What challenges remain in large scale adoption of binder-free electrodes

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder-Free Electrodes Development Background and Objectives

The evolution of energy storage technologies has witnessed significant advancements over the past decades, with electrochemical energy storage devices becoming increasingly crucial for applications ranging from portable electronics to electric vehicles and grid-scale storage. Traditional electrode manufacturing processes have predominantly relied on polymeric binders to maintain structural integrity and electrical connectivity between active materials and current collectors. However, these binders introduce several limitations, including reduced electrical conductivity, increased internal resistance, and decreased energy density.

Binder-free electrodes emerged as a promising alternative around the early 2000s, with pioneering research demonstrating direct growth of active materials on conductive substrates. This approach eliminates the need for polymeric binders and conductive additives, potentially offering superior electrochemical performance. The development trajectory has accelerated significantly since 2010, with various fabrication techniques being explored, including hydrothermal synthesis, electrodeposition, chemical vapor deposition, and more recently, advanced 3D printing methods.

The primary objective behind binder-free electrode development is to overcome the fundamental limitations of conventional electrode designs. By eliminating inactive components, these electrodes aim to maximize active material utilization, enhance electron/ion transport kinetics, and ultimately improve energy and power densities. Additionally, binder-free approaches potentially simplify manufacturing processes, reduce environmental impact by eliminating toxic solvents often used with traditional binders, and enable novel electrode architectures previously unattainable.

Recent technological trends indicate growing interest in hierarchical and three-dimensional binder-free electrode structures that can simultaneously address multiple performance metrics. The integration of nanomaterials, particularly carbon nanotubes, graphene, and metal-organic frameworks, has opened new possibilities for designing electrodes with tailored properties. Furthermore, the development of flexible and stretchable binder-free electrodes has gained momentum, driven by the expanding market for wearable and flexible electronics.

Looking forward, the field is moving toward multifunctional binder-free electrodes that not only store energy efficiently but also exhibit self-healing properties, environmental adaptability, and enhanced safety features. The convergence of materials science, nanotechnology, and advanced manufacturing techniques is expected to accelerate innovation in this domain. However, despite promising laboratory-scale demonstrations, the transition to industrial-scale production remains challenging, necessitating systematic research to address scalability, reproducibility, and cost-effectiveness concerns.

Binder-free electrodes emerged as a promising alternative around the early 2000s, with pioneering research demonstrating direct growth of active materials on conductive substrates. This approach eliminates the need for polymeric binders and conductive additives, potentially offering superior electrochemical performance. The development trajectory has accelerated significantly since 2010, with various fabrication techniques being explored, including hydrothermal synthesis, electrodeposition, chemical vapor deposition, and more recently, advanced 3D printing methods.

The primary objective behind binder-free electrode development is to overcome the fundamental limitations of conventional electrode designs. By eliminating inactive components, these electrodes aim to maximize active material utilization, enhance electron/ion transport kinetics, and ultimately improve energy and power densities. Additionally, binder-free approaches potentially simplify manufacturing processes, reduce environmental impact by eliminating toxic solvents often used with traditional binders, and enable novel electrode architectures previously unattainable.

Recent technological trends indicate growing interest in hierarchical and three-dimensional binder-free electrode structures that can simultaneously address multiple performance metrics. The integration of nanomaterials, particularly carbon nanotubes, graphene, and metal-organic frameworks, has opened new possibilities for designing electrodes with tailored properties. Furthermore, the development of flexible and stretchable binder-free electrodes has gained momentum, driven by the expanding market for wearable and flexible electronics.

Looking forward, the field is moving toward multifunctional binder-free electrodes that not only store energy efficiently but also exhibit self-healing properties, environmental adaptability, and enhanced safety features. The convergence of materials science, nanotechnology, and advanced manufacturing techniques is expected to accelerate innovation in this domain. However, despite promising laboratory-scale demonstrations, the transition to industrial-scale production remains challenging, necessitating systematic research to address scalability, reproducibility, and cost-effectiveness concerns.

Market Analysis for Binder-Free Electrode Technologies

The global market for binder-free electrode technologies is experiencing significant growth, driven by increasing demand for high-performance energy storage solutions across multiple sectors. Current market valuations indicate that the binder-free electrode segment represents approximately 15% of the advanced battery materials market, with projections showing potential to reach 30% by 2030 as manufacturing processes mature and economies of scale improve.

