SACs In Flow Reactors: Design And Mass Transport

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SACs Flow Reactor Technology Background and Objectives

Single-atom catalysts (SACs) in flow reactors represent a revolutionary advancement in catalytic technology, combining the atomic efficiency of homogeneous catalysis with the practical advantages of heterogeneous systems. The evolution of this technology can be traced back to the early 2000s when researchers first began exploring the potential of isolated metal atoms anchored on supports. By 2011, Zhang and colleagues had published groundbreaking work demonstrating the exceptional activity and selectivity of single-atom Pt catalysts, marking a significant milestone in the field.

The technological trajectory has since accelerated, with researchers worldwide focusing on developing more efficient methods for synthesizing stable SACs and integrating them into continuous flow systems. This integration addresses key industrial challenges including catalyst recovery, product separation, and process intensification—all critical factors for sustainable chemical manufacturing.

The primary objective of SAC flow reactor technology development is to establish robust, scalable systems that maintain the unique catalytic properties of isolated metal atoms while enabling continuous operation under industrially relevant conditions. This includes optimizing mass transport phenomena, which is particularly crucial given the distinctive reaction kinetics at single-atom active sites compared to traditional nanoparticle catalysts.

Current research aims to overcome several technical hurdles, including the tendency of single atoms to aggregate under reaction conditions, the challenges in achieving uniform distribution of active sites, and the complexities of mass transport in structured flow environments. These challenges are being addressed through innovative reactor designs that enhance contact efficiency between reactants and catalytic sites while minimizing pressure drop and ensuring thermal stability.

The convergence of SAC technology with flow chemistry offers promising pathways toward more sustainable chemical processes. Flow reactors provide precise control over reaction parameters, enabling optimized conditions for SAC performance while minimizing waste generation. This synergy aligns with global sustainability goals, particularly in reducing the environmental footprint of chemical manufacturing through atom economy and energy efficiency.

Looking forward, the field is moving toward multifunctional flow reactor systems incorporating in-line monitoring and adaptive control mechanisms. These advanced systems aim to maintain optimal catalyst performance through real-time adjustments based on reaction progress and catalyst state, potentially revolutionizing how chemical transformations are conducted in both research and industrial settings.

The technological trajectory has since accelerated, with researchers worldwide focusing on developing more efficient methods for synthesizing stable SACs and integrating them into continuous flow systems. This integration addresses key industrial challenges including catalyst recovery, product separation, and process intensification—all critical factors for sustainable chemical manufacturing.

The primary objective of SAC flow reactor technology development is to establish robust, scalable systems that maintain the unique catalytic properties of isolated metal atoms while enabling continuous operation under industrially relevant conditions. This includes optimizing mass transport phenomena, which is particularly crucial given the distinctive reaction kinetics at single-atom active sites compared to traditional nanoparticle catalysts.

Current research aims to overcome several technical hurdles, including the tendency of single atoms to aggregate under reaction conditions, the challenges in achieving uniform distribution of active sites, and the complexities of mass transport in structured flow environments. These challenges are being addressed through innovative reactor designs that enhance contact efficiency between reactants and catalytic sites while minimizing pressure drop and ensuring thermal stability.

The convergence of SAC technology with flow chemistry offers promising pathways toward more sustainable chemical processes. Flow reactors provide precise control over reaction parameters, enabling optimized conditions for SAC performance while minimizing waste generation. This synergy aligns with global sustainability goals, particularly in reducing the environmental footprint of chemical manufacturing through atom economy and energy efficiency.

Looking forward, the field is moving toward multifunctional flow reactor systems incorporating in-line monitoring and adaptive control mechanisms. These advanced systems aim to maintain optimal catalyst performance through real-time adjustments based on reaction progress and catalyst state, potentially revolutionizing how chemical transformations are conducted in both research and industrial settings.

Market Applications and Demand Analysis for SACs Flow Reactors

The global market for Single-Atom Catalysts (SACs) in flow reactors is experiencing significant growth, driven by increasing demands for sustainable chemical manufacturing processes. Current market valuations indicate that the catalysis market relevant to flow chemistry applications exceeds $20 billion annually, with SACs representing an emerging segment projected to grow at a compound annual rate of 8.3% through 2028.

