Advances in Cellophane’s Optical Clarity for Electronics

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Optics Evolution

The evolution of cellophane's optical properties for electronics applications has been a journey of continuous innovation and refinement. Initially developed as a transparent packaging material in the early 20th century, cellophane's potential for use in electronic devices was not immediately apparent. However, as the electronics industry progressed, the demand for materials with superior optical clarity and functional properties grew exponentially.

In the 1960s and 1970s, researchers began exploring cellophane's potential in display technologies. The material's natural transparency and flexibility made it an attractive candidate for early liquid crystal displays (LCDs). During this period, efforts focused on improving cellophane's dimensional stability and resistance to environmental factors, which were critical for its use in electronic applications.

The 1980s marked a significant turning point in cellophane optics. Advances in polymer science led to the development of modified cellophane with enhanced optical properties. These improvements included reduced haze, increased light transmission, and better control over refractive indices. Such advancements paved the way for cellophane's integration into more sophisticated electronic components, particularly in the burgeoning field of flexible electronics.

The 1990s and early 2000s saw a surge in research aimed at tailoring cellophane's optical characteristics for specific electronic applications. Scientists and engineers worked on creating cellophane variants with customized optical properties, such as selective light filtering and polarization capabilities. These developments expanded cellophane's potential uses in areas like organic light-emitting diodes (OLEDs) and photovoltaic cells.

In recent years, the focus has shifted towards nanoscale modifications of cellophane's structure. By incorporating nanoparticles or creating nanostructured surfaces, researchers have achieved unprecedented levels of optical clarity and functionality. These advancements have opened up new possibilities for cellophane in high-performance displays, smart windows, and advanced sensing devices.

The latest frontier in cellophane optics evolution involves the integration of active optical elements directly into the material. This includes the development of cellophane-based waveguides, photonic crystals, and even optically switchable layers. Such innovations are pushing the boundaries of what's possible with this versatile material, potentially revolutionizing fields like augmented reality displays and optical computing.

Throughout its evolution, cellophane has consistently adapted to meet the changing needs of the electronics industry. From a simple packaging material to a high-tech optical component, its journey reflects the broader trends in materials science and electronic engineering. As we look to the future, the continued evolution of cellophane's optical properties promises to play a crucial role in shaping the next generation of electronic devices and technologies.

In the 1960s and 1970s, researchers began exploring cellophane's potential in display technologies. The material's natural transparency and flexibility made it an attractive candidate for early liquid crystal displays (LCDs). During this period, efforts focused on improving cellophane's dimensional stability and resistance to environmental factors, which were critical for its use in electronic applications.

The 1980s marked a significant turning point in cellophane optics. Advances in polymer science led to the development of modified cellophane with enhanced optical properties. These improvements included reduced haze, increased light transmission, and better control over refractive indices. Such advancements paved the way for cellophane's integration into more sophisticated electronic components, particularly in the burgeoning field of flexible electronics.

The 1990s and early 2000s saw a surge in research aimed at tailoring cellophane's optical characteristics for specific electronic applications. Scientists and engineers worked on creating cellophane variants with customized optical properties, such as selective light filtering and polarization capabilities. These developments expanded cellophane's potential uses in areas like organic light-emitting diodes (OLEDs) and photovoltaic cells.

In recent years, the focus has shifted towards nanoscale modifications of cellophane's structure. By incorporating nanoparticles or creating nanostructured surfaces, researchers have achieved unprecedented levels of optical clarity and functionality. These advancements have opened up new possibilities for cellophane in high-performance displays, smart windows, and advanced sensing devices.

The latest frontier in cellophane optics evolution involves the integration of active optical elements directly into the material. This includes the development of cellophane-based waveguides, photonic crystals, and even optically switchable layers. Such innovations are pushing the boundaries of what's possible with this versatile material, potentially revolutionizing fields like augmented reality displays and optical computing.

Throughout its evolution, cellophane has consistently adapted to meet the changing needs of the electronics industry. From a simple packaging material to a high-tech optical component, its journey reflects the broader trends in materials science and electronic engineering. As we look to the future, the continued evolution of cellophane's optical properties promises to play a crucial role in shaping the next generation of electronic devices and technologies.

