Effects of mechanical separation techniques on malachite purity

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Malachite Purification Background and Objectives

Malachite, a copper carbonate hydroxide mineral, has been prized for its vibrant green color and use in jewelry, ornamental objects, and as a source of copper ore for centuries. The purification of malachite has become increasingly important in recent years due to its growing applications in various industries, including electronics, catalysis, and advanced materials. This technical research report aims to explore the effects of mechanical separation techniques on malachite purity, with a focus on understanding the historical context, current technological landscape, and future objectives in this field.

The journey of malachite purification can be traced back to ancient civilizations, where rudimentary methods were employed to extract and refine the mineral for decorative purposes. As industrial demands grew, particularly during the Industrial Revolution, more sophisticated techniques were developed to process malachite for copper extraction. However, it wasn't until the late 20th century that the need for high-purity malachite in advanced applications drove significant advancements in purification technologies.

In recent decades, the evolution of mechanical separation techniques has played a crucial role in enhancing malachite purity. These methods, which include grinding, sieving, flotation, and gravity separation, have undergone continuous refinement to meet the increasing demands for higher-grade malachite. The primary objective of these techniques is to separate malachite from associated gangue minerals and impurities, thereby increasing its purity and value.

The current technological landscape in malachite purification is characterized by a blend of traditional and innovative approaches. While conventional mechanical methods remain widely used, there is a growing trend towards the integration of more advanced technologies, such as high-intensity magnetic separation and sensor-based sorting. These emerging techniques promise to improve efficiency and achieve higher levels of purity, addressing the limitations of traditional methods.

Looking ahead, the objectives for malachite purification are multifaceted. First and foremost, there is a pressing need to develop more environmentally sustainable purification processes that minimize water usage and reduce the generation of waste materials. Additionally, researchers are focusing on enhancing the selectivity of separation techniques to achieve ultra-high purity levels required for cutting-edge applications in nanotechnology and advanced electronics.

Another key objective is to improve the scalability and cost-effectiveness of purification methods, making high-purity malachite more accessible for a wider range of industrial applications. This includes the development of continuous processing systems that can handle larger volumes of material while maintaining consistent quality.

As we delve deeper into the effects of mechanical separation techniques on malachite purity, it is essential to consider the broader context of technological advancements, market demands, and environmental considerations. This research aims to provide a comprehensive understanding of the current state of malachite purification and chart a course for future innovations in this critical field.

The journey of malachite purification can be traced back to ancient civilizations, where rudimentary methods were employed to extract and refine the mineral for decorative purposes. As industrial demands grew, particularly during the Industrial Revolution, more sophisticated techniques were developed to process malachite for copper extraction. However, it wasn't until the late 20th century that the need for high-purity malachite in advanced applications drove significant advancements in purification technologies.

In recent decades, the evolution of mechanical separation techniques has played a crucial role in enhancing malachite purity. These methods, which include grinding, sieving, flotation, and gravity separation, have undergone continuous refinement to meet the increasing demands for higher-grade malachite. The primary objective of these techniques is to separate malachite from associated gangue minerals and impurities, thereby increasing its purity and value.

The current technological landscape in malachite purification is characterized by a blend of traditional and innovative approaches. While conventional mechanical methods remain widely used, there is a growing trend towards the integration of more advanced technologies, such as high-intensity magnetic separation and sensor-based sorting. These emerging techniques promise to improve efficiency and achieve higher levels of purity, addressing the limitations of traditional methods.

Looking ahead, the objectives for malachite purification are multifaceted. First and foremost, there is a pressing need to develop more environmentally sustainable purification processes that minimize water usage and reduce the generation of waste materials. Additionally, researchers are focusing on enhancing the selectivity of separation techniques to achieve ultra-high purity levels required for cutting-edge applications in nanotechnology and advanced electronics.

Another key objective is to improve the scalability and cost-effectiveness of purification methods, making high-purity malachite more accessible for a wider range of industrial applications. This includes the development of continuous processing systems that can handle larger volumes of material while maintaining consistent quality.

As we delve deeper into the effects of mechanical separation techniques on malachite purity, it is essential to consider the broader context of technological advancements, market demands, and environmental considerations. This research aims to provide a comprehensive understanding of the current state of malachite purification and chart a course for future innovations in this critical field.

