Advancements in Cellophane Recycling Processes

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Recycling Evolution and Objectives

Cellophane, a transparent film made from regenerated cellulose, has been a staple in packaging and various industrial applications since its invention in the early 20th century. The evolution of cellophane recycling processes has been driven by increasing environmental concerns and the need for sustainable packaging solutions. Initially, cellophane was considered non-recyclable due to its complex chemical structure and the lack of efficient recycling technologies.

The journey of cellophane recycling began in the late 1990s when researchers started exploring potential methods to break down and repurpose this material. Early attempts focused on mechanical recycling, which involved shredding and melting cellophane for reuse. However, these methods proved inefficient and resulted in low-quality recycled products.

A significant breakthrough came in the early 2000s with the development of chemical recycling processes. These methods aimed to depolymerize cellophane back into its basic cellulose components, allowing for more versatile reuse options. This marked a turning point in cellophane recycling, opening up new possibilities for closed-loop recycling systems.

As environmental regulations tightened and consumer demand for eco-friendly packaging grew, the cellophane industry faced increasing pressure to improve recycling capabilities. This led to collaborative efforts between academic institutions, research centers, and industry players to advance cellophane recycling technologies.

The objectives of modern cellophane recycling processes are multifaceted. Primarily, they aim to achieve a high recovery rate of cellulose from used cellophane, minimizing waste and reducing the environmental impact of this material. Additionally, there is a focus on developing energy-efficient and cost-effective recycling methods that can be implemented on a large scale.

Another key objective is to improve the quality of recycled cellophane, ensuring that it meets the same performance standards as virgin material. This involves refining purification techniques and exploring ways to maintain the transparency and barrier properties that make cellophane valuable in packaging applications.

Recent advancements in cellophane recycling have also set goals for creating new value-added products from recycled cellulose. This includes the development of bio-based materials and the integration of recycled cellophane into other industries, such as textiles or construction materials.

Looking ahead, the cellophane recycling industry aims to establish a fully circular economy for this material. This involves not only improving recycling processes but also redesigning cellophane products for easier recyclability and encouraging widespread adoption of cellophane recycling programs. The ultimate goal is to transform cellophane from a single-use material into a sustainable, infinitely recyclable resource.

The journey of cellophane recycling began in the late 1990s when researchers started exploring potential methods to break down and repurpose this material. Early attempts focused on mechanical recycling, which involved shredding and melting cellophane for reuse. However, these methods proved inefficient and resulted in low-quality recycled products.

A significant breakthrough came in the early 2000s with the development of chemical recycling processes. These methods aimed to depolymerize cellophane back into its basic cellulose components, allowing for more versatile reuse options. This marked a turning point in cellophane recycling, opening up new possibilities for closed-loop recycling systems.

As environmental regulations tightened and consumer demand for eco-friendly packaging grew, the cellophane industry faced increasing pressure to improve recycling capabilities. This led to collaborative efforts between academic institutions, research centers, and industry players to advance cellophane recycling technologies.

The objectives of modern cellophane recycling processes are multifaceted. Primarily, they aim to achieve a high recovery rate of cellulose from used cellophane, minimizing waste and reducing the environmental impact of this material. Additionally, there is a focus on developing energy-efficient and cost-effective recycling methods that can be implemented on a large scale.

Another key objective is to improve the quality of recycled cellophane, ensuring that it meets the same performance standards as virgin material. This involves refining purification techniques and exploring ways to maintain the transparency and barrier properties that make cellophane valuable in packaging applications.

Recent advancements in cellophane recycling have also set goals for creating new value-added products from recycled cellulose. This includes the development of bio-based materials and the integration of recycled cellophane into other industries, such as textiles or construction materials.

Looking ahead, the cellophane recycling industry aims to establish a fully circular economy for this material. This involves not only improving recycling processes but also redesigning cellophane products for easier recyclability and encouraging widespread adoption of cellophane recycling programs. The ultimate goal is to transform cellophane from a single-use material into a sustainable, infinitely recyclable resource.

