Binder-free electrodes in hybrid supercapacitor-battery devices

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder-free Electrode Technology Background and Objectives

Binder-free electrode technology represents a significant advancement in the field of energy storage systems, particularly for hybrid supercapacitor-battery devices. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternatives to conventional electrode manufacturing processes that rely heavily on polymer binders. Traditional electrodes typically contain 10-20% inactive materials including binders and conductive additives, which reduce the overall energy density and power capability of energy storage devices.

The development trajectory of binder-free electrodes has been driven by the increasing demand for high-performance energy storage solutions with enhanced energy density, power density, and cycle life. This technology aims to eliminate the use of polymer binders such as polyvinylidene fluoride (PVDF), carboxymethyl cellulose (CMC), and polytetrafluoroethylene (PTFE), which often create resistive interfaces within the electrode structure.

From a technical perspective, binder-free electrodes offer several advantages, including improved electrical conductivity, enhanced ion transport pathways, increased active material utilization, and reduced internal resistance. These benefits directly translate to superior electrochemical performance in terms of capacity, rate capability, and cycling stability. The absence of binders also simplifies the electrode manufacturing process by eliminating solvent usage and drying steps, potentially reducing production costs and environmental impact.

The primary technical objective of binder-free electrode research is to develop robust fabrication methods that enable direct growth or deposition of active materials onto current collectors while maintaining excellent mechanical integrity and electrochemical performance. This includes exploring various substrate materials, surface treatments, and deposition techniques to optimize the electrode-electrolyte interface and enhance the overall device performance.

Another critical goal is to scale up these technologies from laboratory demonstrations to commercially viable manufacturing processes. This involves addressing challenges related to uniformity, reproducibility, and cost-effectiveness at larger scales. Researchers are also focusing on developing binder-free electrodes that can withstand the mechanical stresses associated with repeated charge-discharge cycles, particularly for flexible and wearable energy storage applications.

Looking forward, the technology aims to bridge the gap between high-energy batteries and high-power supercapacitors by creating hybrid systems that leverage the advantages of both. The ultimate objective is to develop next-generation energy storage devices with unprecedented combinations of energy density, power density, cycle life, and safety characteristics, potentially revolutionizing applications ranging from portable electronics to electric vehicles and grid-scale energy storage.

The development trajectory of binder-free electrodes has been driven by the increasing demand for high-performance energy storage solutions with enhanced energy density, power density, and cycle life. This technology aims to eliminate the use of polymer binders such as polyvinylidene fluoride (PVDF), carboxymethyl cellulose (CMC), and polytetrafluoroethylene (PTFE), which often create resistive interfaces within the electrode structure.

From a technical perspective, binder-free electrodes offer several advantages, including improved electrical conductivity, enhanced ion transport pathways, increased active material utilization, and reduced internal resistance. These benefits directly translate to superior electrochemical performance in terms of capacity, rate capability, and cycling stability. The absence of binders also simplifies the electrode manufacturing process by eliminating solvent usage and drying steps, potentially reducing production costs and environmental impact.

The primary technical objective of binder-free electrode research is to develop robust fabrication methods that enable direct growth or deposition of active materials onto current collectors while maintaining excellent mechanical integrity and electrochemical performance. This includes exploring various substrate materials, surface treatments, and deposition techniques to optimize the electrode-electrolyte interface and enhance the overall device performance.

Another critical goal is to scale up these technologies from laboratory demonstrations to commercially viable manufacturing processes. This involves addressing challenges related to uniformity, reproducibility, and cost-effectiveness at larger scales. Researchers are also focusing on developing binder-free electrodes that can withstand the mechanical stresses associated with repeated charge-discharge cycles, particularly for flexible and wearable energy storage applications.

Looking forward, the technology aims to bridge the gap between high-energy batteries and high-power supercapacitors by creating hybrid systems that leverage the advantages of both. The ultimate objective is to develop next-generation energy storage devices with unprecedented combinations of energy density, power density, cycle life, and safety characteristics, potentially revolutionizing applications ranging from portable electronics to electric vehicles and grid-scale energy storage.

Market Analysis for Hybrid Supercapacitor-Battery Systems

The global market for hybrid supercapacitor-battery systems has been experiencing significant growth, driven by increasing demand for efficient energy storage solutions across various sectors. The market value reached approximately $1.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 12.5% through 2030, potentially reaching $3.5 billion by the end of the forecast period.