Market Analysis for High-Purity Malachite

The market for high-purity malachite has shown significant growth potential in recent years, driven by increasing demand across various industries. Malachite, a copper carbonate hydroxide mineral, finds applications in jewelry making, decorative objects, and industrial processes. The high-purity form of malachite is particularly sought after for its enhanced properties and versatility.

In the jewelry and ornamental sector, high-purity malachite commands premium prices due to its vibrant green color and distinctive banding patterns. The market for luxury and semi-precious stone jewelry has been expanding, with consumers showing a growing preference for unique, natural materials. This trend has positively impacted the demand for high-quality malachite.

The industrial applications of high-purity malachite have also been expanding. In the field of catalysis, malachite-derived copper catalysts have shown promise in various chemical processes, including the production of methanol and the conversion of syngas. The electronics industry has been exploring the use of malachite in the development of advanced materials for sensors and electronic components, leveraging its unique electrical and thermal properties.

Environmental applications represent another growing market segment for high-purity malachite. Its ability to adsorb heavy metals and organic pollutants has led to increased interest in using malachite for water treatment and soil remediation projects. As environmental regulations become more stringent worldwide, the demand for effective and sustainable purification materials is expected to rise.

The global market size for high-purity malachite, while difficult to quantify precisely due to its niche nature, has been estimated to be in the range of several hundred million dollars annually. Market analysts project a compound annual growth rate (CAGR) of 5-7% over the next five years, driven by technological advancements in purification techniques and expanding applications.

Geographically, the market for high-purity malachite is distributed across several regions. Major consumers include North America, Europe, and Asia-Pacific, with China emerging as a significant player both in production and consumption. The African continent, particularly countries like the Democratic Republic of Congo and Zambia, remains a key source of raw malachite, though local processing capabilities for high-purity grades are still developing.

Market challenges include the limited availability of high-grade malachite deposits and the environmental concerns associated with mining operations. These factors have led to increased focus on sustainable sourcing practices and the development of more efficient purification technologies. The market is also influenced by fluctuations in copper prices, as malachite is often a byproduct of copper mining operations.

In the jewelry and ornamental sector, high-purity malachite commands premium prices due to its vibrant green color and distinctive banding patterns. The market for luxury and semi-precious stone jewelry has been expanding, with consumers showing a growing preference for unique, natural materials. This trend has positively impacted the demand for high-quality malachite.

The industrial applications of high-purity malachite have also been expanding. In the field of catalysis, malachite-derived copper catalysts have shown promise in various chemical processes, including the production of methanol and the conversion of syngas. The electronics industry has been exploring the use of malachite in the development of advanced materials for sensors and electronic components, leveraging its unique electrical and thermal properties.

Environmental applications represent another growing market segment for high-purity malachite. Its ability to adsorb heavy metals and organic pollutants has led to increased interest in using malachite for water treatment and soil remediation projects. As environmental regulations become more stringent worldwide, the demand for effective and sustainable purification materials is expected to rise.

The global market size for high-purity malachite, while difficult to quantify precisely due to its niche nature, has been estimated to be in the range of several hundred million dollars annually. Market analysts project a compound annual growth rate (CAGR) of 5-7% over the next five years, driven by technological advancements in purification techniques and expanding applications.

Geographically, the market for high-purity malachite is distributed across several regions. Major consumers include North America, Europe, and Asia-Pacific, with China emerging as a significant player both in production and consumption. The African continent, particularly countries like the Democratic Republic of Congo and Zambia, remains a key source of raw malachite, though local processing capabilities for high-purity grades are still developing.

Market challenges include the limited availability of high-grade malachite deposits and the environmental concerns associated with mining operations. These factors have led to increased focus on sustainable sourcing practices and the development of more efficient purification technologies. The market is also influenced by fluctuations in copper prices, as malachite is often a byproduct of copper mining operations.

Current Challenges in Mechanical Separation of Malachite

The mechanical separation of malachite presents several significant challenges that hinder the achievement of high purity levels. One of the primary obstacles is the complex mineralogical composition of malachite ores. Malachite often occurs in association with other copper minerals, such as azurite, chrysocolla, and cuprite, as well as gangue minerals like quartz and calcite. This intricate mineral assemblage makes it difficult to achieve clean separation using conventional mechanical techniques.