Market Analysis for Recycled Cellophane Products

The market for recycled cellophane products has been experiencing significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste management. As consumers and businesses alike seek more sustainable packaging solutions, recycled cellophane has emerged as a promising alternative to traditional plastic materials.

The global market for recycled cellophane is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026. This growth is primarily attributed to the rising demand for eco-friendly packaging in various industries, including food and beverage, cosmetics, and pharmaceuticals. The food packaging sector, in particular, has shown a strong inclination towards recycled cellophane due to its biodegradability and compatibility with food products.

Geographically, Europe leads the market for recycled cellophane products, accounting for approximately 35% of the global market share. This dominance is largely due to stringent environmental regulations and high consumer awareness in the region. North America follows closely, with a market share of around 30%, driven by increasing adoption in the retail and e-commerce sectors. The Asia-Pacific region is expected to witness the fastest growth, with countries like China and India showing rapid adoption of sustainable packaging solutions.

Key market drivers include the growing emphasis on circular economy principles, government initiatives promoting recycling, and the increasing willingness of consumers to pay a premium for environmentally friendly products. However, the market faces challenges such as the higher cost of recycled cellophane compared to virgin materials and the need for improved recycling infrastructure.

The competitive landscape of the recycled cellophane market is characterized by a mix of established players and innovative startups. Major companies are investing heavily in research and development to improve the quality and cost-effectiveness of recycled cellophane. Collaborations between packaging manufacturers, recycling companies, and end-users are becoming increasingly common, fostering innovation and market growth.

Consumer trends indicate a growing preference for transparent and minimalist packaging, which aligns well with the properties of recycled cellophane. This trend is particularly evident in the premium and organic product segments, where brands are leveraging sustainable packaging as a key differentiator.

Looking ahead, the market for recycled cellophane products is poised for continued growth. Technological advancements in recycling processes are expected to improve the quality and reduce the cost of recycled cellophane, making it more competitive with traditional packaging materials. Additionally, the development of bio-based cellophane alternatives could further expand the market, offering even more sustainable options for environmentally conscious consumers and businesses.

The global market for recycled cellophane is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026. This growth is primarily attributed to the rising demand for eco-friendly packaging in various industries, including food and beverage, cosmetics, and pharmaceuticals. The food packaging sector, in particular, has shown a strong inclination towards recycled cellophane due to its biodegradability and compatibility with food products.

Geographically, Europe leads the market for recycled cellophane products, accounting for approximately 35% of the global market share. This dominance is largely due to stringent environmental regulations and high consumer awareness in the region. North America follows closely, with a market share of around 30%, driven by increasing adoption in the retail and e-commerce sectors. The Asia-Pacific region is expected to witness the fastest growth, with countries like China and India showing rapid adoption of sustainable packaging solutions.

Key market drivers include the growing emphasis on circular economy principles, government initiatives promoting recycling, and the increasing willingness of consumers to pay a premium for environmentally friendly products. However, the market faces challenges such as the higher cost of recycled cellophane compared to virgin materials and the need for improved recycling infrastructure.

The competitive landscape of the recycled cellophane market is characterized by a mix of established players and innovative startups. Major companies are investing heavily in research and development to improve the quality and cost-effectiveness of recycled cellophane. Collaborations between packaging manufacturers, recycling companies, and end-users are becoming increasingly common, fostering innovation and market growth.

Consumer trends indicate a growing preference for transparent and minimalist packaging, which aligns well with the properties of recycled cellophane. This trend is particularly evident in the premium and organic product segments, where brands are leveraging sustainable packaging as a key differentiator.

Looking ahead, the market for recycled cellophane products is poised for continued growth. Technological advancements in recycling processes are expected to improve the quality and reduce the cost of recycled cellophane, making it more competitive with traditional packaging materials. Additionally, the development of bio-based cellophane alternatives could further expand the market, offering even more sustainable options for environmentally conscious consumers and businesses.