Pharmaceutical manufacturing constitutes the largest application sector, accounting for approximately 35% of the market demand for SACs in flow reactors. This dominance stems from the industry's need for highly selective catalytic processes that minimize side reactions and reduce purification requirements. The ability of SACs to facilitate precise chemical transformations at lower temperatures and pressures aligns perfectly with pharmaceutical green chemistry initiatives.

Fine chemical production represents the second-largest market segment at 28%, where manufacturers seek enhanced atom efficiency and reduced waste generation. The exceptional selectivity of SACs in flow systems enables more efficient synthesis routes for complex molecules, reducing production costs by an estimated 15-20% compared to conventional batch processes using traditional heterogeneous catalysts.

Energy sector applications, particularly in fuel cell technology and hydrogen production, constitute a rapidly growing segment at 18% of the current market. The unique electronic properties of isolated metal atoms in SACs significantly improve catalytic performance in electrochemical reactions, driving adoption in renewable energy applications.

Regional analysis reveals that North America and Europe currently lead market adoption with 37% and 33% market share respectively, primarily due to stringent environmental regulations and established pharmaceutical manufacturing bases. However, the Asia-Pacific region demonstrates the fastest growth rate at 12.5% annually, driven by expanding chemical manufacturing capabilities in China, Japan, and South Korea.

Customer demand analysis indicates five primary market drivers: improved reaction selectivity (cited by 87% of industrial users), reduced catalyst loading requirements (76%), enhanced process sustainability (72%), continuous manufacturing capabilities (68%), and potential for novel reaction pathways (61%). These factors collectively contribute to the strong market pull for SAC flow reactor technologies.

Industry surveys reveal that end-users are willing to pay premium prices for SAC flow reactor systems that demonstrate quantifiable improvements in yield, selectivity, and sustainability metrics. The average return on investment period for industrial implementations has decreased from 3.2 years in 2018 to 2.1 years currently, indicating improving economic viability and growing market acceptance of this technology.

Pharmaceutical manufacturing constitutes the largest application sector, accounting for approximately 35% of the market demand for SACs in flow reactors. This dominance stems from the industry's need for highly selective catalytic processes that minimize side reactions and reduce purification requirements. The ability of SACs to facilitate precise chemical transformations at lower temperatures and pressures aligns perfectly with pharmaceutical green chemistry initiatives.

Fine chemical production represents the second-largest market segment at 28%, where manufacturers seek enhanced atom efficiency and reduced waste generation. The exceptional selectivity of SACs in flow systems enables more efficient synthesis routes for complex molecules, reducing production costs by an estimated 15-20% compared to conventional batch processes using traditional heterogeneous catalysts.

Energy sector applications, particularly in fuel cell technology and hydrogen production, constitute a rapidly growing segment at 18% of the current market. The unique electronic properties of isolated metal atoms in SACs significantly improve catalytic performance in electrochemical reactions, driving adoption in renewable energy applications.

Regional analysis reveals that North America and Europe currently lead market adoption with 37% and 33% market share respectively, primarily due to stringent environmental regulations and established pharmaceutical manufacturing bases. However, the Asia-Pacific region demonstrates the fastest growth rate at 12.5% annually, driven by expanding chemical manufacturing capabilities in China, Japan, and South Korea.

Customer demand analysis indicates five primary market drivers: improved reaction selectivity (cited by 87% of industrial users), reduced catalyst loading requirements (76%), enhanced process sustainability (72%), continuous manufacturing capabilities (68%), and potential for novel reaction pathways (61%). These factors collectively contribute to the strong market pull for SAC flow reactor technologies.

Industry surveys reveal that end-users are willing to pay premium prices for SAC flow reactor systems that demonstrate quantifiable improvements in yield, selectivity, and sustainability metrics. The average return on investment period for industrial implementations has decreased from 3.2 years in 2018 to 2.1 years currently, indicating improving economic viability and growing market acceptance of this technology.

Current Challenges in SACs Flow Reactor Design

Despite significant advancements in Single-Atom Catalysts (SACs) technology, several critical challenges persist in flow reactor design that impede optimal performance and widespread industrial adoption. The primary obstacle remains the effective dispersion and stabilization of single metal atoms on support materials under flow conditions. Unlike batch reactors, flow systems subject catalysts to continuous mechanical stress and varying fluid dynamics, often leading to metal atom aggregation and subsequent loss of catalytic activity.