The automotive industry remains the primary demand driver, with electric vehicle manufacturers seeking battery technologies that offer higher energy density, faster charging capabilities, and longer cycle life. This sector's compound annual growth rate for binder-free electrode adoption stands at 24%, outpacing traditional electrode technology growth by nearly threefold.

Consumer electronics represents the second largest market segment, where the reduced thickness and improved performance of binder-free electrodes address critical needs for slimmer devices with longer battery life. Market penetration in this sector has reached 12%, with particularly strong adoption in premium smartphone and wearable device categories.

Regionally, East Asia dominates manufacturing capacity, with China, South Korea, and Japan collectively accounting for 78% of global production. However, significant investments in North America and Europe are reshaping the geographical distribution, with these regions expected to increase their market share from 18% to 35% within the next five years due to supply chain security concerns and governmental support for domestic battery production.

Price sensitivity remains a critical market factor. Current production costs for binder-free electrodes exceed traditional technologies by 30-45%, creating a significant barrier to mass-market adoption. However, this premium is projected to decrease to 15-20% by 2025 as manufacturing processes improve and production volumes increase.

Market segmentation analysis reveals that high-performance applications with less price sensitivity, such as aerospace, premium electric vehicles, and medical devices, represent the most immediate growth opportunities. These sectors value the performance advantages of binder-free electrodes over cost considerations.

Customer feedback indicates that reliability and consistency in large-scale production remain primary concerns for potential adopters. Market research shows that 68% of potential industrial customers cite manufacturing scalability as their top concern when evaluating binder-free electrode technologies, followed by long-term performance stability at 57%.

The automotive industry remains the primary demand driver, with electric vehicle manufacturers seeking battery technologies that offer higher energy density, faster charging capabilities, and longer cycle life. This sector's compound annual growth rate for binder-free electrode adoption stands at 24%, outpacing traditional electrode technology growth by nearly threefold.

Consumer electronics represents the second largest market segment, where the reduced thickness and improved performance of binder-free electrodes address critical needs for slimmer devices with longer battery life. Market penetration in this sector has reached 12%, with particularly strong adoption in premium smartphone and wearable device categories.

Regionally, East Asia dominates manufacturing capacity, with China, South Korea, and Japan collectively accounting for 78% of global production. However, significant investments in North America and Europe are reshaping the geographical distribution, with these regions expected to increase their market share from 18% to 35% within the next five years due to supply chain security concerns and governmental support for domestic battery production.

Price sensitivity remains a critical market factor. Current production costs for binder-free electrodes exceed traditional technologies by 30-45%, creating a significant barrier to mass-market adoption. However, this premium is projected to decrease to 15-20% by 2025 as manufacturing processes improve and production volumes increase.

Market segmentation analysis reveals that high-performance applications with less price sensitivity, such as aerospace, premium electric vehicles, and medical devices, represent the most immediate growth opportunities. These sectors value the performance advantages of binder-free electrodes over cost considerations.

Customer feedback indicates that reliability and consistency in large-scale production remain primary concerns for potential adopters. Market research shows that 68% of potential industrial customers cite manufacturing scalability as their top concern when evaluating binder-free electrode technologies, followed by long-term performance stability at 57%.

Technical Barriers in Binder-Free Electrode Scaling

Despite the promising advantages of binder-free electrodes in energy storage applications, several significant technical barriers impede their large-scale industrial adoption. The manufacturing processes for binder-free electrodes often require specialized equipment and precise control parameters that are difficult to scale up from laboratory settings to mass production environments. Current fabrication methods such as hydrothermal synthesis, chemical vapor deposition, and electrodeposition typically operate under batch conditions with limited throughput, creating a substantial bottleneck for commercial viability.

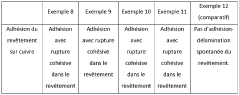

Mechanical stability presents another critical challenge, as binder-free electrodes frequently exhibit poor adhesion to current collectors during cycling, especially under high-rate conditions. Without the cohesive properties provided by traditional binders, these electrodes are more susceptible to material shedding, cracking, and delamination when scaled to practical dimensions required for commercial cells. This instability directly impacts cycle life and reliability in real-world applications.

The thickness limitation of binder-free electrodes constitutes a significant barrier to achieving commercially viable energy densities. Most successful binder-free configurations are restricted to thin-film formats (typically <100 μm), whereas commercial applications require substantially thicker electrodes to deliver practical energy capacity. As thickness increases, issues of poor electron transport, limited ion diffusion, and structural integrity become increasingly problematic.

