Thermal Stability And Sintering Risk In SACs

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SAC Thermal Stability Background and Objectives

Single-atom catalysts (SACs) have emerged as a frontier in heterogeneous catalysis research over the past decade, offering unprecedented atom efficiency and unique catalytic properties. These catalysts feature isolated metal atoms anchored on supports, maximizing metal utilization while exhibiting distinct electronic structures and catalytic behaviors compared to their nanoparticle counterparts. The evolution of SACs represents a significant milestone in the pursuit of atomic-level catalyst design and understanding.

The thermal stability of SACs presents a critical challenge that has shaped research trajectories in this field. As catalytic processes often operate under elevated temperatures, the tendency of single atoms to migrate and aggregate into clusters or nanoparticles (sintering) threatens the fundamental advantage of SACs - their atomic dispersion. This sintering phenomenon has been observed across various metal-support combinations and represents a significant barrier to the practical application of SACs in industrial settings.

Historical developments in SAC research reveal an increasing focus on thermal stability. Early work concentrated primarily on demonstrating the concept and unique properties of isolated metal atoms, while recent efforts have shifted toward understanding and enhancing their stability under reaction conditions. This evolution reflects the maturation of the field from proof-of-concept to addressing practical implementation challenges.

The sintering risk in SACs stems from thermodynamic driving forces that favor metal-metal bonding over metal-support interactions at elevated temperatures. This fundamental challenge has prompted diverse research approaches, including the development of stronger metal-support anchoring strategies, confinement techniques, and the exploration of novel support materials with enhanced metal-binding capabilities.

The primary objectives of current research on SAC thermal stability include: developing quantitative understanding of sintering mechanisms at the atomic level; establishing predictive models for SAC stability across different metal-support combinations; designing novel synthesis strategies that enhance thermal resistance; and creating in-situ characterization techniques capable of monitoring atomic dispersion under realistic reaction conditions.

Future technological goals in this domain focus on creating SACs that maintain atomic dispersion at temperatures exceeding 800°C for extended periods, enabling their application in high-temperature catalytic processes such as automotive emission control, syngas conversion, and hydrocarbon reforming. Additionally, researchers aim to develop regeneration protocols that can restore atomic dispersion after partial sintering, thereby extending catalyst lifetime and economic viability.

The thermal stability of SACs presents a critical challenge that has shaped research trajectories in this field. As catalytic processes often operate under elevated temperatures, the tendency of single atoms to migrate and aggregate into clusters or nanoparticles (sintering) threatens the fundamental advantage of SACs - their atomic dispersion. This sintering phenomenon has been observed across various metal-support combinations and represents a significant barrier to the practical application of SACs in industrial settings.

Historical developments in SAC research reveal an increasing focus on thermal stability. Early work concentrated primarily on demonstrating the concept and unique properties of isolated metal atoms, while recent efforts have shifted toward understanding and enhancing their stability under reaction conditions. This evolution reflects the maturation of the field from proof-of-concept to addressing practical implementation challenges.

The sintering risk in SACs stems from thermodynamic driving forces that favor metal-metal bonding over metal-support interactions at elevated temperatures. This fundamental challenge has prompted diverse research approaches, including the development of stronger metal-support anchoring strategies, confinement techniques, and the exploration of novel support materials with enhanced metal-binding capabilities.

The primary objectives of current research on SAC thermal stability include: developing quantitative understanding of sintering mechanisms at the atomic level; establishing predictive models for SAC stability across different metal-support combinations; designing novel synthesis strategies that enhance thermal resistance; and creating in-situ characterization techniques capable of monitoring atomic dispersion under realistic reaction conditions.

Future technological goals in this domain focus on creating SACs that maintain atomic dispersion at temperatures exceeding 800°C for extended periods, enabling their application in high-temperature catalytic processes such as automotive emission control, syngas conversion, and hydrocarbon reforming. Additionally, researchers aim to develop regeneration protocols that can restore atomic dispersion after partial sintering, thereby extending catalyst lifetime and economic viability.

Market Analysis for Thermally Stable SACs

The global market for Single Atom Catalysts (SACs) is experiencing significant growth, driven by increasing demand for sustainable and efficient catalytic solutions across various industries. The market size for advanced catalysts, including SACs, was valued at approximately $6.8 billion in 2022 and is projected to reach $9.4 billion by 2028, representing a compound annual growth rate of 5.6%.