Mass transport limitations represent another significant hurdle in SAC flow reactor design. The inherent nature of flow systems creates complex concentration gradients that can result in uneven catalyst utilization and reduced efficiency. Particularly challenging is the balance between residence time and reaction rate, as insufficient contact time between reactants and catalytic sites diminishes conversion rates, while excessive residence time may promote unwanted side reactions or catalyst deactivation.

Heat management presents additional complications in SAC flow reactors. Many catalytic processes involving SACs are highly exothermic, and the efficient removal of reaction heat in narrow flow channels remains problematic. Temperature hotspots can develop rapidly, potentially causing catalyst sintering, support degradation, or runaway reactions that compromise both safety and selectivity.

The scalability of SAC flow reactor technology constitutes a formidable challenge for industrial implementation. Laboratory-scale successes often fail to translate directly to production-scale operations due to non-linear scaling effects on fluid dynamics, heat transfer, and mass transport phenomena. This scaling gap significantly hinders the commercial viability of many promising SAC flow reactor systems.

Monitoring and control systems for SAC flow reactors remain underdeveloped compared to conventional catalytic processes. Real-time analysis of catalyst performance, detection of deactivation, and adaptive control of reaction parameters are particularly difficult in flow systems where catalyst accessibility is limited. The lack of suitable in-situ characterization techniques specifically designed for flow environments further complicates performance optimization.

Material compatibility issues also plague current SAC flow reactor designs. The combination of potentially corrosive reaction media, high pressures, and elevated temperatures demands reactor materials that maintain structural integrity while remaining chemically inert. Additionally, these materials must facilitate efficient heat transfer without interfering with the catalytic process or contributing to catalyst poisoning.

Addressing these multifaceted challenges requires interdisciplinary approaches combining advances in materials science, reaction engineering, computational modeling, and process control. Future developments in SAC flow reactor design will likely focus on novel support materials with enhanced stability, innovative reactor geometries optimizing mass transport, and integrated sensing technologies enabling precise reaction control.

Mass transport limitations represent another significant hurdle in SAC flow reactor design. The inherent nature of flow systems creates complex concentration gradients that can result in uneven catalyst utilization and reduced efficiency. Particularly challenging is the balance between residence time and reaction rate, as insufficient contact time between reactants and catalytic sites diminishes conversion rates, while excessive residence time may promote unwanted side reactions or catalyst deactivation.

Heat management presents additional complications in SAC flow reactors. Many catalytic processes involving SACs are highly exothermic, and the efficient removal of reaction heat in narrow flow channels remains problematic. Temperature hotspots can develop rapidly, potentially causing catalyst sintering, support degradation, or runaway reactions that compromise both safety and selectivity.

The scalability of SAC flow reactor technology constitutes a formidable challenge for industrial implementation. Laboratory-scale successes often fail to translate directly to production-scale operations due to non-linear scaling effects on fluid dynamics, heat transfer, and mass transport phenomena. This scaling gap significantly hinders the commercial viability of many promising SAC flow reactor systems.

Monitoring and control systems for SAC flow reactors remain underdeveloped compared to conventional catalytic processes. Real-time analysis of catalyst performance, detection of deactivation, and adaptive control of reaction parameters are particularly difficult in flow systems where catalyst accessibility is limited. The lack of suitable in-situ characterization techniques specifically designed for flow environments further complicates performance optimization.

Material compatibility issues also plague current SAC flow reactor designs. The combination of potentially corrosive reaction media, high pressures, and elevated temperatures demands reactor materials that maintain structural integrity while remaining chemically inert. Additionally, these materials must facilitate efficient heat transfer without interfering with the catalytic process or contributing to catalyst poisoning.

Addressing these multifaceted challenges requires interdisciplinary approaches combining advances in materials science, reaction engineering, computational modeling, and process control. Future developments in SAC flow reactor design will likely focus on novel support materials with enhanced stability, innovative reactor geometries optimizing mass transport, and integrated sensing technologies enabling precise reaction control.