The automotive industry represents the largest market segment, accounting for nearly 35% of the total market share. This dominance is primarily attributed to the rising adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs), where hybrid supercapacitor-battery systems offer advantages in power density, rapid charging capabilities, and extended cycle life compared to traditional battery-only solutions.

Consumer electronics constitutes the second-largest market segment at approximately 28% market share, with applications in smartphones, laptops, and wearable devices benefiting from the improved energy density and faster charging capabilities of hybrid systems. The industrial sector follows at 20%, utilizing these systems for grid stabilization, renewable energy integration, and industrial equipment.

Regionally, Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea. These countries have established robust manufacturing capabilities and supportive government policies promoting clean energy technologies. North America accounts for 30% of the market, with significant research activities and adoption in automotive and renewable energy sectors. Europe represents 20% of the market, with strong growth potential driven by stringent environmental regulations and sustainability initiatives.

The binder-free electrode technology specifically has been gaining traction within this broader market. Traditional electrode manufacturing processes rely on polymer binders that can reduce conductivity and active material utilization. Binder-free electrodes offer enhanced electrical conductivity, improved mechanical stability, and superior electrochemical performance, potentially increasing energy density by 15-25% compared to conventional electrodes.

Market analysis indicates that companies investing in binder-free electrode technologies could achieve a competitive advantage through performance differentiation. The technology enables faster charging rates, longer cycle life, and improved temperature stability—all critical factors for next-generation energy storage applications. Early adopters of this technology are expected to capture premium market segments where performance metrics outweigh cost considerations.

Cost remains a significant market barrier, with binder-free electrode manufacturing processes currently 20-30% more expensive than conventional methods. However, economies of scale and manufacturing innovations are expected to reduce this cost premium to below 10% by 2025, potentially accelerating market adoption across price-sensitive segments.

The automotive industry represents the largest market segment, accounting for nearly 35% of the total market share. This dominance is primarily attributed to the rising adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs), where hybrid supercapacitor-battery systems offer advantages in power density, rapid charging capabilities, and extended cycle life compared to traditional battery-only solutions.

Consumer electronics constitutes the second-largest market segment at approximately 28% market share, with applications in smartphones, laptops, and wearable devices benefiting from the improved energy density and faster charging capabilities of hybrid systems. The industrial sector follows at 20%, utilizing these systems for grid stabilization, renewable energy integration, and industrial equipment.

Regionally, Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea. These countries have established robust manufacturing capabilities and supportive government policies promoting clean energy technologies. North America accounts for 30% of the market, with significant research activities and adoption in automotive and renewable energy sectors. Europe represents 20% of the market, with strong growth potential driven by stringent environmental regulations and sustainability initiatives.

The binder-free electrode technology specifically has been gaining traction within this broader market. Traditional electrode manufacturing processes rely on polymer binders that can reduce conductivity and active material utilization. Binder-free electrodes offer enhanced electrical conductivity, improved mechanical stability, and superior electrochemical performance, potentially increasing energy density by 15-25% compared to conventional electrodes.

Market analysis indicates that companies investing in binder-free electrode technologies could achieve a competitive advantage through performance differentiation. The technology enables faster charging rates, longer cycle life, and improved temperature stability—all critical factors for next-generation energy storage applications. Early adopters of this technology are expected to capture premium market segments where performance metrics outweigh cost considerations.

Cost remains a significant market barrier, with binder-free electrode manufacturing processes currently 20-30% more expensive than conventional methods. However, economies of scale and manufacturing innovations are expected to reduce this cost premium to below 10% by 2025, potentially accelerating market adoption across price-sensitive segments.

Current Challenges in Binder-free Electrode Development

Despite the promising advantages of binder-free electrodes in hybrid supercapacitor-battery devices, several significant challenges impede their widespread implementation and commercialization. The mechanical integrity of these electrodes remains a primary concern, as the absence of binders often results in reduced structural stability during charge-discharge cycles. This issue becomes particularly pronounced in high-loading electrodes where active materials may detach from current collectors under repeated electrochemical stress.