Thermally stable SACs represent a critical segment within this market, addressing one of the most significant limitations of conventional SACs - their tendency to sinter under high-temperature reaction conditions. Industries such as automotive, petrochemical, and fine chemical manufacturing are particularly interested in thermally stable SACs due to their potential to maintain catalytic activity under harsh operating conditions.

The automotive sector constitutes the largest market share for thermally stable SACs, primarily driven by stringent emission regulations worldwide. These catalysts are essential components in catalytic converters, where they must withstand temperatures exceeding 800°C while maintaining their structural integrity and catalytic performance. The global automotive catalyst market alone is expected to grow at 7.3% annually through 2030.

Petrochemical and refining industries represent the second-largest application segment, where thermally stable SACs offer significant advantages in processes such as hydrocracking, reforming, and isomerization. These processes typically operate at temperatures between 300-500°C, conditions that cause conventional catalysts to degrade rapidly.

Regionally, Asia-Pacific dominates the market for thermally stable SACs, accounting for approximately 42% of global demand. This is primarily attributed to the rapid industrialization in countries like China and India, coupled with increasingly stringent environmental regulations. North America and Europe follow, with market shares of 28% and 24% respectively, driven by mature industrial bases and advanced research capabilities.

Customer demand is increasingly focused on catalysts that can maintain performance at temperatures above 700°C for extended periods without significant activity loss. This has created a premium segment within the market, with thermally stable SACs commanding price premiums of 30-40% compared to conventional alternatives.

Market barriers include high production costs, complex manufacturing processes, and challenges in scaling production while maintaining consistent quality. Despite these challenges, the market is expected to expand as technological advancements continue to improve thermal stability and reduce production costs, making these advanced catalysts more accessible across various industrial applications.

Thermally stable SACs represent a critical segment within this market, addressing one of the most significant limitations of conventional SACs - their tendency to sinter under high-temperature reaction conditions. Industries such as automotive, petrochemical, and fine chemical manufacturing are particularly interested in thermally stable SACs due to their potential to maintain catalytic activity under harsh operating conditions.

The automotive sector constitutes the largest market share for thermally stable SACs, primarily driven by stringent emission regulations worldwide. These catalysts are essential components in catalytic converters, where they must withstand temperatures exceeding 800°C while maintaining their structural integrity and catalytic performance. The global automotive catalyst market alone is expected to grow at 7.3% annually through 2030.

Petrochemical and refining industries represent the second-largest application segment, where thermally stable SACs offer significant advantages in processes such as hydrocracking, reforming, and isomerization. These processes typically operate at temperatures between 300-500°C, conditions that cause conventional catalysts to degrade rapidly.

Regionally, Asia-Pacific dominates the market for thermally stable SACs, accounting for approximately 42% of global demand. This is primarily attributed to the rapid industrialization in countries like China and India, coupled with increasingly stringent environmental regulations. North America and Europe follow, with market shares of 28% and 24% respectively, driven by mature industrial bases and advanced research capabilities.

Customer demand is increasingly focused on catalysts that can maintain performance at temperatures above 700°C for extended periods without significant activity loss. This has created a premium segment within the market, with thermally stable SACs commanding price premiums of 30-40% compared to conventional alternatives.

Market barriers include high production costs, complex manufacturing processes, and challenges in scaling production while maintaining consistent quality. Despite these challenges, the market is expected to expand as technological advancements continue to improve thermal stability and reduce production costs, making these advanced catalysts more accessible across various industrial applications.

Current Challenges in SAC Thermal Stability

Solvent-Assisted Crystallization (SAC) technology has emerged as a promising approach in pharmaceutical manufacturing, offering enhanced control over crystal morphology and polymorphism. However, thermal stability remains a critical challenge that significantly impacts the commercial viability and scalability of SAC processes. Current industrial implementations face substantial hurdles related to temperature management during crystallization, which can lead to unpredictable outcomes and product inconsistencies.

The primary thermal stability challenge in SACs involves maintaining precise temperature control throughout the crystallization process. Even minor temperature fluctuations can dramatically alter nucleation rates and crystal growth patterns, resulting in undesired polymorphs or inconsistent particle size distributions. This sensitivity becomes particularly problematic during scale-up operations, where heat transfer dynamics change substantially from laboratory to production environments.