Current Mass Transport Solutions in Flow Reactor Systems

01 Design of SACs for enhanced mass transport in flow reactors

Single-atom catalysts can be specifically designed to optimize mass transport properties in flow reactor systems. This involves controlling the dispersion of single metal atoms on support materials to maximize active site accessibility and minimize diffusion limitations. The atomic-level distribution of catalytic sites allows for efficient contact between reactants and catalysts, enhancing overall mass transport efficiency in continuous flow operations.- Design of flow reactors for SACs: Flow reactors designed specifically for single-atom catalysts (SACs) can enhance mass transport properties by optimizing flow patterns and reactor geometry. These designs focus on improving contact between reactants and catalytic sites while minimizing transport limitations. Advanced flow reactor configurations can include microchannels, structured packings, or monolithic supports that provide high surface area-to-volume ratios, ensuring efficient mass transfer to and from the atomically dispersed active sites.

- Support materials for SACs in flow applications: The choice of support material significantly impacts mass transport in SAC flow systems. Porous materials with controlled pore architectures, such as metal-organic frameworks (MOFs), zeolites, or hierarchical carbon structures, can be engineered to facilitate efficient diffusion of reactants to single-atom active sites. These supports can be functionalized to enhance catalyst stability while maintaining optimal mass transport properties under continuous flow conditions.

- Mass transfer enhancement techniques for SACs: Various techniques can be employed to enhance mass transfer in SAC flow systems, including ultrasonic assistance, pulsed flow, and controlled turbulence generation. These methods help overcome diffusion limitations by improving mixing and reducing boundary layer thickness around catalyst particles. Additionally, the incorporation of structured elements within flow reactors can create localized flow patterns that optimize the transport of reactants to atomically dispersed active sites.

- Multiphase flow systems with SACs: Multiphase flow systems incorporating SACs present unique mass transport challenges and opportunities. Gas-liquid-solid interactions in these systems can be optimized through careful control of flow regimes, interfacial areas, and phase distributions. Specialized reactor designs for multiphase operation with SACs include trickle-bed configurations, Taylor flow microreactors, and structured packings that enhance interfacial mass transfer while maintaining the atomic dispersion of catalytic sites.

- Modeling and simulation of mass transport in SAC flow systems: Computational modeling and simulation tools are essential for understanding and optimizing mass transport phenomena in SAC flow reactors. These include computational fluid dynamics (CFD), molecular dynamics simulations, and multiscale modeling approaches that can predict flow patterns, concentration gradients, and reaction kinetics at the atomic scale. Such models help identify transport limitations and guide the design of improved reactor configurations and operating conditions for SAC-based flow processes.

02 Support materials for SACs affecting mass transport characteristics

The choice of support material significantly impacts mass transport phenomena in single-atom catalyst flow systems. Materials such as metal oxides, carbon-based supports, and porous frameworks can be engineered to provide optimal pore structures and surface properties that facilitate reactant diffusion to catalytic sites. These supports can be functionalized to control hydrophilicity/hydrophobicity balance, further enhancing mass transport in liquid-phase flow reactions.Expand Specific Solutions03 Flow reactor configurations optimized for SAC mass transport

Specialized flow reactor designs can address mass transport limitations when using single-atom catalysts. Microreactor and structured reactor technologies with enhanced mixing capabilities, controlled flow patterns, and optimized channel geometries can significantly improve mass transfer rates. These configurations minimize boundary layer effects and ensure uniform contact between reactants and the atomically dispersed catalytic sites.Expand Specific Solutions04 Mass transport enhancement through process parameter optimization

Process parameters such as flow rate, pressure, temperature, and residence time can be optimized to enhance mass transport in SAC-based flow systems. Higher flow rates can reduce external mass transfer limitations, while pressure and temperature adjustments can improve diffusion rates and reaction kinetics. Advanced control strategies that dynamically adjust these parameters based on reaction progress can further optimize mass transport efficiency.Expand Specific Solutions05 Multiphase flow considerations for SAC mass transport

In multiphase flow systems utilizing single-atom catalysts, special considerations are needed to address interfacial mass transport phenomena. Techniques such as emulsification, microdroplet formation, and gas-liquid segmented flow can enhance interfacial area and reduce mass transfer resistance. The unique properties of SACs, with their atomically dispersed active sites, can be leveraged to facilitate reactions at phase boundaries where mass transport is often limiting.Expand Specific Solutions

Leading Companies and Research Institutions in SACs Technology

The SACs (Structured Activated Carbons) in flow reactors market is currently in a growth phase, with increasing adoption across chemical processing and environmental applications. The market size is expanding steadily, driven by demands for more efficient catalytic processes and sustainable manufacturing solutions. Technologically, SACs in flow reactors are advancing toward maturity, with companies like Corning, Waters Technology, and ExxonMobil leading innovation in reactor design optimization. Honda Motor and Nippon Shokubai are making significant progress in mass transport enhancement within these systems, while Zhejiang University and Dalian University of Technology contribute valuable academic research. BP Corporation and Praxair Technology focus on industrial-scale implementations. The competitive landscape shows a balanced mix of established chemical companies, equipment manufacturers, and research institutions collaborating to overcome mass transport limitations in continuous flow processes.

