Support Defect Engineering To Enhance SAC Binding

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SAC Binding Enhancement Background and Objectives

The field of Spindle Assembly Checkpoint (SAC) binding has emerged as a critical area of research in cell biology and cancer therapeutics over the past two decades. SAC serves as a fundamental quality control mechanism during cell division, ensuring accurate chromosome segregation by delaying anaphase onset until all chromosomes are properly attached to the mitotic spindle. Defects in SAC function have been implicated in chromosomal instability, aneuploidy, and various human diseases, particularly cancer.

Defect engineering represents an innovative approach to enhance SAC binding efficiency through the deliberate introduction and manipulation of structural imperfections at the molecular level. This technique has shown promising results in improving the sensitivity and robustness of the SAC mechanism, potentially offering new therapeutic avenues for addressing mitotic dysregulation in cancer cells.

The evolution of SAC binding research has progressed from initial identification of key components in the 1990s to current sophisticated understanding of its molecular architecture and signaling dynamics. Recent technological advancements in cryo-electron microscopy, super-resolution imaging, and computational modeling have significantly accelerated our comprehension of SAC binding mechanisms and opened new possibilities for targeted interventions.

Our primary objective is to systematically investigate how engineered defects in protein structures, binding interfaces, and signaling pathways can enhance SAC binding efficiency and fidelity. This includes exploring various defect types (point mutations, conformational alterations, post-translational modifications) and their impacts on binding kinetics, signal amplification, and checkpoint sustainability under different cellular conditions.

Additionally, we aim to develop predictive models that can guide rational design of defect engineering strategies for specific SAC components, particularly focusing on the Mad1-Mad2, BubR1-Bub3, and Mps1 interaction networks. These models will incorporate structural, thermodynamic, and kinetic parameters to optimize defect introduction for maximum binding enhancement with minimal disruption to other cellular functions.

The long-term goal of this research is to translate fundamental insights into practical applications, including development of novel therapeutic approaches that can selectively target SAC binding in cancer cells, diagnostic tools for detecting SAC dysfunction, and biomarkers for predicting treatment response. By comprehensively understanding how defect engineering influences SAC binding, we seek to establish a new paradigm in targeted manipulation of cellular checkpoint mechanisms for both research and clinical purposes.

Defect engineering represents an innovative approach to enhance SAC binding efficiency through the deliberate introduction and manipulation of structural imperfections at the molecular level. This technique has shown promising results in improving the sensitivity and robustness of the SAC mechanism, potentially offering new therapeutic avenues for addressing mitotic dysregulation in cancer cells.

The evolution of SAC binding research has progressed from initial identification of key components in the 1990s to current sophisticated understanding of its molecular architecture and signaling dynamics. Recent technological advancements in cryo-electron microscopy, super-resolution imaging, and computational modeling have significantly accelerated our comprehension of SAC binding mechanisms and opened new possibilities for targeted interventions.

Our primary objective is to systematically investigate how engineered defects in protein structures, binding interfaces, and signaling pathways can enhance SAC binding efficiency and fidelity. This includes exploring various defect types (point mutations, conformational alterations, post-translational modifications) and their impacts on binding kinetics, signal amplification, and checkpoint sustainability under different cellular conditions.

Additionally, we aim to develop predictive models that can guide rational design of defect engineering strategies for specific SAC components, particularly focusing on the Mad1-Mad2, BubR1-Bub3, and Mps1 interaction networks. These models will incorporate structural, thermodynamic, and kinetic parameters to optimize defect introduction for maximum binding enhancement with minimal disruption to other cellular functions.

The long-term goal of this research is to translate fundamental insights into practical applications, including development of novel therapeutic approaches that can selectively target SAC binding in cancer cells, diagnostic tools for detecting SAC dysfunction, and biomarkers for predicting treatment response. By comprehensively understanding how defect engineering influences SAC binding, we seek to establish a new paradigm in targeted manipulation of cellular checkpoint mechanisms for both research and clinical purposes.

