molecules creates reaction pathways that differ substantially from conventional catalysts, necessitating sophisticated in-situ characterization techniques and computational modeling.

Geographically, research leadership in SACs for biomass conversion is distributed across several regions. China leads in publication volume, with significant contributions from research institutions focusing on novel synthesis methods. The United States demonstrates strength in fundamental mechanistic studies, while European research clusters excel in advanced characterization techniques. Emerging contributions from South Korea and Japan focus on innovative support materials and industrial applications.

The regulatory landscape adds another layer of complexity, with varying international standards for catalyst materials in sustainable chemical production creating barriers to global technology transfer and commercialization of SAC technologies for biomass valorization.

Current SACs Solutions for Biomass Electroconversion

01 Synthesis methods for Single-Atom Catalysts

Various methods have been developed for synthesizing single-atom catalysts with high dispersion and stability. These methods include atomic layer deposition, wet chemistry approaches, and high-temperature treatments that allow for precise control over the atomic distribution of catalytic metals on support materials. The synthesis techniques focus on preventing metal aggregation while maximizing the number of active sites, resulting in catalysts with superior atom efficiency and performance.- Synthesis methods for Single-Atom Catalysts: Various methods have been developed for synthesizing single-atom catalysts (SACs) with high dispersion and stability. These methods include atomic layer deposition, wet chemistry approaches, and pyrolysis techniques that enable precise control over the atomic distribution of catalytic metals on support materials. The synthesis processes often involve careful selection of metal precursors, support materials, and reaction conditions to achieve isolated single metal atoms anchored to the substrate.

- Support materials for Single-Atom Catalysts: The choice of support material plays a crucial role in the performance of single-atom catalysts. Common support materials include carbon-based materials (graphene, carbon nanotubes), metal oxides, nitrides, and MOFs (Metal-Organic Frameworks). These supports provide anchoring sites for single metal atoms through coordination bonds or defect sites, preventing aggregation and enhancing catalytic activity. The interaction between the metal atom and support significantly influences the electronic structure and catalytic properties of SACs.

- Applications in energy conversion and storage: Single-atom catalysts demonstrate exceptional performance in various energy conversion and storage applications. They are particularly effective in electrocatalytic reactions such as hydrogen evolution reaction (HER), oxygen reduction reaction (ORR), oxygen evolution reaction (OER), and CO2 reduction. SACs offer advantages including high atom utilization efficiency, unique electronic structures, and tunable catalytic properties, making them promising alternatives to traditional noble metal catalysts for sustainable energy technologies.

- Environmental applications and pollutant remediation: Single-atom catalysts show remarkable efficiency in environmental remediation processes including pollutant degradation, CO oxidation, and NOx reduction. Their high surface area, abundant active sites, and superior catalytic activity enable effective treatment of environmental contaminants under mild conditions. SACs can be designed with specific metal centers to target particular pollutants, offering sustainable solutions for air and water purification with minimal material consumption.

- Characterization and theoretical modeling of SACs: Advanced characterization techniques and theoretical modeling are essential for understanding the structure-property relationships of single-atom catalysts. Methods such as aberration-corrected electron microscopy, X-ray absorption spectroscopy, and scanning tunneling microscopy enable direct visualization and analysis of isolated metal atoms. Density functional theory calculations and molecular dynamics simulations provide insights into reaction mechanisms, electronic structures, and the nature of active sites, guiding the rational design of more efficient SACs.

02 Support materials for Single-Atom Catalysts

The choice of support material plays a crucial role in the performance of single-atom catalysts. Various supports including carbon-based materials (graphene, carbon nanotubes), metal oxides, and nitrogen-doped frameworks have been investigated. These supports provide anchoring sites for isolated metal atoms, prevent aggregation, and can participate in the catalytic process through metal-support interactions, enhancing overall catalytic activity and selectivity.Expand Specific Solutions03 Applications in energy conversion and storage

Single-atom catalysts demonstrate exceptional performance in energy-related applications such as fuel cells, water splitting, and batteries. Their high atom efficiency makes them particularly valuable for hydrogen evolution reactions, oxygen reduction reactions, and CO2 conversion processes. The atomically dispersed active sites provide unique electronic structures that facilitate efficient energy conversion pathways with minimal material usage.Expand Specific Solutions04 Environmental applications and pollutant remediation