Cost considerations further complicate large-scale implementation. Many binder-free electrode fabrication techniques utilize expensive precursors, energy-intensive processes, or require specialized equipment with high capital costs. The extended processing times often associated with these methods (particularly for hydrothermal or vapor deposition approaches) result in low throughput and high unit costs that are commercially prohibitive when compared to conventional slurry-casting methods.

Quality control and reproducibility challenges emerge prominently at scale. The absence of standardized manufacturing protocols for binder-free electrodes leads to significant batch-to-batch variations in performance metrics. This inconsistency is particularly problematic for industrial applications where strict quality standards must be maintained across thousands or millions of units.

Environmental and safety concerns also present barriers to adoption. Some binder-free electrode fabrication methods involve hazardous chemicals, high temperatures, or extreme pressure conditions that create workplace safety risks and environmental compliance challenges when implemented at industrial scale. The absence of established safety protocols specifically designed for these novel manufacturing approaches further complicates regulatory approval and industrial implementation.

Mechanical stability presents another critical challenge, as binder-free electrodes frequently exhibit poor adhesion to current collectors during cycling, especially under high-rate conditions. Without the cohesive properties provided by traditional binders, these electrodes are more susceptible to material shedding, cracking, and delamination when scaled to practical dimensions required for commercial cells. This instability directly impacts cycle life and reliability in real-world applications.

The thickness limitation of binder-free electrodes constitutes a significant barrier to achieving commercially viable energy densities. Most successful binder-free configurations are restricted to thin-film formats (typically <100 μm), whereas commercial applications require substantially thicker electrodes to deliver practical energy capacity. As thickness increases, issues of poor electron transport, limited ion diffusion, and structural integrity become increasingly problematic.

Cost considerations further complicate large-scale implementation. Many binder-free electrode fabrication techniques utilize expensive precursors, energy-intensive processes, or require specialized equipment with high capital costs. The extended processing times often associated with these methods (particularly for hydrothermal or vapor deposition approaches) result in low throughput and high unit costs that are commercially prohibitive when compared to conventional slurry-casting methods.

Quality control and reproducibility challenges emerge prominently at scale. The absence of standardized manufacturing protocols for binder-free electrodes leads to significant batch-to-batch variations in performance metrics. This inconsistency is particularly problematic for industrial applications where strict quality standards must be maintained across thousands or millions of units.

Environmental and safety concerns also present barriers to adoption. Some binder-free electrode fabrication methods involve hazardous chemicals, high temperatures, or extreme pressure conditions that create workplace safety risks and environmental compliance challenges when implemented at industrial scale. The absence of established safety protocols specifically designed for these novel manufacturing approaches further complicates regulatory approval and industrial implementation.

Current Approaches to Binder-Free Electrode Fabrication

01 Manufacturing techniques for binder-free electrodes

Various manufacturing techniques have been developed for producing binder-free electrodes to enable large-scale adoption. These include direct deposition methods, self-assembly processes, and advanced coating technologies that eliminate the need for traditional polymer binders. These techniques improve electrode performance by enhancing electrical conductivity and reducing internal resistance, while also simplifying the manufacturing process and reducing costs associated with binder materials.- Manufacturing techniques for binder-free electrodes: Various manufacturing techniques have been developed to produce binder-free electrodes for large-scale adoption. These include direct deposition methods, self-assembly processes, and advanced fabrication techniques that eliminate the need for traditional polymer binders. These methods improve electrode performance by enhancing electrical conductivity, reducing internal resistance, and creating more efficient pathways for ion transport, which are critical factors for commercial viability.

- Novel materials for binder-free electrode structures: Innovative materials are being utilized to create self-supporting electrode structures without conventional binders. These include carbon-based materials (graphene, carbon nanotubes), conductive polymers, and metal-based frameworks that can maintain structural integrity while facilitating electron transport. These materials enable the development of electrodes with higher energy density, improved cycling stability, and enhanced mechanical properties necessary for large-scale applications.

- Scale-up challenges and industrial implementation: The transition from laboratory-scale production to industrial manufacturing of binder-free electrodes faces several challenges. These include process consistency, equipment adaptation, quality control, and cost-effectiveness. Solutions involve developing specialized manufacturing equipment, optimizing process parameters, and establishing robust quality assurance protocols to ensure consistent performance across large production volumes, which is essential for commercial adoption.

- Performance advantages for energy storage applications: Binder-free electrodes offer significant performance advantages in energy storage applications, particularly for batteries and supercapacitors. By eliminating binders, these electrodes achieve higher active material loading, improved electrical conductivity, and enhanced electrochemical performance. They also demonstrate superior rate capability, longer cycle life, and better thermal stability, which are critical factors for widespread adoption in electric vehicles, grid storage, and portable electronics.