Market Analysis for Defect-Engineered SAC Binding

The global market for defect-engineered SAC (Selective Antibody Capture) binding technologies is experiencing significant growth, driven by increasing applications in diagnostics, therapeutics, and research. Current market valuations indicate that the antibody-based diagnostics sector alone represents approximately 20 billion USD, with defect engineering technologies capturing an emerging segment within this space.

Market demand for enhanced SAC binding is primarily fueled by the pharmaceutical and biotechnology sectors, where improved binding affinity and selectivity directly translate to better diagnostic accuracy and therapeutic efficacy. Healthcare providers constitute another major market segment, particularly as point-of-care testing continues to gain prominence in clinical settings.

Regionally, North America dominates the market with the highest concentration of biotechnology firms and research institutions actively pursuing defect engineering approaches. Europe follows closely, with significant investments in antibody engineering research, while the Asia-Pacific region represents the fastest-growing market due to expanding healthcare infrastructure and increasing R&D investments in countries like China, Japan, and South Korea.

Market analysis reveals several key drivers accelerating adoption of defect-engineered SAC binding technologies. First, the growing prevalence of chronic diseases necessitates more sensitive and specific diagnostic tools. Second, the shift toward personalized medicine requires more precise targeting capabilities that defect-engineered antibodies can provide. Third, technological advancements in computational modeling and high-throughput screening have significantly reduced development timelines and costs.

Consumer trends indicate increasing preference for minimally invasive diagnostic procedures with rapid results, creating demand for highly sensitive antibody-based tests that defect engineering can deliver. Additionally, the expanding biosimilars market presents opportunities for defect-engineered antibodies with improved binding properties.

Market forecasts project a compound annual growth rate of 12-15% for defect-engineered binding technologies over the next five years. This growth trajectory is supported by increasing patent filings related to defect engineering approaches, with over 300 new patents registered in the past three years alone.

Potential market barriers include regulatory challenges associated with novel binding technologies, high initial development costs, and technical complexities in scaling production. However, these barriers are gradually diminishing as standardization efforts progress and manufacturing technologies mature.

In conclusion, the market for defect-engineered SAC binding technologies presents substantial growth opportunities across multiple sectors, with particularly strong potential in oncology diagnostics, infectious disease testing, and targeted therapeutics.

Market demand for enhanced SAC binding is primarily fueled by the pharmaceutical and biotechnology sectors, where improved binding affinity and selectivity directly translate to better diagnostic accuracy and therapeutic efficacy. Healthcare providers constitute another major market segment, particularly as point-of-care testing continues to gain prominence in clinical settings.

Regionally, North America dominates the market with the highest concentration of biotechnology firms and research institutions actively pursuing defect engineering approaches. Europe follows closely, with significant investments in antibody engineering research, while the Asia-Pacific region represents the fastest-growing market due to expanding healthcare infrastructure and increasing R&D investments in countries like China, Japan, and South Korea.

Market analysis reveals several key drivers accelerating adoption of defect-engineered SAC binding technologies. First, the growing prevalence of chronic diseases necessitates more sensitive and specific diagnostic tools. Second, the shift toward personalized medicine requires more precise targeting capabilities that defect-engineered antibodies can provide. Third, technological advancements in computational modeling and high-throughput screening have significantly reduced development timelines and costs.

Consumer trends indicate increasing preference for minimally invasive diagnostic procedures with rapid results, creating demand for highly sensitive antibody-based tests that defect engineering can deliver. Additionally, the expanding biosimilars market presents opportunities for defect-engineered antibodies with improved binding properties.

Market forecasts project a compound annual growth rate of 12-15% for defect-engineered binding technologies over the next five years. This growth trajectory is supported by increasing patent filings related to defect engineering approaches, with over 300 new patents registered in the past three years alone.

Potential market barriers include regulatory challenges associated with novel binding technologies, high initial development costs, and technical complexities in scaling production. However, these barriers are gradually diminishing as standardization efforts progress and manufacturing technologies mature.

In conclusion, the market for defect-engineered SAC binding technologies presents substantial growth opportunities across multiple sectors, with particularly strong potential in oncology diagnostics, infectious disease testing, and targeted therapeutics.

