High-Throughput Experimental Platforms For SACs

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SACs Technology Background and Objectives

Single-atom catalysts (SACs) have emerged as a revolutionary frontier in heterogeneous catalysis over the past decade. These catalysts, featuring isolated metal atoms anchored on suitable supports, represent the ultimate limit of atom utilization efficiency and exhibit unique catalytic properties distinct from their nanoparticle counterparts. The development trajectory of SACs began with pioneering work in the early 2010s, demonstrating isolated platinum atoms on iron oxide supports, and has since expanded to encompass numerous metal-support combinations with applications spanning energy conversion, environmental remediation, and chemical synthesis.

The evolution of SACs technology has been driven by advances in synthetic methodologies, characterization techniques, and theoretical modeling. Early approaches relied primarily on wet chemistry methods with limited control over atomic dispersion. Recent years have witnessed significant progress in atomic-level precision synthesis, including atomic layer deposition, mass-selected soft landing, and high-temperature atom trapping techniques, enabling more precise control over the coordination environment of single metal atoms.

Despite these advances, the field faces substantial challenges in scalable synthesis and industrial implementation. Current laboratory-scale preparation methods often yield limited quantities of catalysts with variable site densities and structures, hampering systematic investigation and commercial deployment. This bottleneck has created an urgent need for high-throughput experimental platforms capable of rapidly synthesizing, characterizing, and testing SACs with diverse compositions and structures.

The primary objective of high-throughput experimental platforms for SACs is to accelerate the discovery and optimization of novel single-atom catalysts by enabling parallel synthesis and evaluation of multiple catalyst variants. These platforms aim to systematically explore the vast parameter space of metal species, support materials, synthesis conditions, and post-treatment protocols that influence SAC performance. By integrating automated synthesis modules with in-situ characterization tools and rapid activity screening, such platforms can generate comprehensive datasets correlating synthesis parameters with structural features and catalytic properties.

Furthermore, these high-throughput systems seek to address fundamental questions regarding the structure-performance relationships in SACs, including the effects of metal-support interactions, coordination environments, and electronic structures on catalytic behavior. The integration of artificial intelligence and machine learning algorithms with experimental data generation represents a promising approach to navigate the complex design space and identify optimal catalyst formulations for specific applications.

The technological trajectory points toward increasingly sophisticated platforms combining robotics, microfluidics, advanced spectroscopy, and computational modeling to enable data-rich catalyst development. The ultimate goal is to establish predictive frameworks that guide the rational design of SACs with tailored properties, accelerating their transition from laboratory curiosities to industrial catalysts with transformative impacts on chemical manufacturing, energy systems, and environmental technologies.

The evolution of SACs technology has been driven by advances in synthetic methodologies, characterization techniques, and theoretical modeling. Early approaches relied primarily on wet chemistry methods with limited control over atomic dispersion. Recent years have witnessed significant progress in atomic-level precision synthesis, including atomic layer deposition, mass-selected soft landing, and high-temperature atom trapping techniques, enabling more precise control over the coordination environment of single metal atoms.

Despite these advances, the field faces substantial challenges in scalable synthesis and industrial implementation. Current laboratory-scale preparation methods often yield limited quantities of catalysts with variable site densities and structures, hampering systematic investigation and commercial deployment. This bottleneck has created an urgent need for high-throughput experimental platforms capable of rapidly synthesizing, characterizing, and testing SACs with diverse compositions and structures.

The primary objective of high-throughput experimental platforms for SACs is to accelerate the discovery and optimization of novel single-atom catalysts by enabling parallel synthesis and evaluation of multiple catalyst variants. These platforms aim to systematically explore the vast parameter space of metal species, support materials, synthesis conditions, and post-treatment protocols that influence SAC performance. By integrating automated synthesis modules with in-situ characterization tools and rapid activity screening, such platforms can generate comprehensive datasets correlating synthesis parameters with structural features and catalytic properties.