Electronics Market Demand

The electronics market has witnessed a growing demand for advanced display technologies, creating a significant opportunity for cellophane with enhanced optical clarity. As consumer electronics continue to evolve, there is an increasing need for materials that can provide superior visual experiences while maintaining durability and flexibility. This trend is particularly evident in the smartphone, tablet, and wearable device segments, where high-resolution displays and augmented reality features are becoming standard.

The global smartphone market, a key driver for optically clear materials, is projected to reach 1.5 billion units shipped annually by 2025. This growth is fueled by the continuous upgrade cycle and the expansion of 5G networks, which require advanced display technologies. Tablets and e-readers, while experiencing slower growth, still maintain a steady demand for high-quality display materials, with an estimated market size of 150 million units per year.

Wearable devices, including smartwatches and fitness trackers, represent a rapidly expanding market segment. Industry analysts predict the global wearable device market to grow at a compound annual growth rate (CAGR) of 15% from 2021 to 2026. This growth is driven by increasing health consciousness and the integration of advanced features such as ECG monitoring and blood oxygen level tracking, all of which require clear and responsive displays.

The automotive industry is another significant market for optically clear materials, as vehicle manufacturers increasingly incorporate advanced driver-assistance systems (ADAS) and infotainment displays. The global automotive display market is expected to grow substantially, with a projected value of over $30 billion by 2025. This growth is driven by the increasing adoption of digital cockpits and heads-up displays, which require materials with exceptional optical clarity and durability.

In the consumer electronics sector, there is a growing trend towards foldable and flexible displays. Major smartphone manufacturers have introduced foldable devices, creating a new category that demands materials capable of maintaining optical clarity while withstanding repeated folding and unfolding. This niche market is expected to grow significantly, with some industry experts predicting a CAGR of over 20% for foldable devices in the next five years.

The demand for optically clear materials extends beyond consumer electronics to industrial and medical applications. In the industrial sector, there is a growing need for high-quality display materials in control panels and human-machine interfaces. The medical field requires optically clear materials for various applications, including diagnostic displays and wearable medical devices, contributing to the overall market growth.

As sustainability becomes increasingly important to consumers and regulators, there is a growing demand for eco-friendly materials in electronics. This trend presents an opportunity for cellophane, which is derived from renewable resources, to position itself as a sustainable alternative to petroleum-based plastics in certain applications, potentially expanding its market share in the electronics industry.

The global smartphone market, a key driver for optically clear materials, is projected to reach 1.5 billion units shipped annually by 2025. This growth is fueled by the continuous upgrade cycle and the expansion of 5G networks, which require advanced display technologies. Tablets and e-readers, while experiencing slower growth, still maintain a steady demand for high-quality display materials, with an estimated market size of 150 million units per year.

Wearable devices, including smartwatches and fitness trackers, represent a rapidly expanding market segment. Industry analysts predict the global wearable device market to grow at a compound annual growth rate (CAGR) of 15% from 2021 to 2026. This growth is driven by increasing health consciousness and the integration of advanced features such as ECG monitoring and blood oxygen level tracking, all of which require clear and responsive displays.

The automotive industry is another significant market for optically clear materials, as vehicle manufacturers increasingly incorporate advanced driver-assistance systems (ADAS) and infotainment displays. The global automotive display market is expected to grow substantially, with a projected value of over $30 billion by 2025. This growth is driven by the increasing adoption of digital cockpits and heads-up displays, which require materials with exceptional optical clarity and durability.

In the consumer electronics sector, there is a growing trend towards foldable and flexible displays. Major smartphone manufacturers have introduced foldable devices, creating a new category that demands materials capable of maintaining optical clarity while withstanding repeated folding and unfolding. This niche market is expected to grow significantly, with some industry experts predicting a CAGR of over 20% for foldable devices in the next five years.

