Applications of malachite nanowires in device miniaturization

AUG 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Malachite Nanowires: Background and Objectives

Malachite nanowires have emerged as a promising material in the field of nanotechnology, particularly for device miniaturization applications. These one-dimensional nanostructures, composed of copper carbonate hydroxide, have garnered significant attention due to their unique properties and potential to revolutionize various technological domains.

The development of malachite nanowires can be traced back to the early 2000s when researchers began exploring the synthesis and characterization of nanoscale materials. As the field of nanotechnology progressed, scientists recognized the potential of malachite nanowires for their exceptional electrical, optical, and mechanical properties.

The primary objective of research into malachite nanowires is to harness their unique characteristics for the miniaturization of electronic devices. This aligns with the broader trend in the technology industry towards smaller, more efficient, and more powerful devices. The nanoscale dimensions of these wires make them ideal candidates for integration into micro and nanoelectronic systems.

One of the key advantages of malachite nanowires is their high surface-to-volume ratio, which enhances their reactivity and sensitivity. This property makes them particularly suitable for applications in sensors and catalysts, where maximizing surface area is crucial for performance.

The electrical conductivity of malachite nanowires is another area of interest. While not as conductive as some metallic nanowires, their semiconducting properties offer unique opportunities for developing novel electronic components. Researchers are exploring ways to tune and enhance the conductivity of these nanowires through doping and surface modifications.

In the context of device miniaturization, malachite nanowires show promise in several areas. They could potentially serve as building blocks for nanoscale transistors, allowing for the creation of smaller and more energy-efficient electronic circuits. Additionally, their optical properties make them candidates for use in nanophotonic devices, potentially leading to advancements in optical computing and communication technologies.

The environmental stability and biocompatibility of malachite nanowires are also noteworthy. These characteristics open up possibilities for their use in biomedical applications, such as drug delivery systems and biosensors, where miniaturization is crucial for non-invasive diagnostics and treatments.

As research in this field progresses, the overarching goal is to develop scalable and cost-effective methods for synthesizing and integrating malachite nanowires into practical devices. This involves overcoming challenges related to controlled growth, alignment, and integration of these nanowires into existing manufacturing processes.

The development of malachite nanowires can be traced back to the early 2000s when researchers began exploring the synthesis and characterization of nanoscale materials. As the field of nanotechnology progressed, scientists recognized the potential of malachite nanowires for their exceptional electrical, optical, and mechanical properties.

The primary objective of research into malachite nanowires is to harness their unique characteristics for the miniaturization of electronic devices. This aligns with the broader trend in the technology industry towards smaller, more efficient, and more powerful devices. The nanoscale dimensions of these wires make them ideal candidates for integration into micro and nanoelectronic systems.

One of the key advantages of malachite nanowires is their high surface-to-volume ratio, which enhances their reactivity and sensitivity. This property makes them particularly suitable for applications in sensors and catalysts, where maximizing surface area is crucial for performance.

The electrical conductivity of malachite nanowires is another area of interest. While not as conductive as some metallic nanowires, their semiconducting properties offer unique opportunities for developing novel electronic components. Researchers are exploring ways to tune and enhance the conductivity of these nanowires through doping and surface modifications.

In the context of device miniaturization, malachite nanowires show promise in several areas. They could potentially serve as building blocks for nanoscale transistors, allowing for the creation of smaller and more energy-efficient electronic circuits. Additionally, their optical properties make them candidates for use in nanophotonic devices, potentially leading to advancements in optical computing and communication technologies.

The environmental stability and biocompatibility of malachite nanowires are also noteworthy. These characteristics open up possibilities for their use in biomedical applications, such as drug delivery systems and biosensors, where miniaturization is crucial for non-invasive diagnostics and treatments.

As research in this field progresses, the overarching goal is to develop scalable and cost-effective methods for synthesizing and integrating malachite nanowires into practical devices. This involves overcoming challenges related to controlled growth, alignment, and integration of these nanowires into existing manufacturing processes.

Market Demand Analysis for Miniaturized Devices

The market demand for miniaturized devices has been experiencing significant growth across various industries, driven by the increasing need for compact, portable, and high-performance electronic products. This trend is particularly evident in consumer electronics, medical devices, aerospace, and automotive sectors. The global market for miniaturized devices is projected to expand at a compound annual growth rate of over 8% in the coming years, with the Asia-Pacific region leading in terms of market share and growth potential.

Consumer electronics represent a major driver for miniaturized devices, with smartphones, wearables, and IoT devices at the forefront. The demand for smaller, lighter, and more powerful gadgets continues to push the boundaries of device miniaturization. In the medical field, there is a growing need for minimally invasive diagnostic and therapeutic tools, driving the development of micro-scale sensors and actuators. The aerospace and defense industries are also significant contributors to this market, requiring compact and lightweight components for satellites, drones, and advanced avionics systems.