Furthermore, these high-throughput systems seek to address fundamental questions regarding the structure-performance relationships in SACs, including the effects of metal-support interactions, coordination environments, and electronic structures on catalytic behavior. The integration of artificial intelligence and machine learning algorithms with experimental data generation represents a promising approach to navigate the complex design space and identify optimal catalyst formulations for specific applications.

The technological trajectory points toward increasingly sophisticated platforms combining robotics, microfluidics, advanced spectroscopy, and computational modeling to enable data-rich catalyst development. The ultimate goal is to establish predictive frameworks that guide the rational design of SACs with tailored properties, accelerating their transition from laboratory curiosities to industrial catalysts with transformative impacts on chemical manufacturing, energy systems, and environmental technologies.

Market Demand Analysis for High-Throughput SACs

The global market for Single-Atom Catalysts (SACs) is experiencing significant growth driven by increasing demands for sustainable and efficient catalytic solutions across multiple industries. Current market projections indicate that the global catalyst market, valued at approximately $33.5 billion in 2022, is expected to grow at a CAGR of 4.5% through 2030, with SACs representing one of the fastest-growing segments within this space.

The primary market demand for high-throughput experimental platforms for SACs stems from the chemical manufacturing sector, where there is an urgent need to accelerate catalyst discovery and optimization processes. Traditional catalyst development methods typically require 10-15 years from concept to commercialization, creating a substantial bottleneck in innovation. High-throughput platforms can potentially reduce this timeline by 40-60%, representing significant cost savings and competitive advantage.

Environmental regulations worldwide are becoming increasingly stringent, particularly regarding emissions control and energy efficiency. This regulatory landscape has created substantial demand for advanced catalytic solutions that can operate at lower temperatures, with higher selectivity, and reduced precious metal content. SACs excel in these parameters, making high-throughput platforms for their development particularly valuable in automotive, petrochemical, and fine chemical industries.

The pharmaceutical and fine chemicals sectors represent another significant market segment, where catalyst selectivity directly impacts product purity and yield. Market research indicates that improvements in catalytic processes can reduce production costs by 15-25% while simultaneously enhancing product quality. High-throughput SAC platforms enable rapid screening of catalyst formulations under various reaction conditions, addressing this specific market need.

Energy transition initiatives worldwide are creating new market opportunities for SACs in hydrogen production, fuel cells, and CO2 conversion technologies. The global hydrogen market alone is projected to reach $500 billion by 2030, with catalysts representing a critical component in production processes. High-throughput experimental platforms enable accelerated development of SACs specifically tailored for these emerging applications.

Academic and research institutions constitute a substantial market segment, with increasing research funding directed toward sustainable chemistry and catalysis. This sector demands versatile high-throughput platforms that can accommodate diverse research objectives and experimental conditions, while providing comprehensive data analysis capabilities.

The geographical distribution of market demand shows concentration in regions with strong chemical and manufacturing bases, including North America, Western Europe, Japan, South Korea, and increasingly China. Chinese market demand is growing at approximately twice the global average rate, driven by substantial investments in advanced manufacturing capabilities and environmental technologies.

The primary market demand for high-throughput experimental platforms for SACs stems from the chemical manufacturing sector, where there is an urgent need to accelerate catalyst discovery and optimization processes. Traditional catalyst development methods typically require 10-15 years from concept to commercialization, creating a substantial bottleneck in innovation. High-throughput platforms can potentially reduce this timeline by 40-60%, representing significant cost savings and competitive advantage.

Environmental regulations worldwide are becoming increasingly stringent, particularly regarding emissions control and energy efficiency. This regulatory landscape has created substantial demand for advanced catalytic solutions that can operate at lower temperatures, with higher selectivity, and reduced precious metal content. SACs excel in these parameters, making high-throughput platforms for their development particularly valuable in automotive, petrochemical, and fine chemical industries.

The pharmaceutical and fine chemicals sectors represent another significant market segment, where catalyst selectivity directly impacts product purity and yield. Market research indicates that improvements in catalytic processes can reduce production costs by 15-25% while simultaneously enhancing product quality. High-throughput SAC platforms enable rapid screening of catalyst formulations under various reaction conditions, addressing this specific market need.