Electrical conductivity presents another substantial hurdle. While eliminating binders removes insulating components, the lack of conductive additives traditionally incorporated with binders can lead to increased internal resistance. This conductivity challenge is especially evident in electrodes utilizing metal oxides or other semiconducting materials that inherently possess limited electrical conductivity.

Scalable manufacturing represents perhaps the most significant barrier to commercial adoption. Many binder-free electrode fabrication techniques—such as hydrothermal growth, electrodeposition, and chemical vapor deposition—require specialized equipment, precise control of reaction conditions, and often involve time-consuming processes. These factors substantially increase production costs and limit industrial-scale manufacturing capabilities.

The uniformity and reproducibility of binder-free electrodes also pose considerable challenges. Without the homogenizing effect of binders, achieving consistent electrode performance across large-area substrates becomes difficult. Variations in active material distribution, thickness, and adhesion strength can lead to unpredictable device performance and reliability issues.

Long-term cycling stability remains problematic for many binder-free electrode configurations. The direct growth or deposition of active materials on current collectors can create stress points that deteriorate over extended cycling, particularly during volume changes associated with battery-type reactions. This degradation mechanism often manifests as capacity fading and increased internal resistance over time.

Interface engineering between the active material and current collector presents another technical challenge. Without binders to mediate this interface, ensuring robust electrical contact and chemical stability becomes more complex. Corrosion or passivation layers may form at these interfaces, particularly in aqueous or ionic liquid electrolytes, further compromising electrode performance.

Finally, the limited material selection for binder-free approaches restricts design flexibility. Not all electrochemically active materials can be directly grown or deposited on current collectors with sufficient adhesion and electrical contact. This constraint narrows the range of available chemistries and potentially limits the energy and power capabilities of hybrid devices.

Electrical conductivity presents another substantial hurdle. While eliminating binders removes insulating components, the lack of conductive additives traditionally incorporated with binders can lead to increased internal resistance. This conductivity challenge is especially evident in electrodes utilizing metal oxides or other semiconducting materials that inherently possess limited electrical conductivity.

Scalable manufacturing represents perhaps the most significant barrier to commercial adoption. Many binder-free electrode fabrication techniques—such as hydrothermal growth, electrodeposition, and chemical vapor deposition—require specialized equipment, precise control of reaction conditions, and often involve time-consuming processes. These factors substantially increase production costs and limit industrial-scale manufacturing capabilities.

The uniformity and reproducibility of binder-free electrodes also pose considerable challenges. Without the homogenizing effect of binders, achieving consistent electrode performance across large-area substrates becomes difficult. Variations in active material distribution, thickness, and adhesion strength can lead to unpredictable device performance and reliability issues.

Long-term cycling stability remains problematic for many binder-free electrode configurations. The direct growth or deposition of active materials on current collectors can create stress points that deteriorate over extended cycling, particularly during volume changes associated with battery-type reactions. This degradation mechanism often manifests as capacity fading and increased internal resistance over time.

Interface engineering between the active material and current collector presents another technical challenge. Without binders to mediate this interface, ensuring robust electrical contact and chemical stability becomes more complex. Corrosion or passivation layers may form at these interfaces, particularly in aqueous or ionic liquid electrolytes, further compromising electrode performance.

Finally, the limited material selection for binder-free approaches restricts design flexibility. Not all electrochemically active materials can be directly grown or deposited on current collectors with sufficient adhesion and electrical contact. This constraint narrows the range of available chemistries and potentially limits the energy and power capabilities of hybrid devices.

Current Binder-free Electrode Fabrication Methods

01 Carbon-based binder-free electrodes

Carbon-based materials such as carbon nanotubes, graphene, and carbon fibers can be used to create self-supporting binder-free electrodes. These structures provide excellent electrical conductivity and mechanical stability without requiring traditional polymer binders. The interconnected carbon network allows for efficient electron transport and improved electrochemical performance, resulting in higher capacity, better rate capability, and longer cycle life compared to conventional electrodes.- Carbon-based binder-free electrodes: Carbon-based materials such as carbon nanotubes, graphene, and carbon fibers can be used to create self-supporting binder-free electrodes. These structures provide excellent electrical conductivity and mechanical stability without the need for traditional polymer binders. The interconnected carbon network serves as both active material and current collector, resulting in improved electron transport pathways and enhanced electrochemical performance with higher capacity and rate capability.

