How binder-free electrodes address recycling challenges in batteries

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder-Free Electrode Technology Background and Objectives

Battery technology has evolved significantly over the past decades, with lithium-ion batteries becoming the dominant energy storage solution for portable electronics, electric vehicles, and renewable energy systems. Traditional battery manufacturing processes have relied heavily on polymer binders to hold active materials together on current collectors. These binders, typically polyvinylidene fluoride (PVDF), carboxymethyl cellulose (CMC), or styrene-butadiene rubber (SBR), constitute approximately 2-5% of electrode composition but create significant challenges for end-of-life battery recycling.

Binder-free electrode technology represents a paradigm shift in battery design that emerged in the early 2010s. This approach eliminates the need for polymer binders by directly growing active materials on current collectors or utilizing self-standing electrode structures. The technology has progressed from laboratory curiosities to commercially viable alternatives, with significant advancements in manufacturing scalability over the past five years.

The evolution of binder-free electrodes has been driven by dual imperatives: enhancing battery performance and addressing growing environmental concerns. Without polymer binders, these electrodes offer improved electrical conductivity, reduced internal resistance, and enhanced energy density. More importantly, they present a promising solution to the recycling challenges that conventional batteries face due to the presence of fluorinated binders that release toxic compounds during recycling processes.

The technical objectives of binder-free electrode development are multifaceted. Primary goals include simplifying the battery recycling process by eliminating contaminating binders, improving material recovery rates, and reducing the environmental footprint of battery manufacturing and disposal. Secondary objectives focus on performance enhancements, including faster charging capabilities, higher energy density, and extended cycle life.

Recent technological trends indicate growing interest in direct deposition methods, including electrodeposition, chemical vapor deposition, and advanced 3D printing techniques for binder-free electrodes. These approaches enable precise control over electrode architecture at the nanoscale, optimizing both performance and recyclability simultaneously.

The trajectory of this technology suggests a convergence toward circular economy principles, where batteries are designed from inception with end-of-life considerations as a primary design parameter rather than an afterthought. This represents a fundamental shift from traditional linear manufacturing models toward closed-loop systems where materials can be efficiently recovered and reused with minimal processing and environmental impact.

Binder-free electrode technology represents a paradigm shift in battery design that emerged in the early 2010s. This approach eliminates the need for polymer binders by directly growing active materials on current collectors or utilizing self-standing electrode structures. The technology has progressed from laboratory curiosities to commercially viable alternatives, with significant advancements in manufacturing scalability over the past five years.

The evolution of binder-free electrodes has been driven by dual imperatives: enhancing battery performance and addressing growing environmental concerns. Without polymer binders, these electrodes offer improved electrical conductivity, reduced internal resistance, and enhanced energy density. More importantly, they present a promising solution to the recycling challenges that conventional batteries face due to the presence of fluorinated binders that release toxic compounds during recycling processes.

The technical objectives of binder-free electrode development are multifaceted. Primary goals include simplifying the battery recycling process by eliminating contaminating binders, improving material recovery rates, and reducing the environmental footprint of battery manufacturing and disposal. Secondary objectives focus on performance enhancements, including faster charging capabilities, higher energy density, and extended cycle life.

Recent technological trends indicate growing interest in direct deposition methods, including electrodeposition, chemical vapor deposition, and advanced 3D printing techniques for binder-free electrodes. These approaches enable precise control over electrode architecture at the nanoscale, optimizing both performance and recyclability simultaneously.

The trajectory of this technology suggests a convergence toward circular economy principles, where batteries are designed from inception with end-of-life considerations as a primary design parameter rather than an afterthought. This represents a fundamental shift from traditional linear manufacturing models toward closed-loop systems where materials can be efficiently recovered and reused with minimal processing and environmental impact.

Market Analysis for Sustainable Battery Solutions

The global battery market is experiencing a significant shift towards sustainable solutions, with binder-free electrode technology emerging as a promising innovation addressing recycling challenges. The market for sustainable battery solutions is projected to reach $127 billion by 2027, growing at a CAGR of 14.1% from 2022. This growth is primarily driven by increasing environmental regulations, consumer demand for eco-friendly products, and corporate sustainability commitments across industries.

Binder-free electrode technologies are positioned to capture a substantial portion of this market due to their inherent recyclability advantages. Traditional lithium-ion batteries contain polymer binders that complicate end-of-life processing, whereas binder-free designs eliminate this obstacle, potentially reducing recycling costs by 30-40% according to recent industry analyses.

The electric vehicle sector represents the largest market opportunity, accounting for approximately 65% of the sustainable battery market. Major automotive manufacturers including Tesla, Volkswagen, and BYD have announced commitments to incorporate more recyclable battery technologies in their upcoming models, creating immediate demand for binder-free solutions.