Nippon Shokubai Co., Ltd.

Technical Solution: Nippon Shokubai has developed advanced SAC flow reactor technology specifically optimized for selective oxidation and polymerization processes. Their approach features structured catalytic elements with precisely controlled geometric characteristics, including channel dimensions of 0.5-2.5mm and wall thicknesses of 100-300μm. The company's proprietary catalyst formulations are applied using specialized sol-gel techniques that create highly adherent coatings with controlled porosity (typically 30-60% void fraction) and thickness uniformity within ±10%. Nippon Shokubai's reactors incorporate innovative flow distribution systems that achieve coefficient of variation in flow distribution below 0.1 across the reactor cross-section. Their mass transport enhancement features include engineered surface textures that create controlled secondary flows, improving gas-liquid mass transfer coefficients by factors of 2-4 compared to smooth channels. The technology has demonstrated exceptional performance in partial oxidation reactions, achieving selectivity improvements of 5-15% and space-time yields up to 3 times higher than conventional fixed-bed reactors. Their systems also feature integrated heat recovery mechanisms that capture and utilize reaction heat, improving overall energy efficiency by 20-35%.

Strengths: Exceptional selectivity control in complex reaction networks; excellent catalyst utilization efficiency; superior heat management for highly exothermic reactions. Weaknesses: Relatively complex manufacturing process increases production costs; specialized catalyst formulations may limit application flexibility; higher pressure drop compared to some alternative technologies.

Corning, Inc.

Technical Solution: Corning has developed advanced flow reactor technologies specifically designed for structured catalytic applications (SACs). Their proprietary Advanced-Flow™ Reactors utilize precision-engineered glass and ceramic materials with optimized microstructures that enhance mass transport phenomena. These reactors feature precisely controlled channel geometries (typically 0.5-2mm in diameter) that create high surface-area-to-volume ratios exceeding 10,000 m²/m³, significantly improving reaction efficiency. Corning's technology incorporates specialized coating techniques for catalyst deposition, ensuring uniform distribution of catalytic materials throughout the flow channels. Their systems achieve exceptional heat transfer coefficients (>10 kW/m²K) through integrated heat exchange capabilities, allowing for precise temperature control even in highly exothermic reactions. The company has demonstrated up to 99% selectivity in various chemical processes using their SAC flow reactor designs, with residence times reduced by factors of 5-10 compared to conventional batch processes.

Strengths: Superior thermal management capabilities allow for precise temperature control in exothermic reactions; highly uniform flow distribution minimizes pressure drop; excellent scalability from laboratory to production scale. Weaknesses: Higher initial capital investment compared to conventional reactors; specialized expertise required for operation and maintenance; limited flexibility for process modifications once installed.

Key Innovations in SACs Design for Enhanced Mass Transfer

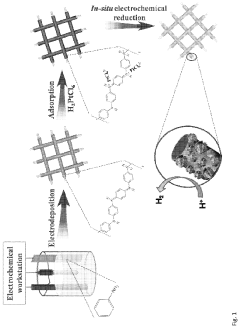

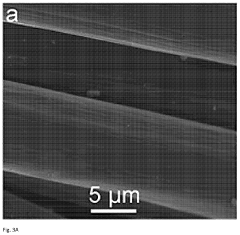

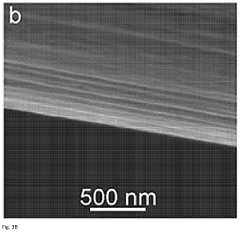

Single-atom catalysts and method of manufacture thereof

PatentPendingUS20230366111A1

Innovation

- The synthesis of single-atom catalysts (SACs) comprising nanofibers with uniformly dispersed single-atom metal sites, particularly Pt, Ru, and Pd, anchored on conductive polymers like polyaniline (PANI), which are produced through an electrochemical method that avoids the formation of metal clusters and nanoparticles, thereby maximizing active site exposure and catalytic efficiency.