The demand for optically clear materials extends beyond consumer electronics to industrial and medical applications. In the industrial sector, there is a growing need for high-quality display materials in control panels and human-machine interfaces. The medical field requires optically clear materials for various applications, including diagnostic displays and wearable medical devices, contributing to the overall market growth.

As sustainability becomes increasingly important to consumers and regulators, there is a growing demand for eco-friendly materials in electronics. This trend presents an opportunity for cellophane, which is derived from renewable resources, to position itself as a sustainable alternative to petroleum-based plastics in certain applications, potentially expanding its market share in the electronics industry.

Current Optical Challenges

Cellophane, a transparent film derived from regenerated cellulose, has long been used in various industries, including electronics. However, as electronic devices become increasingly sophisticated, the optical clarity requirements for protective films and packaging materials have become more stringent. This has led to several challenges in the current state of cellophane's optical properties for electronic applications.

One of the primary challenges is achieving consistent optical clarity across large surface areas. While cellophane generally offers good transparency, variations in thickness and material composition can lead to inconsistencies in light transmission. This becomes particularly problematic for large display screens or multi-layered electronic components where even minor optical distortions can significantly impact visual quality.

Another significant challenge lies in reducing haze and improving overall light transmission. Although cellophane is inherently transparent, it still exhibits a certain degree of haze, which can affect the clarity of displays and reduce the efficiency of light-sensitive components. This becomes especially critical in applications such as touchscreens, where even slight reductions in optical clarity can impact user experience and device functionality.

The issue of birefringence also poses a considerable challenge for cellophane in electronic applications. Birefringence, the optical property where a material has different refractive indices depending on the polarization and propagation direction of light, can cause unwanted optical effects in displays and other light-sensitive components. Minimizing birefringence while maintaining other desirable properties of cellophane remains a significant technical hurdle.

Furthermore, the long-term stability of cellophane's optical properties under various environmental conditions presents another challenge. Electronic devices are often exposed to fluctuating temperatures, humidity levels, and UV radiation. Ensuring that cellophane maintains its optical clarity and does not degrade or yellow over time in these conditions is crucial for its widespread adoption in electronics.

The challenge of achieving ultra-thin cellophane films without compromising optical quality is also at the forefront of current research. As electronic devices continue to shrink in size, there is a growing demand for thinner protective films. However, reducing the thickness of cellophane while maintaining its optical clarity and mechanical strength remains a complex balancing act.

Lastly, the integration of additional functionalities into cellophane without affecting its optical properties presents a multifaceted challenge. There is increasing interest in developing cellophane films with anti-glare, anti-reflective, or even self-healing properties. Incorporating these features while preserving the film's transparency and clarity requires innovative approaches in material science and manufacturing processes.

One of the primary challenges is achieving consistent optical clarity across large surface areas. While cellophane generally offers good transparency, variations in thickness and material composition can lead to inconsistencies in light transmission. This becomes particularly problematic for large display screens or multi-layered electronic components where even minor optical distortions can significantly impact visual quality.

Another significant challenge lies in reducing haze and improving overall light transmission. Although cellophane is inherently transparent, it still exhibits a certain degree of haze, which can affect the clarity of displays and reduce the efficiency of light-sensitive components. This becomes especially critical in applications such as touchscreens, where even slight reductions in optical clarity can impact user experience and device functionality.

The issue of birefringence also poses a considerable challenge for cellophane in electronic applications. Birefringence, the optical property where a material has different refractive indices depending on the polarization and propagation direction of light, can cause unwanted optical effects in displays and other light-sensitive components. Minimizing birefringence while maintaining other desirable properties of cellophane remains a significant technical hurdle.

Furthermore, the long-term stability of cellophane's optical properties under various environmental conditions presents another challenge. Electronic devices are often exposed to fluctuating temperatures, humidity levels, and UV radiation. Ensuring that cellophane maintains its optical clarity and does not degrade or yellow over time in these conditions is crucial for its widespread adoption in electronics.

The challenge of achieving ultra-thin cellophane films without compromising optical quality is also at the forefront of current research. As electronic devices continue to shrink in size, there is a growing demand for thinner protective films. However, reducing the thickness of cellophane while maintaining its optical clarity and mechanical strength remains a complex balancing act.