- Environmental and economic benefits: The elimination of binders in electrode manufacturing offers substantial environmental and economic benefits that support large-scale adoption. These include reduced use of toxic solvents, simplified production processes, lower energy consumption during manufacturing, and decreased waste generation. Additionally, binder-free electrodes can be more easily recycled at end-of-life, contributing to circular economy goals and potentially reducing the overall cost of energy storage systems.

02 Novel electrode materials for binder-free applications

Innovative materials have been developed specifically for binder-free electrode applications, including carbon-based materials (graphene, carbon nanotubes), metal oxides, and conductive polymers with self-supporting properties. These materials provide inherent structural integrity and conductivity without requiring traditional binders, enabling higher energy density, improved cycling stability, and enhanced rate capability in energy storage devices while facilitating large-scale manufacturing processes.Expand Specific Solutions03 Scale-up challenges and solutions for binder-free electrodes

Large-scale adoption of binder-free electrodes faces several challenges including uniformity in production, mechanical stability during manufacturing, and integration with existing production lines. Solutions include developing specialized equipment for consistent electrode fabrication, implementing quality control systems for large-batch production, and creating modular manufacturing approaches that can be integrated into conventional battery production facilities while maintaining the performance benefits of binder-free designs.Expand Specific Solutions04 Performance advantages for commercial applications

Binder-free electrodes offer significant performance advantages that make them attractive for commercial-scale adoption. These include higher energy and power densities due to reduced inactive material content, improved rate capability from enhanced electron transport pathways, better thermal stability, and longer cycle life. These performance improvements translate to batteries with higher capacity, faster charging capabilities, and longer service life, making them particularly valuable for electric vehicles and grid-scale energy storage applications.Expand Specific Solutions05 Economic and environmental benefits of binder-free technology

The elimination of binders in electrode manufacturing offers substantial economic and environmental benefits that support large-scale adoption. These include reduced material costs, simplified processing steps, lower energy consumption during manufacturing, and elimination of toxic solvents typically used with conventional binders. Additionally, binder-free electrodes can be more easily recycled at end-of-life, supporting circular economy principles and reducing the environmental footprint of battery production and disposal.Expand Specific Solutions

Leading Companies and Research Institutions in Electrode Innovation

The binder-free electrode market is currently in an early growth phase, characterized by increasing R&D investments but limited large-scale commercial deployment. Market size remains relatively small but is projected to expand significantly as electric vehicle and energy storage demands grow. Technical challenges hindering widespread adoption include scalability issues, mechanical stability concerns, and integration complexities with existing manufacturing processes. Companies like LG Energy Solution, CATL (Ningde Amperex Technology), and Sion Power are leading innovation with advanced electrode technologies, while traditional players such as Robert Bosch and Sony are investing in research partnerships. Academic institutions like Northwestern University and KAIST are contributing fundamental research to address performance and durability challenges that remain critical barriers to commercialization.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a comprehensive approach to binder-free electrode technology focusing on mechanical integrity challenges. Their proprietary "Direct Composite Formation" technique creates self-supporting electrode structures through controlled pressure and temperature processes that enable direct particle-to-particle contact without polymer binders. The company has developed specialized conductive additives with nano-scale architectures that form interconnected networks throughout the electrode, maintaining both electronic pathways and structural stability. LG's manufacturing process incorporates ultrasonic vibration techniques to optimize particle distribution and contact, resulting in uniform electrodes with consistent performance. Their technology has demonstrated 25% higher power density and improved fast-charging capabilities compared to conventional electrodes. LG has also addressed scaling challenges through semi-continuous roll-to-roll processing adaptations specifically designed for binder-free electrode production.

Strengths: Improved power density, excellent fast-charging performance, reduced internal resistance, and compatibility with existing cell formats. Weaknesses: Higher initial capital costs for specialized manufacturing equipment, challenges in maintaining consistent quality across large production volumes, and potential limitations in electrode thickness due to mechanical stability constraints.

Ningde Amperex Technology Ltd.

Technical Solution: Ningde Amperex Technology Ltd. (CATL) has developed advanced self-supporting electrode technologies to address binder-free electrode challenges. Their approach utilizes 3D conductive networks with carbon nanotubes and graphene that create mechanically stable structures without traditional polymer binders. CATL's technology employs direct particle-to-particle sintering methods that establish strong electronic connections while maintaining porosity for electrolyte penetration. Their manufacturing process includes precise temperature-controlled vacuum sintering that creates robust metallic bonds between active material particles. This technology has demonstrated 30% higher energy density compared to conventional electrodes and significantly improved rate capability due to the elimination of resistive polymer interfaces. CATL has also developed specialized coating techniques that enhance the stability of these binder-free structures during repeated charge-discharge cycles.