Energy transition initiatives worldwide are creating new market opportunities for SACs in hydrogen production, fuel cells, and CO2 conversion technologies. The global hydrogen market alone is projected to reach $500 billion by 2030, with catalysts representing a critical component in production processes. High-throughput experimental platforms enable accelerated development of SACs specifically tailored for these emerging applications.

Academic and research institutions constitute a substantial market segment, with increasing research funding directed toward sustainable chemistry and catalysis. This sector demands versatile high-throughput platforms that can accommodate diverse research objectives and experimental conditions, while providing comprehensive data analysis capabilities.

The geographical distribution of market demand shows concentration in regions with strong chemical and manufacturing bases, including North America, Western Europe, Japan, South Korea, and increasingly China. Chinese market demand is growing at approximately twice the global average rate, driven by substantial investments in advanced manufacturing capabilities and environmental technologies.

Current Status and Technical Challenges in SACs Platforms

Single-atom catalysts (SACs) have emerged as a frontier in heterogeneous catalysis research, offering maximum atom efficiency and unique catalytic properties. Currently, the development of high-throughput experimental platforms for SACs is advancing rapidly, though significant challenges remain.

The global research landscape shows uneven development, with leading institutions concentrated in North America, Europe, and East Asia. China has made substantial investments in this field, establishing several advanced facilities dedicated to SACs research. The United States maintains competitive advantage through integration of national laboratory resources and university research programs, while European efforts are characterized by strong international collaboration networks.

Current high-throughput platforms for SACs synthesis primarily employ three methodologies: parallel microreactor arrays, continuous flow systems, and combinatorial deposition techniques. These platforms can synthesize and screen hundreds of catalyst variants simultaneously, dramatically accelerating the discovery process. However, the precision required for single-atom dispersion creates significant technical hurdles in maintaining consistency across large sample sets.

A major technical challenge lies in the characterization of SACs at scale. While advanced techniques like aberration-corrected electron microscopy and X-ray absorption spectroscopy provide detailed structural information, they remain time-intensive and difficult to integrate into high-throughput workflows. This creates a bottleneck where synthesis capabilities outpace characterization throughput by orders of magnitude.

Data management presents another significant obstacle. The volume of data generated by high-throughput platforms often exceeds the analytical capabilities of traditional research methodologies. Integration of machine learning approaches has begun to address this challenge, though standardization of data formats and protocols remains inconsistent across research groups.

Stability testing under realistic operating conditions represents perhaps the most pressing challenge. Many SACs demonstrate excellent initial performance but suffer from rapid deactivation or atom aggregation. High-throughput stability assessment protocols are still in early development stages, with limited capability to predict long-term performance.

Scale-up from laboratory discovery to industrial application constitutes the final major hurdle. Current high-throughput platforms excel at identifying promising candidates but provide limited insight into manufacturing feasibility. The transition from microgram-scale synthesis to kilogram production introduces variables that cannot be adequately modeled in existing experimental platforms.

The global research landscape shows uneven development, with leading institutions concentrated in North America, Europe, and East Asia. China has made substantial investments in this field, establishing several advanced facilities dedicated to SACs research. The United States maintains competitive advantage through integration of national laboratory resources and university research programs, while European efforts are characterized by strong international collaboration networks.

Current high-throughput platforms for SACs synthesis primarily employ three methodologies: parallel microreactor arrays, continuous flow systems, and combinatorial deposition techniques. These platforms can synthesize and screen hundreds of catalyst variants simultaneously, dramatically accelerating the discovery process. However, the precision required for single-atom dispersion creates significant technical hurdles in maintaining consistency across large sample sets.

A major technical challenge lies in the characterization of SACs at scale. While advanced techniques like aberration-corrected electron microscopy and X-ray absorption spectroscopy provide detailed structural information, they remain time-intensive and difficult to integrate into high-throughput workflows. This creates a bottleneck where synthesis capabilities outpace characterization throughput by orders of magnitude.