The variable hardness and friability of malachite pose another challenge. Malachite has a Mohs hardness ranging from 3.5 to 4, which is relatively soft compared to some associated minerals. This disparity in hardness can lead to preferential grinding and over-comminution of malachite during size reduction processes, resulting in the generation of fine particles that are challenging to recover efficiently.

Particle shape and surface properties of malachite also contribute to separation difficulties. Malachite tends to form irregular, platy, or fibrous particles during comminution, which can affect their behavior in gravity separation and flotation processes. The surface properties of malachite, including its natural hydrophobicity and tendency to form slimes, further complicate the separation process, particularly in flotation circuits.

The presence of clay minerals in malachite ores presents additional challenges. Clay minerals can coat malachite particles, altering their surface properties and interfering with separation mechanisms. Moreover, clay minerals often lead to increased viscosity in slurries, affecting the efficiency of classification and separation equipment.

Water quality and chemistry play a crucial role in the mechanical separation of malachite. The presence of dissolved ions, particularly calcium and magnesium, can affect the surface properties of malachite and impact the performance of flotation reagents. Maintaining optimal pH levels is also challenging, as malachite dissolution can occur at low pH values, potentially leading to copper losses in the process water.

The heterogeneity of malachite deposits presents operational challenges in maintaining consistent separation performance. Variations in ore grade, mineralogy, and texture across a deposit require frequent adjustments to process parameters, which can be difficult to implement in real-time.

Lastly, environmental considerations pose increasing challenges to malachite separation processes. The need to minimize water consumption, reduce energy usage, and manage tailings disposal while maintaining high recovery rates and product purity requires innovative approaches to mechanical separation techniques.

The variable hardness and friability of malachite pose another challenge. Malachite has a Mohs hardness ranging from 3.5 to 4, which is relatively soft compared to some associated minerals. This disparity in hardness can lead to preferential grinding and over-comminution of malachite during size reduction processes, resulting in the generation of fine particles that are challenging to recover efficiently.

Particle shape and surface properties of malachite also contribute to separation difficulties. Malachite tends to form irregular, platy, or fibrous particles during comminution, which can affect their behavior in gravity separation and flotation processes. The surface properties of malachite, including its natural hydrophobicity and tendency to form slimes, further complicate the separation process, particularly in flotation circuits.

The presence of clay minerals in malachite ores presents additional challenges. Clay minerals can coat malachite particles, altering their surface properties and interfering with separation mechanisms. Moreover, clay minerals often lead to increased viscosity in slurries, affecting the efficiency of classification and separation equipment.

Water quality and chemistry play a crucial role in the mechanical separation of malachite. The presence of dissolved ions, particularly calcium and magnesium, can affect the surface properties of malachite and impact the performance of flotation reagents. Maintaining optimal pH levels is also challenging, as malachite dissolution can occur at low pH values, potentially leading to copper losses in the process water.

The heterogeneity of malachite deposits presents operational challenges in maintaining consistent separation performance. Variations in ore grade, mineralogy, and texture across a deposit require frequent adjustments to process parameters, which can be difficult to implement in real-time.

Lastly, environmental considerations pose increasing challenges to malachite separation processes. The need to minimize water consumption, reduce energy usage, and manage tailings disposal while maintaining high recovery rates and product purity requires innovative approaches to mechanical separation techniques.

Existing Mechanical Separation Methods for Malachite

01 Purification methods for malachite

Various techniques are employed to purify malachite, including chemical treatments, physical separation processes, and thermal methods. These approaches aim to remove impurities and enhance the quality of the mineral for industrial and commercial applications.- Purification methods for malachite: Various techniques are employed to purify malachite, including chemical treatments, physical separation processes, and thermal methods. These approaches aim to remove impurities and enhance the quality of the mineral for industrial and commercial applications.

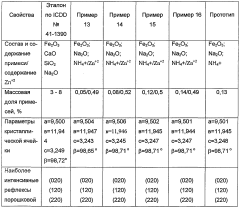

- Malachite purity analysis techniques: Advanced analytical methods are used to determine the purity of malachite samples. These include spectroscopic techniques, X-ray diffraction, and chemical assays, which provide accurate measurements of mineral composition and identify trace impurities.