The automotive sector is another key player in the miniaturized device market, with the increasing adoption of advanced driver assistance systems (ADAS) and the move towards autonomous vehicles. These technologies rely heavily on compact sensors, processors, and communication modules, further fueling the demand for miniaturization solutions.

The integration of malachite nanowires in device miniaturization offers several potential advantages that align with market demands. Malachite nanowires possess unique electrical and optical properties that can enhance the performance of miniaturized devices while reducing their size and power consumption. This aligns well with the market's need for more efficient and compact electronic components.

However, challenges remain in scaling up the production of malachite nanowires and integrating them into existing manufacturing processes. The market's readiness to adopt this new technology will depend on factors such as cost-effectiveness, reliability, and compatibility with current device architectures. As research and development in this area progress, it is expected that the applications of malachite nanowires in device miniaturization will expand, potentially disrupting traditional approaches and opening new market opportunities.

The success of malachite nanowires in the miniaturized device market will also depend on addressing specific industry requirements. For instance, in the medical field, biocompatibility and long-term stability are crucial factors. In consumer electronics, the focus will be on enhancing battery life and improving device performance without increasing costs significantly. The automotive and aerospace sectors will prioritize durability and reliability under extreme conditions.

As the demand for smaller, more powerful devices continues to grow, the potential applications of malachite nanowires in device miniaturization represent a promising avenue for innovation. The market's receptiveness to this technology will be influenced by its ability to meet or exceed current performance standards while offering tangible benefits in terms of size reduction, energy efficiency, and enhanced functionality.

Consumer electronics represent a major driver for miniaturized devices, with smartphones, wearables, and IoT devices at the forefront. The demand for smaller, lighter, and more powerful gadgets continues to push the boundaries of device miniaturization. In the medical field, there is a growing need for minimally invasive diagnostic and therapeutic tools, driving the development of micro-scale sensors and actuators. The aerospace and defense industries are also significant contributors to this market, requiring compact and lightweight components for satellites, drones, and advanced avionics systems.

The automotive sector is another key player in the miniaturized device market, with the increasing adoption of advanced driver assistance systems (ADAS) and the move towards autonomous vehicles. These technologies rely heavily on compact sensors, processors, and communication modules, further fueling the demand for miniaturization solutions.

The integration of malachite nanowires in device miniaturization offers several potential advantages that align with market demands. Malachite nanowires possess unique electrical and optical properties that can enhance the performance of miniaturized devices while reducing their size and power consumption. This aligns well with the market's need for more efficient and compact electronic components.

However, challenges remain in scaling up the production of malachite nanowires and integrating them into existing manufacturing processes. The market's readiness to adopt this new technology will depend on factors such as cost-effectiveness, reliability, and compatibility with current device architectures. As research and development in this area progress, it is expected that the applications of malachite nanowires in device miniaturization will expand, potentially disrupting traditional approaches and opening new market opportunities.

The success of malachite nanowires in the miniaturized device market will also depend on addressing specific industry requirements. For instance, in the medical field, biocompatibility and long-term stability are crucial factors. In consumer electronics, the focus will be on enhancing battery life and improving device performance without increasing costs significantly. The automotive and aerospace sectors will prioritize durability and reliability under extreme conditions.

As the demand for smaller, more powerful devices continues to grow, the potential applications of malachite nanowires in device miniaturization represent a promising avenue for innovation. The market's receptiveness to this technology will be influenced by its ability to meet or exceed current performance standards while offering tangible benefits in terms of size reduction, energy efficiency, and enhanced functionality.

Current State and Challenges in Nanowire Technology

Nanowire technology has made significant strides in recent years, particularly in the field of device miniaturization. The current state of nanowire technology is characterized by rapid advancements in synthesis methods, improved control over nanowire properties, and expanding applications across various industries. However, several challenges persist that hinder the widespread adoption and commercialization of nanowire-based devices.

One of the primary achievements in nanowire technology is the development of precise and scalable fabrication techniques. Methods such as vapor-liquid-solid (VLS) growth, template-assisted synthesis, and electrochemical deposition have enabled the production of nanowires with controlled dimensions, composition, and crystal structure. These advancements have paved the way for the integration of nanowires into miniaturized devices, offering enhanced performance and functionality.

Despite these achievements, significant challenges remain in the large-scale production of uniform and defect-free nanowires. Consistency in nanowire properties across batches and the ability to produce them in high volumes are crucial for commercial viability. Additionally, the integration of nanowires into existing manufacturing processes and device architectures presents technical hurdles that need to be overcome.

Another critical aspect of nanowire technology is the control and manipulation of their electronic and optical properties. Researchers have made progress in tailoring these properties through doping, surface functionalization, and heterostructure formation. However, achieving precise and reproducible control over these properties at the nanoscale remains a challenge, particularly for complex nanowire systems like malachite nanowires.