Consumer electronics constitutes the second-largest market segment at 22%, with companies like Apple and Samsung exploring sustainable battery options to meet their environmental targets and appeal to eco-conscious consumers. The remaining market share is distributed across energy storage systems, industrial applications, and emerging sectors such as wearable technology.

Regionally, Asia-Pacific dominates the sustainable battery market with 45% share, followed by Europe (30%) and North America (20%). Europe's market is particularly receptive to binder-free technologies due to stringent regulations like the European Battery Directive, which mandates high recycling rates for batteries and accumulators.

Market barriers include higher initial production costs of binder-free electrodes compared to conventional alternatives, with a current premium of 15-20%. However, this gap is expected to narrow as manufacturing scales up and as lifecycle cost benefits become more apparent to end-users.

Investment in sustainable battery technologies has surged, with venture capital funding reaching $8.5 billion in 2022, a 35% increase from the previous year. Strategic partnerships between battery manufacturers, recycling companies, and OEMs are becoming increasingly common, creating an ecosystem that favors technologies enabling closed-loop battery lifecycles.

Consumer willingness to pay premiums for sustainable products is also driving market growth, with surveys indicating that 68% of consumers would pay 10-15% more for products with demonstrably sustainable batteries.

Binder-free electrode technologies are positioned to capture a substantial portion of this market due to their inherent recyclability advantages. Traditional lithium-ion batteries contain polymer binders that complicate end-of-life processing, whereas binder-free designs eliminate this obstacle, potentially reducing recycling costs by 30-40% according to recent industry analyses.

The electric vehicle sector represents the largest market opportunity, accounting for approximately 65% of the sustainable battery market. Major automotive manufacturers including Tesla, Volkswagen, and BYD have announced commitments to incorporate more recyclable battery technologies in their upcoming models, creating immediate demand for binder-free solutions.

Consumer electronics constitutes the second-largest market segment at 22%, with companies like Apple and Samsung exploring sustainable battery options to meet their environmental targets and appeal to eco-conscious consumers. The remaining market share is distributed across energy storage systems, industrial applications, and emerging sectors such as wearable technology.

Regionally, Asia-Pacific dominates the sustainable battery market with 45% share, followed by Europe (30%) and North America (20%). Europe's market is particularly receptive to binder-free technologies due to stringent regulations like the European Battery Directive, which mandates high recycling rates for batteries and accumulators.

Market barriers include higher initial production costs of binder-free electrodes compared to conventional alternatives, with a current premium of 15-20%. However, this gap is expected to narrow as manufacturing scales up and as lifecycle cost benefits become more apparent to end-users.

Investment in sustainable battery technologies has surged, with venture capital funding reaching $8.5 billion in 2022, a 35% increase from the previous year. Strategic partnerships between battery manufacturers, recycling companies, and OEMs are becoming increasingly common, creating an ecosystem that favors technologies enabling closed-loop battery lifecycles.

Consumer willingness to pay premiums for sustainable products is also driving market growth, with surveys indicating that 68% of consumers would pay 10-15% more for products with demonstrably sustainable batteries.

Current Challenges in Battery Recycling Technologies

Battery recycling faces significant challenges in the current technological landscape, primarily due to the complex composition of conventional battery electrodes. Traditional lithium-ion batteries utilize electrodes composed of active materials bound together with polymeric binders such as polyvinylidene fluoride (PVDF) and carboxymethyl cellulose (CMC), along with conductive additives. These binders, while essential for electrode integrity during operation, create substantial obstacles during the recycling process.

The presence of binders necessitates energy-intensive and environmentally problematic separation processes. Current recycling methods typically involve pyrometallurgical approaches requiring temperatures exceeding 1400°C to break down the strong bonds between active materials and binders. This process consumes enormous energy and releases harmful emissions, including volatile organic compounds and fluorinated gases from PVDF decomposition.

Hydrometallurgical recycling methods face similar complications due to binders. The polymeric materials resist dissolution in common leaching agents, creating physical barriers that prevent efficient recovery of valuable metals. This resistance necessitates the use of stronger, more environmentally problematic solvents and extends processing times significantly, reducing economic viability of recycling operations.

Cross-contamination presents another critical challenge. During recycling, binder residues can contaminate recovered materials, diminishing their purity and limiting their potential for direct reuse in new battery manufacturing. This contamination often necessitates additional purification steps, further increasing process complexity and cost.