- Synthetic malachite production with high purity: Processes for synthesizing high-purity malachite in laboratory or industrial settings have been developed. These methods often involve controlled precipitation reactions and careful manipulation of reaction conditions to achieve desired purity levels.

- Applications of high-purity malachite: High-purity malachite finds applications in various fields, including catalysis, pigment production, and advanced materials. The enhanced purity allows for improved performance and reliability in these applications.

- Environmental considerations in malachite purification: Eco-friendly methods for purifying malachite have been developed to minimize environmental impact. These approaches focus on reducing chemical usage, recycling process materials, and implementing sustainable practices in mineral processing.

02 Malachite purity analysis techniques

Advanced analytical methods are used to determine the purity of malachite samples. These include spectroscopic techniques, X-ray diffraction, and chemical assays, which provide accurate measurements of mineral composition and identify trace impurities.Expand Specific Solutions03 Synthetic malachite production

Processes for synthesizing high-purity malachite in laboratory or industrial settings have been developed. These methods allow for controlled production of malachite with specific characteristics and purity levels, often surpassing naturally occurring samples.Expand Specific Solutions04 Applications of high-purity malachite

High-purity malachite finds applications in various fields, including catalysis, pigment production, and advanced materials. The increased purity enhances the mineral's performance and enables its use in specialized industrial and technological processes.Expand Specific Solutions05 Environmental considerations in malachite purification

Eco-friendly approaches to malachite purification have been developed to minimize environmental impact. These methods focus on reducing chemical usage, implementing closed-loop systems, and utilizing sustainable practices in the purification process.Expand Specific Solutions

Key Players in Mineral Processing Industry

The mechanical separation of malachite is in a developing stage, with a growing market driven by increasing demand for copper and green technologies. The technology's maturity varies across companies, with established players like Vale SA and Tata Steel Ltd. having more advanced processes. Emerging firms such as PT QMB New Energy Materials and GEM Co., Ltd. are focusing on innovative approaches, particularly in e-waste recycling. The competitive landscape is diverse, including traditional mining companies, specialized recycling firms, and research institutions like the Korea Institute of Geoscience & Mineral Resources, indicating a multifaceted approach to improving malachite purity through mechanical separation techniques.

GEM Co., Ltd.

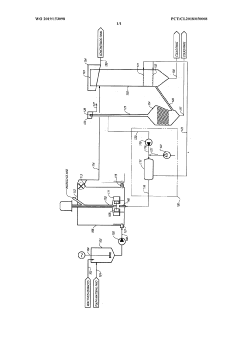

Technical Solution: GEM Co., Ltd. has pioneered a novel mechanical separation technique for malachite purification focusing on environmental sustainability. Their process begins with a controlled crushing and grinding circuit to minimize fines generation. The company employs a unique dry separation method combining air classification and electrostatic separation, reducing water consumption significantly [2]. GEM's innovation lies in their patented vibrating screen technology that utilizes precisely controlled frequency and amplitude to achieve high-efficiency particle size separation. For finer fractions, they have developed a centrifugal separator that exploits slight differences in particle shape and density to further purify malachite [4]. The final stage involves a low-intensity magnetic separation to remove any remaining magnetic impurities.

Strengths: Water-efficient process, reduced environmental impact, high selectivity for fine particles. Weaknesses: Potentially lower throughput compared to wet processes, higher initial equipment costs.

Vale SA

Technical Solution: Vale SA has developed advanced mechanical separation techniques for malachite purification. Their process involves a combination of crushing, grinding, and screening to achieve initial size reduction. This is followed by gravity separation methods such as jigging and spiral concentration to exploit density differences. The company has also implemented innovative flotation techniques using specially formulated reagents to selectively separate malachite from gangue minerals [1]. Vale's approach incorporates multiple stages of magnetic separation to remove iron-bearing impurities, significantly enhancing malachite purity. The final stages involve advanced optical sorting technology to identify and remove any remaining non-malachite particles based on color and reflectance properties [3].

Strengths: Comprehensive multi-stage process, high purity output, large-scale applicability. Weaknesses: High energy consumption, potential for fine particle loss during processing.