The characterization and measurement of nanowire properties pose additional challenges. While advanced microscopy and spectroscopy techniques have improved our ability to analyze nanowires, there is still a need for more sophisticated tools and methodologies to accurately assess their performance in device applications. This is particularly important for understanding the behavior of nanowires in miniaturized devices where quantum effects and surface phenomena play significant roles.

Environmental stability and long-term reliability of nanowire-based devices are also areas of concern. Nanowires, due to their high surface-to-volume ratio, are susceptible to degradation and performance changes over time. Developing effective encapsulation and passivation techniques to protect nanowires without compromising their unique properties is an ongoing challenge in the field.

Lastly, the integration of nanowires into functional devices, especially in the context of miniaturization, presents its own set of challenges. Issues such as precise positioning, electrical contacting, and interfacing with other device components need to be addressed. The development of scalable and cost-effective assembly techniques for nanowire-based devices remains a significant hurdle in realizing their full potential in commercial applications.

One of the primary achievements in nanowire technology is the development of precise and scalable fabrication techniques. Methods such as vapor-liquid-solid (VLS) growth, template-assisted synthesis, and electrochemical deposition have enabled the production of nanowires with controlled dimensions, composition, and crystal structure. These advancements have paved the way for the integration of nanowires into miniaturized devices, offering enhanced performance and functionality.

Despite these achievements, significant challenges remain in the large-scale production of uniform and defect-free nanowires. Consistency in nanowire properties across batches and the ability to produce them in high volumes are crucial for commercial viability. Additionally, the integration of nanowires into existing manufacturing processes and device architectures presents technical hurdles that need to be overcome.

Another critical aspect of nanowire technology is the control and manipulation of their electronic and optical properties. Researchers have made progress in tailoring these properties through doping, surface functionalization, and heterostructure formation. However, achieving precise and reproducible control over these properties at the nanoscale remains a challenge, particularly for complex nanowire systems like malachite nanowires.

The characterization and measurement of nanowire properties pose additional challenges. While advanced microscopy and spectroscopy techniques have improved our ability to analyze nanowires, there is still a need for more sophisticated tools and methodologies to accurately assess their performance in device applications. This is particularly important for understanding the behavior of nanowires in miniaturized devices where quantum effects and surface phenomena play significant roles.

Environmental stability and long-term reliability of nanowire-based devices are also areas of concern. Nanowires, due to their high surface-to-volume ratio, are susceptible to degradation and performance changes over time. Developing effective encapsulation and passivation techniques to protect nanowires without compromising their unique properties is an ongoing challenge in the field.

Lastly, the integration of nanowires into functional devices, especially in the context of miniaturization, presents its own set of challenges. Issues such as precise positioning, electrical contacting, and interfacing with other device components need to be addressed. The development of scalable and cost-effective assembly techniques for nanowire-based devices remains a significant hurdle in realizing their full potential in commercial applications.

Existing Applications of Malachite Nanowires

01 Synthesis and characterization of malachite nanowires

Methods for synthesizing malachite nanowires and techniques for characterizing their size and morphology. This includes various synthesis routes, such as hydrothermal methods, and analytical techniques like electron microscopy to determine nanowire dimensions.- Synthesis and characterization of malachite nanowires: Methods for synthesizing malachite nanowires and techniques for characterizing their size and properties. This includes various synthesis routes, such as hydrothermal methods, and analytical techniques like electron microscopy to determine nanowire dimensions.

- Size control of malachite nanowires: Techniques for controlling the size of malachite nanowires during synthesis. This involves adjusting parameters such as temperature, pH, and precursor concentrations to achieve desired nanowire dimensions, typically ranging from tens to hundreds of nanometers in diameter and up to several micrometers in length.

- Applications of malachite nanowires based on size: Various applications of malachite nanowires that depend on their specific size characteristics. This includes their use in electronic devices, sensors, catalysts, and energy storage systems, where the nanowire dimensions play a crucial role in determining performance.

- Size-dependent properties of malachite nanowires: Investigation of how the size of malachite nanowires affects their physical and chemical properties. This includes studies on electrical conductivity, optical properties, and catalytic activity as a function of nanowire dimensions.

- Measurement and analysis techniques for malachite nanowire size: Advanced measurement and analysis methods used to accurately determine the size of malachite nanowires. This includes electron microscopy techniques, spectroscopic methods, and other analytical approaches for precise size characterization.