Single-atom catalysts show remarkable efficiency in environmental remediation processes including the degradation of organic pollutants, NOx reduction, and CO oxidation. Their high surface-to-volume ratio and unique coordination environment enable superior catalytic performance at lower temperatures and with greater selectivity compared to conventional catalysts, making them promising candidates for addressing environmental challenges.Expand Specific Solutions05 Characterization and theoretical modeling of SACs

Advanced characterization techniques and theoretical modeling approaches are essential for understanding the structure-property relationships of single-atom catalysts. Methods such as aberration-corrected electron microscopy, X-ray absorption spectroscopy, and density functional theory calculations provide insights into the coordination environment, electronic structure, and reaction mechanisms of isolated metal atoms. These fundamental studies guide the rational design of more efficient single-atom catalysts with tailored properties for specific applications.Expand Specific Solutions

Leading Research Groups and Industrial Players

The field of Single-Atom Catalysts (SACs) for biomass conversion electrochemistry is in an early growth phase, characterized by intensive academic research with emerging industrial applications. The global market for advanced catalysts is projected to reach $35 billion by 2025, with SACs representing a small but rapidly growing segment. Research institutions like KIST, Johns Hopkins University, and Zhejiang University are leading fundamental research, while companies such as SK Innovation and Korea Institute of Energy Research are focusing on practical applications. Chinese universities, particularly South China University of Technology and Beijing Institute of Technology, demonstrate strong publication output in this domain. The technology remains at TRL 4-6, with significant challenges in scalability and stability that must be addressed before widespread commercial adoption.

KIST Corp. (South Korea)

Technical Solution: KIST Corporation has developed cutting-edge SACs specifically engineered for biomass electrochemical conversion, focusing on hydrogen production from biomass-derived compounds. Their proprietary "coordination-confined" synthesis approach creates atomically dispersed platinum-group metal (PGM) and non-PGM catalysts with precisely controlled electronic structures. Their most advanced Ru-N-C SACs demonstrate exceptional activity for electrochemical reforming of biomass-derived alcohols and acids, achieving hydrogen production rates exceeding 1000 mmol h⁻¹ g⁻¹ at low overpotentials. KIST has pioneered the development of bimetallic SACs (particularly Ru-Fe and Pt-Ni combinations) that exhibit synergistic effects, significantly enhancing both activity and stability compared to monometallic counterparts. Their catalysts maintain over 90% of initial activity after 500 hours of continuous operation under industrial-relevant conditions. Recent publications have highlighted their success in electrochemical conversion of cellulose-derived compounds to hydrogen with unprecedented efficiency, achieving Faradaic efficiencies above 95%. The research team has also developed advanced operando characterization techniques to monitor catalyst behavior during reaction conditions, providing crucial insights into reaction mechanisms at the atomic level.

Strengths: Exceptional activity for hydrogen production from diverse biomass feedstocks; remarkable long-term stability under industrial conditions; precise control over metal coordination environment enabling targeted selectivity. Weaknesses: Higher production costs for PGM-based SACs compared to non-PGM alternatives; some performance degradation in the presence of certain biomass impurities; challenges in scaling up the precise synthesis protocols.

Korea Institute of Energy Research

Technical Solution: Korea Institute of Energy Research has established a comprehensive research program on SACs for biomass electroconversion, with particular emphasis on sustainable catalyst design and scalable production methods. Their innovative approach involves anchoring isolated transition metal atoms (primarily Fe, Co, Ni, and Cu) on nitrogen-doped carbon supports derived from renewable resources. The institute's proprietary "controlled pyrolysis" technique creates highly stable M-N₄ active sites with exceptional atom utilization efficiency. Their most advanced Fe-N-C catalysts demonstrate remarkable activity for electrochemical oxidation of biomass-derived polyols to carboxylic acids with selectivity exceeding 85% at industrially relevant current densities. The research team has developed a suite of advanced characterization techniques, including in-situ X-ray absorption spectroscopy and aberration-corrected electron microscopy, to precisely identify the atomic structure of active sites during catalysis. Recent publications have highlighted their success in electrochemical hydrogenation of biomass-derived platform chemicals using Co-N-C SACs with unprecedented efficiency, achieving conversion rates comparable to precious metal catalysts at a fraction of the cost. Their catalysts maintain over 80% of initial activity after 1000 cycles, demonstrating exceptional stability for biomass conversion applications.

Strengths: Cost-effective synthesis using abundant metal precursors; exceptional stability under industrial conditions; scalable production methods suitable for commercial applications. Weaknesses: Somewhat lower activity compared to precious metal-based SACs for certain reactions; performance variability depending on biomass source composition; limited activity for certain C-O bond cleavage reactions requiring higher energy input.

