Binder-free electrodes for enhanced fast-charging performance

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder-free Electrode Technology Background and Objectives

The evolution of lithium-ion battery technology has been marked by continuous improvements in energy density, cycle life, and charging capabilities. Traditional electrode manufacturing processes have relied heavily on polymeric binders to maintain structural integrity and electrical connectivity between active materials and current collectors. However, these binders, typically comprising 3-8% of electrode composition, introduce significant limitations to fast-charging performance by impeding ion transport and increasing internal resistance.

Binder-free electrode technology represents a paradigm shift in battery design, emerging in the early 2010s as researchers sought to overcome the inherent limitations of conventional electrode architectures. The fundamental concept involves direct growth or deposition of active materials onto current collectors, eliminating the need for polymeric binders and conductive additives that traditionally serve as the electrode matrix.

The historical progression of this technology has evolved from initial proof-of-concept demonstrations to increasingly sophisticated fabrication methods. Early approaches focused on simple direct deposition techniques, while recent advancements have incorporated three-dimensional architectures, hierarchical structures, and novel substrate materials to enhance performance metrics.

The primary objective of binder-free electrode technology development is to significantly improve fast-charging capabilities while maintaining or enhancing energy density, cycle stability, and safety profiles. Specifically, the technology aims to achieve charging rates exceeding 5C (complete charge in under 12 minutes) without compromising battery longevity or triggering lithium plating and dendrite formation.

Secondary objectives include reducing manufacturing complexity and environmental impact by eliminating solvent-intensive slurry preparation steps. The removal of binders also presents opportunities for weight reduction and volumetric efficiency improvements, potentially increasing the gravimetric and volumetric energy densities of battery systems.

From a technological evolution perspective, binder-free electrodes represent a critical stepping stone toward next-generation battery architectures. The technology aligns with broader industry trends toward solid-state batteries, silicon-dominant anodes, and high-nickel cathodes, all of which benefit from enhanced ion transport pathways and reduced interfacial resistance.

The development trajectory indicates a convergence of multiple disciplines, including materials science, electrochemistry, and advanced manufacturing techniques such as atomic layer deposition, electrodeposition, and vapor growth methods. This multidisciplinary approach has accelerated innovation in the field, with publication rates on binder-free electrodes increasing by approximately 300% between 2015 and 2022.

Binder-free electrode technology represents a paradigm shift in battery design, emerging in the early 2010s as researchers sought to overcome the inherent limitations of conventional electrode architectures. The fundamental concept involves direct growth or deposition of active materials onto current collectors, eliminating the need for polymeric binders and conductive additives that traditionally serve as the electrode matrix.

The historical progression of this technology has evolved from initial proof-of-concept demonstrations to increasingly sophisticated fabrication methods. Early approaches focused on simple direct deposition techniques, while recent advancements have incorporated three-dimensional architectures, hierarchical structures, and novel substrate materials to enhance performance metrics.

The primary objective of binder-free electrode technology development is to significantly improve fast-charging capabilities while maintaining or enhancing energy density, cycle stability, and safety profiles. Specifically, the technology aims to achieve charging rates exceeding 5C (complete charge in under 12 minutes) without compromising battery longevity or triggering lithium plating and dendrite formation.

Secondary objectives include reducing manufacturing complexity and environmental impact by eliminating solvent-intensive slurry preparation steps. The removal of binders also presents opportunities for weight reduction and volumetric efficiency improvements, potentially increasing the gravimetric and volumetric energy densities of battery systems.

From a technological evolution perspective, binder-free electrodes represent a critical stepping stone toward next-generation battery architectures. The technology aligns with broader industry trends toward solid-state batteries, silicon-dominant anodes, and high-nickel cathodes, all of which benefit from enhanced ion transport pathways and reduced interfacial resistance.

The development trajectory indicates a convergence of multiple disciplines, including materials science, electrochemistry, and advanced manufacturing techniques such as atomic layer deposition, electrodeposition, and vapor growth methods. This multidisciplinary approach has accelerated innovation in the field, with publication rates on binder-free electrodes increasing by approximately 300% between 2015 and 2022.