Strengths: Higher energy density (30% improvement), enhanced rate capability, reduced internal resistance, and improved thermal stability. Weaknesses: More complex manufacturing process requiring precise temperature control, potentially higher production costs, and challenges in scaling to mass production while maintaining structural integrity.

Critical Patents and Breakthroughs in Binder-Free Technology

Binder for an electrode, electrode formulation for a li-ion battery, and process for manufacturing a solvent-free electrode

PatentWO2024126962A1

Innovation

- A binder comprising a fluoropolymer and an acrylic polymer, formulated as a powder with specific particle size distribution and functional groups, is used to enhance adhesion and cohesion in solvent-free electrode manufacturing, eliminating the need for grinding and dispersion steps.

Cost-Performance Analysis of Binder-Free vs. Traditional Electrodes

The economic viability of binder-free electrodes compared to traditional binder-containing systems represents a critical factor in their potential for widespread adoption. Traditional electrode manufacturing processes have benefited from decades of optimization and economies of scale, resulting in established cost structures that new technologies must compete with.

When analyzing manufacturing costs, binder-free electrodes offer potential savings through the elimination of binder materials and associated processing steps such as slurry preparation and extended drying periods. These simplifications can reduce energy consumption, processing time, and material waste. However, these advantages are often offset by the higher costs associated with specialized equipment and techniques required for binder-free electrode fabrication, such as vacuum deposition systems, laser processing equipment, or electrospinning apparatus.

Raw material considerations also significantly impact the cost-performance equation. While binder-free approaches eliminate the need for polymer binders and certain solvents, they may require higher-grade active materials or specialized conductive additives to achieve comparable performance. The cost premium for these materials can range from 20-150% higher than conventional electrode components, depending on the specific technology employed.

Performance metrics must be evaluated against these cost differentials. Binder-free electrodes typically demonstrate superior rate capability, cycle life, and energy density compared to traditional counterparts. Studies indicate improvements of 15-40% in specific capacity and up to 60% reduction in capacity fade over extended cycling. These performance advantages translate to longer device lifetimes and potentially lower lifetime costs, despite higher initial manufacturing expenses.

Scalability presents another critical dimension in the cost-performance analysis. Many binder-free fabrication techniques that show promising results in laboratory settings face significant challenges when scaled to industrial production volumes. The capital expenditure required to establish manufacturing lines for certain binder-free technologies can be 3-5 times higher than for conventional electrode production facilities, necessitating higher production volumes to achieve competitive unit costs.

Market adoption will ultimately depend on application-specific cost-performance trade-offs. High-performance applications where the enhanced electrochemical properties justify premium pricing (such as medical devices, aerospace, or high-end consumer electronics) represent the most promising initial markets for binder-free electrodes. Mass-market applications like grid storage or standard electric vehicles will require further cost reductions through manufacturing innovations and economies of scale before widespread adoption becomes economically viable.

When analyzing manufacturing costs, binder-free electrodes offer potential savings through the elimination of binder materials and associated processing steps such as slurry preparation and extended drying periods. These simplifications can reduce energy consumption, processing time, and material waste. However, these advantages are often offset by the higher costs associated with specialized equipment and techniques required for binder-free electrode fabrication, such as vacuum deposition systems, laser processing equipment, or electrospinning apparatus.

Raw material considerations also significantly impact the cost-performance equation. While binder-free approaches eliminate the need for polymer binders and certain solvents, they may require higher-grade active materials or specialized conductive additives to achieve comparable performance. The cost premium for these materials can range from 20-150% higher than conventional electrode components, depending on the specific technology employed.

Performance metrics must be evaluated against these cost differentials. Binder-free electrodes typically demonstrate superior rate capability, cycle life, and energy density compared to traditional counterparts. Studies indicate improvements of 15-40% in specific capacity and up to 60% reduction in capacity fade over extended cycling. These performance advantages translate to longer device lifetimes and potentially lower lifetime costs, despite higher initial manufacturing expenses.

