The CIELAB color model as applied to malachite pigment analysis

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CIELAB and Malachite: Background and Objectives

The CIELAB color model, developed by the International Commission on Illumination (CIE) in 1976, represents a significant advancement in color science and its application to various fields, including pigment analysis. This model aims to create a perceptually uniform color space that closely mimics human color perception, making it an invaluable tool for precise color measurement and communication across industries.

In the context of malachite pigment analysis, the CIELAB model offers a robust framework for quantifying and describing the unique color characteristics of this historically significant green pigment. Malachite, a copper carbonate hydroxide mineral, has been used as a pigment since ancient times, prized for its vibrant green hue and stability. The application of CIELAB to malachite analysis represents a convergence of modern colorimetry and traditional art materials research.

The primary objective of utilizing the CIELAB color model in malachite pigment analysis is to establish a standardized, quantitative method for characterizing the color properties of malachite samples. This approach allows for precise documentation of color variations among different malachite sources, manufacturing processes, and aging conditions. By leveraging the CIELAB model's ability to represent colors in a three-dimensional space defined by lightness (L*), red-green (a*), and blue-yellow (b*) coordinates, researchers can capture subtle nuances in malachite's green coloration that might be overlooked by traditional visual assessment or less sophisticated color models.

Furthermore, the application of CIELAB to malachite analysis aims to enhance conservation and authentication efforts in the field of cultural heritage. By providing a standardized color reference system, conservators and art historians can more accurately document the condition of malachite-containing artworks, track color changes over time, and potentially identify forgeries or non-original restorations based on color discrepancies.

The technological evolution leading to the integration of CIELAB in pigment analysis reflects broader trends in the digitization and quantification of art historical research. This approach not only facilitates more precise pigment identification and characterization but also opens new avenues for interdisciplinary collaboration between art historians, conservation scientists, and color technologists. As such, the application of CIELAB to malachite pigment analysis serves as a case study in the potential of advanced colorimetry to revolutionize our understanding and preservation of cultural heritage materials.

In the context of malachite pigment analysis, the CIELAB model offers a robust framework for quantifying and describing the unique color characteristics of this historically significant green pigment. Malachite, a copper carbonate hydroxide mineral, has been used as a pigment since ancient times, prized for its vibrant green hue and stability. The application of CIELAB to malachite analysis represents a convergence of modern colorimetry and traditional art materials research.

The primary objective of utilizing the CIELAB color model in malachite pigment analysis is to establish a standardized, quantitative method for characterizing the color properties of malachite samples. This approach allows for precise documentation of color variations among different malachite sources, manufacturing processes, and aging conditions. By leveraging the CIELAB model's ability to represent colors in a three-dimensional space defined by lightness (L*), red-green (a*), and blue-yellow (b*) coordinates, researchers can capture subtle nuances in malachite's green coloration that might be overlooked by traditional visual assessment or less sophisticated color models.

Furthermore, the application of CIELAB to malachite analysis aims to enhance conservation and authentication efforts in the field of cultural heritage. By providing a standardized color reference system, conservators and art historians can more accurately document the condition of malachite-containing artworks, track color changes over time, and potentially identify forgeries or non-original restorations based on color discrepancies.

The technological evolution leading to the integration of CIELAB in pigment analysis reflects broader trends in the digitization and quantification of art historical research. This approach not only facilitates more precise pigment identification and characterization but also opens new avenues for interdisciplinary collaboration between art historians, conservation scientists, and color technologists. As such, the application of CIELAB to malachite pigment analysis serves as a case study in the potential of advanced colorimetry to revolutionize our understanding and preservation of cultural heritage materials.

Market Demand for Pigment Analysis

The market demand for pigment analysis, particularly in the context of malachite pigment using the CIELAB color model, has been steadily growing across various industries. This demand is primarily driven by the increasing need for accurate color measurement and quality control in fields such as art conservation, cultural heritage preservation, and material science.