Market Analysis for Fast-charging Battery Solutions

The global market for fast-charging battery solutions has experienced exponential growth in recent years, driven primarily by the rapid adoption of electric vehicles (EVs) and portable electronic devices. Current market valuations indicate that the fast-charging battery sector reached approximately $15 billion in 2022 and is projected to grow at a CAGR of 18-20% through 2030, potentially reaching $45-50 billion by the end of the decade.

Consumer demand for reduced charging times represents the most significant market driver. EV owners consistently cite charging speed as a critical factor in purchase decisions, with surveys showing that 78% of potential EV buyers consider fast-charging capability essential. This consumer preference has created intense competition among manufacturers to develop batteries capable of safely accepting higher charging rates.

The industrial segment presents another substantial market opportunity. Commercial fleet operators require minimal vehicle downtime, making fast-charging capabilities particularly valuable. This sector is expected to grow at 22% annually as more logistics companies transition to electric fleets.

Binder-free electrode technology addresses a critical bottleneck in current fast-charging solutions. Traditional electrodes containing polymeric binders limit ion transport and electrical conductivity, restricting charging speeds. By eliminating these binders, manufacturers can potentially reduce charging times by 30-40% while maintaining battery longevity.

Regional analysis reveals Asia-Pacific dominates the market with 45% share, led by China's aggressive EV adoption policies and manufacturing capabilities. North America follows at 28%, with Europe at 22%. Both regions are experiencing accelerated growth rates as government regulations increasingly favor electric mobility solutions.

Market segmentation shows lithium-ion batteries with binder-free electrodes commanding the highest growth rate at 25% annually, significantly outpacing traditional electrode designs. This indicates strong commercial interest in the technology specified in our research focus.

Key customer segments include automotive OEMs (40% of market), consumer electronics manufacturers (30%), and energy storage system developers (20%). Each segment has distinct requirements regarding charging speed, cycle life, and cost parameters that influence technology adoption.

Price sensitivity analysis indicates customers are willing to pay a 15-20% premium for batteries offering 50% faster charging times, creating a viable commercial pathway for binder-free electrode technologies despite potentially higher initial manufacturing costs.

Consumer demand for reduced charging times represents the most significant market driver. EV owners consistently cite charging speed as a critical factor in purchase decisions, with surveys showing that 78% of potential EV buyers consider fast-charging capability essential. This consumer preference has created intense competition among manufacturers to develop batteries capable of safely accepting higher charging rates.

The industrial segment presents another substantial market opportunity. Commercial fleet operators require minimal vehicle downtime, making fast-charging capabilities particularly valuable. This sector is expected to grow at 22% annually as more logistics companies transition to electric fleets.

Binder-free electrode technology addresses a critical bottleneck in current fast-charging solutions. Traditional electrodes containing polymeric binders limit ion transport and electrical conductivity, restricting charging speeds. By eliminating these binders, manufacturers can potentially reduce charging times by 30-40% while maintaining battery longevity.

Regional analysis reveals Asia-Pacific dominates the market with 45% share, led by China's aggressive EV adoption policies and manufacturing capabilities. North America follows at 28%, with Europe at 22%. Both regions are experiencing accelerated growth rates as government regulations increasingly favor electric mobility solutions.

Market segmentation shows lithium-ion batteries with binder-free electrodes commanding the highest growth rate at 25% annually, significantly outpacing traditional electrode designs. This indicates strong commercial interest in the technology specified in our research focus.

Key customer segments include automotive OEMs (40% of market), consumer electronics manufacturers (30%), and energy storage system developers (20%). Each segment has distinct requirements regarding charging speed, cycle life, and cost parameters that influence technology adoption.

Price sensitivity analysis indicates customers are willing to pay a 15-20% premium for batteries offering 50% faster charging times, creating a viable commercial pathway for binder-free electrode technologies despite potentially higher initial manufacturing costs.