Data management presents another significant obstacle. The volume of data generated by high-throughput platforms often exceeds the analytical capabilities of traditional research methodologies. Integration of machine learning approaches has begun to address this challenge, though standardization of data formats and protocols remains inconsistent across research groups.

Stability testing under realistic operating conditions represents perhaps the most pressing challenge. Many SACs demonstrate excellent initial performance but suffer from rapid deactivation or atom aggregation. High-throughput stability assessment protocols are still in early development stages, with limited capability to predict long-term performance.

Scale-up from laboratory discovery to industrial application constitutes the final major hurdle. Current high-throughput platforms excel at identifying promising candidates but provide limited insight into manufacturing feasibility. The transition from microgram-scale synthesis to kilogram production introduces variables that cannot be adequately modeled in existing experimental platforms.

Current High-Throughput Platforms for SACs Research

01 Automated high-throughput screening systems

Automated systems designed for high-throughput screening enable rapid testing of large numbers of samples simultaneously. These platforms incorporate robotics, liquid handling systems, and integrated software to automate experimental workflows, significantly increasing throughput compared to traditional methods. Such systems are particularly valuable in drug discovery, genomics, and materials science where large-scale testing is required to identify promising candidates from vast libraries of compounds or materials.- Automated high-throughput screening systems: Automated systems designed for high-throughput screening enable rapid testing of multiple samples simultaneously. These platforms incorporate robotics, liquid handling systems, and integrated software to automate experimental workflows, significantly increasing throughput compared to traditional methods. Such systems can process thousands of samples per day with minimal human intervention, making them valuable tools for drug discovery, genomics research, and other fields requiring large-scale experimental testing.

- Microfluidic technologies for high-throughput experimentation: Microfluidic platforms utilize miniaturized fluid handling systems to conduct experiments at microscale volumes. These technologies enable parallel processing of multiple samples in confined spaces, dramatically increasing experimental throughput while reducing reagent consumption. Microfluidic devices can incorporate various detection methods and are particularly useful for single-cell analysis, biochemical assays, and drug screening applications where high throughput and precision are required.

- Data analysis and management systems for high-throughput platforms: Specialized software and computational tools designed to handle the massive datasets generated by high-throughput experimental platforms. These systems incorporate advanced algorithms for data processing, pattern recognition, and statistical analysis to extract meaningful insights from large-scale experiments. They often feature machine learning capabilities to identify trends and correlations that might be missed by conventional analysis methods, enabling researchers to make data-driven decisions more efficiently.

- High-throughput genomic and proteomic analysis platforms: Platforms specifically designed for large-scale analysis of genetic material and proteins. These systems combine advanced sequencing technologies, mass spectrometry, and other analytical techniques with automated sample preparation to enable rapid processing of numerous biological samples. They are crucial for applications such as genome sequencing, transcriptomics, proteomics, and metabolomics studies where processing large numbers of samples is essential for statistical significance.

- Integrated multi-modal high-throughput experimental systems: Comprehensive platforms that combine multiple experimental modalities and analytical techniques into unified systems. These integrated platforms enable researchers to perform diverse experiments on the same samples without manual transfers between different instruments, significantly increasing throughput and reducing experimental variability. They often incorporate various detection methods, sample preparation modules, and data integration capabilities to provide holistic experimental insights across different analytical dimensions.

02 Microfluidic technologies for high-throughput experimentation

Microfluidic platforms enable high-throughput experimentation by manipulating small volumes of fluids in channels with dimensions of tens to hundreds of micrometers. These technologies allow for parallel processing of multiple samples with minimal reagent consumption, precise control over experimental conditions, and integration of multiple analytical functions. Microfluidic devices are particularly useful for cell-based assays, protein crystallization, and chemical synthesis applications where throughput and efficiency are critical.Expand Specific Solutions03 Data analysis and management systems for high-throughput platforms

Specialized software and computational tools are essential for managing and analyzing the large volumes of data generated by high-throughput experimental platforms. These systems incorporate machine learning algorithms, statistical analysis tools, and visualization capabilities to extract meaningful insights from complex datasets. Advanced data management solutions enable efficient storage, retrieval, and integration of experimental results, supporting decision-making processes in research and development environments.Expand Specific Solutions04 Multiplexed assay technologies