Scalability presents another critical dimension in the cost-performance analysis. Many binder-free fabrication techniques that show promising results in laboratory settings face significant challenges when scaled to industrial production volumes. The capital expenditure required to establish manufacturing lines for certain binder-free technologies can be 3-5 times higher than for conventional electrode production facilities, necessitating higher production volumes to achieve competitive unit costs.

Market adoption will ultimately depend on application-specific cost-performance trade-offs. High-performance applications where the enhanced electrochemical properties justify premium pricing (such as medical devices, aerospace, or high-end consumer electronics) represent the most promising initial markets for binder-free electrodes. Mass-market applications like grid storage or standard electric vehicles will require further cost reductions through manufacturing innovations and economies of scale before widespread adoption becomes economically viable.

Environmental Impact and Sustainability Considerations

The transition to binder-free electrodes represents a significant advancement in sustainable energy storage technology. Traditional electrode manufacturing processes rely heavily on polymer binders that often contain environmentally harmful substances such as polyvinylidene fluoride (PVDF), which requires toxic solvents like N-methyl-2-pyrrolidone (NMP) during processing. The elimination of these components in binder-free electrodes substantially reduces the environmental footprint of battery production by decreasing hazardous waste generation and lowering the emission of volatile organic compounds.

Energy consumption during electrode manufacturing presents another critical environmental consideration. Conventional electrode production involves energy-intensive mixing, coating, and drying processes. Binder-free approaches can potentially reduce energy requirements by simplifying manufacturing steps and eliminating the need for extended drying periods. This energy reduction translates directly to lower carbon emissions associated with battery production, contributing to climate change mitigation efforts.

From a life-cycle perspective, binder-free electrodes offer enhanced recyclability compared to conventional counterparts. The absence of polymer binders facilitates more efficient material recovery at end-of-life, enabling higher-quality recycled materials and reducing the demand for virgin resource extraction. This improved recyclability aligns with circular economy principles and addresses growing concerns about critical material scarcity in battery supply chains.

Water consumption represents another significant environmental factor in electrode manufacturing. Traditional processes often require substantial water usage for slurry preparation and equipment cleaning. Binder-free technologies can potentially reduce water requirements, addressing water scarcity concerns in regions where battery manufacturing is concentrated.

The sustainability benefits extend to operational performance as well. Binder-free electrodes typically demonstrate superior electrical conductivity and reduced internal resistance, potentially extending battery lifespan and improving energy efficiency during use. This longevity reduces the frequency of battery replacement and associated environmental impacts from manufacturing replacement units.

Despite these advantages, comprehensive life-cycle assessment (LCA) studies comparing binder-free and conventional electrode technologies remain limited. More robust environmental impact data is needed to quantify benefits across different manufacturing scales and battery chemistries. Additionally, the environmental implications of alternative manufacturing methods for binder-free electrodes, such as increased energy requirements for certain deposition techniques, require further investigation to ensure that environmental benefits are not offset by impacts elsewhere in the production process.

Energy consumption during electrode manufacturing presents another critical environmental consideration. Conventional electrode production involves energy-intensive mixing, coating, and drying processes. Binder-free approaches can potentially reduce energy requirements by simplifying manufacturing steps and eliminating the need for extended drying periods. This energy reduction translates directly to lower carbon emissions associated with battery production, contributing to climate change mitigation efforts.

From a life-cycle perspective, binder-free electrodes offer enhanced recyclability compared to conventional counterparts. The absence of polymer binders facilitates more efficient material recovery at end-of-life, enabling higher-quality recycled materials and reducing the demand for virgin resource extraction. This improved recyclability aligns with circular economy principles and addresses growing concerns about critical material scarcity in battery supply chains.

Water consumption represents another significant environmental factor in electrode manufacturing. Traditional processes often require substantial water usage for slurry preparation and equipment cleaning. Binder-free technologies can potentially reduce water requirements, addressing water scarcity concerns in regions where battery manufacturing is concentrated.

The sustainability benefits extend to operational performance as well. Binder-free electrodes typically demonstrate superior electrical conductivity and reduced internal resistance, potentially extending battery lifespan and improving energy efficiency during use. This longevity reduces the frequency of battery replacement and associated environmental impacts from manufacturing replacement units.

Despite these advantages, comprehensive life-cycle assessment (LCA) studies comparing binder-free and conventional electrode technologies remain limited. More robust environmental impact data is needed to quantify benefits across different manufacturing scales and battery chemistries. Additionally, the environmental implications of alternative manufacturing methods for binder-free electrodes, such as increased energy requirements for certain deposition techniques, require further investigation to ensure that environmental benefits are not offset by impacts elsewhere in the production process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!