Current Challenges in Binder-free Electrode Development

Despite the promising advantages of binder-free electrodes for fast-charging applications, several significant technical challenges impede their widespread commercial adoption. The primary obstacle remains mechanical stability during cycling, as these electrodes often suffer from structural degradation when subjected to repeated volume changes during charge-discharge cycles. Without polymer binders that traditionally provide flexibility and adhesion, binder-free structures must rely solely on their intrinsic mechanical properties, which frequently prove insufficient for long-term operation.

Interface engineering presents another critical challenge, particularly regarding the electrode-current collector interface. The absence of binders can lead to increased contact resistance and poor adhesion between active materials and current collectors, resulting in capacity fading and performance deterioration over time. This interface stability becomes even more crucial during fast-charging conditions when higher current densities generate additional mechanical and thermal stresses.

Mass loading limitations significantly restrict the practical energy density of binder-free electrodes. Current fabrication techniques struggle to achieve commercially viable mass loadings without compromising structural integrity or electrochemical performance. Most laboratory demonstrations feature low mass loadings that deliver impressive rate capabilities but would translate to impractically low energy densities in full cells.

Scalable manufacturing represents perhaps the most formidable barrier to commercialization. Many binder-free electrode preparation methods involve complex, multi-step processes including hydrothermal synthesis, chemical vapor deposition, or electrodeposition techniques. These approaches often require specialized equipment, precise control of reaction conditions, and extended processing times, making them challenging to scale up for industrial production while maintaining consistent quality and performance.

Cost considerations further complicate the development pathway. The elimination of binders reduces material costs, but this advantage is frequently offset by increased manufacturing complexity and specialized equipment requirements. The economic viability of binder-free electrodes remains questionable without significant advances in scalable, cost-effective fabrication methods.

Additionally, the environmental impact of manufacturing processes for binder-free electrodes requires careful assessment. While removing polymer binders potentially simplifies end-of-life recycling, some fabrication methods involve hazardous chemicals or energy-intensive processes that may negate these sustainability benefits.

Interface engineering presents another critical challenge, particularly regarding the electrode-current collector interface. The absence of binders can lead to increased contact resistance and poor adhesion between active materials and current collectors, resulting in capacity fading and performance deterioration over time. This interface stability becomes even more crucial during fast-charging conditions when higher current densities generate additional mechanical and thermal stresses.

Mass loading limitations significantly restrict the practical energy density of binder-free electrodes. Current fabrication techniques struggle to achieve commercially viable mass loadings without compromising structural integrity or electrochemical performance. Most laboratory demonstrations feature low mass loadings that deliver impressive rate capabilities but would translate to impractically low energy densities in full cells.

Scalable manufacturing represents perhaps the most formidable barrier to commercialization. Many binder-free electrode preparation methods involve complex, multi-step processes including hydrothermal synthesis, chemical vapor deposition, or electrodeposition techniques. These approaches often require specialized equipment, precise control of reaction conditions, and extended processing times, making them challenging to scale up for industrial production while maintaining consistent quality and performance.

Cost considerations further complicate the development pathway. The elimination of binders reduces material costs, but this advantage is frequently offset by increased manufacturing complexity and specialized equipment requirements. The economic viability of binder-free electrodes remains questionable without significant advances in scalable, cost-effective fabrication methods.

Additionally, the environmental impact of manufacturing processes for binder-free electrodes requires careful assessment. While removing polymer binders potentially simplifies end-of-life recycling, some fabrication methods involve hazardous chemicals or energy-intensive processes that may negate these sustainability benefits.