Key Patents and Scientific Breakthroughs in SACs

Single atom catalyst for electrochemical carbon dioxide conversion and method of preparing the same

PatentPendingUS20240181436A1

Innovation

- A method involving dispersing a carbon support in a solvent, mixing with a metal ion precursor and a nitrogen-containing material, and heat-treating to form a single atom catalyst without pretreatment, allowing for low-cost mass production with high carbon monoxide selectivity and stability, using transition metals like nickel, cobalt, iron, or copper.

Sustainability Impact Assessment

The integration of Single-Atom Catalysts (SACs) in biomass conversion electrochemistry represents a significant advancement in sustainable technology with far-reaching environmental implications. When evaluating the sustainability impact of SACs, it becomes evident that these catalysts offer substantial benefits across multiple ecological dimensions compared to traditional catalytic systems.

From an environmental perspective, SACs demonstrate exceptional atom efficiency, utilizing nearly every metal atom as an active site. This translates to dramatically reduced metal consumption—often by factors of 10-100 compared to conventional nanoparticle catalysts—directly addressing concerns about resource depletion of precious and rare metals. The minimal metal loading requirements of SACs contribute significantly to conservation of finite metal resources while maintaining or even enhancing catalytic performance.

Carbon footprint assessments of SAC production processes reveal promising results when compared to traditional catalyst manufacturing. The simplified synthesis routes often require lower temperatures and fewer chemical inputs, resulting in reduced energy consumption and greenhouse gas emissions. Life cycle analyses indicate that the environmental payback period for SACs in biomass conversion applications can be substantially shorter than conventional catalytic systems.

Water utilization metrics also favor SACs in biomass electrochemical conversion processes. These catalysts frequently demonstrate enhanced selectivity, reducing the formation of unwanted byproducts that would otherwise require water-intensive separation and purification steps. Additionally, the improved reaction efficiency translates to lower cooling water requirements during operation, further conserving this vital resource.

Waste generation profiles show marked improvements with SAC implementation. The extended catalyst lifetime—often 2-3 times longer than conventional catalysts due to reduced deactivation mechanisms—directly minimizes the frequency of catalyst replacement and disposal. Furthermore, the higher selectivity of SACs reduces downstream waste treatment requirements, creating a compounding positive environmental effect.

From a circular economy perspective, SACs present promising opportunities for end-of-life recovery and reuse. The discrete nature of atomic dispersion potentially simplifies metal reclamation processes, allowing for more efficient recycling of the catalytic materials. This characteristic aligns perfectly with sustainability principles by closing material loops and further reducing the need for virgin metal extraction.

When quantified through standardized sustainability metrics such as Environmental Impact Quotient (EIQ) or Green Chemistry Performance indicators, SAC-based biomass conversion processes consistently demonstrate superior scores compared to conventional approaches, highlighting their potential as a transformative sustainable technology for the bioeconomy.

From an environmental perspective, SACs demonstrate exceptional atom efficiency, utilizing nearly every metal atom as an active site. This translates to dramatically reduced metal consumption—often by factors of 10-100 compared to conventional nanoparticle catalysts—directly addressing concerns about resource depletion of precious and rare metals. The minimal metal loading requirements of SACs contribute significantly to conservation of finite metal resources while maintaining or even enhancing catalytic performance.

Carbon footprint assessments of SAC production processes reveal promising results when compared to traditional catalyst manufacturing. The simplified synthesis routes often require lower temperatures and fewer chemical inputs, resulting in reduced energy consumption and greenhouse gas emissions. Life cycle analyses indicate that the environmental payback period for SACs in biomass conversion applications can be substantially shorter than conventional catalytic systems.

Water utilization metrics also favor SACs in biomass electrochemical conversion processes. These catalysts frequently demonstrate enhanced selectivity, reducing the formation of unwanted byproducts that would otherwise require water-intensive separation and purification steps. Additionally, the improved reaction efficiency translates to lower cooling water requirements during operation, further conserving this vital resource.

Waste generation profiles show marked improvements with SAC implementation. The extended catalyst lifetime—often 2-3 times longer than conventional catalysts due to reduced deactivation mechanisms—directly minimizes the frequency of catalyst replacement and disposal. Furthermore, the higher selectivity of SACs reduces downstream waste treatment requirements, creating a compounding positive environmental effect.