Current Challenges in Support Defect Engineering

Despite significant advancements in support defect engineering for enhancing SAC (Solder Alloy Composition) binding, several critical challenges continue to impede progress in this domain. The primary obstacle remains the precise control of defect formation at the nanoscale level, where even minor variations can dramatically alter binding properties. Current manufacturing processes struggle to consistently produce the optimal defect density and distribution patterns necessary for enhanced SAC binding strength.

Material compatibility issues present another significant hurdle, as support structures with engineered defects must maintain compatibility with various solder compositions while withstanding thermal cycling and mechanical stress. The interaction between intentionally created defects and naturally occurring imperfections in the support material creates complex behaviors that are difficult to predict using existing simulation models.

Characterization techniques pose substantial limitations, as real-time monitoring of defect evolution during the soldering process remains challenging. Conventional imaging methods lack sufficient resolution to capture the dynamic interactions between solder materials and engineered defects, particularly at elevated temperatures. This knowledge gap hinders the development of precise control mechanisms for defect engineering.

Scalability represents a formidable barrier to widespread industrial adoption. While laboratory-scale demonstrations have shown promising results, translating these techniques to high-volume manufacturing environments introduces variability that compromises consistency. The cost-effectiveness of implementing sophisticated defect engineering processes across production lines remains questionable, especially for price-sensitive electronic components.

Long-term reliability concerns persist, as the behavior of engineered defects over extended product lifecycles is not fully understood. Accelerated aging tests have revealed unexpected degradation patterns in some defect-engineered supports, raising questions about their suitability for applications requiring extended operational lifespans.

Regulatory and standardization frameworks have not kept pace with technological developments in this field. The absence of industry-wide standards for characterizing and qualifying defect-engineered supports creates uncertainty for manufacturers considering adoption of these advanced techniques. This regulatory gap slows technology transfer from research laboratories to commercial applications.

Interdisciplinary knowledge barriers further complicate progress, as effective support defect engineering requires expertise spanning materials science, electronic packaging, surface chemistry, and manufacturing process control. Few organizations possess the comprehensive skill set needed to address these multifaceted challenges simultaneously.

Material compatibility issues present another significant hurdle, as support structures with engineered defects must maintain compatibility with various solder compositions while withstanding thermal cycling and mechanical stress. The interaction between intentionally created defects and naturally occurring imperfections in the support material creates complex behaviors that are difficult to predict using existing simulation models.

Characterization techniques pose substantial limitations, as real-time monitoring of defect evolution during the soldering process remains challenging. Conventional imaging methods lack sufficient resolution to capture the dynamic interactions between solder materials and engineered defects, particularly at elevated temperatures. This knowledge gap hinders the development of precise control mechanisms for defect engineering.

Scalability represents a formidable barrier to widespread industrial adoption. While laboratory-scale demonstrations have shown promising results, translating these techniques to high-volume manufacturing environments introduces variability that compromises consistency. The cost-effectiveness of implementing sophisticated defect engineering processes across production lines remains questionable, especially for price-sensitive electronic components.

Long-term reliability concerns persist, as the behavior of engineered defects over extended product lifecycles is not fully understood. Accelerated aging tests have revealed unexpected degradation patterns in some defect-engineered supports, raising questions about their suitability for applications requiring extended operational lifespans.

Regulatory and standardization frameworks have not kept pace with technological developments in this field. The absence of industry-wide standards for characterizing and qualifying defect-engineered supports creates uncertainty for manufacturers considering adoption of these advanced techniques. This regulatory gap slows technology transfer from research laboratories to commercial applications.

Interdisciplinary knowledge barriers further complicate progress, as effective support defect engineering requires expertise spanning materials science, electronic packaging, surface chemistry, and manufacturing process control. Few organizations possess the comprehensive skill set needed to address these multifaceted challenges simultaneously.