Flow reactors for chemical conversions with hetergeneouos catalysts

PatentInactiveEP1412077B8

Innovation

- The design of flow reactors with a plurality of walled conduits having varying cross-sectional areas along their length, where each downstream zone has a larger cross-section and volume than the contiguous upstream zone, ensuring effective heat transfer and maintaining the outer surface in contact with a heat-transfer medium to manage the exotherm.

Scalability and Industrial Implementation Considerations

The scalability of Single-Atom Catalysts (SACs) in flow reactors represents a critical frontier for industrial implementation. Current laboratory-scale demonstrations must overcome significant engineering challenges to achieve commercial viability. The primary scaling consideration involves maintaining uniform catalyst distribution and preventing aggregation when reactor dimensions increase, as the exceptional catalytic properties of SACs derive from their isolated atomic nature.

Mass transport phenomena become increasingly complex at industrial scales, requiring sophisticated modeling approaches that account for fluid dynamics, heat transfer, and reaction kinetics simultaneously. Computational Fluid Dynamics (CFD) coupled with reaction engineering models has emerged as an essential tool for predicting performance at larger scales, though validation remains challenging due to the multi-parameter nature of these systems.

Material considerations present another crucial aspect of scalability. Industrial implementation demands catalyst supports with mechanical stability under high flow rates and pressure differentials. Advanced manufacturing techniques such as 3D printing and microfabrication offer promising approaches for creating structured supports with optimized flow patterns, potentially addressing mass transport limitations inherent in conventional packed-bed configurations.

Economic feasibility represents a significant hurdle, as SAC production methods often involve sophisticated synthesis protocols with expensive precursors. Recent advances in green synthesis routes and continuous manufacturing of the catalysts themselves may provide pathways to cost reduction. Life cycle assessment studies indicate that despite higher initial investment, the superior atom efficiency and selectivity of SACs can potentially offset costs through reduced waste treatment and higher-value products.

Regulatory considerations cannot be overlooked when scaling SAC flow reactor technology. Safety protocols for handling atomically dispersed noble metals differ from conventional catalysts, requiring specialized containment strategies and monitoring systems. Environmental impact assessments must account for potential metal leaching during long-term operation, though preliminary studies suggest minimal environmental footprint compared to traditional catalytic processes.

Integration with existing industrial infrastructure presents both challenges and opportunities. Modular flow reactor designs allow for gradual implementation and capacity expansion, potentially reducing capital risk. However, process control systems require significant adaptation to accommodate the unique kinetic profiles and sensitivity of SACs to process conditions, necessitating advanced sensing technologies and feedback control algorithms.

Mass transport phenomena become increasingly complex at industrial scales, requiring sophisticated modeling approaches that account for fluid dynamics, heat transfer, and reaction kinetics simultaneously. Computational Fluid Dynamics (CFD) coupled with reaction engineering models has emerged as an essential tool for predicting performance at larger scales, though validation remains challenging due to the multi-parameter nature of these systems.

Material considerations present another crucial aspect of scalability. Industrial implementation demands catalyst supports with mechanical stability under high flow rates and pressure differentials. Advanced manufacturing techniques such as 3D printing and microfabrication offer promising approaches for creating structured supports with optimized flow patterns, potentially addressing mass transport limitations inherent in conventional packed-bed configurations.

Economic feasibility represents a significant hurdle, as SAC production methods often involve sophisticated synthesis protocols with expensive precursors. Recent advances in green synthesis routes and continuous manufacturing of the catalysts themselves may provide pathways to cost reduction. Life cycle assessment studies indicate that despite higher initial investment, the superior atom efficiency and selectivity of SACs can potentially offset costs through reduced waste treatment and higher-value products.

Regulatory considerations cannot be overlooked when scaling SAC flow reactor technology. Safety protocols for handling atomically dispersed noble metals differ from conventional catalysts, requiring specialized containment strategies and monitoring systems. Environmental impact assessments must account for potential metal leaching during long-term operation, though preliminary studies suggest minimal environmental footprint compared to traditional catalytic processes.

Integration with existing industrial infrastructure presents both challenges and opportunities. Modular flow reactor designs allow for gradual implementation and capacity expansion, potentially reducing capital risk. However, process control systems require significant adaptation to accommodate the unique kinetic profiles and sensitivity of SACs to process conditions, necessitating advanced sensing technologies and feedback control algorithms.