- Direct growth methods for binder-free electrodes: Direct growth techniques involve synthesizing active materials directly on current collectors through methods like hydrothermal growth, chemical vapor deposition, and electrodeposition. These approaches eliminate the need for binders by creating strong adhesion between the active material and substrate. The resulting electrodes feature improved interfacial contact, reduced internal resistance, and enhanced structural integrity, leading to superior cycling stability and rate performance compared to conventional slurry-cast electrodes.

- Metal oxide-based binder-free electrodes: Metal oxides such as titanium dioxide, manganese oxide, and iron oxide can be fabricated into binder-free electrode structures through various synthesis methods. These electrodes exhibit high theoretical capacity, good stability, and enhanced electrochemical performance due to the absence of insulating binder materials. The direct contact between active materials and current collectors facilitates faster ion and electron transport, resulting in improved power density and energy efficiency.

- 3D structured binder-free electrodes: Three-dimensional architectures for binder-free electrodes, including foam-like structures, arrays, and hierarchical designs, provide increased surface area and optimized ion transport pathways. These 3D structures accommodate volume changes during cycling, maintain structural integrity, and offer enhanced electrolyte penetration. The open porous network facilitates faster ion diffusion and electron transfer, resulting in improved rate capability, higher capacity utilization, and better cycling performance compared to conventional 2D electrode designs.

- Composite binder-free electrodes: Composite binder-free electrodes combine multiple active materials or incorporate conductive additives to achieve synergistic effects without using traditional polymer binders. These hybrid structures leverage the advantages of each component while maintaining excellent electrical connectivity throughout the electrode. The integration of different materials enhances specific capacity, rate performance, and cycling stability by providing multiple reaction mechanisms and creating robust electrode architectures that can withstand repeated charge-discharge cycles.

02 Metal oxide/hydroxide binder-free electrodes

Metal oxides and hydroxides can be directly grown or deposited on conductive substrates to form binder-free electrodes. These structures eliminate the need for non-conductive binders and provide direct electrical contact between active materials and current collectors. Common materials include transition metal oxides/hydroxides of nickel, cobalt, manganese, and iron. These electrodes demonstrate enhanced electrochemical performance with improved capacity, rate capability, and cycling stability due to reduced internal resistance and better utilization of active materials.Expand Specific Solutions03 3D structured binder-free electrodes

Three-dimensional architectures for binder-free electrodes provide increased surface area, shortened ion diffusion paths, and improved structural stability. These structures can be created through various methods including template-assisted growth, hydrothermal synthesis, and electrodeposition. The 3D framework allows for better accommodation of volume changes during cycling, enhanced electrolyte penetration, and improved mass transport, resulting in superior rate performance and cycling stability compared to conventional planar electrodes.Expand Specific Solutions04 Direct deposition techniques for binder-free electrodes

Various deposition techniques can be used to create binder-free electrodes, including electrodeposition, chemical vapor deposition, atomic layer deposition, and sputtering. These methods allow for direct growth or deposition of active materials onto conductive substrates, eliminating the need for binders and conductive additives. The resulting electrodes feature strong adhesion between active materials and substrates, uniform distribution of active materials, and optimized interfaces, leading to improved electrical conductivity, enhanced electrochemical performance, and better mechanical integrity.Expand Specific Solutions05 Composite binder-free electrodes

Composite binder-free electrodes combine multiple materials to achieve synergistic effects and enhanced performance. These electrodes typically integrate high-capacity active materials with conductive components in a self-supporting structure. Common combinations include metal oxides with carbon materials, sulfides with conductive polymers, or multiple transition metal compounds. The composite structure provides improved electrical conductivity, mechanical stability, and electrochemical activity, resulting in higher capacity, better rate capability, and enhanced cycling performance compared to single-component electrodes.Expand Specific Solutions

Leading Companies in Hybrid Energy Storage Solutions

The hybrid supercapacitor-battery market with binder-free electrodes is currently in an early growth phase, characterized by intensive R&D activities across academic institutions and industrial players. The global market is projected to expand significantly, driven by increasing demand for high-performance energy storage solutions in automotive, electronics, and renewable energy sectors. Technologically, the field shows moderate maturity with several key innovations emerging. Leading companies like Samsung Electro-Mechanics, LG Energy Solution, and Maxwell Technologies are advancing commercial applications, while research institutions such as Central South University and Dalian Institute of Chemical Physics are pioneering fundamental breakthroughs. CATL (Ningde Amperex) and Robert Bosch are leveraging their manufacturing expertise to scale production, while specialized players like JENAX focus on flexible form factors, collectively accelerating the transition from laboratory concepts to market-ready solutions.