The heterogeneous nature of binder distribution within electrodes creates inconsistent recycling outcomes. Variations in binder concentration throughout the electrode structure lead to unpredictable recovery rates and quality of reclaimed materials, making standardized recycling protocols difficult to establish and maintain at industrial scale.

Current sorting and separation technologies struggle with binder-containing electrodes. Automated systems cannot easily distinguish between different electrode compositions, complicating the pre-processing stage of recycling. Manual sorting remains prevalent but introduces inefficiencies and increased labor costs to the recycling value chain.

Additionally, the diverse formulations of binders used by different manufacturers create standardization problems across the recycling industry. Each formulation may require specific treatment protocols, preventing the development of universal recycling solutions and limiting economies of scale that could otherwise make battery recycling more economically attractive.

The presence of binders necessitates energy-intensive and environmentally problematic separation processes. Current recycling methods typically involve pyrometallurgical approaches requiring temperatures exceeding 1400°C to break down the strong bonds between active materials and binders. This process consumes enormous energy and releases harmful emissions, including volatile organic compounds and fluorinated gases from PVDF decomposition.

Hydrometallurgical recycling methods face similar complications due to binders. The polymeric materials resist dissolution in common leaching agents, creating physical barriers that prevent efficient recovery of valuable metals. This resistance necessitates the use of stronger, more environmentally problematic solvents and extends processing times significantly, reducing economic viability of recycling operations.

Cross-contamination presents another critical challenge. During recycling, binder residues can contaminate recovered materials, diminishing their purity and limiting their potential for direct reuse in new battery manufacturing. This contamination often necessitates additional purification steps, further increasing process complexity and cost.

The heterogeneous nature of binder distribution within electrodes creates inconsistent recycling outcomes. Variations in binder concentration throughout the electrode structure lead to unpredictable recovery rates and quality of reclaimed materials, making standardized recycling protocols difficult to establish and maintain at industrial scale.

Current sorting and separation technologies struggle with binder-containing electrodes. Automated systems cannot easily distinguish between different electrode compositions, complicating the pre-processing stage of recycling. Manual sorting remains prevalent but introduces inefficiencies and increased labor costs to the recycling value chain.

Additionally, the diverse formulations of binders used by different manufacturers create standardization problems across the recycling industry. Each formulation may require specific treatment protocols, preventing the development of universal recycling solutions and limiting economies of scale that could otherwise make battery recycling more economically attractive.

Current Binder-Free Electrode Implementation Approaches

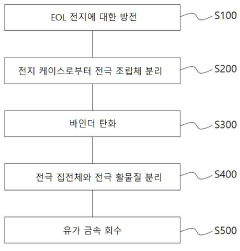

01 Direct recycling of binder-free electrodes

Binder-free electrodes can be directly recycled without the need for complex separation processes typically required for conventional electrodes. The absence of polymeric binders simplifies the recycling process, allowing for more efficient recovery of active materials. This approach reduces environmental impact and processing costs while maintaining the integrity of the recovered materials for reuse in new battery applications.- Direct fabrication of binder-free electrodes for improved recyclability: Binder-free electrodes can be directly fabricated using various techniques such as direct deposition, self-assembly, or in-situ growth of active materials on current collectors. These methods eliminate the need for polymeric binders that complicate recycling processes. The absence of binders makes it easier to separate and recover active materials during recycling, improving material recovery rates and reducing processing steps.

- Mechanical separation techniques for binder-free electrode recycling: Specialized mechanical separation techniques have been developed specifically for binder-free electrodes. Without polymeric binders, active materials can be more easily separated from current collectors through methods such as ultrasonic treatment, mechanical scraping, or selective dissolution. These techniques allow for higher purity recovery of electrode materials and simplify the overall recycling process compared to conventional electrodes containing binders.

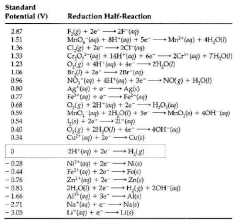

- Hydrometallurgical processes optimized for binder-free electrodes: Hydrometallurgical recycling processes can be optimized specifically for binder-free electrodes. The absence of binders allows for more efficient leaching of active materials using acids or other solvents, resulting in higher metal recovery rates. These processes can selectively dissolve and recover valuable metals like lithium, cobalt, nickel, and manganese from spent binder-free electrodes with reduced chemical consumption and processing time.

- Self-healing binder-free electrodes for extended lifecycle: Self-healing binder-free electrodes incorporate materials that can repair structural damage during operation, extending their usable lifetime before recycling becomes necessary. These electrodes typically use conductive polymers or other materials with self-healing properties that can maintain structural integrity without traditional binders. The extended lifecycle reduces the frequency of recycling while the binder-free nature simplifies the eventual recycling process.