Current Challenges in Cellophane Recycling Technology

Cellophane recycling technology faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary obstacles is the lack of established infrastructure for collecting and sorting cellophane waste. Unlike more common plastics, cellophane is often mixed with other materials in consumer products, making separation a complex and labor-intensive process.

The chemical composition of cellophane presents another major hurdle. As a regenerated cellulose material, cellophane has unique properties that make it difficult to recycle using conventional plastic recycling methods. Its biodegradability, while beneficial for the environment, complicates the recycling process as the material can degrade during collection and processing stages.

Contamination is a persistent issue in cellophane recycling. Food residues, adhesives, and other substances often adhere to cellophane packaging, requiring thorough cleaning before recycling. This additional step increases the cost and energy consumption of the recycling process, making it less economically viable.

The limited market demand for recycled cellophane products further complicates the recycling efforts. Without a strong end-market for recycled cellophane, there is little incentive for companies to invest in developing and implementing advanced recycling technologies.

Technical limitations in the recycling process itself pose significant challenges. Current methods often result in a degradation of the cellophane's properties, making it difficult to maintain the material's original quality through multiple recycling cycles. This downgrading of material quality limits the potential applications for recycled cellophane.

Energy efficiency is another concern in cellophane recycling. The processes required to break down and reconstitute cellophane are often energy-intensive, raising questions about the overall environmental benefit of recycling compared to producing new cellophane or using alternative materials.

Regulatory challenges also play a role in hindering cellophane recycling advancements. The lack of standardized guidelines for cellophane recycling across different regions creates inconsistencies in collection and processing methods, making it difficult to implement large-scale recycling programs.

Lastly, the cost-effectiveness of cellophane recycling remains a significant barrier. The complex processes required, combined with the current low demand for recycled cellophane, make it economically challenging for companies to justify investments in advanced recycling technologies. Overcoming these financial hurdles is crucial for the widespread adoption of cellophane recycling processes.

The chemical composition of cellophane presents another major hurdle. As a regenerated cellulose material, cellophane has unique properties that make it difficult to recycle using conventional plastic recycling methods. Its biodegradability, while beneficial for the environment, complicates the recycling process as the material can degrade during collection and processing stages.

Contamination is a persistent issue in cellophane recycling. Food residues, adhesives, and other substances often adhere to cellophane packaging, requiring thorough cleaning before recycling. This additional step increases the cost and energy consumption of the recycling process, making it less economically viable.

The limited market demand for recycled cellophane products further complicates the recycling efforts. Without a strong end-market for recycled cellophane, there is little incentive for companies to invest in developing and implementing advanced recycling technologies.

Technical limitations in the recycling process itself pose significant challenges. Current methods often result in a degradation of the cellophane's properties, making it difficult to maintain the material's original quality through multiple recycling cycles. This downgrading of material quality limits the potential applications for recycled cellophane.

Energy efficiency is another concern in cellophane recycling. The processes required to break down and reconstitute cellophane are often energy-intensive, raising questions about the overall environmental benefit of recycling compared to producing new cellophane or using alternative materials.

Regulatory challenges also play a role in hindering cellophane recycling advancements. The lack of standardized guidelines for cellophane recycling across different regions creates inconsistencies in collection and processing methods, making it difficult to implement large-scale recycling programs.

Lastly, the cost-effectiveness of cellophane recycling remains a significant barrier. The complex processes required, combined with the current low demand for recycled cellophane, make it economically challenging for companies to justify investments in advanced recycling technologies. Overcoming these financial hurdles is crucial for the widespread adoption of cellophane recycling processes.

Existing Cellophane Recycling Methodologies

01 Chemical dissolution and regeneration

This process involves dissolving cellophane in a suitable solvent, followed by regeneration of the cellulose material. The dissolved cellophane can be purified and reformed into new products, allowing for efficient recycling of the material.- Chemical dissolution and regeneration: This process involves dissolving cellophane in a suitable solvent, followed by regeneration of the cellulose material. The dissolved cellophane can be purified and reformed into new cellulose-based products. This method allows for the recovery of high-quality cellulose material from cellophane waste.