Lastly, the integration of additional functionalities into cellophane without affecting its optical properties presents a multifaceted challenge. There is increasing interest in developing cellophane films with anti-glare, anti-reflective, or even self-healing properties. Incorporating these features while preserving the film's transparency and clarity requires innovative approaches in material science and manufacturing processes.

Optical Clarity Solutions

01 Improving optical clarity of cellophane

Various methods are employed to enhance the optical clarity of cellophane, including chemical treatments, manufacturing process improvements, and the use of specific additives. These techniques aim to reduce haze, increase light transmission, and improve overall transparency of the cellophane film.- Improving optical clarity of cellophane: Various methods are employed to enhance the optical clarity of cellophane, including chemical treatments, physical modifications, and the use of additives. These techniques aim to reduce light scattering and increase transparency, resulting in improved visual properties of the cellophane film.

- Optical clarity measurement techniques: Different methods and devices are used to measure and evaluate the optical clarity of cellophane. These include spectrophotometric analysis, light transmission tests, and specialized imaging systems that can quantify the transparency and clarity of cellophane films.

- Surface treatment for enhanced clarity: Surface treatments are applied to cellophane to improve its optical clarity. These treatments may involve coating the cellophane with specific materials, modifying the surface structure, or applying physical or chemical processes to reduce surface irregularities that can affect clarity.

- Composition modifications for clarity: The optical clarity of cellophane can be enhanced by modifying its composition. This includes incorporating specific additives, adjusting the cellulose content, or introducing other materials that can improve the overall transparency and visual properties of the cellophane.

- Applications utilizing cellophane's optical clarity: The high optical clarity of cellophane is exploited in various applications, including packaging, display technologies, and optical devices. These applications leverage the transparent nature of cellophane to create visually appealing products or to enhance the performance of optical systems.

02 Optical clarity measurement techniques

Different methods and devices are used to measure and evaluate the optical clarity of cellophane. These include spectrophotometric analysis, light transmission tests, and specialized imaging equipment to quantify transparency, haze, and other optical properties of cellophane films.Expand Specific Solutions03 Surface treatment for enhanced clarity

Surface treatments are applied to cellophane to improve its optical clarity. These treatments may include plasma processing, coating applications, or chemical modifications to reduce surface roughness and minimize light scattering, resulting in improved transparency and visual appearance.Expand Specific Solutions04 Packaging applications utilizing cellophane's optical clarity

The optical clarity of cellophane is exploited in various packaging applications. These include food packaging, display windows, and protective coverings where transparency is crucial. The high clarity of cellophane allows for clear visibility of the packaged contents while providing protection.Expand Specific Solutions05 Composite materials for improved optical properties

Cellophane is combined with other materials to create composite structures with enhanced optical properties. These composites may incorporate nanoparticles, polymers, or specialized coatings to improve clarity, reduce glare, or add functionalities while maintaining transparency.Expand Specific Solutions

Key Industry Players

The cellophane optical clarity market for electronics is in a growth phase, driven by increasing demand for high-performance displays and optoelectronic devices. The market size is expanding rapidly, with major players like BOE Technology, Sharp, and Huawei investing heavily in research and development. Technological maturity varies, with companies like Wuhan Tianma Microelectronics and OmniVision Technologies leading in advanced display technologies. Emerging players such as Guangdong Huagong Borun and Shenzhen Guohua Optoelectronics are also making significant strides in developing innovative optical materials. The competitive landscape is characterized by a mix of established electronics giants and specialized materials firms, all vying to enhance cellophane's optical properties for next-generation electronic applications.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced cellophane-based flexible display technologies with enhanced optical clarity for electronics. Their approach involves using nano-scale cellulose fibers to create ultra-thin, highly transparent cellophane films. These films are then integrated with organic light-emitting diodes (OLEDs) to produce flexible displays with improved brightness and color accuracy. BOE's cellophane displays reportedly achieve over 90% light transmittance[1], significantly higher than traditional plastic-based flexible displays. The company has also implemented a proprietary surface treatment process to reduce light reflection and improve visibility in bright environments[3].