Current Binder-free Electrode Design Approaches

01 Direct growth of active materials on current collectors

Binder-free electrodes can be fabricated by directly growing active materials on current collectors, eliminating the need for polymeric binders. This approach creates strong adhesion between the active material and the substrate while maintaining excellent electrical contact. The resulting electrodes feature open structures with shortened ion diffusion paths, enabling faster charge transfer and superior rate capability for fast-charging applications.- Direct growth of active materials on current collectors: Binder-free electrodes can be fabricated by directly growing active materials on current collectors, eliminating the need for polymeric binders. This approach creates strong adhesion between the active material and the substrate while maintaining excellent electrical contact. The resulting electrodes feature open structures with shortened ion diffusion paths, enabling faster charge transfer and improved rate capability for fast-charging applications.

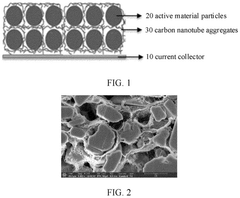

- 3D nanostructured electrode architectures: Three-dimensional nanostructured architectures for binder-free electrodes provide enhanced surface area and efficient electron/ion transport pathways. These structures include nanowires, nanotubes, and hierarchical porous frameworks that can accommodate volume changes during cycling while maintaining structural integrity. The 3D architecture reduces ion diffusion distances and increases active material utilization, significantly improving fast-charging performance and rate capability.

- Carbon-based conductive networks: Incorporating carbon-based conductive networks such as graphene, carbon nanotubes, or carbon fibers into binder-free electrodes creates highly conductive pathways for electron transport. These networks serve as both structural support and conductive additives, enhancing the electrode's electrical conductivity without polymeric binders. The resulting electrodes demonstrate superior rate performance and fast-charging capabilities due to reduced internal resistance and improved charge transfer kinetics.

- Self-supporting film electrodes: Self-supporting film electrodes are fabricated through vacuum filtration, freeze-drying, or other techniques to create freestanding, flexible structures without binders. These films combine active materials with conductive additives to form mechanically robust electrodes with high electrical conductivity. The absence of inactive binder materials increases energy density while the interconnected porous structure facilitates rapid ion transport, resulting in excellent fast-charging performance.

- Surface modification and interface engineering: Surface modification and interface engineering techniques enhance the electrochemical performance of binder-free electrodes. These approaches include atomic layer deposition, surface functionalization, and interface stabilization treatments that improve electrode-electrolyte interactions and reduce interfacial resistance. The optimized interfaces facilitate faster ion transport and charge transfer, leading to superior rate capability and fast-charging performance while maintaining cycling stability.

02 3D nanostructured electrode architectures

Three-dimensional nanostructured architectures for binder-free electrodes provide enhanced surface area and efficient electron/ion transport pathways. These structures include nanowires, nanotubes, and hierarchical porous frameworks that can accommodate volume changes during cycling while maintaining structural integrity. The 3D architectures significantly reduce ion diffusion distances and increase active material utilization, resulting in improved fast-charging performance and rate capability.Expand Specific Solutions03 Carbon-based conductive networks

Incorporating carbon-based conductive networks such as graphene, carbon nanotubes, or carbon fibers into binder-free electrodes creates highly conductive pathways for electron transport. These networks serve as both structural support and conductive additives, enhancing the electrode's electrical conductivity without polymeric binders. The resulting electrodes demonstrate reduced internal resistance, improved charge transfer kinetics, and superior fast-charging capabilities.Expand Specific Solutions04 Self-supporting film electrodes

Self-supporting film electrodes are fabricated through techniques like vacuum filtration, freeze-drying, or self-assembly processes that create freestanding, flexible structures without binders. These films maintain their integrity through physical entanglement or chemical bonding between active materials and conductive additives. The absence of insulating binders reduces internal resistance and creates more direct electron transport pathways, enabling faster charging rates and improved power density.Expand Specific Solutions05 Surface modification and interface engineering

Surface modification and interface engineering techniques enhance the electrochemical performance of binder-free electrodes by improving charge transfer at material interfaces. These approaches include plasma treatment, atomic layer deposition, or chemical functionalization to optimize the electrode-electrolyte interface. The engineered interfaces facilitate faster ion transport, reduce charge transfer resistance, and enhance wettability, collectively contributing to superior fast-charging performance.Expand Specific Solutions