02 Size control of malachite nanowires

Techniques for controlling the size of malachite nanowires during synthesis. This involves adjusting parameters such as temperature, pH, and precursor concentrations to achieve desired nanowire dimensions, typically ranging from tens to hundreds of nanometers in diameter and up to several micrometers in length.Expand Specific Solutions03 Applications of malachite nanowires based on size

Various applications of malachite nanowires that depend on their specific size characteristics. This includes their use in electronic devices, sensors, catalysts, and energy storage systems, where the nanowire dimensions play a crucial role in determining performance.Expand Specific Solutions04 Size-dependent properties of malachite nanowires

Investigation of how the size of malachite nanowires affects their physical and chemical properties. This includes studies on electrical conductivity, optical properties, and catalytic activity as a function of nanowire dimensions.Expand Specific Solutions05 Measurement and analysis techniques for malachite nanowire size

Advanced measurement and analysis methods used to accurately determine the size of malachite nanowires. This includes electron microscopy techniques, spectroscopic methods, and computational analysis tools for precise size characterization.Expand Specific Solutions

Key Players in Malachite Nanowire Research and Development

The competitive landscape for applications of malachite nanowires in device miniaturization is in an early development stage, with significant potential for growth. The market size is expanding as nanotechnology advances, but remains relatively niche. Technical maturity is progressing, with key players like Intel, Samsung, and HP Development Co. investing in research and development. Universities such as Zhejiang University and California Institute of Technology are contributing to fundamental research, while companies like OneD Material and Cambrios Technologies are focusing on practical applications. The involvement of diverse players from academia, industry, and research institutions indicates a competitive and collaborative environment driving innovation in this emerging field.

Intel Corp.

Technical Solution: Intel has been exploring nanowire technology for advanced semiconductor devices. While not specifically focused on malachite nanowires, their research in silicon nanowires for transistors can be applicable. Intel's gate-all-around (GAA) nanowire transistor technology, part of their future node development, demonstrates potential for extreme device miniaturization[3]. This technology could be adapted for malachite nanowires, leveraging their unique properties for enhanced performance in miniaturized devices. Intel's advanced manufacturing processes and expertise in integrating novel materials into semiconductor fabrication could accelerate the development of malachite nanowire-based miniaturized devices[4].

Strengths: Advanced semiconductor manufacturing capabilities, extensive R&D resources. Weaknesses: Primary focus on silicon-based technologies, may require significant investment to adapt to malachite nanowires.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has been investing in nanowire technology for various applications, including display technologies and energy storage. Their research into quantum dot displays using nanowires could potentially be extended to malachite nanowires for ultra-thin, energy-efficient displays[5]. Samsung's work on nanowire-based batteries for improved energy density could also be adapted to malachite nanowires, potentially leading to more compact and efficient energy storage solutions for miniaturized devices[6]. The company's vertical integration and diverse product portfolio provide opportunities for implementing malachite nanowire technology across multiple device categories.

Strengths: Diverse product range for potential applications, strong manufacturing capabilities. Weaknesses: May face challenges in adapting existing nanowire technologies to malachite-specific properties.