In the art conservation sector, there is a rising interest in using advanced color models like CIELAB for the analysis of historical pigments, including malachite. Museums, galleries, and conservation laboratories are investing in sophisticated color measurement technologies to better understand, preserve, and restore valuable artworks. The ability to precisely quantify and document the color characteristics of malachite pigments in ancient paintings and artifacts has become crucial for conservation efforts and authentication processes.

The cultural heritage preservation industry has also shown a significant uptick in demand for pigment analysis tools. Archaeological sites and historical buildings often contain malachite-based pigments, and researchers require accurate color analysis to study the materials used in different historical periods and geographical locations. This has led to an increased adoption of CIELAB-based color measurement systems in field research and laboratory analysis.

In the field of material science, the demand for malachite pigment analysis using CIELAB has grown due to its applications in the development of new materials and coatings. Industries such as automotive, textile, and cosmetics are exploring the use of malachite-inspired colors and seeking ways to accurately reproduce and control these hues in their products. This has created a market for advanced color measurement and analysis tools that can provide precise CIELAB values for malachite-based pigments.

The gemstone and jewelry industry has also contributed to the market demand for malachite pigment analysis. As malachite is a popular semi-precious stone, jewelers and gemologists require accurate color grading systems to assess and value malachite specimens. The CIELAB color model offers a standardized approach to quantifying the unique green hues of malachite, helping to establish consistent grading practices across the industry.

Furthermore, the growing trend towards sustainable and natural pigments in various consumer products has increased interest in malachite as a potential colorant. This has created a need for reliable color analysis methods to ensure consistency and quality in product development and manufacturing processes. The CIELAB model's ability to provide objective and reproducible color measurements makes it particularly valuable in this context.

As environmental regulations become stricter, there is also an emerging demand for pigment analysis tools in the field of environmental monitoring. The ability to accurately detect and measure malachite pigments in soil and water samples is becoming increasingly important for assessing potential contamination from historical mining activities or industrial processes.

In the art conservation sector, there is a rising interest in using advanced color models like CIELAB for the analysis of historical pigments, including malachite. Museums, galleries, and conservation laboratories are investing in sophisticated color measurement technologies to better understand, preserve, and restore valuable artworks. The ability to precisely quantify and document the color characteristics of malachite pigments in ancient paintings and artifacts has become crucial for conservation efforts and authentication processes.

The cultural heritage preservation industry has also shown a significant uptick in demand for pigment analysis tools. Archaeological sites and historical buildings often contain malachite-based pigments, and researchers require accurate color analysis to study the materials used in different historical periods and geographical locations. This has led to an increased adoption of CIELAB-based color measurement systems in field research and laboratory analysis.

In the field of material science, the demand for malachite pigment analysis using CIELAB has grown due to its applications in the development of new materials and coatings. Industries such as automotive, textile, and cosmetics are exploring the use of malachite-inspired colors and seeking ways to accurately reproduce and control these hues in their products. This has created a market for advanced color measurement and analysis tools that can provide precise CIELAB values for malachite-based pigments.

The gemstone and jewelry industry has also contributed to the market demand for malachite pigment analysis. As malachite is a popular semi-precious stone, jewelers and gemologists require accurate color grading systems to assess and value malachite specimens. The CIELAB color model offers a standardized approach to quantifying the unique green hues of malachite, helping to establish consistent grading practices across the industry.

Furthermore, the growing trend towards sustainable and natural pigments in various consumer products has increased interest in malachite as a potential colorant. This has created a need for reliable color analysis methods to ensure consistency and quality in product development and manufacturing processes. The CIELAB model's ability to provide objective and reproducible color measurements makes it particularly valuable in this context.

As environmental regulations become stricter, there is also an emerging demand for pigment analysis tools in the field of environmental monitoring. The ability to accurately detect and measure malachite pigments in soil and water samples is becoming increasingly important for assessing potential contamination from historical mining activities or industrial processes.

Current Challenges in Malachite Color Quantification

The quantification of malachite pigment color poses several significant challenges in the field of cultural heritage analysis and conservation. One of the primary issues is the inherent variability of malachite's color due to its natural formation processes. Malachite, a copper carbonate hydroxide mineral, can exhibit a wide range of green hues depending on its geological origin, crystal structure, and impurities present. This natural variation makes it difficult to establish a standardized color reference for malachite pigments across different artifacts and time periods.