Strengths: High transparency, flexibility, and improved color reproduction. Weaknesses: Potential durability concerns and higher production costs compared to traditional display technologies.

Sharp Corp.

Technical Solution: Sharp has made significant strides in cellophane-based display technology, focusing on improving optical clarity for electronic devices. Their approach combines high-purity cellophane with advanced light management techniques. Sharp's proprietary "IGZO" (Indium Gallium Zinc Oxide) technology is integrated with cellophane substrates to create ultra-high resolution displays with exceptional clarity. The company has reported achieving pixel densities of over 1000 PPI (pixels per inch) on their cellophane-based displays[2], surpassing many conventional LCD and OLED displays. Additionally, Sharp has developed a unique lamination process that bonds the cellophane layer with other display components, minimizing air gaps and reducing internal reflections, thus enhancing overall optical clarity[4].

Strengths: Ultra-high resolution, excellent optical clarity, and potential for energy efficiency. Weaknesses: Higher production complexity and potential limitations in large-scale manufacturing.

Breakthrough Innovations

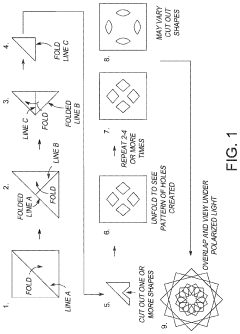

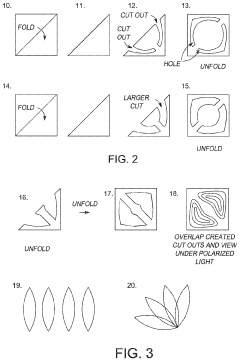

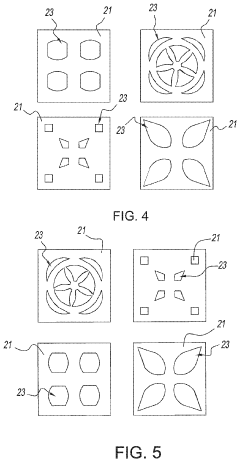

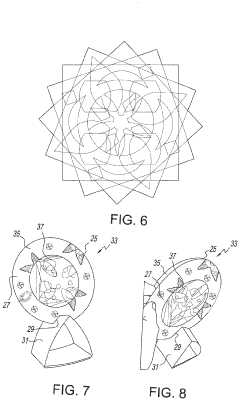

Cellophane cut out kits for optical art

PatentActiveUS20200294415A1

Innovation

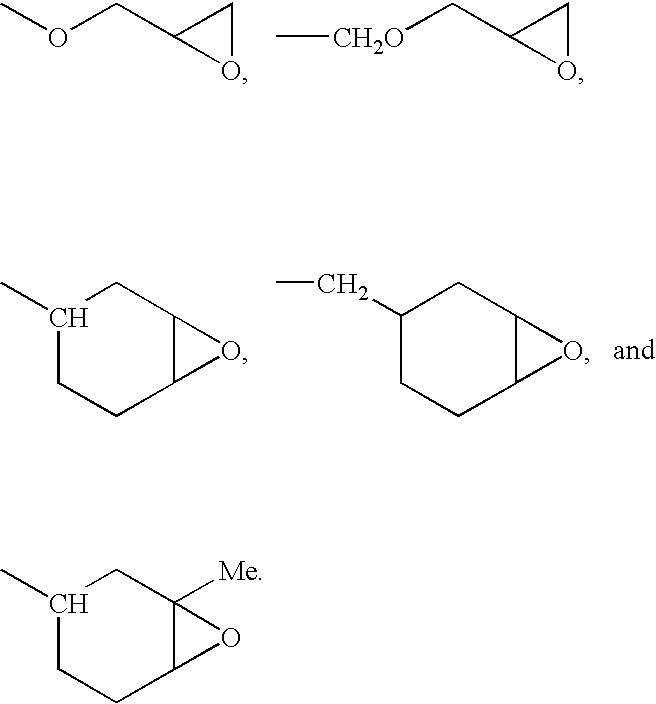

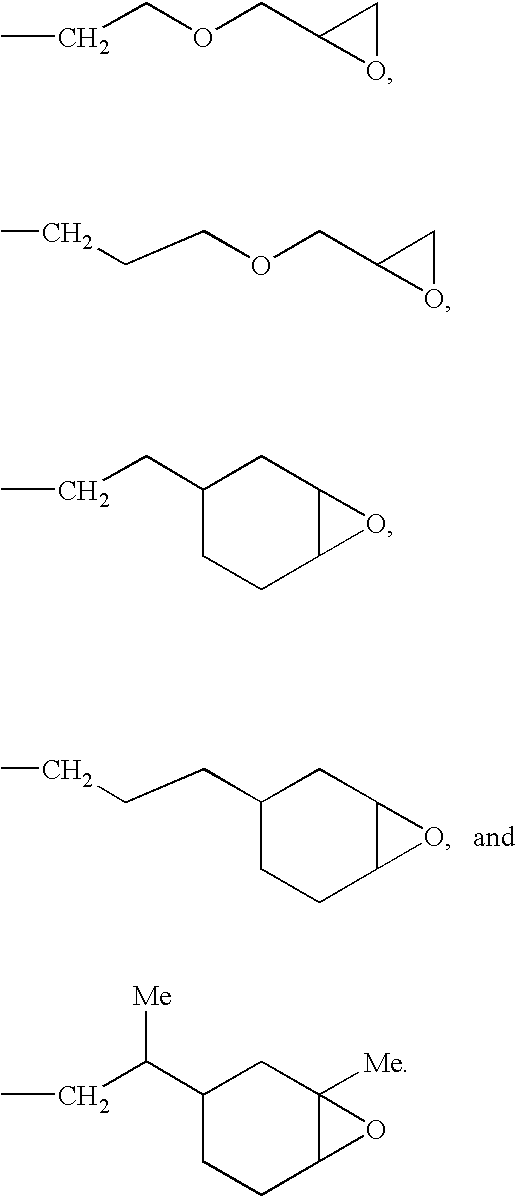

- The use of transparent or translucent cellophane sheets, which are folded and cut to create symmetric patterns, exhibiting diffraction patterns visible under polarized light, combined with glow-in-the-dark materials and layered structures to produce dynamic optical effects, enhancing the experience through light reflection, refraction, and interference.

Epoxy-Functional Polysiloxanes, Silicone Composition, and Coated

PatentInactiveUS20080260337A1

Innovation

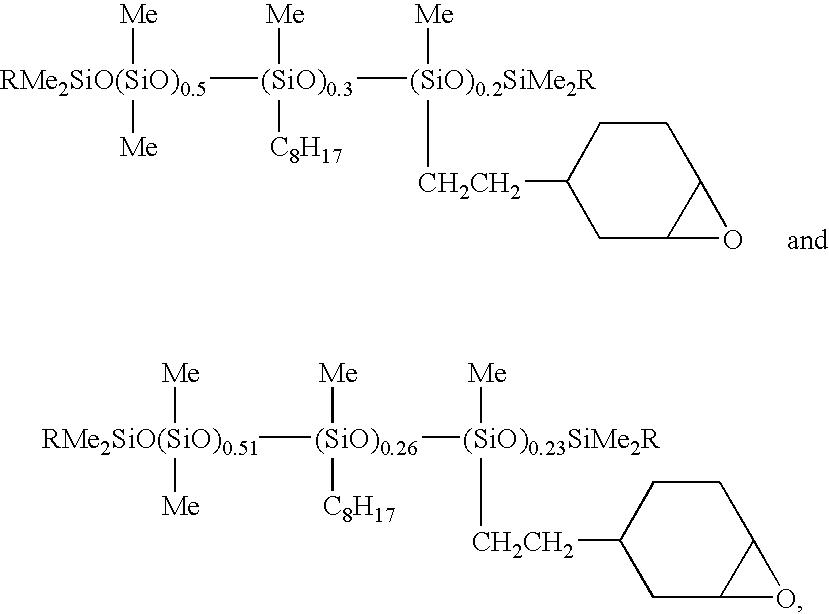

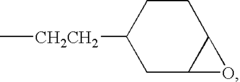

- Development of epoxy-functional polysiloxanes with low ultraviolet absorbance, which can be cured rapidly to form a durable, transparent coating that allows for direct writing of Bragg gratings through the coating, eliminating the need for stripping and recoating, and providing excellent adhesion and mechanical strength.