Environmental Impact and Sustainability of SACs Flow Systems

The integration of Single-Atom Catalysts (SACs) in flow reactor systems represents a significant advancement in sustainable chemical processing technologies. These systems demonstrate remarkable potential for reducing environmental footprints across multiple industrial applications. The inherent atomic efficiency of SACs minimizes material waste, as nearly every catalytic atom participates in the reaction process, dramatically reducing the consumption of precious metals compared to traditional catalysts.

Flow reactor configurations further enhance this sustainability profile by enabling precise reaction control, resulting in higher selectivity and fewer unwanted by-products. This combination effectively addresses waste reduction challenges that have long plagued batch processing methods. Studies indicate that SAC flow systems can achieve up to 95% atom economy in certain reactions, representing a substantial improvement over conventional heterogeneous catalysis approaches.

Energy efficiency constitutes another critical environmental advantage of SAC flow systems. The continuous nature of flow processing eliminates the energy-intensive heating and cooling cycles characteristic of batch operations. Additionally, the superior activity of SACs often permits reactions to proceed under milder conditions, further reducing energy requirements. Recent research demonstrates that certain SAC flow configurations can operate at temperatures 30-50°C lower than their conventional counterparts while maintaining equivalent conversion rates.

Water consumption and pollution metrics also favor SAC flow technologies. The controlled reaction environment minimizes solvent requirements, with some systems achieving up to 80% reduction in process water usage. The enhanced catalytic efficiency simultaneously reduces the concentration of contaminants in effluent streams, simplifying downstream water treatment processes and reducing associated environmental impacts.

Life cycle assessments of SAC flow systems reveal promising sustainability profiles. When considering the entire production chain—from catalyst synthesis through operational lifetime to eventual deactivation—these systems typically demonstrate reduced carbon footprints compared to traditional catalytic processes. The extended catalyst lifetime, facilitated by controlled flow conditions that minimize deactivation mechanisms, further enhances their environmental credentials.

Challenges remain in scaling these environmental benefits to industrial levels. Current limitations in large-scale SAC production and stability under prolonged operation conditions must be addressed to fully realize the sustainability potential. Nevertheless, ongoing innovations in synthesis methods and support materials continue to improve the environmental performance of these systems, positioning SAC flow reactor technology as a cornerstone of future green chemistry initiatives and sustainable manufacturing practices.

Flow reactor configurations further enhance this sustainability profile by enabling precise reaction control, resulting in higher selectivity and fewer unwanted by-products. This combination effectively addresses waste reduction challenges that have long plagued batch processing methods. Studies indicate that SAC flow systems can achieve up to 95% atom economy in certain reactions, representing a substantial improvement over conventional heterogeneous catalysis approaches.

Energy efficiency constitutes another critical environmental advantage of SAC flow systems. The continuous nature of flow processing eliminates the energy-intensive heating and cooling cycles characteristic of batch operations. Additionally, the superior activity of SACs often permits reactions to proceed under milder conditions, further reducing energy requirements. Recent research demonstrates that certain SAC flow configurations can operate at temperatures 30-50°C lower than their conventional counterparts while maintaining equivalent conversion rates.

Water consumption and pollution metrics also favor SAC flow technologies. The controlled reaction environment minimizes solvent requirements, with some systems achieving up to 80% reduction in process water usage. The enhanced catalytic efficiency simultaneously reduces the concentration of contaminants in effluent streams, simplifying downstream water treatment processes and reducing associated environmental impacts.

Life cycle assessments of SAC flow systems reveal promising sustainability profiles. When considering the entire production chain—from catalyst synthesis through operational lifetime to eventual deactivation—these systems typically demonstrate reduced carbon footprints compared to traditional catalytic processes. The extended catalyst lifetime, facilitated by controlled flow conditions that minimize deactivation mechanisms, further enhances their environmental credentials.

Challenges remain in scaling these environmental benefits to industrial levels. Current limitations in large-scale SAC production and stability under prolonged operation conditions must be addressed to fully realize the sustainability potential. Nevertheless, ongoing innovations in synthesis methods and support materials continue to improve the environmental performance of these systems, positioning SAC flow reactor technology as a cornerstone of future green chemistry initiatives and sustainable manufacturing practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!