- Mechanical recycling and repurposing: Mechanical recycling processes involve shredding, grinding, or pulverizing cellophane waste into smaller particles. These particles can then be used as fillers in various applications or reprocessed into new materials. This method is often more cost-effective and energy-efficient compared to chemical recycling.

- Enzymatic degradation and recovery: This process utilizes specific enzymes to break down cellophane into its constituent components. The resulting products can be further processed or used as raw materials for other applications. Enzymatic degradation offers a more environmentally friendly approach to cellophane recycling compared to chemical methods.

- Thermal processing and energy recovery: Thermal processing involves the controlled heating of cellophane waste to recover energy or produce useful byproducts. This can include incineration for energy recovery or pyrolysis to produce fuel gases and char. While not a traditional recycling method, it can be an effective way to manage cellophane waste and recover value.

- Biodegradation and composting: This approach focuses on the natural decomposition of cellophane in controlled environments. By creating optimal conditions for microbial activity, cellophane can be broken down into environmentally benign components. This method is particularly suitable for cellophane products that are contaminated or mixed with organic waste.

02 Mechanical recycling and repurposing

Mechanical recycling processes involve shredding, grinding, or cutting cellophane waste into smaller pieces. These pieces can then be used as filler material in various applications or melted and reformed into new products, reducing waste and promoting circular economy.Expand Specific Solutions03 Biological degradation and composting

This approach utilizes microorganisms to break down cellophane into simpler compounds. The process can be accelerated in controlled composting environments, allowing for the conversion of cellophane waste into useful organic matter for soil enrichment.Expand Specific Solutions04 Thermal processing and energy recovery

Thermal recycling processes involve the controlled heating of cellophane waste to recover energy or produce new materials. This can include pyrolysis to generate fuel gases or incineration for energy recovery, providing alternative uses for non-recyclable cellophane waste.Expand Specific Solutions05 Advanced separation and purification techniques

These processes focus on separating cellophane from mixed waste streams and purifying it for reuse. Techniques may include advanced sorting technologies, chemical treatments to remove contaminants, or novel filtration methods to isolate pure cellulose materials.Expand Specific Solutions

Key Industry Players in Cellophane Recycling

The cellophane recycling industry is in a nascent stage, with growing market potential driven by increasing environmental concerns and sustainability initiatives. The global market size for cellophane recycling is relatively small but expected to expand rapidly in the coming years. Technologically, the field is still developing, with various approaches being explored by key players. Companies like Lenzing AG, Infinited Fiber Co. Oy, and Novozymes A/S are at the forefront, leveraging their expertise in fiber technologies and biotechnology to develop innovative recycling processes. Academic institutions such as Donghua University and Aalto University Foundation are also contributing to research and development efforts. While the technology is not yet fully mature, significant progress is being made towards more efficient and cost-effective cellophane recycling solutions.

Lenzing AG

Technical Solution: Lenzing AG has developed an innovative cellophane recycling process that utilizes their proprietary LENZING™ technology. This process involves dissolving used cellophane in a non-toxic solvent, removing impurities, and then regenerating the cellulose into new fibers. The company has implemented a closed-loop system that recovers and reuses up to 99% of the solvent[1]. Additionally, Lenzing has integrated enzymatic treatments to enhance the breakdown of cellophane, improving the overall efficiency of the recycling process[2]. The recycled cellulose can be used to produce high-quality fibers for textiles and other applications, effectively closing the loop in cellophane production and usage[3].

Strengths: Highly efficient solvent recovery, reduced environmental impact, and production of high-quality recycled fibers. Weaknesses: Potentially high initial investment costs and limited to cellulose-based materials.