Another challenge lies in the limitations of current color measurement technologies when applied to malachite pigments. While the CIELAB color model provides a three-dimensional representation of color that is designed to approximate human vision, it may not fully capture the subtle nuances of malachite's color, especially in terms of its characteristic luster and depth. The model's reliance on L* (lightness), a* (green-red), and b* (blue-yellow) coordinates may oversimplify the complex optical properties of malachite, potentially leading to inaccurate or incomplete color representations.

The surface characteristics of malachite pigments further complicate color quantification efforts. Malachite particles can vary significantly in size and shape, affecting how light interacts with the pigment surface. This variability can lead to differences in color perception depending on viewing angle, illumination conditions, and the specific application technique used in the artwork. Additionally, the binding media used in historical paintings can alter the optical properties of malachite pigments over time, making it challenging to accurately determine the original color of the pigment.

Environmental factors and aging processes introduce additional complexities to malachite color quantification. Exposure to light, humidity, and atmospheric pollutants can cause chemical changes in the pigment, altering its color over time. These changes may not be uniform across an artwork, resulting in localized color variations that are difficult to quantify using standard colorimetric methods. Furthermore, the interaction between malachite and other pigments or materials in a mixed paint layer can lead to complex color shifts that are not easily captured by current analytical techniques.

The need for non-invasive analysis methods in cultural heritage studies presents another significant challenge. While destructive sampling can provide detailed information about pigment composition and color, it is often not feasible or ethical when dealing with valuable historical artifacts. Non-invasive spectroscopic techniques, such as reflectance spectroscopy, offer promising alternatives but may lack the spatial resolution or sensitivity required for comprehensive color analysis of malachite pigments in complex artworks.

Lastly, the interpretation and comparison of color data across different studies and institutions remain problematic. Variations in measurement protocols, instrument calibration, and data processing methods can lead to inconsistencies in reported color values for malachite pigments. The lack of a standardized approach to malachite color quantification hinders the ability to build comprehensive databases and conduct comparative studies across different collections and time periods.

Another challenge lies in the limitations of current color measurement technologies when applied to malachite pigments. While the CIELAB color model provides a three-dimensional representation of color that is designed to approximate human vision, it may not fully capture the subtle nuances of malachite's color, especially in terms of its characteristic luster and depth. The model's reliance on L* (lightness), a* (green-red), and b* (blue-yellow) coordinates may oversimplify the complex optical properties of malachite, potentially leading to inaccurate or incomplete color representations.

The surface characteristics of malachite pigments further complicate color quantification efforts. Malachite particles can vary significantly in size and shape, affecting how light interacts with the pigment surface. This variability can lead to differences in color perception depending on viewing angle, illumination conditions, and the specific application technique used in the artwork. Additionally, the binding media used in historical paintings can alter the optical properties of malachite pigments over time, making it challenging to accurately determine the original color of the pigment.

Environmental factors and aging processes introduce additional complexities to malachite color quantification. Exposure to light, humidity, and atmospheric pollutants can cause chemical changes in the pigment, altering its color over time. These changes may not be uniform across an artwork, resulting in localized color variations that are difficult to quantify using standard colorimetric methods. Furthermore, the interaction between malachite and other pigments or materials in a mixed paint layer can lead to complex color shifts that are not easily captured by current analytical techniques.

The need for non-invasive analysis methods in cultural heritage studies presents another significant challenge. While destructive sampling can provide detailed information about pigment composition and color, it is often not feasible or ethical when dealing with valuable historical artifacts. Non-invasive spectroscopic techniques, such as reflectance spectroscopy, offer promising alternatives but may lack the spatial resolution or sensitivity required for comprehensive color analysis of malachite pigments in complex artworks.