Core Innovations in Malachite Nanowire Synthesis

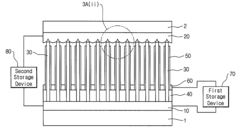

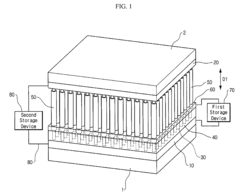

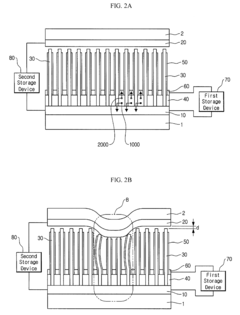

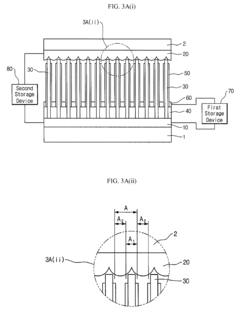

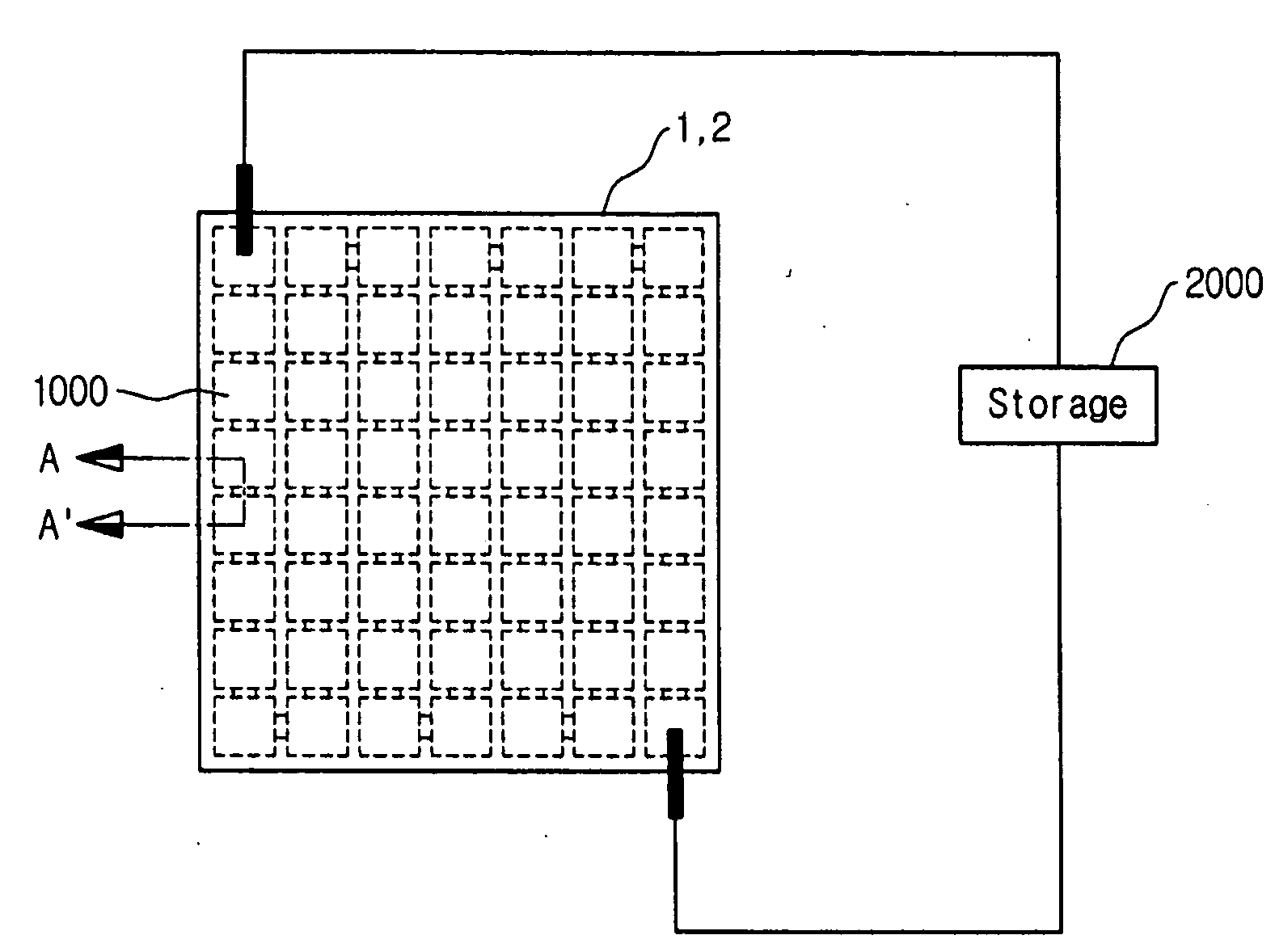

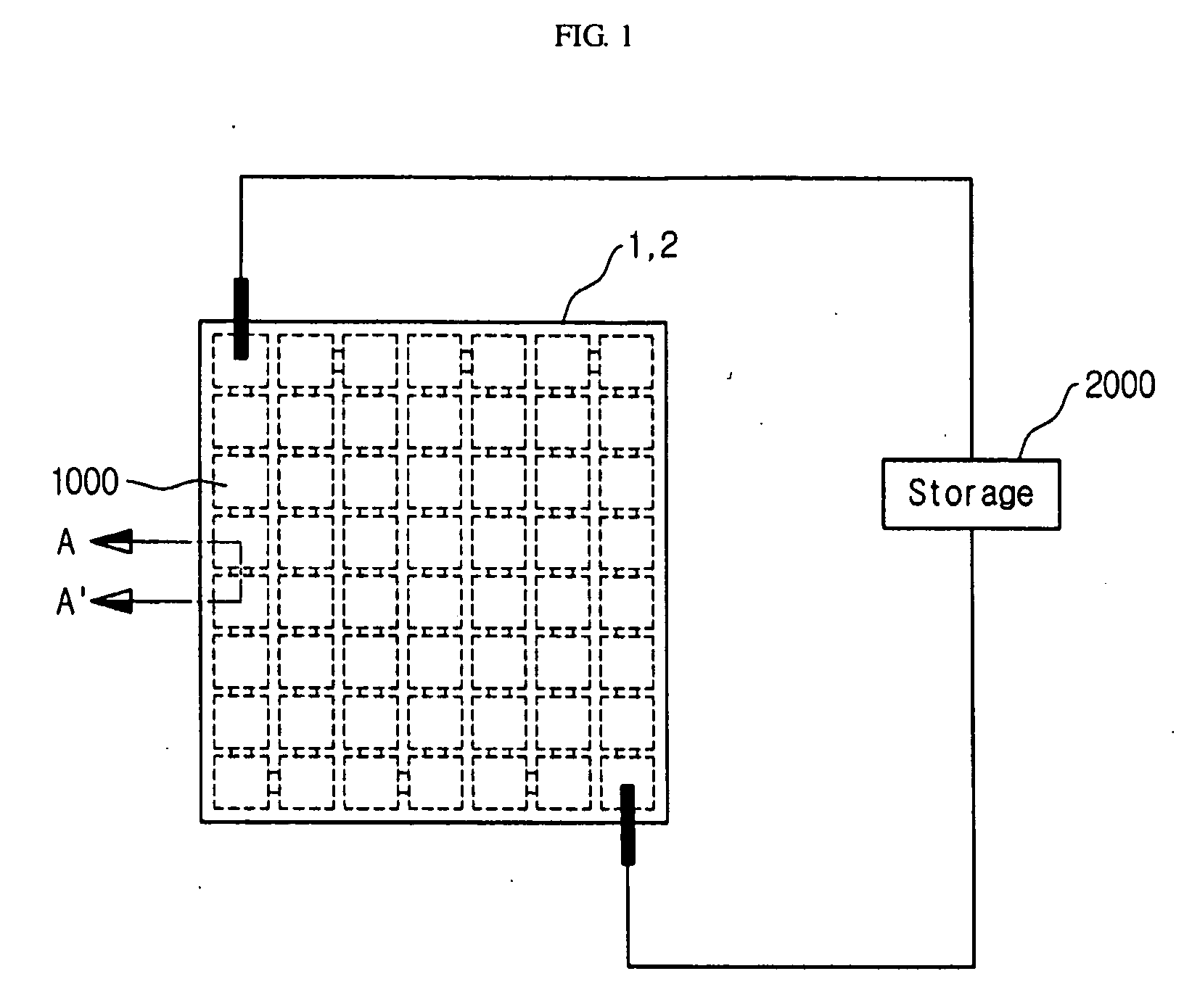

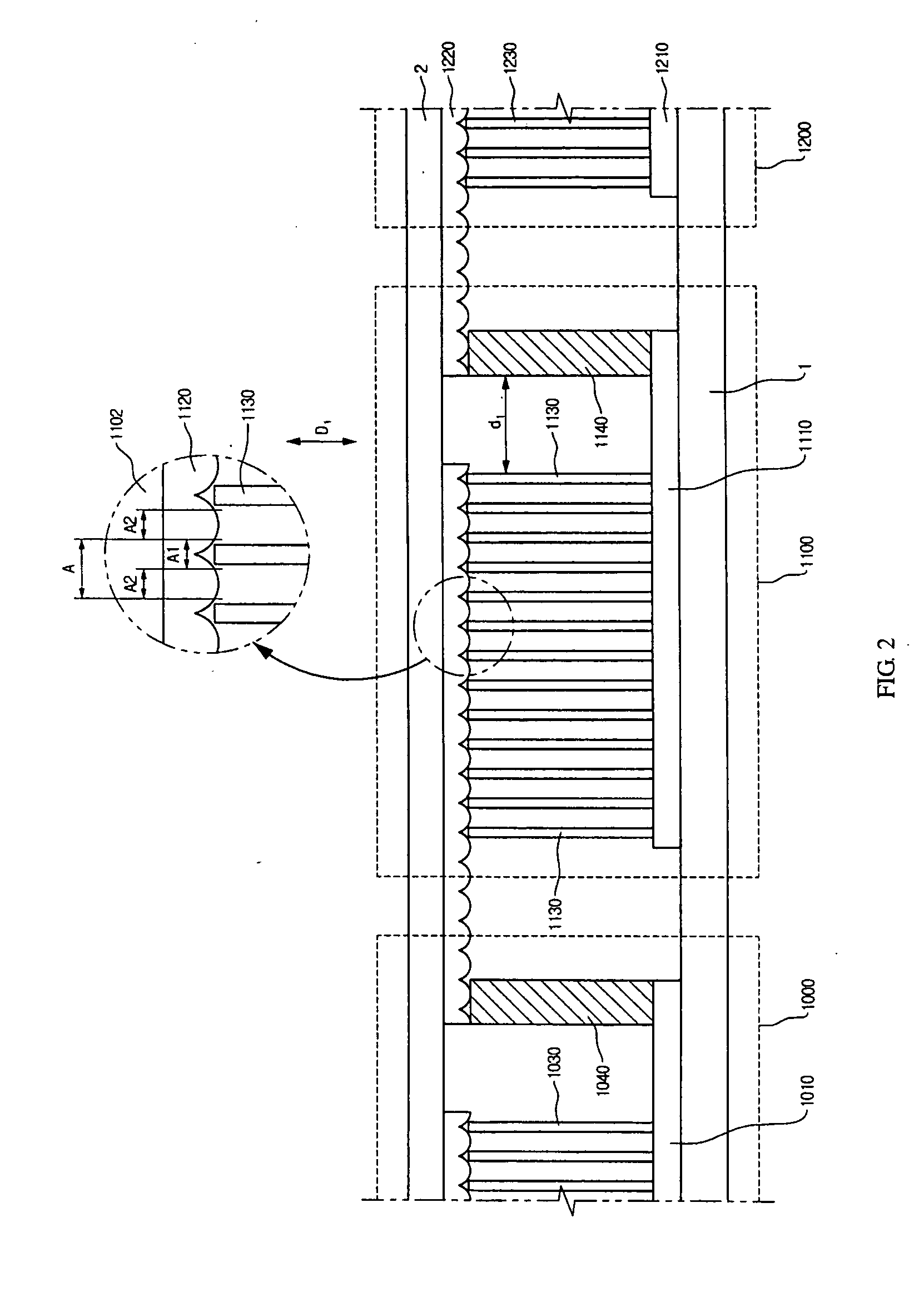

Apparatus for generating electrical energy using electrically connected nanowire and active layer and method for manufacturing the same

PatentActiveUS8227957B2

Innovation

- An apparatus for generating electrical energy is developed, comprising a first electrode, a second electrode, a nanowire with piezoelectric material, an active layer, a conductive layer, and an insulating film, which can generate energy by absorbing light or in response to applied stress, allowing for wireless rechargeability.

Apparatus for storing energy and method for manufacturing the same

PatentActiveUS20100136414A1

Innovation

- An apparatus and method for storing energy using nanowire cells made of piezoelectric materials, where multiple nanowire cells are electrically connected to increase voltage or current, and a storage unit, such as a rechargeable battery or capacitor, is connected to store the generated electrical energy.

Environmental Impact of Malachite Nanowire Production

The production of malachite nanowires, while promising for device miniaturization applications, raises significant environmental concerns that warrant careful consideration. The synthesis process typically involves chemical reactions and high-temperature treatments, which can lead to the release of potentially harmful substances into the environment. These may include copper-containing compounds, organic solvents, and other reagents used in the fabrication process.