Sintering risk presents another significant concern in SAC processes. When exposed to elevated temperatures or temperature gradients, partially formed crystals may undergo sintering—a phenomenon where particles fuse together at temperatures below their melting point. This results in agglomeration, reduced surface area, and altered dissolution properties of the final product. The pharmaceutical industry has documented numerous cases where sintering has compromised batch quality and necessitated costly reprocessing or disposal.

Equipment limitations further exacerbate thermal stability challenges. Current industrial crystallizers often struggle to provide the uniform temperature profiles required for optimal SAC performance. Hot spots and cold zones within crystallization vessels create microenvironments with varying supersaturation levels, leading to heterogeneous crystallization outcomes. The heat generated during solvent evaporation or removal phases compounds these issues, creating additional thermal management complexities.

Solvent selection introduces another layer of complexity to thermal stability management. Different solvents exhibit varying thermal properties, evaporation rates, and interactions with solutes under temperature changes. The industry currently lacks comprehensive guidelines for solvent selection specifically optimized for thermal stability in SAC processes, forcing manufacturers to rely heavily on empirical approaches and extensive trial-and-error experimentation.

Continuous processing implementations of SAC technology face particular thermal challenges. Maintaining consistent temperature profiles along continuous crystallization channels or tubes requires sophisticated control systems that many manufacturers have yet to master. Temperature gradients along process equipment can trigger premature nucleation, clogging, or yield inconsistent crystal properties, limiting the adoption of continuous SAC processes despite their potential efficiency advantages.

The primary thermal stability challenge in SACs involves maintaining precise temperature control throughout the crystallization process. Even minor temperature fluctuations can dramatically alter nucleation rates and crystal growth patterns, resulting in undesired polymorphs or inconsistent particle size distributions. This sensitivity becomes particularly problematic during scale-up operations, where heat transfer dynamics change substantially from laboratory to production environments.

Sintering risk presents another significant concern in SAC processes. When exposed to elevated temperatures or temperature gradients, partially formed crystals may undergo sintering—a phenomenon where particles fuse together at temperatures below their melting point. This results in agglomeration, reduced surface area, and altered dissolution properties of the final product. The pharmaceutical industry has documented numerous cases where sintering has compromised batch quality and necessitated costly reprocessing or disposal.

Equipment limitations further exacerbate thermal stability challenges. Current industrial crystallizers often struggle to provide the uniform temperature profiles required for optimal SAC performance. Hot spots and cold zones within crystallization vessels create microenvironments with varying supersaturation levels, leading to heterogeneous crystallization outcomes. The heat generated during solvent evaporation or removal phases compounds these issues, creating additional thermal management complexities.

Solvent selection introduces another layer of complexity to thermal stability management. Different solvents exhibit varying thermal properties, evaporation rates, and interactions with solutes under temperature changes. The industry currently lacks comprehensive guidelines for solvent selection specifically optimized for thermal stability in SAC processes, forcing manufacturers to rely heavily on empirical approaches and extensive trial-and-error experimentation.

Continuous processing implementations of SAC technology face particular thermal challenges. Maintaining consistent temperature profiles along continuous crystallization channels or tubes requires sophisticated control systems that many manufacturers have yet to master. Temperature gradients along process equipment can trigger premature nucleation, clogging, or yield inconsistent crystal properties, limiting the adoption of continuous SAC processes despite their potential efficiency advantages.

Current Anti-Sintering Solutions for SACs

01 Support materials for enhancing SAC thermal stability

Various support materials can significantly enhance the thermal stability of single-atom catalysts (SACs). Materials such as metal oxides, carbon-based supports, and zeolites provide strong metal-support interactions that anchor single atoms and prevent aggregation at high temperatures. The selection of appropriate support materials with specific surface properties and defect structures is crucial for maintaining the dispersion of single atoms during thermal treatments and catalytic reactions.- Support materials for enhancing SAC thermal stability: Various support materials can significantly enhance the thermal stability of single-atom catalysts (SACs). Materials such as metal oxides, carbon-based supports, and zeolites provide strong metal-support interactions that anchor single atoms and prevent their aggregation at high temperatures. The specific surface chemistry and defect structures of these supports play crucial roles in maintaining the dispersion of single atoms during thermal treatments.