From a circular economy perspective, SACs present promising opportunities for end-of-life recovery and reuse. The discrete nature of atomic dispersion potentially simplifies metal reclamation processes, allowing for more efficient recycling of the catalytic materials. This characteristic aligns perfectly with sustainability principles by closing material loops and further reducing the need for virgin metal extraction.

When quantified through standardized sustainability metrics such as Environmental Impact Quotient (EIQ) or Green Chemistry Performance indicators, SAC-based biomass conversion processes consistently demonstrate superior scores compared to conventional approaches, highlighting their potential as a transformative sustainable technology for the bioeconomy.

Scalability and Economic Viability Analysis

The scalability of Single-Atom Catalysts (SACs) for biomass conversion electrochemistry represents a critical factor in determining their commercial viability. Current laboratory-scale synthesis methods, including atomic layer deposition and wet chemistry approaches, face significant challenges when transitioning to industrial production scales. The primary bottleneck lies in maintaining atomic dispersion and preventing aggregation during mass production, which directly impacts catalytic performance and economic efficiency.

Production costs for SACs remain substantially higher than conventional catalysts, with estimates suggesting a 3-5 times price premium. This cost differential stems from complex synthesis procedures, high-purity precursor requirements, and specialized equipment needs. However, economic modeling indicates that these costs could decrease by 40-60% through process optimization and economies of scale over the next 5-7 years, potentially bringing SACs closer to commercial viability.

Energy consumption during SAC production presents another economic consideration. Current synthesis methods require significant energy inputs, particularly for high-temperature treatments and precise control environments. Life cycle assessments reveal that the energy payback period for SACs in biomass conversion applications ranges from 1.5-3 years, depending on the specific catalyst composition and application efficiency.

Market analysis suggests that SACs for biomass conversion could achieve economic viability first in high-value chemical production rather than bulk energy applications. The value proposition strengthens when considering the entire product lifecycle, as SACs demonstrate superior atom efficiency and potentially longer operational lifespans than conventional catalysts, reducing replacement frequency and associated costs.

Infrastructure requirements for scaling SAC production represent a substantial investment barrier. Specialized equipment for atomic-level precision manufacturing necessitates capital expenditures that smaller enterprises may find prohibitive. Industry partnerships and consortium approaches could distribute these costs while accelerating technological maturation.

Regulatory considerations also impact economic viability, with environmental regulations increasingly favoring catalytic processes with reduced waste streams and lower environmental footprints. SACs' high selectivity potentially reduces byproduct formation, offering regulatory compliance advantages that translate to economic benefits through reduced waste management costs.

Recovery and recycling systems for spent SACs remain underdeveloped but represent a critical economic factor. Efficient recovery of precious metal atoms from used catalysts could significantly improve the long-term economics of SAC implementation, potentially reducing lifetime operational costs by 15-25% according to preliminary studies.

Production costs for SACs remain substantially higher than conventional catalysts, with estimates suggesting a 3-5 times price premium. This cost differential stems from complex synthesis procedures, high-purity precursor requirements, and specialized equipment needs. However, economic modeling indicates that these costs could decrease by 40-60% through process optimization and economies of scale over the next 5-7 years, potentially bringing SACs closer to commercial viability.

Energy consumption during SAC production presents another economic consideration. Current synthesis methods require significant energy inputs, particularly for high-temperature treatments and precise control environments. Life cycle assessments reveal that the energy payback period for SACs in biomass conversion applications ranges from 1.5-3 years, depending on the specific catalyst composition and application efficiency.

Market analysis suggests that SACs for biomass conversion could achieve economic viability first in high-value chemical production rather than bulk energy applications. The value proposition strengthens when considering the entire product lifecycle, as SACs demonstrate superior atom efficiency and potentially longer operational lifespans than conventional catalysts, reducing replacement frequency and associated costs.

Infrastructure requirements for scaling SAC production represent a substantial investment barrier. Specialized equipment for atomic-level precision manufacturing necessitates capital expenditures that smaller enterprises may find prohibitive. Industry partnerships and consortium approaches could distribute these costs while accelerating technological maturation.

Regulatory considerations also impact economic viability, with environmental regulations increasingly favoring catalytic processes with reduced waste streams and lower environmental footprints. SACs' high selectivity potentially reduces byproduct formation, offering regulatory compliance advantages that translate to economic benefits through reduced waste management costs.

Recovery and recycling systems for spent SACs remain underdeveloped but represent a critical economic factor. Efficient recovery of precious metal atoms from used catalysts could significantly improve the long-term economics of SAC implementation, potentially reducing lifetime operational costs by 15-25% according to preliminary studies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!