Innovative Approaches in Malachite Purification

Malachite and method for the production thereof

PatentWO2004076354A1

Innovation

- The process involves evaporating a solution of basic copper carbonate and ammonium carbonate with controlled zinc content, forming polycrystalline malachite with alternating light and dark green layers, and condensing vapor to achieve malachite with enhanced mechanical properties and reduced impurities.

Froth flotation system for physicochemical separation of ultra fine ore particles

PatentWO2019153098A1

Innovation

- A physical-chemical separation system utilizing air microbubbles and specific chemical reagents to induce selective rise of mineral particles, employing a dual-reactor approach with collective and selective flotation stages, where microbubbles are formed through direct injection of dissolved air in the primary stage and only water injection in the cleaning stage to maximize recovery and grade of ultrafine minerals.

Environmental Impact of Malachite Processing

The environmental impact of malachite processing, particularly through mechanical separation techniques, is a critical consideration in the mining and mineral processing industry. These techniques, while effective in improving malachite purity, can have significant environmental consequences that must be carefully managed.

One of the primary environmental concerns associated with mechanical separation of malachite is the generation of fine particulate matter. As the ore is crushed, ground, and separated, dust particles are released into the air. These particles can pose respiratory hazards to workers and nearby communities if not properly controlled. Additionally, the dispersion of fine malachite dust can lead to soil and water contamination in surrounding areas.

Water usage and contamination are also major environmental issues in malachite processing. Many mechanical separation techniques, such as froth flotation and gravity separation, require substantial amounts of water. This can strain local water resources, especially in arid regions where malachite deposits are often found. Furthermore, the process water becomes contaminated with suspended solids, dissolved metals, and potentially harmful chemicals used in the separation process.

The disposal of tailings and waste rock from malachite processing presents another significant environmental challenge. These byproducts can contain residual copper and other heavy metals, which may leach into groundwater or surface water if not properly managed. Acid mine drainage is a particular concern, as the oxidation of sulfide minerals in the waste material can generate acidic runoff that further mobilizes heavy metals.

Energy consumption in mechanical separation processes contributes to the overall carbon footprint of malachite processing. The operation of crushers, grinders, and other separation equipment requires substantial electrical or fossil fuel energy, leading to increased greenhouse gas emissions. This aspect of environmental impact is becoming increasingly important as the mining industry faces pressure to reduce its carbon footprint.

Noise pollution is another environmental factor to consider. The operation of heavy machinery involved in mechanical separation can generate significant noise levels, potentially affecting wildlife and nearby human populations. This can lead to habitat disruption and quality of life issues for local communities.

To mitigate these environmental impacts, the industry is increasingly adopting more sustainable practices. These include the implementation of dust suppression systems, water recycling and treatment technologies, and improved tailings management techniques. Additionally, there is a growing focus on developing more energy-efficient separation processes and exploring renewable energy sources to power processing operations.

In conclusion, while mechanical separation techniques are crucial for improving malachite purity, their environmental impacts are substantial and multifaceted. Balancing the need for efficient mineral processing with environmental protection remains a key challenge for the industry, driving ongoing research and innovation in more sustainable processing methods.

One of the primary environmental concerns associated with mechanical separation of malachite is the generation of fine particulate matter. As the ore is crushed, ground, and separated, dust particles are released into the air. These particles can pose respiratory hazards to workers and nearby communities if not properly controlled. Additionally, the dispersion of fine malachite dust can lead to soil and water contamination in surrounding areas.

Water usage and contamination are also major environmental issues in malachite processing. Many mechanical separation techniques, such as froth flotation and gravity separation, require substantial amounts of water. This can strain local water resources, especially in arid regions where malachite deposits are often found. Furthermore, the process water becomes contaminated with suspended solids, dissolved metals, and potentially harmful chemicals used in the separation process.

The disposal of tailings and waste rock from malachite processing presents another significant environmental challenge. These byproducts can contain residual copper and other heavy metals, which may leach into groundwater or surface water if not properly managed. Acid mine drainage is a particular concern, as the oxidation of sulfide minerals in the waste material can generate acidic runoff that further mobilizes heavy metals.

Energy consumption in mechanical separation processes contributes to the overall carbon footprint of malachite processing. The operation of crushers, grinders, and other separation equipment requires substantial electrical or fossil fuel energy, leading to increased greenhouse gas emissions. This aspect of environmental impact is becoming increasingly important as the mining industry faces pressure to reduce its carbon footprint.