- Metal-organic frameworks as SAC precursors: Metal-organic frameworks (MOFs) serve as excellent precursors for thermally stable single-atom catalysts. The well-defined structure of MOFs allows for precise control over the distribution of metal atoms, which can be converted to single-atom catalysts through controlled pyrolysis. The resulting SACs inherit the uniform dispersion of metal sites from the MOF structure, leading to enhanced thermal stability even at elevated temperatures.

- Confinement strategies for preventing atom migration: Confinement strategies effectively prevent the migration and aggregation of single atoms during high-temperature operations. These include embedding single atoms in porous structures, creating coordination environments with high binding energies, and utilizing spatial confinement in nanochannels or cavities. Such approaches create energy barriers that inhibit atom mobility, thereby maintaining catalytic performance under thermal stress.

- Alloying and doping techniques for stabilization: Alloying and doping techniques can significantly improve the thermal stability of single-atom catalysts. Introduction of secondary elements creates electronic interactions that strengthen the binding of single atoms to their supports. These modifications can alter the local electronic structure around the catalytic sites, creating more stable configurations that resist sintering and maintain dispersion at elevated temperatures.

- Advanced characterization methods for thermal stability assessment: Advanced characterization methods are essential for evaluating the thermal stability of single-atom catalysts. In-situ techniques such as high-temperature X-ray absorption spectroscopy, environmental transmission electron microscopy, and temperature-programmed studies provide real-time information about structural changes during thermal treatments. These methods help identify degradation mechanisms and guide the development of more thermally stable SAC formulations.

02 Metal-organic frameworks as SAC precursors

Metal-organic frameworks (MOFs) serve as excellent precursors for thermally stable single-atom catalysts. The well-defined structure of MOFs allows for precise control over the distribution of metal atoms, which can be converted to single-atom catalysts through controlled pyrolysis. This approach creates strong coordination environments that enhance thermal stability by preventing metal atom migration and aggregation even at elevated temperatures, resulting in catalysts that maintain their activity during high-temperature applications.Expand Specific Solutions03 Coordination strategies for stabilizing single atoms

Specific coordination environments play a crucial role in stabilizing single atoms against thermal sintering. By engineering the coordination number and type of ligands surrounding the metal atoms, researchers can create strong anchoring sites that prevent mobility at high temperatures. Strategies include nitrogen-doping, oxygen-coordination, and the use of specific functional groups that form stable complexes with metal atoms, effectively increasing the energy barrier for migration and aggregation during thermal exposure.Expand Specific Solutions04 Confinement approaches for thermal stabilization

Physical confinement strategies effectively enhance the thermal stability of single-atom catalysts by restricting the mobility of metal atoms. These approaches include encapsulation within porous structures, embedding in layered materials, and trapping within defect sites. By creating spatial barriers that limit the migration pathways of single atoms, these confinement methods prevent sintering and aggregation even under severe thermal conditions, thereby preserving the unique catalytic properties of isolated metal atoms.Expand Specific Solutions05 Advanced synthesis methods for thermally robust SACs

Innovative synthesis techniques have been developed to create single-atom catalysts with exceptional thermal stability. These methods include atomic layer deposition, high-temperature vapor deposition, and electrochemical atom trapping. By precisely controlling the synthesis conditions and incorporating stabilizing agents during the formation process, these approaches create robust metal-support interactions that withstand thermal stress. Post-synthesis treatments such as controlled calcination and selective leaching further enhance the thermal durability of the resulting catalysts.Expand Specific Solutions