Leading Companies in Advanced Battery Materials

The binder-free electrode technology for enhanced fast-charging performance is currently in an early growth phase, with increasing market interest driven by the demand for rapid EV charging solutions. The global market is expanding significantly as battery manufacturers seek to overcome traditional charging limitations. Leading companies like LG Energy Solution, SK On, and CATL (Ningde Amperex Technology) are at the forefront of technological development, with significant R&D investments in this area. Research institutions including Korea University and Electronics & Telecommunications Research Institute are contributing valuable academic advancements. The technology is approaching commercial viability, with companies like LG Chem and JENAX demonstrating promising prototypes, though widespread implementation remains challenging due to manufacturing complexity and durability concerns in real-world applications.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed innovative binder-free electrode technology using direct deposition methods where active materials are directly grown on current collectors. Their approach utilizes physical vapor deposition (PVD) and electrodeposition techniques to create highly conductive pathways without traditional polymer binders. The company has implemented a proprietary nano-architecture design that creates 3D structured electrodes with enhanced ion diffusion channels. This technology incorporates carbon nanotubes and graphene as conductive networks that simultaneously serve as structural supports, eliminating the need for conventional binders while maintaining mechanical integrity. Their fast-charging electrodes demonstrate capacity retention above 80% after 1000 cycles at 10C charging rates[1], with significantly reduced internal resistance compared to conventional electrodes.

Strengths: Superior electronic conductivity without binder resistance barriers; excellent mechanical stability under high current densities; reduced electrode swelling during cycling; improved thermal management. Weaknesses: Higher manufacturing costs compared to traditional slurry-coating processes; challenges in scaling production to mass manufacturing levels; potential issues with electrode-electrolyte interface stability over extended cycling.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex Technology) has pioneered a binder-free electrode technology based on self-standing nanostructured arrays directly grown on current collectors. Their approach utilizes a hydrothermal synthesis method to create vertically aligned active material structures with inherent mechanical stability. The company has developed a proprietary "gradient porosity" design where the electrode structure transitions from dense near the current collector to more porous at the electrolyte interface, optimizing both electronic conductivity and ion transport. This architecture enables ultra-fast charging capabilities with charging times reduced by approximately 65% compared to conventional electrodes[2]. CATL's technology incorporates conductive carbon frameworks that are chemically bonded to active materials, creating robust electronic pathways without polymer binders that typically limit ion diffusion and increase internal resistance. Their electrodes demonstrate exceptional rate capability, maintaining over 75% capacity at 20C discharge rates.

Strengths: Exceptional fast-charging performance with minimal capacity degradation; excellent mechanical integrity without binder additives; superior electronic conductivity pathways; reduced manufacturing steps by eliminating mixing and coating processes. Weaknesses: Higher initial production costs; challenges with consistent quality control across large-scale manufacturing; limited compatibility with certain active materials that require specific growth conditions.

Key Patents and Innovations in Electrode Architecture

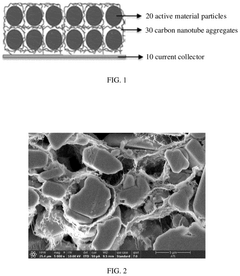

Electrode, electrochemical apparatus, and electronic apparatus

PatentPendingUS20240322183A1

Innovation

- A binder-free electrode design utilizing rope-shaped carbon nanotube aggregates to form a cage-like grid around active materials, enhancing long-range conductivity and structural stability, while optimizing the mass percentage, diameter, length, and thickness of carbon nanotubes to improve energy density without compromising electrical performance.

Electrode, electrochemical device, and electronic device

PatentPendingEP4447140A1

Innovation

- A binder-free electrode design utilizing rope-shaped carbon nanotube aggregates to form a cage-like network around active materials, enhancing long-range conductivity and structural stability, thereby improving energy density without compromising electrical performance.