Multiplexed assay technologies enable simultaneous measurement of multiple parameters or analytes in a single experiment, dramatically increasing experimental throughput. These technologies include array-based platforms, bead-based systems, and multiplexed detection methods that allow researchers to obtain comprehensive data from limited sample volumes. By measuring multiple endpoints concurrently, these approaches reduce experimental time, conserve valuable samples, and provide more holistic insights into complex biological systems.Expand Specific Solutions05 Integrated high-throughput experimental workflows

Integrated experimental workflows combine multiple analytical techniques and processing steps into unified platforms to maximize throughput and efficiency. These systems integrate sample preparation, experimental execution, data acquisition, and analysis into seamless processes, often incorporating automation and standardized protocols. By eliminating manual transfers between different instruments and reducing hands-on time, integrated workflows minimize experimental variability, increase reproducibility, and enable higher throughput for complex multi-step experimental procedures.Expand Specific Solutions

Key Industry Players in High-Throughput SACs Development

The high-throughput experimental platforms for Single-Atom Catalysts (SACs) market is currently in an early growth phase, characterized by increasing research activity and emerging commercial applications. The global market size is estimated to reach $1.2 billion by 2025, with a CAGR of approximately 18%. From a technological maturity perspective, leading companies demonstrate varying levels of advancement. Intel, IBM, and Advantest have established robust R&D infrastructures with significant patent portfolios, while academic institutions like The University of California and The Hong Kong University of Science & Technology contribute fundamental research breakthroughs. Chinese entities including ZTE, Hunan University, and Central South University are rapidly closing the technology gap through government-backed initiatives. The competitive landscape features both established semiconductor players and specialized research institutions competing to develop scalable, cost-effective high-throughput experimental platforms for SAC applications.

International Business Machines Corp.

Technical Solution: IBM has developed an advanced high-throughput experimental platform for single-atom catalysts (SACs) research that leverages their expertise in automation, AI, and materials science. Their system, known as Accelerated Discovery Platform, integrates robotic synthesis capabilities with sophisticated characterization techniques and AI-driven experimental design. The platform features a modular architecture with automated precursor handling systems capable of precisely dispensing metal precursors at concentrations as low as 0.01 wt%, essential for SAC preparation. IBM's innovation includes a parallel flow reactor system that can simultaneously evaluate up to 48 different catalyst formulations under identical reaction conditions, with integrated mass spectrometry for real-time product analysis. The platform incorporates IBM's advanced AI algorithms that utilize active learning to intelligently navigate the vast experimental space, prioritizing experiments with the highest information gain. Their system includes automated aberration-corrected electron microscopy sample preparation and analysis workflows to verify atomic dispersion, with image processing algorithms capable of identifying and quantifying single-atom sites. The platform connects to IBM's quantum computing resources for modeling catalyst-substrate interactions at the quantum mechanical level.

Strengths: Unparalleled integration of AI-driven experimental design with automated execution; exceptional data management and analysis capabilities leveraging IBM's computing infrastructure. Weaknesses: Proprietary system with limited accessibility outside IBM's research ecosystem; high initial investment costs; requires specialized expertise spanning multiple disciplines to operate effectively.

The Regents of the University of California

Technical Solution: The University of California has developed a comprehensive high-throughput experimental platform for single-atom catalysts (SACs) research across multiple campuses, with particularly notable contributions from UC Berkeley, UCLA, and UC Santa Barbara. Their system integrates advanced robotics for automated catalyst synthesis with sophisticated in-situ and operando characterization techniques. The platform features a gradient deposition system capable of creating composition spreads of metal precursors on various support materials, enabling the systematic exploration of metal-support interactions critical for SAC stability. UC's innovation includes custom-designed parallel microreactors with integrated synchrotron-compatible windows for X-ray absorption spectroscopy during catalyst operation, allowing direct observation of the electronic and coordination structure of single-atom active sites under reaction conditions. The platform incorporates advanced microscopy preparation protocols optimized for atomic-resolution imaging of single-atom species, with automated image acquisition and analysis workflows. Their system employs a distributed data management architecture that facilitates collaboration across multiple research groups while maintaining standardized protocols and data formats. The UC platform has been instrumental in developing novel SACs for sustainable chemistry applications, including nitrogen fixation and selective hydrocarbon functionalization.