Infinited Fiber Co. Oy

Technical Solution: Infinited Fiber Co. Oy has pioneered a groundbreaking cellophane recycling technology that transforms cellulose-rich waste, including cellophane, into a regenerated fiber called Infinna™. Their process utilizes a unique chemical treatment that breaks down the cellophane into a cellulose carbamate solution, which is then extruded into new fibers[1]. The company claims that their process can recycle cellophane multiple times without significant degradation in quality[2]. Infinited Fiber's technology also incorporates a water recycling system that reduces freshwater consumption by up to 90% compared to conventional viscose production methods[3]. The resulting Infinna™ fibers have properties similar to cotton and can be used in various textile applications.

Strengths: Ability to recycle cellophane multiple times, significant reduction in water consumption, and production of high-quality fibers. Weaknesses: May require specialized equipment and expertise for implementation.

Innovative Approaches in Cellophane Recycling

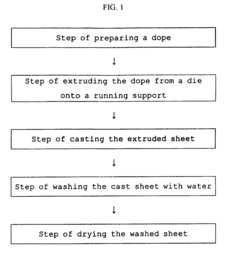

Method for preparing cellulose-based film and cellulose-based film

PatentActiveUS8883056B2

Innovation

- A method involving the preparation of a dope from alpha-cellulose pulp and an aqueous N-methylmorpholine-N-oxide solution, extrusion, casting, washing, and drying, which omits the use of NaOH or H2SO4 and avoids the use of CS2, allowing for the production of an environmentally friendly cellulose-based film with excellent properties.

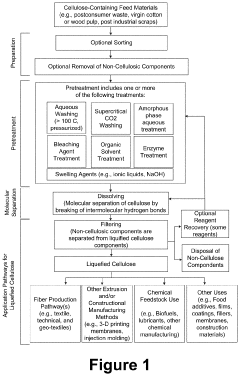

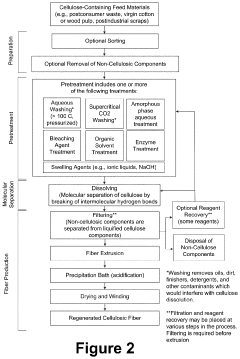

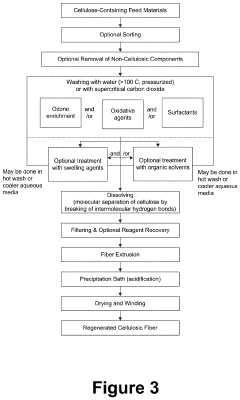

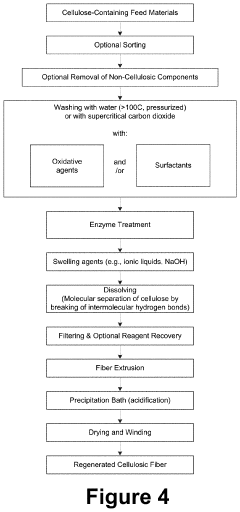

Processing cellulose-containing materials for paper or packaging materials

PatentInactiveUS20210381166A1

Innovation

- A multi-stage process involving pretreatment and pulping stages to isolate cellulose polymers from recycled textiles and biomass, using methods like high-temperature aqueous washing, supercritical CO2 treatment, and enzymatic treatments to produce regenerated cellulose fibers with customizable properties, reducing environmental impact and promoting closed-loop recycling.

Environmental Impact of Cellophane Recycling

The environmental impact of cellophane recycling processes is a critical consideration in the advancement of sustainable packaging solutions. As the global focus on reducing plastic waste intensifies, the recycling of cellophane presents both challenges and opportunities for environmental stewardship.

Cellophane, a biodegradable material derived from cellulose, offers potential advantages over traditional plastics in terms of its environmental footprint. However, the recycling process itself can have significant environmental implications. The energy consumption associated with cellophane recycling is a key factor to consider. Depending on the specific recycling method employed, the process may require substantial energy inputs, potentially offsetting some of the material's inherent environmental benefits.

Water usage is another important aspect of cellophane recycling's environmental impact. The cleaning and processing stages of recycling often involve water-intensive procedures, which can strain local water resources if not managed efficiently. Additionally, the chemicals used in these processes may introduce pollutants into wastewater streams, necessitating proper treatment and disposal protocols to mitigate environmental harm.