Environmental Impact

The environmental impact of cellophane's optical clarity advancements in electronics is a crucial aspect to consider as the technology progresses. These improvements have both positive and negative implications for the environment, which need to be carefully evaluated.

On the positive side, enhanced optical clarity in cellophane can lead to more efficient electronic displays, potentially reducing energy consumption. This increased efficiency may result in longer-lasting devices, reducing electronic waste and the need for frequent replacements. Additionally, the improved clarity may enable the production of thinner and lighter devices, potentially reducing material usage and transportation-related emissions.

However, the production process for optically enhanced cellophane may involve additional chemical treatments or manufacturing steps, potentially increasing the environmental footprint of the material. The use of specialized coatings or additives to achieve higher clarity could introduce new challenges in terms of recyclability and biodegradability.

The disposal of electronic devices containing advanced cellophane components also raises concerns. While the material itself is biodegradable, the integration with other electronic components may complicate end-of-life management. Proper recycling and disposal methods need to be developed to ensure that these advanced materials do not contribute to electronic waste pollution.

Water usage and pollution are additional environmental factors to consider. The production of high-clarity cellophane may require increased water consumption and potentially generate wastewater containing chemical residues. Implementing effective water treatment and recycling systems in manufacturing facilities is essential to mitigate these impacts.

The carbon footprint associated with the production and transportation of optically enhanced cellophane is another environmental consideration. As demand for these advanced materials grows, there may be an increase in energy consumption and greenhouse gas emissions related to their manufacture and distribution.

To address these environmental challenges, research and development efforts should focus on sustainable production methods, eco-friendly additives, and improved recycling technologies. Life cycle assessments of electronic devices incorporating advanced cellophane should be conducted to identify areas for environmental optimization.

Collaboration between material scientists, electronics manufacturers, and environmental experts is crucial to develop holistic solutions that balance technological advancements with environmental stewardship. By addressing these environmental concerns proactively, the electronics industry can ensure that the benefits of improved cellophane optical clarity are realized without compromising ecological sustainability.

On the positive side, enhanced optical clarity in cellophane can lead to more efficient electronic displays, potentially reducing energy consumption. This increased efficiency may result in longer-lasting devices, reducing electronic waste and the need for frequent replacements. Additionally, the improved clarity may enable the production of thinner and lighter devices, potentially reducing material usage and transportation-related emissions.

However, the production process for optically enhanced cellophane may involve additional chemical treatments or manufacturing steps, potentially increasing the environmental footprint of the material. The use of specialized coatings or additives to achieve higher clarity could introduce new challenges in terms of recyclability and biodegradability.

The disposal of electronic devices containing advanced cellophane components also raises concerns. While the material itself is biodegradable, the integration with other electronic components may complicate end-of-life management. Proper recycling and disposal methods need to be developed to ensure that these advanced materials do not contribute to electronic waste pollution.

Water usage and pollution are additional environmental factors to consider. The production of high-clarity cellophane may require increased water consumption and potentially generate wastewater containing chemical residues. Implementing effective water treatment and recycling systems in manufacturing facilities is essential to mitigate these impacts.

The carbon footprint associated with the production and transportation of optically enhanced cellophane is another environmental consideration. As demand for these advanced materials grows, there may be an increase in energy consumption and greenhouse gas emissions related to their manufacture and distribution.

To address these environmental challenges, research and development efforts should focus on sustainable production methods, eco-friendly additives, and improved recycling technologies. Life cycle assessments of electronic devices incorporating advanced cellophane should be conducted to identify areas for environmental optimization.