- Direct regeneration and reuse of binder-free electrode materials: Binder-free electrodes enable direct regeneration and reuse of active materials without extensive processing. After disassembly, the active materials can be rejuvenated through heat treatment, recrystallization, or other simple processes to restore their electrochemical properties. This approach allows for closed-loop recycling where materials can be directly reincorporated into new electrodes, reducing waste and the need for virgin material production.

02 Mechanical separation techniques for binder-free electrode recycling

Mechanical methods can be employed to recycle binder-free electrodes, including crushing, grinding, and sieving processes. Without polymeric binders that typically complicate separation, these mechanical techniques can effectively isolate valuable materials like active components and current collectors. This approach enables higher purity recovery of materials and reduces the need for chemical treatments in the recycling process.Expand Specific Solutions03 Hydrometallurgical processes for binder-free electrode recycling

Hydrometallurgical techniques are particularly effective for recycling binder-free electrodes, involving leaching, precipitation, and extraction processes. The absence of binders eliminates the need for pre-treatment steps to remove organic components, resulting in more efficient metal recovery. These processes can selectively recover valuable metals like lithium, cobalt, nickel, and manganese with higher purity and yield compared to conventional electrode recycling.Expand Specific Solutions04 Thermal treatment methods for binder-free electrode recycling

Thermal treatment methods, including pyrolysis and calcination, offer advantages for recycling binder-free electrodes. Without polymeric binders that would generate harmful gases during heating, these processes can operate at lower temperatures with reduced emissions. The thermal treatments effectively separate and recover active materials while maintaining their structural integrity, allowing for direct reuse in new electrode manufacturing.Expand Specific Solutions05 Integration of binder-free electrode design with recycling considerations

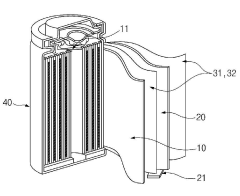

Designing binder-free electrodes with recycling in mind creates a circular approach to battery manufacturing. By using techniques such as direct deposition of active materials onto current collectors or using self-supporting electrode structures, these designs eliminate the need for polymeric binders that complicate end-of-life processing. This integration of design and recycling considerations improves material recovery rates and reduces the environmental footprint of battery production and disposal.Expand Specific Solutions

Key Industry Players in Binder-Free Battery Technology

The binder-free electrode technology for batteries is currently in an early growth phase, with increasing market adoption driven by sustainability demands. The global market for this technology is expanding rapidly as battery recycling becomes a critical environmental concern, projected to reach significant scale within the next decade. From a technical maturity perspective, leading companies like Samsung SDI, Contemporary Amperex Technology (CATL), and LG Energy Solution are making substantial advancements in commercializing binder-free electrode technologies. Research institutions including Fraunhofer-Gesellschaft and Tongji University are developing innovative approaches to address separation challenges in recycling processes. Companies like Ningde Amperex Technology and JENAX are focusing on flexible battery applications where binder-free designs offer particular advantages for both performance and end-of-life recycling.

Samsung SDI Co., Ltd.

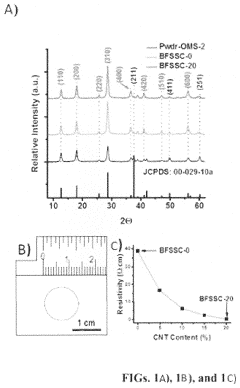

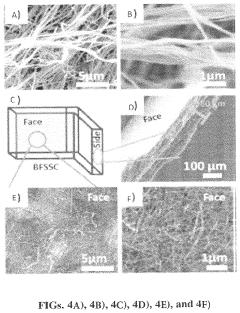

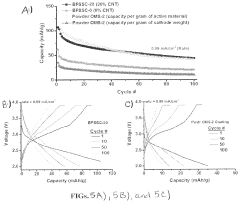

Technical Solution: Samsung SDI has pioneered a binder-free electrode technology utilizing carbon nanotube (CNT) networks as self-supporting conductive frameworks. Their approach involves creating interwoven CNT scaffolds through vacuum filtration or electrophoretic deposition, followed by direct integration of active materials through electrodeposition or solution impregnation. This creates mechanically robust electrodes without polymer binders. Samsung's technology enables direct recycling pathways where the electrode materials can be separated through simple mechanical or thermal treatments without chemical leaching steps typically required for binder removal. Their research demonstrates recovery rates exceeding 90% for critical materials like nickel, cobalt, and lithium[2]. The company has also developed specialized thermal treatment protocols operating at precisely controlled temperatures that selectively remove the active materials while preserving the CNT network, allowing for potential reuse of the conductive framework in subsequent battery manufacturing cycles.