Leading Companies in SAC Development

The thermal stability and sintering risk in Single Atom Catalysts (SACs) market is currently in a growth phase, with increasing research focus due to SACs' potential in various industrial applications. The market is expanding rapidly, estimated to reach significant value as industries seek more efficient catalytic solutions. Technologically, SACs are advancing from experimental to commercial applications, with varying maturity levels across sectors. Leading players include established industrial giants like Siemens AG, General Electric, and Honeywell International Technologies, alongside specialized materials companies such as Murata Manufacturing and LG Chem. Academic institutions like University of Science & Technology of China and research organizations like Dalian Institute of Chemical Physics are driving fundamental innovations, while companies like Beijing Single Atom Site Catalysis Technology are commercializing these advancements.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has pioneered a multi-layered approach to thermal stability in SAC solders for their electronic components, particularly focusing on ceramic capacitors and other passive components that experience significant thermal stress. Their technology incorporates nano-scale ceramic particles (0.1-1μm diameter) as reinforcement within the SAC matrix, creating a composite solder material with enhanced mechanical properties. These ceramic additions act as barriers to dislocation movement and grain boundary migration, effectively inhibiting the sintering processes that lead to joint degradation. Murata's research has shown that their composite SAC materials maintain stable microstructures even after 1000 hours at 125°C, with shear strength retention exceeding 85% of initial values. The company has also developed specialized surface metallization techniques for their components that form optimized intermetallic compounds with their SAC formulations, further enhancing thermal stability at the critical component-solder interface where failures often initiate.

Strengths: Their integrated approach addresses both the solder material and component interface, providing comprehensive thermal stability solutions specifically optimized for electronic components. Their materials show excellent performance in vibration and drop-test reliability. Weaknesses: Solutions are primarily optimized for their own component lines and may not be universally applicable across all electronic assembly applications without modification.

Siemens AG

Technical Solution: Siemens has developed a sophisticated approach to thermal stability in SAC solders focused on power electronics and industrial control systems where reliability under thermal stress is critical. Their technology combines metallurgical innovations with advanced manufacturing processes to mitigate sintering risks. Siemens' proprietary SAC formulations incorporate nano-scale metal oxide particles (primarily Al2O3 and TiO2) that are uniformly dispersed throughout the solder matrix during manufacturing. These particles, typically 20-100nm in diameter and comprising 0.5-2% of the solder volume, act as effective barriers to grain boundary movement and dislocation motion, significantly inhibiting the microstructural coarsening that leads to thermal degradation. Their research demonstrates that these composite solders maintain stable grain structures even after 2000 hours at 150°C, with shear strength retention exceeding 80% of initial values. Additionally, Siemens has developed specialized surface preparation techniques for power modules that create optimized interfacial structures with their SAC formulations, further enhancing thermal stability at the critical solder-substrate boundary where failures often initiate under thermal cycling conditions.

Strengths: Comprehensive solution addressing both material composition and manufacturing processes, with proven performance in demanding industrial environments. Their technology demonstrates excellent resistance to thermal fatigue and creep deformation. Weaknesses: Implementation requires specialized manufacturing equipment and tight process control, potentially increasing production complexity and costs.

Key Patents in SAC Thermal Stability

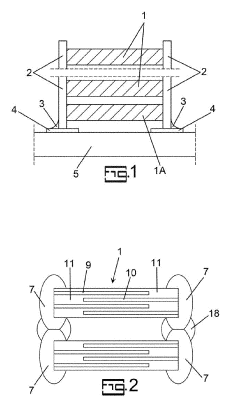

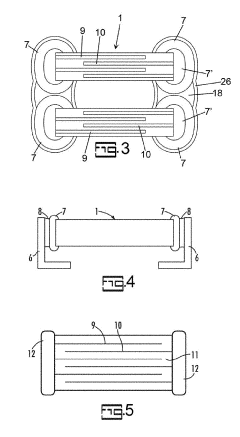

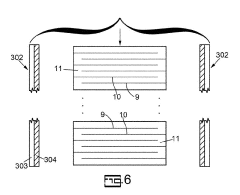

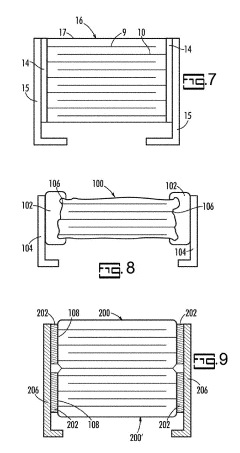

Leadless stack comprising multiple components

PatentActiveEP3306631A3

Innovation

- The use of transient liquid phase sintering (TLPS) adhesives and materials to form conductive bonds between MLCCs and other electronic elements, allowing for low-temperature initial bonding followed by high-temperature stability, and the integration of microphonic noise reduction structures to minimize noise propagation.