One of the primary environmental impacts is the potential for water pollution. The production of malachite nanowires often requires the use of aqueous solutions, and improper disposal of these solutions can contaminate water sources with heavy metals and other toxic substances. This contamination can have far-reaching effects on aquatic ecosystems and potentially enter the food chain, posing risks to both wildlife and human health.

Air pollution is another significant concern. The high-temperature processes involved in nanowire synthesis can release particulate matter and gaseous emissions into the atmosphere. These emissions may contain trace amounts of copper and other metals, as well as volatile organic compounds (VOCs) from the solvents used. Such air pollutants can contribute to smog formation and have adverse effects on respiratory health in surrounding communities.

Energy consumption is a notable factor in the environmental impact of malachite nanowire production. The synthesis processes often require substantial amounts of electricity, particularly for maintaining high temperatures and powering specialized equipment. This energy demand can indirectly contribute to greenhouse gas emissions if the electricity is sourced from fossil fuel-based power plants.

The extraction of raw materials for malachite nanowire production, primarily copper and carbonate minerals, also has environmental implications. Mining activities can lead to habitat destruction, soil erosion, and the release of pollutants into local ecosystems. The transportation of these raw materials to production facilities further adds to the carbon footprint of the manufacturing process.

Waste management is a critical aspect of mitigating the environmental impact of nanowire production. The process generates various waste streams, including chemical byproducts, unused reagents, and contaminated equipment. Proper disposal and treatment of these wastes are essential to prevent soil and groundwater contamination.