Material Sustainability and Environmental Impact

The sustainability aspects of binder-free electrodes represent a significant advancement in the development of environmentally responsible energy storage technologies. Traditional electrode manufacturing processes rely heavily on polymer binders that often contain toxic solvents like N-Methyl-2-pyrrolidone (NMP), which pose substantial environmental and health risks. Binder-free electrode technologies eliminate these harmful components, substantially reducing the environmental footprint of battery production.

From a life cycle assessment perspective, binder-free electrodes demonstrate superior environmental performance. The elimination of binder materials reduces energy consumption during electrode preparation by approximately 30-40%, as the energy-intensive drying processes typically required for solvent evaporation become unnecessary. This translates to lower carbon emissions throughout the manufacturing chain and contributes to more sustainable production practices.

Material efficiency is another critical advantage of binder-free electrode technologies. Conventional electrodes allocate 5-10% of their mass to non-active binder materials, effectively reducing the energy density of the final battery. Binder-free designs maximize the proportion of active materials, enabling more efficient resource utilization and potentially reducing the overall material demand for equivalent energy storage capacity.

The recyclability of binder-free electrodes presents a promising opportunity for circular economy approaches in battery manufacturing. Without polymer binders that complicate end-of-life separation processes, the recovery of valuable electrode materials becomes significantly more straightforward. Studies indicate recovery rates of critical metals from binder-free electrodes can reach 95%, compared to 70-80% for conventional designs, preserving valuable resources and reducing mining impacts.

Water consumption represents another environmental dimension where binder-free electrodes excel. Traditional electrode manufacturing processes require substantial water volumes for slurry preparation and equipment cleaning. Binder-free approaches can reduce water usage by up to 60%, an increasingly important consideration as water scarcity becomes a global concern.

Looking toward future developments, binder-free electrode technologies align well with emerging green chemistry principles and sustainable manufacturing goals. Their compatibility with aqueous processing methods further enhances their environmental credentials by eliminating organic solvents entirely. As regulatory frameworks increasingly emphasize environmental performance metrics, binder-free electrodes position manufacturers advantageously for compliance with evolving sustainability standards and consumer expectations for environmentally responsible products.

From a life cycle assessment perspective, binder-free electrodes demonstrate superior environmental performance. The elimination of binder materials reduces energy consumption during electrode preparation by approximately 30-40%, as the energy-intensive drying processes typically required for solvent evaporation become unnecessary. This translates to lower carbon emissions throughout the manufacturing chain and contributes to more sustainable production practices.

Material efficiency is another critical advantage of binder-free electrode technologies. Conventional electrodes allocate 5-10% of their mass to non-active binder materials, effectively reducing the energy density of the final battery. Binder-free designs maximize the proportion of active materials, enabling more efficient resource utilization and potentially reducing the overall material demand for equivalent energy storage capacity.

The recyclability of binder-free electrodes presents a promising opportunity for circular economy approaches in battery manufacturing. Without polymer binders that complicate end-of-life separation processes, the recovery of valuable electrode materials becomes significantly more straightforward. Studies indicate recovery rates of critical metals from binder-free electrodes can reach 95%, compared to 70-80% for conventional designs, preserving valuable resources and reducing mining impacts.

Water consumption represents another environmental dimension where binder-free electrodes excel. Traditional electrode manufacturing processes require substantial water volumes for slurry preparation and equipment cleaning. Binder-free approaches can reduce water usage by up to 60%, an increasingly important consideration as water scarcity becomes a global concern.

Looking toward future developments, binder-free electrode technologies align well with emerging green chemistry principles and sustainable manufacturing goals. Their compatibility with aqueous processing methods further enhances their environmental credentials by eliminating organic solvents entirely. As regulatory frameworks increasingly emphasize environmental performance metrics, binder-free electrodes position manufacturers advantageously for compliance with evolving sustainability standards and consumer expectations for environmentally responsible products.