Leadless Stack Comprising Multiple Components

PatentActiveUS20190318877A1

Innovation

- The use of transient liquid phase sintering (TLPS) technology to form conductive bonds between MLCCs and other electronic elements, utilizing low melting point metals like indium and high melting point metals like silver, which diffuse to create a solid solution with a higher melting point, allowing for bonding at lower initial temperatures and achieving high secondary reflow temperatures, thus forming a robust and reliable connection without the need for lead frames and minimizing microphonic noise.

Environmental Impact of SAC Materials

The environmental impact of SAC (Solder Alloy Composition) materials is increasingly becoming a critical consideration in electronics manufacturing, particularly when evaluating their thermal stability and sintering risks. SAC materials, primarily composed of tin, silver, and copper, present several environmental challenges throughout their lifecycle that must be addressed for sustainable electronics production.

The mining and extraction processes for tin, silver, and copper contribute significantly to environmental degradation. These processes often involve extensive land disturbance, habitat destruction, and the generation of substantial waste material. Additionally, the energy-intensive refining processes required to achieve the high purity levels needed for SAC solders result in considerable carbon emissions.

During the manufacturing phase, the thermal processes required for SAC solder application contribute to energy consumption and associated greenhouse gas emissions. The higher melting points of certain SAC compositions (compared to traditional lead-based solders) necessitate greater energy inputs during reflow soldering, potentially increasing the carbon footprint of electronics assembly operations.

The sintering behavior of SAC materials presents additional environmental concerns. When SAC solders undergo thermal cycling in service conditions, microstructural changes can occur that affect not only reliability but also end-of-life recyclability. The formation of intermetallic compounds during sintering can complicate separation processes in recycling operations, potentially reducing recovery rates of valuable metals.

Leaching of metals from improperly disposed SAC materials poses risks to soil and water systems. While SAC solders were developed as environmentally friendly alternatives to lead-based solders, the silver content in particular can be ecotoxic if released into aquatic environments. Studies have shown that silver ions can be highly toxic to aquatic organisms even at low concentrations.

Recent research has focused on developing SAC formulations with enhanced thermal stability that minimize sintering risks while also reducing environmental impact. These include modifications with dopants that improve thermal performance while using lower percentages of precious metals like silver, thereby reducing resource extraction demands.

Life cycle assessment (LCA) studies comparing various SAC compositions have revealed that the environmental impact varies significantly based on specific formulations. SAC alloys with lower silver content generally show reduced environmental footprints, though this must be balanced against performance requirements and thermal stability considerations.

The electronics industry continues to explore recycling technologies specifically designed for SAC materials to improve end-of-life management. Advanced separation techniques are being developed to better recover the valuable metals from SAC solders, creating a more circular economy approach that reduces the need for virgin material extraction.

The mining and extraction processes for tin, silver, and copper contribute significantly to environmental degradation. These processes often involve extensive land disturbance, habitat destruction, and the generation of substantial waste material. Additionally, the energy-intensive refining processes required to achieve the high purity levels needed for SAC solders result in considerable carbon emissions.

During the manufacturing phase, the thermal processes required for SAC solder application contribute to energy consumption and associated greenhouse gas emissions. The higher melting points of certain SAC compositions (compared to traditional lead-based solders) necessitate greater energy inputs during reflow soldering, potentially increasing the carbon footprint of electronics assembly operations.

The sintering behavior of SAC materials presents additional environmental concerns. When SAC solders undergo thermal cycling in service conditions, microstructural changes can occur that affect not only reliability but also end-of-life recyclability. The formation of intermetallic compounds during sintering can complicate separation processes in recycling operations, potentially reducing recovery rates of valuable metals.

Leaching of metals from improperly disposed SAC materials poses risks to soil and water systems. While SAC solders were developed as environmentally friendly alternatives to lead-based solders, the silver content in particular can be ecotoxic if released into aquatic environments. Studies have shown that silver ions can be highly toxic to aquatic organisms even at low concentrations.

Recent research has focused on developing SAC formulations with enhanced thermal stability that minimize sintering risks while also reducing environmental impact. These include modifications with dopants that improve thermal performance while using lower percentages of precious metals like silver, thereby reducing resource extraction demands.

Life cycle assessment (LCA) studies comparing various SAC compositions have revealed that the environmental impact varies significantly based on specific formulations. SAC alloys with lower silver content generally show reduced environmental footprints, though this must be balanced against performance requirements and thermal stability considerations.