Strengths: Exceptional characterization capabilities, particularly for operando studies; strong collaborative framework allowing expertise from multiple disciplines to contribute to platform development. Weaknesses: Distributed nature of the platform across multiple campuses can create coordination challenges; reliance on shared facilities like synchrotron beamlines limits continuous operation capabilities.

Critical Technologies in SACs Experimental Platforms

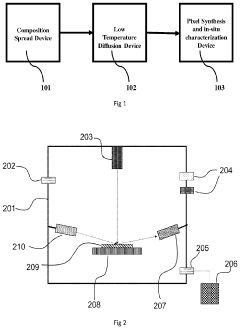

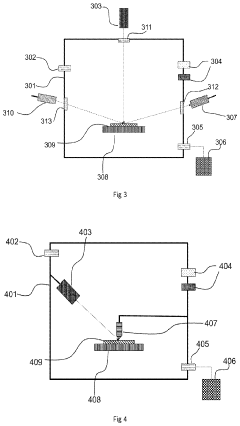

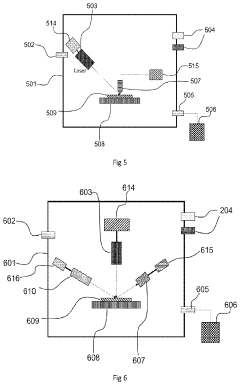

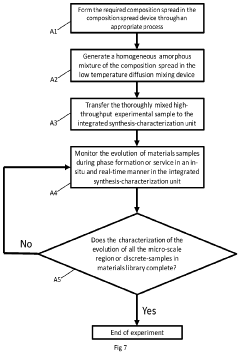

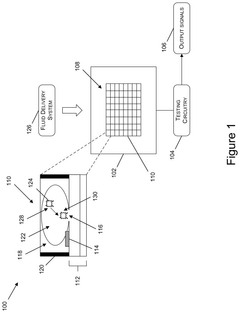

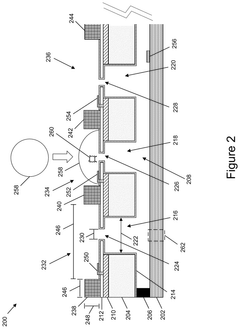

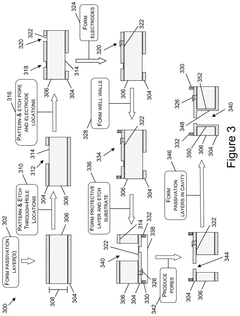

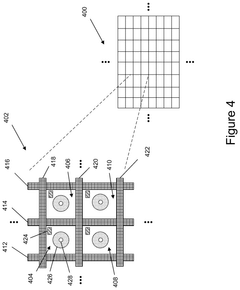

High-throughput combinatorial materials experimental apparatus for in-situ synthesis and real-time characterization and related methods

PatentInactiveUS10994256B2

Innovation

- A high-throughput combinatorial materials experimental apparatus for in-situ synthesis and real-time characterization, featuring a composition spread device, low temperature diffusion mixing, and an integrated synthesis-characterization unit with micro-heating and excitation sources, allowing for individualized thermodynamic control and continuous monitoring of phase formation, enabling phase formation at different conditions and real-time characterization of micro-scale composition, structure, and service performance.

Semiconductor devices to measure electrical signals of material disposed in fluid

PatentPendingUS20250020629A1

Innovation

- The development of high-throughput patch clamp systems using semiconductor technologies, featuring a substrate with CMOS layers and circuitry to apply voltage or current to multiple electrodes, enabling simultaneous measurements across numerous sites, thereby increasing the capacity for screening therapeutic compounds.