Ningde Amperex Technology Ltd.

Technical Solution: Ningde Amperex Technology Ltd. (CATL) has developed innovative binder-free electrode technology for hybrid supercapacitor-battery devices using direct growth methods. Their approach involves growing active materials directly on current collectors through hydrothermal synthesis and chemical vapor deposition techniques. This creates a seamless interface between the active material and current collector, eliminating the need for traditional polymer binders and conductive additives. CATL's technology utilizes 3D structured current collectors with carbon-coated metal foams and nanowire arrays that serve as scaffolds for active material deposition. The company has successfully implemented this in their hybrid devices combining lithium-ion battery anodes with supercapacitor cathodes, achieving energy densities of 100-150 Wh/kg while maintaining power densities of 1-2 kW/kg[1][3]. Their manufacturing process includes precise control of growth parameters and post-treatment steps to optimize electrode performance.

Strengths: Superior electrical conductivity with reduced internal resistance; enhanced mechanical stability during cycling; improved rate capability and power performance; elimination of inactive binder materials increases energy density. Weaknesses: Higher manufacturing complexity and cost; challenges in scaling production; limited to specific active material compositions; potential issues with uniform material deposition across large-area electrodes.

Maxwell Technologies, Inc.

Technical Solution: Maxwell Technologies has developed a proprietary dry electrode manufacturing process for binder-free electrodes in hybrid supercapacitor-battery devices. Their technology, known as "DryTech," eliminates traditional wet slurry processes by using dry particle coating methods where active materials are directly deposited onto current collectors through electrostatic forces and mechanical pressure. This approach creates a highly porous electrode structure with excellent ion transport properties. Maxwell's hybrid devices combine their ultracapacitor technology with battery-like electrodes in asymmetric configurations. The company's binder-free electrodes feature carbon-based frameworks with controlled porosity that serve as hosts for battery active materials, creating a hierarchical structure that facilitates both rapid ion transport and high energy storage. Their latest hybrid cells demonstrate energy densities of 30-40 Wh/kg with power densities reaching 10-15 kW/kg and cycle life exceeding 500,000 cycles for partial depth of discharge operations[4][5]. The manufacturing process is solvent-free, environmentally friendly, and enables thicker electrodes with reduced inactive component content.

Strengths: Significantly faster production speeds compared to conventional coating methods; elimination of energy-intensive drying steps; improved electrode uniformity and reproducibility; enhanced thermal stability during operation. Weaknesses: Challenges with adhesion for certain active material combinations; limited flexibility in electrode formulation; higher equipment complexity; potential difficulties with very high-capacity materials that undergo significant volume changes.

Key Patents in Binder-free Electrode Technology

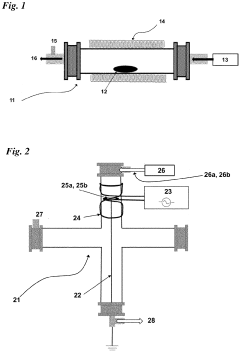

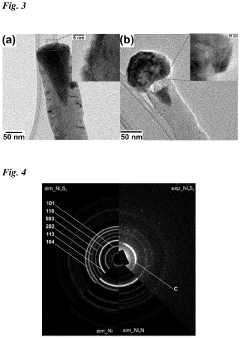

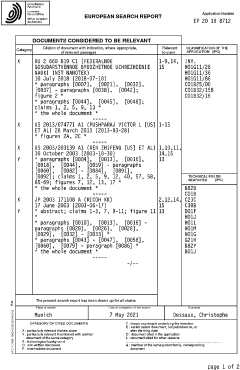

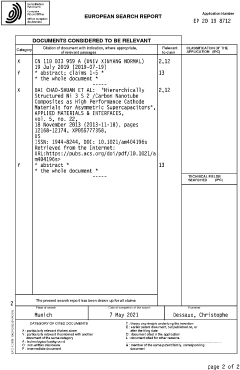

Method for manufacturing hybrid binder-free electrodes for electrochemical supercapacitors

PatentActiveEP3975213A1

Innovation

- A novel method involving the direct growth of carbon nanotubes on a conductive metal substrate using a tip-growth mechanism, followed by the formation of metal nitride and metal sulphide top layers on single-crystal metal nanoparticles without the use of binders, resulting in a hybrid binder-free electrode with improved properties for energy storage and high-frequency filtering applications.