The carbon footprint of cellophane recycling extends beyond the immediate recycling facility. Transportation of collected cellophane to recycling centers contributes to greenhouse gas emissions, particularly if long distances are involved. Furthermore, the production of recycled cellophane products may require additional energy and resources, which must be factored into the overall environmental assessment.

On the positive side, successful cellophane recycling can significantly reduce the amount of waste sent to landfills or incineration facilities. This diversion from waste streams helps to conserve landfill space and reduce the environmental impacts associated with waste disposal, such as methane emissions from decomposing organic materials.

The quality of recycled cellophane is a crucial factor in determining its environmental impact. High-quality recycled cellophane can be used to produce new products, potentially reducing the demand for virgin materials and the associated environmental costs of production. However, if the recycled material is of lower quality, it may be downcycled into less valuable products, limiting its long-term sustainability benefits.

Advancements in cellophane recycling technologies are continually improving the environmental profile of the process. Innovations in energy-efficient recycling equipment, water recycling systems, and chemical recovery processes are helping to minimize the ecological footprint of cellophane recycling operations. Additionally, the development of more effective sorting and cleaning techniques is enhancing the quality of recycled cellophane, expanding its potential applications and environmental benefits.

As the cellophane recycling industry evolves, life cycle assessments (LCAs) are becoming increasingly important tools for evaluating the net environmental impact of different recycling approaches. These comprehensive analyses consider all stages of the recycling process, from collection to end-use, providing valuable insights for optimizing environmental performance and guiding future advancements in cellophane recycling technologies.

Cellophane, a biodegradable material derived from cellulose, offers potential advantages over traditional plastics in terms of its environmental footprint. However, the recycling process itself can have significant environmental implications. The energy consumption associated with cellophane recycling is a key factor to consider. Depending on the specific recycling method employed, the process may require substantial energy inputs, potentially offsetting some of the material's inherent environmental benefits.

Water usage is another important aspect of cellophane recycling's environmental impact. The cleaning and processing stages of recycling often involve water-intensive procedures, which can strain local water resources if not managed efficiently. Additionally, the chemicals used in these processes may introduce pollutants into wastewater streams, necessitating proper treatment and disposal protocols to mitigate environmental harm.

The carbon footprint of cellophane recycling extends beyond the immediate recycling facility. Transportation of collected cellophane to recycling centers contributes to greenhouse gas emissions, particularly if long distances are involved. Furthermore, the production of recycled cellophane products may require additional energy and resources, which must be factored into the overall environmental assessment.

On the positive side, successful cellophane recycling can significantly reduce the amount of waste sent to landfills or incineration facilities. This diversion from waste streams helps to conserve landfill space and reduce the environmental impacts associated with waste disposal, such as methane emissions from decomposing organic materials.

The quality of recycled cellophane is a crucial factor in determining its environmental impact. High-quality recycled cellophane can be used to produce new products, potentially reducing the demand for virgin materials and the associated environmental costs of production. However, if the recycled material is of lower quality, it may be downcycled into less valuable products, limiting its long-term sustainability benefits.

Advancements in cellophane recycling technologies are continually improving the environmental profile of the process. Innovations in energy-efficient recycling equipment, water recycling systems, and chemical recovery processes are helping to minimize the ecological footprint of cellophane recycling operations. Additionally, the development of more effective sorting and cleaning techniques is enhancing the quality of recycled cellophane, expanding its potential applications and environmental benefits.

As the cellophane recycling industry evolves, life cycle assessments (LCAs) are becoming increasingly important tools for evaluating the net environmental impact of different recycling approaches. These comprehensive analyses consider all stages of the recycling process, from collection to end-use, providing valuable insights for optimizing environmental performance and guiding future advancements in cellophane recycling technologies.