Collaboration between material scientists, electronics manufacturers, and environmental experts is crucial to develop holistic solutions that balance technological advancements with environmental stewardship. By addressing these environmental concerns proactively, the electronics industry can ensure that the benefits of improved cellophane optical clarity are realized without compromising ecological sustainability.

Manufacturing Processes

The manufacturing processes for enhancing cellophane's optical clarity for electronics applications have undergone significant advancements in recent years. These improvements have been driven by the increasing demand for high-quality, transparent materials in various electronic devices, such as displays, touchscreens, and flexible electronics.

One of the key manufacturing processes involves the careful control of cellulose dissolution and regeneration. Advanced techniques have been developed to ensure a more uniform and consistent cellulose solution, which is critical for producing cellophane with superior optical properties. This includes the use of precise temperature and pressure control systems, as well as the implementation of advanced filtration methods to remove impurities that could affect clarity.

The extrusion process has also seen notable improvements. Modern extrusion equipment now incorporates high-precision dies and advanced cooling systems, allowing for better control over the film thickness and surface quality. This results in cellophane sheets with enhanced transparency and reduced optical distortions.

Post-extrusion treatments have become increasingly sophisticated. Surface modification techniques, such as plasma treatment or the application of specialized coatings, are now commonly used to improve the optical clarity and reduce light scattering. These treatments can also enhance the material's resistance to scratches and environmental factors that might degrade its transparency over time.

The incorporation of nanotechnology in cellophane production has opened up new possibilities for optical clarity enhancement. Nanoparticles or nanostructures can be integrated into the cellophane matrix during manufacturing, altering its optical properties at the molecular level. This approach has shown promise in reducing haze and increasing light transmission.

Quality control processes have also evolved significantly. Advanced optical measurement systems, including high-resolution spectrophotometers and laser-based inspection tools, are now standard in cellophane production lines. These systems allow for real-time monitoring and adjustment of manufacturing parameters to maintain consistent optical quality.

Sustainable manufacturing practices are increasingly being adopted in cellophane production for electronics. This includes the development of eco-friendly solvents for cellulose dissolution and the implementation of closed-loop systems to recover and reuse chemicals. These practices not only reduce environmental impact but also contribute to the production of higher-quality cellophane with fewer impurities that could affect optical clarity.

One of the key manufacturing processes involves the careful control of cellulose dissolution and regeneration. Advanced techniques have been developed to ensure a more uniform and consistent cellulose solution, which is critical for producing cellophane with superior optical properties. This includes the use of precise temperature and pressure control systems, as well as the implementation of advanced filtration methods to remove impurities that could affect clarity.

The extrusion process has also seen notable improvements. Modern extrusion equipment now incorporates high-precision dies and advanced cooling systems, allowing for better control over the film thickness and surface quality. This results in cellophane sheets with enhanced transparency and reduced optical distortions.

Post-extrusion treatments have become increasingly sophisticated. Surface modification techniques, such as plasma treatment or the application of specialized coatings, are now commonly used to improve the optical clarity and reduce light scattering. These treatments can also enhance the material's resistance to scratches and environmental factors that might degrade its transparency over time.

The incorporation of nanotechnology in cellophane production has opened up new possibilities for optical clarity enhancement. Nanoparticles or nanostructures can be integrated into the cellophane matrix during manufacturing, altering its optical properties at the molecular level. This approach has shown promise in reducing haze and increasing light transmission.

Quality control processes have also evolved significantly. Advanced optical measurement systems, including high-resolution spectrophotometers and laser-based inspection tools, are now standard in cellophane production lines. These systems allow for real-time monitoring and adjustment of manufacturing parameters to maintain consistent optical quality.

Sustainable manufacturing practices are increasingly being adopted in cellophane production for electronics. This includes the development of eco-friendly solvents for cellulose dissolution and the implementation of closed-loop systems to recover and reuse chemicals. These practices not only reduce environmental impact but also contribute to the production of higher-quality cellophane with fewer impurities that could affect optical clarity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!