Noise pollution is another environmental factor to consider. The operation of heavy machinery involved in mechanical separation can generate significant noise levels, potentially affecting wildlife and nearby human populations. This can lead to habitat disruption and quality of life issues for local communities.

To mitigate these environmental impacts, the industry is increasingly adopting more sustainable practices. These include the implementation of dust suppression systems, water recycling and treatment technologies, and improved tailings management techniques. Additionally, there is a growing focus on developing more energy-efficient separation processes and exploring renewable energy sources to power processing operations.

In conclusion, while mechanical separation techniques are crucial for improving malachite purity, their environmental impacts are substantial and multifaceted. Balancing the need for efficient mineral processing with environmental protection remains a key challenge for the industry, driving ongoing research and innovation in more sustainable processing methods.

Economic Feasibility of Advanced Separation Techniques

The economic feasibility of advanced separation techniques for malachite purification is a critical consideration in the mining and mineral processing industry. These techniques, while potentially offering higher purity levels, must be evaluated against their operational costs and market demands. The capital investment required for implementing advanced separation methods, such as high-intensity magnetic separation or advanced flotation cells, can be substantial. However, the long-term benefits of producing higher-grade malachite may justify these initial expenditures.

One of the primary economic drivers for adopting advanced separation techniques is the increasing demand for high-purity copper compounds in various industries, including electronics and renewable energy sectors. As these industries grow, the premium for high-grade malachite is likely to increase, potentially offsetting the higher production costs associated with advanced separation methods. Additionally, more efficient separation techniques can lead to reduced waste and improved resource utilization, contributing to both economic and environmental sustainability.

The operational costs of advanced separation techniques must be carefully analyzed. While they may require more energy and specialized equipment, they often result in higher recovery rates and reduced processing times. This increased efficiency can lead to lower per-unit costs in the long run, especially for large-scale operations. Furthermore, the ability to process lower-grade ores economically through advanced techniques can extend the life of mining operations and increase the overall resource base, enhancing the long-term economic viability of malachite extraction projects.

Market dynamics play a crucial role in determining the economic feasibility of these techniques. The price volatility of copper and its compounds in the global market can significantly impact the return on investment for advanced separation technologies. A thorough market analysis and forecasting are essential to justify the implementation of these techniques. Moreover, the potential for developing value-added products from high-purity malachite could open new market opportunities, further improving the economic outlook.

Regulatory factors also influence the economic feasibility of advanced separation techniques. Stricter environmental regulations may necessitate the adoption of more sophisticated separation methods to meet emission and waste management standards. While this presents an additional cost factor, it also aligns with growing market preferences for sustainably sourced materials, potentially commanding premium prices and enhancing brand value.

One of the primary economic drivers for adopting advanced separation techniques is the increasing demand for high-purity copper compounds in various industries, including electronics and renewable energy sectors. As these industries grow, the premium for high-grade malachite is likely to increase, potentially offsetting the higher production costs associated with advanced separation methods. Additionally, more efficient separation techniques can lead to reduced waste and improved resource utilization, contributing to both economic and environmental sustainability.

The operational costs of advanced separation techniques must be carefully analyzed. While they may require more energy and specialized equipment, they often result in higher recovery rates and reduced processing times. This increased efficiency can lead to lower per-unit costs in the long run, especially for large-scale operations. Furthermore, the ability to process lower-grade ores economically through advanced techniques can extend the life of mining operations and increase the overall resource base, enhancing the long-term economic viability of malachite extraction projects.

Market dynamics play a crucial role in determining the economic feasibility of these techniques. The price volatility of copper and its compounds in the global market can significantly impact the return on investment for advanced separation technologies. A thorough market analysis and forecasting are essential to justify the implementation of these techniques. Moreover, the potential for developing value-added products from high-purity malachite could open new market opportunities, further improving the economic outlook.

Regulatory factors also influence the economic feasibility of advanced separation techniques. Stricter environmental regulations may necessitate the adoption of more sophisticated separation methods to meet emission and waste management standards. While this presents an additional cost factor, it also aligns with growing market preferences for sustainably sourced materials, potentially commanding premium prices and enhancing brand value.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!