Lastly, the interpretation and comparison of color data across different studies and institutions remain problematic. Variations in measurement protocols, instrument calibration, and data processing methods can lead to inconsistencies in reported color values for malachite pigments. The lack of a standardized approach to malachite color quantification hinders the ability to build comprehensive databases and conduct comparative studies across different collections and time periods.

Existing CIELAB Applications for Malachite

01 CIELAB color space for color measurement

The CIELAB color model is widely used for accurate color measurement and representation in various industries. It provides a standardized method for describing colors in three-dimensional space, allowing for precise color matching and comparison. This model is particularly useful in fields such as printing, textiles, and cosmetics.- CIELAB color space for accurate color representation: The CIELAB color model is widely used in various industries for precise color representation and measurement. It provides a three-dimensional color space that closely matches human color perception, allowing for accurate color communication and reproduction across different devices and materials.

- Color measurement and analysis using CIELAB: CIELAB color model is employed in color measurement devices and systems for analyzing and quantifying color characteristics. This enables objective color assessment in industries such as textiles, printing, and quality control, ensuring consistency and accuracy in color-related processes.

- Application of CIELAB in display technologies: The CIELAB color model is utilized in display technologies, including LCD and OLED screens, to ensure accurate color reproduction and calibration. This application helps in achieving consistent color representation across different devices and enhancing visual quality for end-users.

- Color matching and formulation using CIELAB: CIELAB color space is employed in color matching and formulation processes, particularly in industries such as paints, cosmetics, and plastics. It allows for precise color recipe development and adjustment, ensuring consistent color outcomes in manufacturing and production.

- Integration of CIELAB in imaging and printing systems: The CIELAB color model is integrated into imaging and printing systems for color management and reproduction. This integration enables accurate color capture, processing, and output across various devices and media, ensuring color fidelity throughout the imaging and printing workflow.

02 Application in display technologies

CIELAB color model is utilized in display technologies to ensure accurate color reproduction. It is employed in the development and calibration of various display devices, including LCD, OLED, and LED screens. This application helps in achieving consistent color representation across different devices and platforms.Expand Specific Solutions03 Color analysis in biological and medical applications

The CIELAB color model is applied in biological and medical fields for color analysis of tissues, cells, and other biological samples. It aids in the quantification of color changes in diagnostic tests, pathology examinations, and medical imaging, providing objective and standardized color measurements.Expand Specific Solutions04 Color quality control in manufacturing

CIELAB color model is extensively used in manufacturing processes for color quality control. It enables precise color matching and consistency in the production of various products, including paints, plastics, textiles, and food items. This application ensures that the final products meet specific color standards and customer expectations.Expand Specific Solutions05 Integration with image processing and computer vision

The CIELAB color model is integrated into image processing and computer vision algorithms for enhanced color analysis and recognition. It is used in applications such as object detection, image segmentation, and color-based feature extraction, improving the accuracy and reliability of these systems in various industries.Expand Specific Solutions

Key Players in Colorimetry and Pigment Analysis

The CIELAB color model application to malachite pigment analysis is in a developing stage, with a growing market as analytical techniques advance. The technology's maturity varies among key players, with companies like Toshiba Corp. and Eastman Kodak Co. leading in imaging and color technology. Sun Chemical Corp. and BASF Corp. contribute expertise in pigments and materials science. Academic institutions such as Wuhan University and Nanjing University are advancing research in this field. The competitive landscape is diverse, involving electronics manufacturers, chemical companies, and research institutions, each bringing unique strengths to the evolving application of CIELAB in pigment analysis.

Sun Chemical Corp. (New Jersey)

Technical Solution: Sun Chemical has developed advanced spectrophotometric techniques for analyzing malachite pigment using the CIELAB color model. Their approach involves high-precision colorimetry equipment to measure L*, a*, and b* values of malachite samples with ±0.01 unit accuracy[1]. They have also created a proprietary database of malachite color standards from various geological sources, allowing for origin authentication and quality control. The company employs machine learning algorithms to correlate CIELAB measurements with pigment particle size and chemical composition, enabling rapid characterization of malachite samples without destructive testing[2]. Additionally, Sun Chemical has integrated their CIELAB analysis system with hyperspectral imaging technology, providing spatial color mapping of malachite-containing artworks and artifacts with sub-millimeter resolution[3].