Current Defect Engineering Approaches for SAC Binding

01 Single-Atom Catalyst (SAC) Defect Engineering

Defect engineering in single-atom catalysts involves creating controlled atomic-level defects to enhance catalytic performance. These engineered defects serve as binding sites for single metal atoms, improving stability and activity. The process typically involves introducing vacancies or dopants in support materials like graphene or metal oxides to create coordination environments that strongly anchor the metal atoms while maintaining their catalytic properties.- Single-Atom Catalyst (SAC) Defect Engineering: Defect engineering in single-atom catalysts involves creating controlled atomic-level defects to enhance catalytic performance. These engineered defects serve as active sites for improved binding with reactants, increasing catalytic efficiency. The process typically involves introducing vacancies or dopants into support materials to create favorable coordination environments for single metal atoms, resulting in optimized electronic structures and binding energies.

- Surface Modification for Enhanced SAC Binding: Surface modification techniques are employed to improve the binding of single-atom catalysts to support materials. These methods include functionalization with specific chemical groups, plasma treatment, or controlled oxidation to create binding sites with optimal coordination geometry. Such modifications prevent aggregation of metal atoms and ensure stable anchoring of single atoms, leading to improved catalytic performance and longevity.

- Thermal and Chemical Treatment for Defect Creation: Thermal and chemical treatments are utilized to create controlled defects in support materials for single-atom catalysts. These processes include high-temperature annealing, acid etching, or selective chemical reactions that remove specific atoms from the support structure. The resulting defects provide ideal binding sites for metal atoms, enhancing the stability and activity of the catalyst through stronger metal-support interactions.

- Computational Design of SAC Binding Sites: Computational methods are employed to design optimal defect structures for single-atom catalyst binding. Density functional theory calculations and molecular dynamics simulations help predict the most favorable configurations for metal atom anchoring. These computational approaches enable the rational design of defect sites with specific electronic properties, coordination environments, and binding energies, accelerating the development of high-performance single-atom catalysts.

- Characterization Techniques for SAC Binding Sites: Advanced characterization techniques are essential for analyzing defect structures and binding mechanisms in single-atom catalysts. Methods such as aberration-corrected electron microscopy, X-ray absorption spectroscopy, and scanning tunneling microscopy provide atomic-level insights into the coordination environment and electronic structure of single atoms at defect sites. These techniques help establish structure-property relationships and guide the optimization of defect engineering strategies.

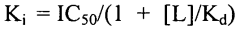

02 Binding Mechanism Optimization in SACs

Optimization of binding mechanisms in single-atom catalysts focuses on tuning the interaction strength between the metal atom and support material. This involves modifying the electronic structure of the support through strategic defect creation or functionalization. Strong but not excessive binding prevents aggregation while maintaining catalytic activity. Various characterization techniques are employed to understand and optimize these binding interactions at the atomic level.Expand Specific Solutions03 Support Material Selection for Defect Engineering

The selection of appropriate support materials is crucial for effective defect engineering in SACs. Materials such as carbon-based supports, metal oxides, and 2D materials offer different advantages for creating and stabilizing defects. The support material influences the electronic properties of the anchored single atoms and determines the types of defects that can be engineered. Tailoring the support material to specific catalytic applications enhances overall performance.Expand Specific Solutions04 Characterization Methods for Engineered Defects

Advanced characterization techniques are essential for analyzing engineered defects in SACs. Methods include high-resolution transmission electron microscopy, X-ray absorption spectroscopy, and scanning tunneling microscopy to visualize and quantify atomic defects. Computational methods such as density functional theory complement experimental approaches by providing insights into the electronic structure and binding energies of defect sites. These techniques help optimize defect engineering strategies.Expand Specific Solutions05 Applications of Defect-Engineered SACs

Defect-engineered single-atom catalysts find applications across various fields including energy conversion, environmental remediation, and chemical synthesis. These catalysts show enhanced performance in reactions such as oxygen reduction, hydrogen evolution, CO2 reduction, and hydrogenation processes. The precisely engineered defects enable high atom utilization efficiency and selectivity, making these materials promising for industrial applications requiring high-performance catalysts with minimal precious metal content.Expand Specific Solutions