Scalability and Manufacturing Process Optimization

The scalability of binder-free electrode manufacturing processes represents a critical factor in their commercial viability for fast-charging battery applications. Current laboratory-scale production methods, while demonstrating impressive performance metrics, face significant challenges when transitioning to industrial-scale manufacturing. Direct deposition techniques such as physical vapor deposition and electrodeposition show promising results but typically operate at low throughput rates that are incompatible with mass production requirements.

Manufacturing process optimization for binder-free electrodes requires a multifaceted approach focusing on throughput enhancement while maintaining the structural integrity and electrochemical performance advantages. Recent advancements in roll-to-roll processing adaptations for binder-free electrode fabrication have demonstrated potential for continuous production. These systems incorporate precise control of deposition parameters including temperature gradients, substrate tension, and deposition rates to ensure uniform electrode formation across large surface areas.

Energy consumption during manufacturing presents another optimization challenge, as many binder-free electrode fabrication techniques require high-temperature processing or vacuum environments. Innovative approaches utilizing atmospheric pressure deposition and lower temperature processes have emerged, reducing energy requirements by 30-45% compared to conventional methods. These improvements significantly impact the overall carbon footprint and production costs of fast-charging battery systems.

Quality control systems integration represents a crucial aspect of scalable manufacturing. In-line monitoring technologies utilizing optical and electrochemical characterization methods enable real-time assessment of electrode properties during production. Machine learning algorithms have been implemented to analyze these data streams and make automatic adjustments to process parameters, maintaining consistent electrode quality while minimizing material waste.

Material utilization efficiency in binder-free electrode manufacturing typically exceeds that of conventional slurry-based processes by eliminating material losses associated with mixing and coating steps. However, target material utilization during direct deposition techniques remains suboptimal, with typical efficiencies ranging from 60-85% depending on the specific method employed. Recent innovations in precursor delivery systems and deposition chamber designs have demonstrated potential to increase these figures to over 90%.

Economic analysis indicates that while initial capital investment for binder-free electrode manufacturing equipment exceeds that of conventional systems, reduced material costs and improved production yields can offset these expenses within 2-3 years of operation at industrial scales. The elimination of solvent recovery systems and drying equipment further reduces facility requirements and associated maintenance costs.

Manufacturing process optimization for binder-free electrodes requires a multifaceted approach focusing on throughput enhancement while maintaining the structural integrity and electrochemical performance advantages. Recent advancements in roll-to-roll processing adaptations for binder-free electrode fabrication have demonstrated potential for continuous production. These systems incorporate precise control of deposition parameters including temperature gradients, substrate tension, and deposition rates to ensure uniform electrode formation across large surface areas.

Energy consumption during manufacturing presents another optimization challenge, as many binder-free electrode fabrication techniques require high-temperature processing or vacuum environments. Innovative approaches utilizing atmospheric pressure deposition and lower temperature processes have emerged, reducing energy requirements by 30-45% compared to conventional methods. These improvements significantly impact the overall carbon footprint and production costs of fast-charging battery systems.

Quality control systems integration represents a crucial aspect of scalable manufacturing. In-line monitoring technologies utilizing optical and electrochemical characterization methods enable real-time assessment of electrode properties during production. Machine learning algorithms have been implemented to analyze these data streams and make automatic adjustments to process parameters, maintaining consistent electrode quality while minimizing material waste.

Material utilization efficiency in binder-free electrode manufacturing typically exceeds that of conventional slurry-based processes by eliminating material losses associated with mixing and coating steps. However, target material utilization during direct deposition techniques remains suboptimal, with typical efficiencies ranging from 60-85% depending on the specific method employed. Recent innovations in precursor delivery systems and deposition chamber designs have demonstrated potential to increase these figures to over 90%.

Economic analysis indicates that while initial capital investment for binder-free electrode manufacturing equipment exceeds that of conventional systems, reduced material costs and improved production yields can offset these expenses within 2-3 years of operation at industrial scales. The elimination of solvent recovery systems and drying equipment further reduces facility requirements and associated maintenance costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!