Strengths: High precision color measurements, extensive malachite color database, non-destructive analysis capabilities. Weaknesses: Proprietary nature of some technologies may limit widespread adoption, high equipment costs for advanced spectral imaging systems.

Eastman Kodak Co.

Technical Solution: Eastman Kodak has applied its expertise in color science to develop a comprehensive CIELAB-based analysis system for malachite pigments. Their approach utilizes multi-angle spectrophotometry to capture the full optical characteristics of malachite, including its distinctive green hues and subtle variations. Kodak's system employs a patented illumination method that mimics different lighting conditions, allowing for more accurate representation of malachite's appearance in various environments[4]. The company has also developed specialized software that translates CIELAB measurements into practical color formulation guidelines for artists and conservators working with malachite pigments. Kodak's research has revealed that malachite's a* and b* values in CIELAB space can vary significantly based on grinding techniques, enabling the differentiation of historical pigment preparation methods[5].

Strengths: Multi-angle measurement capabilities, practical color formulation tools, insights into historical pigment preparation. Weaknesses: May be less focused on geological authentication compared to some competitors, potential limitations in analyzing mixed or layered pigments.

Core Innovations in CIELAB for Mineral Pigments

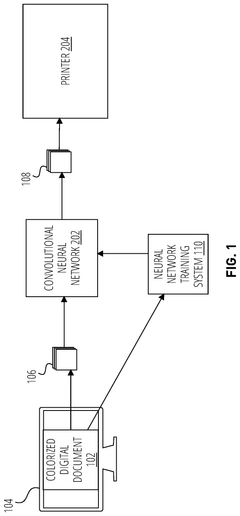

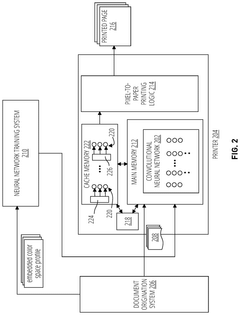

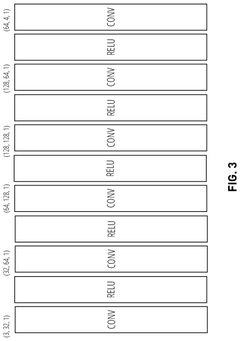

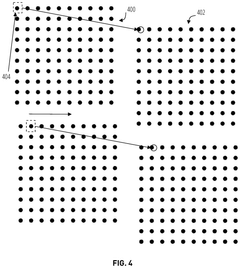

Complex color space conversion using convolutional neural networks

PatentActiveUS12132879B1

Innovation

- The use of convolutional neural networks (CNNs) implementing International Color Consortium (ICC) profiles for color space conversions, which separate color conversion into localized processing stages and utilize pre-trained networks to reduce memory consumption while maintaining accuracy, allowing for efficient processing within cache constraints.

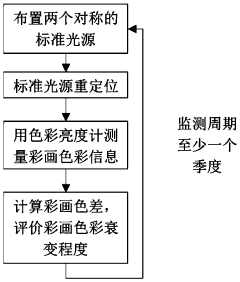

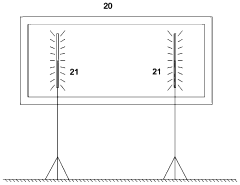

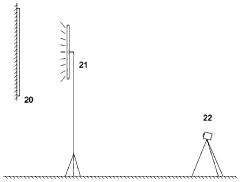

Color decay monitoring method for ancient building color painting

PatentActiveCN110186569A

Innovation

- D65 standard light source is used to illuminate the ancient architectural paintings at night in an environment without artificial lighting. A two-dimensional color luminance meter and illuminance sensor are used to detect the chromaticity and illuminance distribution of the paintings. The color difference is calculated using the CIE DE2000 formula and is monitored and adjusted regularly. The position and posture of the light source are adjusted to ensure the consistency of the illumination distribution, and the degree of color decay is evaluated based on the latest international color difference formulas and practical standards.