Economic Feasibility of Advanced Recycling Processes

The economic feasibility of advanced cellophane recycling processes is a critical factor in determining the viability of implementing new technologies in this field. As the global focus on sustainability intensifies, the recycling of cellophane, a biodegradable material derived from cellulose, has gained significant attention. However, the economic aspects of these advanced processes must be carefully evaluated to ensure their long-term sustainability and adoption by industry stakeholders.

One of the primary considerations in assessing the economic feasibility is the initial capital investment required for implementing advanced recycling technologies. This includes the cost of specialized equipment, facility modifications, and training of personnel. While these upfront costs can be substantial, they must be weighed against the potential long-term benefits and cost savings that advanced recycling processes can offer.

Operating costs are another crucial factor in determining economic viability. Advanced recycling processes may require more energy, water, or chemical inputs compared to traditional methods. However, they often result in higher quality recycled materials, which can command premium prices in the market. The balance between increased operational expenses and improved output value is a key consideration for businesses contemplating the adoption of these technologies.

The market demand for recycled cellophane products plays a significant role in the economic equation. As consumer awareness of environmental issues grows, there is an increasing preference for products made from recycled materials. This trend can potentially drive up the value of recycled cellophane, making advanced recycling processes more economically attractive. However, market volatility and competition from virgin materials must also be factored into the analysis.

Government policies and regulations can significantly impact the economic feasibility of advanced recycling processes. Incentives such as tax breaks, grants, or subsidies for recycling initiatives can improve the financial outlook for these technologies. Conversely, stringent environmental regulations may necessitate the adoption of advanced recycling methods, regardless of immediate economic considerations, to ensure compliance and avoid penalties.

The scalability of advanced recycling processes is another important economic consideration. Technologies that can be easily scaled up to handle large volumes of cellophane waste are more likely to achieve economies of scale, reducing per-unit processing costs and improving overall economic viability. This aspect is particularly relevant for large-scale industrial applications or regional recycling facilities.

Lastly, the potential for technological advancements and process improvements over time should not be overlooked. As research and development in cellophane recycling continue, more efficient and cost-effective methods are likely to emerge. Companies that invest in advanced recycling technologies may benefit from future improvements, potentially enhancing the long-term economic feasibility of their operations.

One of the primary considerations in assessing the economic feasibility is the initial capital investment required for implementing advanced recycling technologies. This includes the cost of specialized equipment, facility modifications, and training of personnel. While these upfront costs can be substantial, they must be weighed against the potential long-term benefits and cost savings that advanced recycling processes can offer.

Operating costs are another crucial factor in determining economic viability. Advanced recycling processes may require more energy, water, or chemical inputs compared to traditional methods. However, they often result in higher quality recycled materials, which can command premium prices in the market. The balance between increased operational expenses and improved output value is a key consideration for businesses contemplating the adoption of these technologies.

The market demand for recycled cellophane products plays a significant role in the economic equation. As consumer awareness of environmental issues grows, there is an increasing preference for products made from recycled materials. This trend can potentially drive up the value of recycled cellophane, making advanced recycling processes more economically attractive. However, market volatility and competition from virgin materials must also be factored into the analysis.

Government policies and regulations can significantly impact the economic feasibility of advanced recycling processes. Incentives such as tax breaks, grants, or subsidies for recycling initiatives can improve the financial outlook for these technologies. Conversely, stringent environmental regulations may necessitate the adoption of advanced recycling methods, regardless of immediate economic considerations, to ensure compliance and avoid penalties.

The scalability of advanced recycling processes is another important economic consideration. Technologies that can be easily scaled up to handle large volumes of cellophane waste are more likely to achieve economies of scale, reducing per-unit processing costs and improving overall economic viability. This aspect is particularly relevant for large-scale industrial applications or regional recycling facilities.

Lastly, the potential for technological advancements and process improvements over time should not be overlooked. As research and development in cellophane recycling continue, more efficient and cost-effective methods are likely to emerge. Companies that invest in advanced recycling technologies may benefit from future improvements, potentially enhancing the long-term economic feasibility of their operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!