The electronics industry continues to explore recycling technologies specifically designed for SAC materials to improve end-of-life management. Advanced separation techniques are being developed to better recover the valuable metals from SAC solders, creating a more circular economy approach that reduces the need for virgin material extraction.

Performance Testing Standards for SAC Durability

The standardization of performance testing for SAC (Silver-Antimony-Copper) solder alloys has become increasingly critical as these materials gain prominence in high-reliability electronics applications. Current testing standards for SAC durability primarily focus on thermal cycling, thermal shock, and isothermal aging to evaluate the long-term reliability under various operating conditions. Organizations such as IPC, JEDEC, and ASTM have developed specific protocols like IPC-9701 for solder joint reliability testing and JEDEC JESD22-A104 for temperature cycling that address thermal stability aspects.

These standards typically require test specimens to undergo controlled temperature excursions between defined extremes (commonly -40°C to +125°C) for predetermined cycles, with subsequent analysis of microstructural changes and mechanical property degradation. The testing methodologies incorporate accelerated aging protocols designed to simulate years of service conditions within manageable timeframes, allowing manufacturers to predict long-term performance characteristics.

Sintering risk assessment has recently been incorporated into these standards, with specialized protocols focusing on the coarsening of intermetallic compounds and the growth of Kirkendall voids during thermal exposure. These phenomena are particularly relevant for SAC alloys due to their relatively low melting points compared to traditional lead-based solders. Testing standards now include high-temperature storage tests (typically at 150°C for 1000 hours) specifically designed to evaluate microstructural stability and sintering propensity.

Mechanical testing standards complement thermal evaluations, with shear strength testing (per ASTM D5656) and pull testing (per JEDEC JESD22-B115) serving as quantitative measures of joint integrity after thermal exposure. These mechanical tests provide critical data on how thermal aging affects the structural reliability of SAC interconnects. Modern standards increasingly incorporate statistical analysis requirements to ensure test result validity across production variations.

Emerging standards are beginning to address the unique challenges posed by miniaturization trends in electronics, with specialized protocols for fine-pitch components and heterogeneous integration scenarios. These newer standards recognize that traditional testing approaches may not fully capture the reliability concerns in advanced packaging technologies where SAC alloys experience more complex stress states.

Industry consortia like iNEMI and CALCE have contributed significantly to the evolution of these standards, publishing research-based recommendations that often precede formal standardization. Their work has been particularly valuable in addressing the thermal stability concerns specific to SAC alloys with varying silver content, recognizing that minor compositional differences can substantially impact sintering behavior and long-term reliability under thermal stress.

These standards typically require test specimens to undergo controlled temperature excursions between defined extremes (commonly -40°C to +125°C) for predetermined cycles, with subsequent analysis of microstructural changes and mechanical property degradation. The testing methodologies incorporate accelerated aging protocols designed to simulate years of service conditions within manageable timeframes, allowing manufacturers to predict long-term performance characteristics.

Sintering risk assessment has recently been incorporated into these standards, with specialized protocols focusing on the coarsening of intermetallic compounds and the growth of Kirkendall voids during thermal exposure. These phenomena are particularly relevant for SAC alloys due to their relatively low melting points compared to traditional lead-based solders. Testing standards now include high-temperature storage tests (typically at 150°C for 1000 hours) specifically designed to evaluate microstructural stability and sintering propensity.

Mechanical testing standards complement thermal evaluations, with shear strength testing (per ASTM D5656) and pull testing (per JEDEC JESD22-B115) serving as quantitative measures of joint integrity after thermal exposure. These mechanical tests provide critical data on how thermal aging affects the structural reliability of SAC interconnects. Modern standards increasingly incorporate statistical analysis requirements to ensure test result validity across production variations.

Emerging standards are beginning to address the unique challenges posed by miniaturization trends in electronics, with specialized protocols for fine-pitch components and heterogeneous integration scenarios. These newer standards recognize that traditional testing approaches may not fully capture the reliability concerns in advanced packaging technologies where SAC alloys experience more complex stress states.

Industry consortia like iNEMI and CALCE have contributed significantly to the evolution of these standards, publishing research-based recommendations that often precede formal standardization. Their work has been particularly valuable in addressing the thermal stability concerns specific to SAC alloys with varying silver content, recognizing that minor compositional differences can substantially impact sintering behavior and long-term reliability under thermal stress.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!