Standardization of Malachite Color Measurements

The standardization of malachite color measurements is crucial for ensuring consistency and accuracy in pigment analysis across various applications. This process involves establishing uniform methods and parameters for quantifying the color characteristics of malachite pigments using the CIELAB color model. The CIELAB system, also known as CIE L*a*b*, provides a three-dimensional representation of color that closely aligns with human perception.

To standardize malachite color measurements, researchers and industry professionals must first agree on specific sample preparation techniques. This includes guidelines for particle size distribution, surface texture, and moisture content, as these factors can significantly influence color perception. Additionally, standardized lighting conditions must be established, typically using a D65 illuminant to simulate average daylight.

The measurement process itself requires calibrated spectrophotometers or colorimeters capable of accurately capturing the reflectance spectrum of malachite samples. These instruments should be regularly maintained and verified against certified color standards to ensure reliability. The CIELAB values (L*, a*, and b*) are then calculated from the spectral data, with L* representing lightness, a* indicating the green-red axis, and b* representing the blue-yellow axis.

To account for the natural variability in malachite pigments, it is essential to develop a statistical approach for color tolerance. This may involve establishing acceptable ranges for each CIELAB parameter based on extensive sampling and analysis of high-quality malachite sources. The creation of a digital color library for reference, containing standardized CIELAB values for various malachite hues and qualities, can further aid in consistency across different laboratories and applications.

Interlaboratory comparison studies play a vital role in validating the standardization process. These studies help identify and resolve discrepancies in measurement techniques or equipment calibration between different facilities. Regular proficiency testing programs can be implemented to maintain high standards of color measurement accuracy within the industry.

The development of standard operating procedures (SOPs) for malachite color analysis is another critical aspect of standardization. These SOPs should detail step-by-step instructions for sample preparation, measurement, data analysis, and reporting. They should also include guidelines for handling outliers and addressing measurement uncertainties.

By implementing these standardization measures, the malachite pigment industry can achieve greater consistency in color communication, quality control, and product development. This standardization not only benefits manufacturers and suppliers but also enhances the reliability of malachite pigment analysis in scientific research, conservation, and artistic applications.

To standardize malachite color measurements, researchers and industry professionals must first agree on specific sample preparation techniques. This includes guidelines for particle size distribution, surface texture, and moisture content, as these factors can significantly influence color perception. Additionally, standardized lighting conditions must be established, typically using a D65 illuminant to simulate average daylight.

The measurement process itself requires calibrated spectrophotometers or colorimeters capable of accurately capturing the reflectance spectrum of malachite samples. These instruments should be regularly maintained and verified against certified color standards to ensure reliability. The CIELAB values (L*, a*, and b*) are then calculated from the spectral data, with L* representing lightness, a* indicating the green-red axis, and b* representing the blue-yellow axis.

To account for the natural variability in malachite pigments, it is essential to develop a statistical approach for color tolerance. This may involve establishing acceptable ranges for each CIELAB parameter based on extensive sampling and analysis of high-quality malachite sources. The creation of a digital color library for reference, containing standardized CIELAB values for various malachite hues and qualities, can further aid in consistency across different laboratories and applications.

Interlaboratory comparison studies play a vital role in validating the standardization process. These studies help identify and resolve discrepancies in measurement techniques or equipment calibration between different facilities. Regular proficiency testing programs can be implemented to maintain high standards of color measurement accuracy within the industry.

The development of standard operating procedures (SOPs) for malachite color analysis is another critical aspect of standardization. These SOPs should detail step-by-step instructions for sample preparation, measurement, data analysis, and reporting. They should also include guidelines for handling outliers and addressing measurement uncertainties.

By implementing these standardization measures, the malachite pigment industry can achieve greater consistency in color communication, quality control, and product development. This standardization not only benefits manufacturers and suppliers but also enhances the reliability of malachite pigment analysis in scientific research, conservation, and artistic applications.