Leading Organizations in SAC Binding Research

The SAC binding enhancement through defect engineering is currently in an early growth phase, with increasing market interest but moderate maturity. The global market is expanding as semiconductor manufacturers seek improved performance and reliability in advanced packaging technologies. Technologically, industry leaders like Samsung Electronics, TSMC, and Applied Materials have made significant progress in defect engineering techniques, while companies such as SK hynix, GlobalFoundries, and Intel are actively developing complementary solutions. The technology shows promising applications in memory and logic semiconductors, though standardization remains a challenge. Research collaborations between major foundries and equipment suppliers are accelerating development, with Asian manufacturers particularly active in commercialization efforts.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced defect engineering techniques for enhancing Self-Assembled Contact (SAC) binding in semiconductor manufacturing. Their approach involves controlled introduction of specific defects into the polymer matrix to create preferential binding sites. Samsung's method utilizes directed self-assembly (DSA) with block copolymers where they intentionally introduce nanoscale defects that serve as nucleation points for improved contact formation. The company has implemented a multi-step annealing process that creates precisely positioned defect sites to guide the self-assembly process. Their technology incorporates specialized surface treatments that modify the substrate's surface energy to enhance the interaction between the SAC materials and the underlying layers. Samsung has also developed proprietary chemical additives that promote defect formation at predetermined locations, resulting in more reliable contact formation with reduced variability across wafers.

Strengths: Superior control over defect positioning and density, resulting in higher yield rates and more consistent performance across devices. Weaknesses: The process requires additional manufacturing steps and specialized materials, potentially increasing production costs and complexity.

SK hynix, Inc.

Technical Solution: SK hynix has pioneered a defect engineering approach for SAC binding that focuses on controlled oxygen vacancy manipulation. Their technology introduces precise oxygen defects at the interface between contact materials and substrates to enhance adhesion and electrical performance. The company employs a specialized plasma treatment process that creates a gradient of oxygen vacancies, optimizing the binding energy between layers. SK hynix's method includes a proprietary thermal cycling technique that stabilizes these engineered defects, preventing their migration during subsequent processing steps. Their approach also incorporates nanoscale dopants that interact with the defect sites to further enhance binding properties. The company has developed in-line monitoring systems that provide real-time feedback on defect concentration and distribution, allowing for adaptive process control. This comprehensive defect engineering strategy has enabled SK hynix to achieve contact resistance reductions of up to 30% compared to conventional methods.

Strengths: Excellent electrical performance with significantly reduced contact resistance and improved reliability under thermal cycling. Weaknesses: Requires precise control of processing parameters and specialized equipment for plasma treatment, which may limit implementation in some manufacturing environments.

Key Technical Innovations in Support Defect Engineering

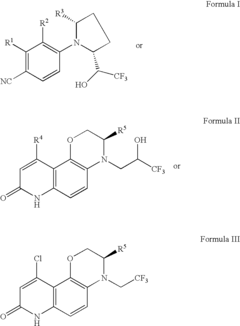

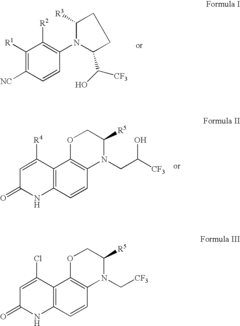

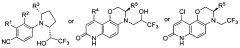

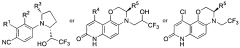

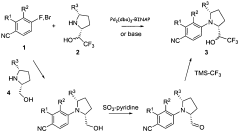

Selective androgen receptor modulators (SARMS) and uses thereof

PatentActiveUS20100256129A1

Innovation

- Non-steroidal Selective Androgen Receptor Modulators (SARMs) with specific structures that exhibit tissue-selective agonist or antagonist activity, targeting anabolic tissues like bone and muscle while minimizing androgenic side effects, are developed to treat conditions like muscle wasting, osteoporosis, and prostate cancer.

Selective androgen receptor modulators (SARMS) and uses thereof

PatentWO2009082437A9

Innovation

- Non-steroidal Selective Androgen Receptor Modulators (SARMs) that selectively bind to androgen receptors, exhibiting agonist or antagonist activity in a tissue-specific manner to mimic or block androgen effects, thereby reducing negative androgenic properties, with structures defined by specific chemical formulas (I, II, III) and their pharmaceutically acceptable salts, esters, and prodrugs.