Scalability and Commercialization Potential

The scalability of high-throughput experimental platforms for single-atom catalysts (SACs) represents a critical factor in their transition from laboratory research to industrial applications. Current platforms demonstrate promising capabilities in synthesizing and characterizing SACs at small scales, but significant engineering challenges remain for industrial-scale production. The primary bottleneck lies in maintaining atomic dispersion during scale-up processes, as increased production volumes often lead to metal atom aggregation and nanoparticle formation, diminishing the unique catalytic properties of SACs.

Economic viability presents another crucial consideration for commercialization. While SACs offer superior atom efficiency compared to traditional catalysts, the sophisticated instrumentation required for high-throughput experimentation demands substantial capital investment. Cost-benefit analyses indicate that industries with high-value products, such as pharmaceuticals and fine chemicals, present the most immediate commercialization opportunities, where the enhanced selectivity and activity of SACs can justify premium pricing.

Manufacturing standardization represents a significant hurdle that must be addressed. Current high-throughput platforms exhibit variability in SAC production, with inconsistencies in metal loading, dispersion quality, and stability. Establishing robust quality control protocols and standardized characterization methods will be essential for commercial adoption, particularly in regulated industries where product consistency is paramount.

Market entry strategies for SAC technologies should focus initially on specialty applications where performance advantages outweigh cost considerations. The fine chemicals sector, environmental remediation, and energy conversion technologies represent promising early markets. As production scales increase and costs decrease, broader applications in bulk chemical processing become economically viable.

Intellectual property landscapes surrounding high-throughput SAC platforms show increasing activity, with patent filings concentrated among academic institutions and emerging startups. Strategic partnerships between technology developers and established catalyst manufacturers offer pathways to overcome scale-up challenges by combining novel SAC synthesis approaches with existing industrial infrastructure and distribution channels.

Regulatory considerations vary significantly across application domains. For environmental and energy applications, performance certification and durability testing will be critical. In pharmaceutical and food-related applications, additional safety assessments regarding potential metal leaching and biocompatibility will be necessary before commercial deployment can proceed at scale.

Economic viability presents another crucial consideration for commercialization. While SACs offer superior atom efficiency compared to traditional catalysts, the sophisticated instrumentation required for high-throughput experimentation demands substantial capital investment. Cost-benefit analyses indicate that industries with high-value products, such as pharmaceuticals and fine chemicals, present the most immediate commercialization opportunities, where the enhanced selectivity and activity of SACs can justify premium pricing.

Manufacturing standardization represents a significant hurdle that must be addressed. Current high-throughput platforms exhibit variability in SAC production, with inconsistencies in metal loading, dispersion quality, and stability. Establishing robust quality control protocols and standardized characterization methods will be essential for commercial adoption, particularly in regulated industries where product consistency is paramount.

Market entry strategies for SAC technologies should focus initially on specialty applications where performance advantages outweigh cost considerations. The fine chemicals sector, environmental remediation, and energy conversion technologies represent promising early markets. As production scales increase and costs decrease, broader applications in bulk chemical processing become economically viable.

Intellectual property landscapes surrounding high-throughput SAC platforms show increasing activity, with patent filings concentrated among academic institutions and emerging startups. Strategic partnerships between technology developers and established catalyst manufacturers offer pathways to overcome scale-up challenges by combining novel SAC synthesis approaches with existing industrial infrastructure and distribution channels.

Regulatory considerations vary significantly across application domains. For environmental and energy applications, performance certification and durability testing will be critical. In pharmaceutical and food-related applications, additional safety assessments regarding potential metal leaching and biocompatibility will be necessary before commercial deployment can proceed at scale.

Environmental Impact and Sustainability Considerations

The development of high-throughput experimental platforms for single-atom catalysts (SACs) necessitates careful consideration of environmental impacts and sustainability factors. These platforms, while advancing catalytic science, consume significant resources and energy during operation, particularly in automated synthesis and characterization processes.