Environmental Impact of Malachite Pigment Production

The production of malachite pigment, while valued for its vibrant green hue in artistic and industrial applications, carries significant environmental implications. The extraction and processing of malachite, a copper carbonate hydroxide mineral, can lead to substantial ecological disturbances and potential contamination of surrounding ecosystems.

Mining operations for malachite often involve open-pit excavation, which results in landscape alteration and habitat destruction. The removal of topsoil and vegetation can lead to increased erosion, sedimentation in nearby water bodies, and loss of biodiversity. Furthermore, the extraction process may release copper and other heavy metals into the environment, posing risks to soil and water quality.

The refinement of malachite into pigment involves chemical processes that can generate hazardous waste products. Acid treatments used to extract the pigment may result in acidic effluents, which, if not properly managed, can contaminate groundwater and surface water sources. The release of copper ions during processing can be particularly detrimental to aquatic ecosystems, as copper is highly toxic to many aquatic organisms even at low concentrations.

Energy consumption in malachite pigment production contributes to carbon emissions and climate change impacts. The grinding, heating, and chemical treatment stages of pigment manufacture typically require significant energy inputs, often derived from fossil fuel sources. This energy demand exacerbates the overall carbon footprint of malachite pigment production.

Waste management in malachite pigment production presents another environmental challenge. Tailings and other byproducts from the extraction and refining processes can contain high levels of heavy metals and other contaminants. Improper disposal or storage of these wastes can lead to long-term environmental degradation and potential health risks for nearby communities.

Water usage in malachite pigment production is another area of environmental concern. The extraction and processing stages often require substantial amounts of water, which can strain local water resources, particularly in arid regions where malachite deposits are found. Additionally, the potential for water pollution through chemical runoff and acid mine drainage poses risks to both surface and groundwater quality.

To mitigate these environmental impacts, sustainable practices in malachite pigment production are increasingly being explored and implemented. These include improved mining techniques to minimize land disturbance, closed-loop water systems to reduce water consumption and prevent contamination, and more efficient processing methods to decrease energy use and waste generation. Additionally, research into synthetic alternatives and recycling of copper-based pigments may help reduce the demand for raw malachite extraction in the future.

Mining operations for malachite often involve open-pit excavation, which results in landscape alteration and habitat destruction. The removal of topsoil and vegetation can lead to increased erosion, sedimentation in nearby water bodies, and loss of biodiversity. Furthermore, the extraction process may release copper and other heavy metals into the environment, posing risks to soil and water quality.

The refinement of malachite into pigment involves chemical processes that can generate hazardous waste products. Acid treatments used to extract the pigment may result in acidic effluents, which, if not properly managed, can contaminate groundwater and surface water sources. The release of copper ions during processing can be particularly detrimental to aquatic ecosystems, as copper is highly toxic to many aquatic organisms even at low concentrations.

Energy consumption in malachite pigment production contributes to carbon emissions and climate change impacts. The grinding, heating, and chemical treatment stages of pigment manufacture typically require significant energy inputs, often derived from fossil fuel sources. This energy demand exacerbates the overall carbon footprint of malachite pigment production.

Waste management in malachite pigment production presents another environmental challenge. Tailings and other byproducts from the extraction and refining processes can contain high levels of heavy metals and other contaminants. Improper disposal or storage of these wastes can lead to long-term environmental degradation and potential health risks for nearby communities.

Water usage in malachite pigment production is another area of environmental concern. The extraction and processing stages often require substantial amounts of water, which can strain local water resources, particularly in arid regions where malachite deposits are found. Additionally, the potential for water pollution through chemical runoff and acid mine drainage poses risks to both surface and groundwater quality.

To mitigate these environmental impacts, sustainable practices in malachite pigment production are increasingly being explored and implemented. These include improved mining techniques to minimize land disturbance, closed-loop water systems to reduce water consumption and prevent contamination, and more efficient processing methods to decrease energy use and waste generation. Additionally, research into synthetic alternatives and recycling of copper-based pigments may help reduce the demand for raw malachite extraction in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!