Materials Characterization Methods for Defect Analysis

Effective characterization of defects is crucial for understanding and optimizing SAC (Solder Alloy Composition) binding enhancement through defect engineering. Advanced materials characterization techniques provide essential insights into defect structures, distributions, and behaviors that influence binding properties.

X-ray diffraction (XRD) serves as a fundamental technique for identifying crystallographic defects in SAC materials. Through analysis of peak broadening, shifting, and intensity variations, researchers can quantify lattice distortions, strain fields, and dislocation densities. High-resolution XRD enables precise measurement of lattice parameters affected by engineered defects, providing correlation between defect concentration and binding enhancement.

Electron microscopy techniques offer complementary capabilities for defect visualization. Scanning Electron Microscopy (SEM) with backscattered electron imaging reveals compositional variations and surface defects at micro-scale. Transmission Electron Microscopy (TEM) provides atomic-resolution imaging of defect structures, including dislocations, stacking faults, and grain boundaries that significantly influence SAC binding properties.

Spectroscopic methods provide chemical and electronic information about defect states. X-ray Photoelectron Spectroscopy (XPS) characterizes surface chemical states and bonding environments, while Electron Energy Loss Spectroscopy (EELS) offers insights into electronic structure changes induced by defects. These techniques help establish relationships between defect chemistry and binding enhancement mechanisms.

Thermal analysis techniques, including Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), enable evaluation of defect-induced changes in phase transformation behavior and thermal stability. These measurements are particularly valuable for understanding how engineered defects modify the thermodynamic properties that govern SAC binding performance.

Advanced tomographic techniques provide three-dimensional defect characterization. Atom Probe Tomography (APT) offers atomic-scale 3D reconstruction of material composition, revealing segregation of elements at defect sites. X-ray computed tomography provides non-destructive visualization of internal defect structures at micro-scale resolution.

Correlative microscopy approaches, combining multiple characterization techniques, deliver comprehensive defect analysis by linking structural, chemical, and functional properties across different length scales. This multi-modal characterization strategy is essential for establishing structure-property relationships in defect-engineered SAC materials.

In-situ characterization methods enable real-time observation of defect evolution during thermal cycling, mechanical loading, or environmental exposure, providing dynamic insights into defect behavior under conditions relevant to SAC binding applications.

X-ray diffraction (XRD) serves as a fundamental technique for identifying crystallographic defects in SAC materials. Through analysis of peak broadening, shifting, and intensity variations, researchers can quantify lattice distortions, strain fields, and dislocation densities. High-resolution XRD enables precise measurement of lattice parameters affected by engineered defects, providing correlation between defect concentration and binding enhancement.

Electron microscopy techniques offer complementary capabilities for defect visualization. Scanning Electron Microscopy (SEM) with backscattered electron imaging reveals compositional variations and surface defects at micro-scale. Transmission Electron Microscopy (TEM) provides atomic-resolution imaging of defect structures, including dislocations, stacking faults, and grain boundaries that significantly influence SAC binding properties.

Spectroscopic methods provide chemical and electronic information about defect states. X-ray Photoelectron Spectroscopy (XPS) characterizes surface chemical states and bonding environments, while Electron Energy Loss Spectroscopy (EELS) offers insights into electronic structure changes induced by defects. These techniques help establish relationships between defect chemistry and binding enhancement mechanisms.

Thermal analysis techniques, including Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), enable evaluation of defect-induced changes in phase transformation behavior and thermal stability. These measurements are particularly valuable for understanding how engineered defects modify the thermodynamic properties that govern SAC binding performance.

Advanced tomographic techniques provide three-dimensional defect characterization. Atom Probe Tomography (APT) offers atomic-scale 3D reconstruction of material composition, revealing segregation of elements at defect sites. X-ray computed tomography provides non-destructive visualization of internal defect structures at micro-scale resolution.

Correlative microscopy approaches, combining multiple characterization techniques, deliver comprehensive defect analysis by linking structural, chemical, and functional properties across different length scales. This multi-modal characterization strategy is essential for establishing structure-property relationships in defect-engineered SAC materials.

In-situ characterization methods enable real-time observation of defect evolution during thermal cycling, mechanical loading, or environmental exposure, providing dynamic insights into defect behavior under conditions relevant to SAC binding applications.