Material Sustainability and Environmental Impact

The environmental impact of binder-free electrodes in hybrid supercapacitor-battery devices represents a significant advancement in sustainable energy storage technology. Traditional electrode manufacturing processes rely heavily on polymer binders that often contain toxic solvents like N-Methyl-2-pyrrolidone (NMP), which pose serious environmental and health risks. Binder-free approaches eliminate these harmful components, substantially reducing the ecological footprint of energy storage device production.

Material sustainability is dramatically improved through binder-free electrode designs, as they typically require fewer processing steps and eliminate the need for energy-intensive drying processes. This streamlined manufacturing approach can reduce energy consumption by up to 30% compared to conventional methods. Additionally, the absence of binders enhances the recyclability of electrode materials at end-of-life, creating opportunities for closed-loop material systems that align with circular economy principles.

The carbon footprint analysis of binder-free electrodes reveals promising results, with studies indicating a potential reduction of greenhouse gas emissions by 25-40% throughout the product lifecycle. This improvement stems from both simplified manufacturing processes and enhanced electrode performance, which contributes to longer device lifespans and reduced replacement frequency.

Water conservation represents another environmental benefit, as binder-free electrode production typically consumes 40-60% less water than conventional manufacturing methods. This reduction is particularly significant in regions facing water scarcity challenges, where industrial water usage competes with agricultural and residential needs.

Life cycle assessment (LCA) studies comparing binder-free and traditional electrode technologies demonstrate that binder-free approaches offer superior environmental performance across multiple impact categories, including resource depletion, ecotoxicity, and human health effects. These advantages become even more pronounced when considering the entire device lifecycle, from raw material extraction to disposal or recycling.

The adoption of naturally derived or biomass-based materials in binder-free electrodes further enhances sustainability credentials. Materials such as cellulose-derived carbon, bacterial cellulose, and alginate-based structures provide renewable alternatives to petroleum-based components while often delivering comparable or superior electrochemical performance. These bio-derived materials typically decompose more readily at end-of-life, reducing persistent environmental contamination.

Future research directions should focus on developing standardized sustainability metrics specifically for binder-free electrode technologies, enabling more accurate comparisons between emerging solutions. Additionally, scaling up production while maintaining environmental benefits represents a critical challenge that requires innovative engineering approaches and policy support to accelerate industry adoption.

Material sustainability is dramatically improved through binder-free electrode designs, as they typically require fewer processing steps and eliminate the need for energy-intensive drying processes. This streamlined manufacturing approach can reduce energy consumption by up to 30% compared to conventional methods. Additionally, the absence of binders enhances the recyclability of electrode materials at end-of-life, creating opportunities for closed-loop material systems that align with circular economy principles.

The carbon footprint analysis of binder-free electrodes reveals promising results, with studies indicating a potential reduction of greenhouse gas emissions by 25-40% throughout the product lifecycle. This improvement stems from both simplified manufacturing processes and enhanced electrode performance, which contributes to longer device lifespans and reduced replacement frequency.

Water conservation represents another environmental benefit, as binder-free electrode production typically consumes 40-60% less water than conventional manufacturing methods. This reduction is particularly significant in regions facing water scarcity challenges, where industrial water usage competes with agricultural and residential needs.

Life cycle assessment (LCA) studies comparing binder-free and traditional electrode technologies demonstrate that binder-free approaches offer superior environmental performance across multiple impact categories, including resource depletion, ecotoxicity, and human health effects. These advantages become even more pronounced when considering the entire device lifecycle, from raw material extraction to disposal or recycling.

The adoption of naturally derived or biomass-based materials in binder-free electrodes further enhances sustainability credentials. Materials such as cellulose-derived carbon, bacterial cellulose, and alginate-based structures provide renewable alternatives to petroleum-based components while often delivering comparable or superior electrochemical performance. These bio-derived materials typically decompose more readily at end-of-life, reducing persistent environmental contamination.