To address these environmental concerns, researchers and manufacturers are exploring more sustainable production methods. These include the development of green synthesis techniques that use less toxic reagents, lower temperatures, and more environmentally friendly solvents. Additionally, efforts are being made to improve recycling and recovery processes for copper and other materials used in nanowire production, aiming to reduce the reliance on raw material extraction and minimize waste generation.

One of the primary environmental impacts is the potential for water pollution. The production of malachite nanowires often requires the use of aqueous solutions, and improper disposal of these solutions can contaminate water sources with heavy metals and other toxic substances. This contamination can have far-reaching effects on aquatic ecosystems and potentially enter the food chain, posing risks to both wildlife and human health.

Air pollution is another significant concern. The high-temperature processes involved in nanowire synthesis can release particulate matter and gaseous emissions into the atmosphere. These emissions may contain trace amounts of copper and other metals, as well as volatile organic compounds (VOCs) from the solvents used. Such air pollutants can contribute to smog formation and have adverse effects on respiratory health in surrounding communities.

Energy consumption is a notable factor in the environmental impact of malachite nanowire production. The synthesis processes often require substantial amounts of electricity, particularly for maintaining high temperatures and powering specialized equipment. This energy demand can indirectly contribute to greenhouse gas emissions if the electricity is sourced from fossil fuel-based power plants.

The extraction of raw materials for malachite nanowire production, primarily copper and carbonate minerals, also has environmental implications. Mining activities can lead to habitat destruction, soil erosion, and the release of pollutants into local ecosystems. The transportation of these raw materials to production facilities further adds to the carbon footprint of the manufacturing process.