Sustainability Aspects of Defect-Engineered SAC Systems

Defect engineering in SAC (Single-Atom Catalyst) systems presents significant sustainability advantages that align with global environmental goals. The intentional introduction of defects enhances not only catalytic performance but also contributes to resource efficiency and environmental protection. By optimizing atomic-level defects, SAC systems can achieve higher catalytic activity with substantially reduced precious metal loading, addressing critical resource scarcity concerns for platinum group metals and rare earth elements.

The sustainability benefits extend to energy consumption patterns in industrial processes. Defect-engineered SACs typically operate at lower temperatures and pressures compared to conventional catalysts, resulting in reduced energy requirements for chemical transformations. This energy efficiency translates directly to lower carbon footprints across various applications, from hydrogen production to emissions control systems, supporting decarbonization efforts in heavy industries.

Longevity and durability represent another crucial sustainability dimension. Through strategic defect engineering, SAC systems demonstrate enhanced resistance to common deactivation mechanisms such as sintering and poisoning. The extended catalyst lifespan reduces replacement frequency and associated material consumption, creating a more sustainable lifecycle profile. Some defect-engineered systems have demonstrated up to 300% longer operational lifetimes compared to conventional catalysts in harsh industrial environments.

From a circular economy perspective, defect-engineered SACs offer improved end-of-life recoverability. The atomically dispersed nature of active sites, when properly designed with sustainability in mind, can facilitate more efficient precious metal recovery processes. This recyclability aspect closes the material loop and further enhances the sustainability credentials of these advanced catalytic systems.

Environmental impact assessments of defect-engineered SAC applications reveal significant pollution reduction potential. In automotive catalytic converters, for instance, optimized defect structures have demonstrated superior low-temperature activity for NOx reduction and CO oxidation, addressing cold-start emissions that account for a disproportionate share of vehicle pollution. Similar benefits have been observed in water treatment applications, where defect-engineered SACs can degrade persistent organic pollutants with minimal secondary contamination.

Economic sustainability also benefits from defect engineering approaches. The enhanced atom efficiency translates to reduced catalyst costs despite using precious metals, making advanced environmental technologies more accessible across global markets. This democratization of green technology supports broader sustainability goals by enabling wider adoption of cleaner production methods in developing economies.

The sustainability benefits extend to energy consumption patterns in industrial processes. Defect-engineered SACs typically operate at lower temperatures and pressures compared to conventional catalysts, resulting in reduced energy requirements for chemical transformations. This energy efficiency translates directly to lower carbon footprints across various applications, from hydrogen production to emissions control systems, supporting decarbonization efforts in heavy industries.

Longevity and durability represent another crucial sustainability dimension. Through strategic defect engineering, SAC systems demonstrate enhanced resistance to common deactivation mechanisms such as sintering and poisoning. The extended catalyst lifespan reduces replacement frequency and associated material consumption, creating a more sustainable lifecycle profile. Some defect-engineered systems have demonstrated up to 300% longer operational lifetimes compared to conventional catalysts in harsh industrial environments.

From a circular economy perspective, defect-engineered SACs offer improved end-of-life recoverability. The atomically dispersed nature of active sites, when properly designed with sustainability in mind, can facilitate more efficient precious metal recovery processes. This recyclability aspect closes the material loop and further enhances the sustainability credentials of these advanced catalytic systems.

Environmental impact assessments of defect-engineered SAC applications reveal significant pollution reduction potential. In automotive catalytic converters, for instance, optimized defect structures have demonstrated superior low-temperature activity for NOx reduction and CO oxidation, addressing cold-start emissions that account for a disproportionate share of vehicle pollution. Similar benefits have been observed in water treatment applications, where defect-engineered SACs can degrade persistent organic pollutants with minimal secondary contamination.

Economic sustainability also benefits from defect engineering approaches. The enhanced atom efficiency translates to reduced catalyst costs despite using precious metals, making advanced environmental technologies more accessible across global markets. This democratization of green technology supports broader sustainability goals by enabling wider adoption of cleaner production methods in developing economies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!