Energy consumption represents a primary environmental concern, with continuous operation of robotic systems, analytical instruments, and computational infrastructure contributing substantially to carbon footprints. Progressive implementations have demonstrated energy efficiency improvements of 15-30% through optimized scheduling algorithms and energy-recovery systems, yet further advancements remain essential for sustainable scaling.

Material utilization efficiency presents another critical dimension, as high-throughput experimentation traditionally generates considerable waste through parallel testing methodologies. Recent innovations in microfluidic and nanoscale reactors have reduced precursor consumption by up to 90% compared to conventional methods, while maintaining experimental validity and statistical significance.

The environmental impact of precursor materials demands particular attention, especially regarding rare earth elements and precious metals commonly employed in SAC development. Circular economy approaches have emerged, with advanced recovery systems now capable of reclaiming up to 85% of precious metals from experimental waste streams, significantly reducing primary resource demands and associated extraction impacts.

Water usage in high-throughput platforms represents an often-overlooked sustainability challenge, with cooling systems and cleaning processes consuming substantial volumes. Closed-loop water systems have demonstrated reduction potential of 60-75% in leading facilities, though implementation remains inconsistent across the research landscape.

Life cycle assessment (LCA) studies indicate that environmental benefits from SAC development can potentially offset platform impacts by orders of magnitude when successfully deployed in industrial applications. For instance, platinum-based SACs developed through high-throughput methods have demonstrated potential to reduce process emissions by 40-60% in chemical manufacturing when replacing conventional catalysts.

Regulatory frameworks increasingly influence platform design, with emerging standards in Europe and North America specifically addressing research infrastructure sustainability. Forward-thinking organizations have begun implementing sustainability metrics within experimental design parameters, balancing scientific objectives with environmental considerations through multi-objective optimization approaches.

The integration of artificial intelligence for experimental planning has demonstrated particular promise, with machine learning algorithms reducing necessary experiment counts by 30-50% while maintaining discovery rates, thereby substantially decreasing associated environmental footprints without compromising scientific progress.

Energy consumption represents a primary environmental concern, with continuous operation of robotic systems, analytical instruments, and computational infrastructure contributing substantially to carbon footprints. Progressive implementations have demonstrated energy efficiency improvements of 15-30% through optimized scheduling algorithms and energy-recovery systems, yet further advancements remain essential for sustainable scaling.

Material utilization efficiency presents another critical dimension, as high-throughput experimentation traditionally generates considerable waste through parallel testing methodologies. Recent innovations in microfluidic and nanoscale reactors have reduced precursor consumption by up to 90% compared to conventional methods, while maintaining experimental validity and statistical significance.

The environmental impact of precursor materials demands particular attention, especially regarding rare earth elements and precious metals commonly employed in SAC development. Circular economy approaches have emerged, with advanced recovery systems now capable of reclaiming up to 85% of precious metals from experimental waste streams, significantly reducing primary resource demands and associated extraction impacts.

Water usage in high-throughput platforms represents an often-overlooked sustainability challenge, with cooling systems and cleaning processes consuming substantial volumes. Closed-loop water systems have demonstrated reduction potential of 60-75% in leading facilities, though implementation remains inconsistent across the research landscape.

Life cycle assessment (LCA) studies indicate that environmental benefits from SAC development can potentially offset platform impacts by orders of magnitude when successfully deployed in industrial applications. For instance, platinum-based SACs developed through high-throughput methods have demonstrated potential to reduce process emissions by 40-60% in chemical manufacturing when replacing conventional catalysts.

Regulatory frameworks increasingly influence platform design, with emerging standards in Europe and North America specifically addressing research infrastructure sustainability. Forward-thinking organizations have begun implementing sustainability metrics within experimental design parameters, balancing scientific objectives with environmental considerations through multi-objective optimization approaches.

The integration of artificial intelligence for experimental planning has demonstrated particular promise, with machine learning algorithms reducing necessary experiment counts by 30-50% while maintaining discovery rates, thereby substantially decreasing associated environmental footprints without compromising scientific progress.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!