Future research directions should focus on developing standardized sustainability metrics specifically for binder-free electrode technologies, enabling more accurate comparisons between emerging solutions. Additionally, scaling up production while maintaining environmental benefits represents a critical challenge that requires innovative engineering approaches and policy support to accelerate industry adoption.

Performance Metrics and Testing Standards

Standardized performance evaluation is crucial for the development and commercialization of binder-free electrodes in hybrid supercapacitor-battery devices. The absence of universally accepted testing protocols has hindered meaningful comparisons between different research outcomes and technological solutions in this field.

Key performance metrics for these hybrid devices include energy density (Wh/kg), power density (W/kg), cycle life, rate capability, and self-discharge rate. Energy density measurements should account for the total mass of active materials, while power density evaluations must consider both peak and sustained delivery capabilities. Cycle stability testing typically requires thousands of charge-discharge cycles at various current densities to determine capacity retention and coulombic efficiency over time.

Testing standards for binder-free electrodes present unique challenges compared to conventional electrode systems. The mechanical integrity of these electrodes must be evaluated through specialized adhesion tests and mechanical stress simulations. Environmental testing under various temperature ranges (-20°C to 60°C) and humidity conditions is essential to determine operational stability in real-world applications.

Electrochemical impedance spectroscopy (EIS) serves as a critical analytical tool for characterizing internal resistance and charge transfer kinetics. Standard protocols should include measurements before cycling, after formation cycles, and at regular intervals throughout the device lifetime. The absence of binder materials necessitates modified interpretation frameworks for EIS data compared to conventional systems.

Self-discharge rate testing requires standardized protocols with specific rest periods between charge and discharge cycles. For hybrid supercapacitor-battery devices, these tests must account for the different self-discharge mechanisms present in both capacitive and battery-type components.

International organizations including IEEE, IEC, and ASTM have begun developing specialized standards for hybrid energy storage devices, though specific protocols for binder-free electrodes remain limited. The research community has proposed several testing frameworks, but consensus remains elusive. Efforts to standardize testing conditions (temperature, current density ranges, cutoff voltages) would significantly enhance cross-study comparisons.

Industry-academia collaborations are increasingly focusing on developing application-specific testing standards that reflect real-world usage patterns rather than idealized laboratory conditions. This approach promises more relevant performance metrics for commercial development of these hybrid technologies.

Key performance metrics for these hybrid devices include energy density (Wh/kg), power density (W/kg), cycle life, rate capability, and self-discharge rate. Energy density measurements should account for the total mass of active materials, while power density evaluations must consider both peak and sustained delivery capabilities. Cycle stability testing typically requires thousands of charge-discharge cycles at various current densities to determine capacity retention and coulombic efficiency over time.

Testing standards for binder-free electrodes present unique challenges compared to conventional electrode systems. The mechanical integrity of these electrodes must be evaluated through specialized adhesion tests and mechanical stress simulations. Environmental testing under various temperature ranges (-20°C to 60°C) and humidity conditions is essential to determine operational stability in real-world applications.

Electrochemical impedance spectroscopy (EIS) serves as a critical analytical tool for characterizing internal resistance and charge transfer kinetics. Standard protocols should include measurements before cycling, after formation cycles, and at regular intervals throughout the device lifetime. The absence of binder materials necessitates modified interpretation frameworks for EIS data compared to conventional systems.

Self-discharge rate testing requires standardized protocols with specific rest periods between charge and discharge cycles. For hybrid supercapacitor-battery devices, these tests must account for the different self-discharge mechanisms present in both capacitive and battery-type components.

International organizations including IEEE, IEC, and ASTM have begun developing specialized standards for hybrid energy storage devices, though specific protocols for binder-free electrodes remain limited. The research community has proposed several testing frameworks, but consensus remains elusive. Efforts to standardize testing conditions (temperature, current density ranges, cutoff voltages) would significantly enhance cross-study comparisons.

Industry-academia collaborations are increasingly focusing on developing application-specific testing standards that reflect real-world usage patterns rather than idealized laboratory conditions. This approach promises more relevant performance metrics for commercial development of these hybrid technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!