Waste management is a critical aspect of mitigating the environmental impact of nanowire production. The process generates various waste streams, including chemical byproducts, unused reagents, and contaminated equipment. Proper disposal and treatment of these wastes are essential to prevent soil and groundwater contamination.

To address these environmental concerns, researchers and manufacturers are exploring more sustainable production methods. These include the development of green synthesis techniques that use less toxic reagents, lower temperatures, and more environmentally friendly solvents. Additionally, efforts are being made to improve recycling and recovery processes for copper and other materials used in nanowire production, aiming to reduce the reliance on raw material extraction and minimize waste generation.

Scalability and Manufacturing Challenges

The scalability and manufacturing challenges associated with malachite nanowires for device miniaturization are significant and multifaceted. One of the primary obstacles is achieving consistent and uniform growth of nanowires at scale. While laboratory-scale production has shown promising results, translating these processes to industrial-scale manufacturing remains a considerable challenge.

The synthesis of malachite nanowires typically involves hydrothermal or solution-based methods, which can be difficult to control precisely in large-scale reactors. Maintaining uniform temperature, pressure, and chemical concentrations across larger volumes is crucial for producing nanowires with consistent properties. Variations in these parameters can lead to inconsistencies in nanowire dimensions, crystallinity, and overall quality, potentially compromising their performance in miniaturized devices.

Another significant challenge lies in the integration of malachite nanowires into existing semiconductor fabrication processes. The delicate nature of these nanostructures makes them susceptible to damage during handling and processing. Developing techniques for precise placement and alignment of nanowires on substrates at high throughput is essential for their practical application in device miniaturization.

The issue of scalability extends to the purification and post-synthesis processing of malachite nanowires. Removing impurities and ensuring a high yield of usable nanowires is critical for cost-effective production. Additionally, developing methods for sorting nanowires based on their dimensions and properties is necessary to meet the stringent requirements of various miniaturized device applications.

Environmental and safety considerations also pose challenges in scaling up production. Malachite, being a copper-based compound, requires careful handling and waste management to minimize environmental impact and ensure worker safety. Implementing robust containment and filtration systems in large-scale manufacturing facilities adds complexity and cost to the production process.

Furthermore, the long-term stability and reliability of malachite nanowires in miniaturized devices need to be thoroughly addressed. Accelerated aging tests and reliability studies must be conducted to ensure that these nanomaterials can withstand the operational conditions of various devices over extended periods. This is particularly crucial for applications in sensitive areas such as medical devices or high-performance electronics.

Overcoming these scalability and manufacturing challenges will require collaborative efforts between materials scientists, process engineers, and device manufacturers. Innovations in synthesis techniques, such as continuous flow reactors or advanced templating methods, may offer solutions to some of the current limitations. Additionally, the development of specialized handling and integration equipment tailored to the unique properties of malachite nanowires will be essential for their successful incorporation into miniaturized devices at a commercial scale.

The synthesis of malachite nanowires typically involves hydrothermal or solution-based methods, which can be difficult to control precisely in large-scale reactors. Maintaining uniform temperature, pressure, and chemical concentrations across larger volumes is crucial for producing nanowires with consistent properties. Variations in these parameters can lead to inconsistencies in nanowire dimensions, crystallinity, and overall quality, potentially compromising their performance in miniaturized devices.

Another significant challenge lies in the integration of malachite nanowires into existing semiconductor fabrication processes. The delicate nature of these nanostructures makes them susceptible to damage during handling and processing. Developing techniques for precise placement and alignment of nanowires on substrates at high throughput is essential for their practical application in device miniaturization.

The issue of scalability extends to the purification and post-synthesis processing of malachite nanowires. Removing impurities and ensuring a high yield of usable nanowires is critical for cost-effective production. Additionally, developing methods for sorting nanowires based on their dimensions and properties is necessary to meet the stringent requirements of various miniaturized device applications.

Environmental and safety considerations also pose challenges in scaling up production. Malachite, being a copper-based compound, requires careful handling and waste management to minimize environmental impact and ensure worker safety. Implementing robust containment and filtration systems in large-scale manufacturing facilities adds complexity and cost to the production process.

Furthermore, the long-term stability and reliability of malachite nanowires in miniaturized devices need to be thoroughly addressed. Accelerated aging tests and reliability studies must be conducted to ensure that these nanomaterials can withstand the operational conditions of various devices over extended periods. This is particularly crucial for applications in sensitive areas such as medical devices or high-performance electronics.

Overcoming these scalability and manufacturing challenges will require collaborative efforts between materials scientists, process engineers, and device manufacturers. Innovations in synthesis techniques, such as continuous flow reactors or advanced templating methods, may offer solutions to some of the current limitations. Additionally, the development of specialized handling and integration equipment tailored to the unique properties of malachite nanowires will be essential for their successful incorporation into miniaturized devices at a commercial scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!