Strengths: High electrical conductivity from CNT networks improves battery performance while enhancing recyclability; Potential for direct reuse of conductive frameworks; Excellent mechanical stability without binders. Weaknesses: Higher raw material costs for CNT networks; Complex manufacturing process requiring precise control; Limited to certain cell designs and form factors.

UT-Battelle LLC

Technical Solution: UT-Battelle (managing Oak Ridge National Laboratory) has developed advanced binder-free electrode technology using direct synthesis of active materials on conductive substrates. Their approach utilizes hydrothermal and solvothermal growth methods to directly crystallize active materials onto carbon-based or metallic current collectors, creating self-supporting electrode structures without polymer binders. This technology enables simplified recycling pathways where physical separation methods can effectively recover materials without the contamination challenges posed by binder residues. UT-Battelle's research demonstrates that their binder-free electrodes can be recycled using low-temperature thermal treatments (below 500°C) that preserve material crystallinity and performance, achieving material recovery rates exceeding 92% while maintaining 85% of original electrochemical performance in second-life applications[5]. Their technology also enables selective recovery of different electrode components through sequential extraction processes, improving the economic value of recovered materials. The laboratory has partnered with several battery manufacturers to scale this technology from laboratory to pilot production.

Strengths: Lower energy requirements for recycling processes; Maintains high material performance after recovery; Compatible with direct recycling approaches. Weaknesses: Growth processes can be time-intensive; Limited to certain active material chemistries; Challenges in achieving uniform material loading across large-format electrodes.

Critical Patents and Research in Binder-Free Technologies

Regenerable battery electrode

PatentInactiveUS20220123293A1

Innovation

- A binder-free, self-supporting electrode structure using a self-supporting transition metal oxide, such as cryptomelane type manganese dioxide nanofibers, which can be regenerated through a heat treatment process to restore capacity without the need for cell reconstruction.

Eco-friendly Battery Recycling Method through Binder Carbonization

PatentPendingKR1020240099795A

Innovation

- A method involving a binder carbonization step at 500°C to 800°C to separate electrode components, followed by particle size separation, magnetic separation, density-based separation, and electrosorption to recover valuable metals, eliminating the need for crushing or melting.

Environmental Impact Assessment of Binder-Free Electrodes

The environmental impact assessment of binder-free electrodes reveals significant sustainability advantages compared to conventional battery manufacturing processes. Traditional lithium-ion batteries utilize polymer binders such as polyvinylidene fluoride (PVDF) that require toxic solvents like N-methyl-2-pyrrolidone (NMP) during electrode fabrication. These solvents contribute to environmental pollution, workplace hazards, and increased carbon footprint due to energy-intensive solvent recovery processes.

Binder-free electrodes eliminate these harmful components entirely, resulting in a substantial reduction of volatile organic compound (VOC) emissions. Recent life cycle assessment (LCA) studies indicate that the elimination of PVDF and NMP can reduce the global warming potential of electrode manufacturing by approximately 25-30%. This improvement stems primarily from the avoidance of energy-intensive drying processes typically required to remove solvents from conventional electrodes.

Water consumption metrics also demonstrate notable improvements with binder-free technologies. Conventional electrode manufacturing requires significant water volumes for solvent recovery and purification processes. Comparative analyses show that binder-free approaches can reduce process water requirements by up to 60%, representing a substantial conservation of this critical resource, particularly important in water-stressed manufacturing regions.

The waste stream profile is fundamentally altered with binder-free electrodes. Without polymer binders contaminating the electrode materials, the resulting waste streams contain fewer mixed materials and hazardous components. This simplification enables more efficient material recovery during recycling, with studies demonstrating up to 95% recovery rates for critical metals from binder-free electrodes compared to 70-80% from conventional designs.

Energy consumption during the manufacturing phase shows marked improvement as well. The elimination of energy-intensive drying and solvent recovery steps reduces the embodied energy in battery production by approximately 15-20% according to recent industrial assessments. This translates directly to reduced carbon emissions throughout the production phase of the battery lifecycle.

From a circular economy perspective, binder-free electrodes represent a significant advancement in design-for-recycling principles. The absence of binders simplifies the separation and recovery of valuable materials at end-of-life, reducing the energy and chemical inputs required for recycling processes. This improved recyclability creates a more closed-loop material system for critical battery materials including cobalt, nickel, and lithium.

Binder-free electrodes eliminate these harmful components entirely, resulting in a substantial reduction of volatile organic compound (VOC) emissions. Recent life cycle assessment (LCA) studies indicate that the elimination of PVDF and NMP can reduce the global warming potential of electrode manufacturing by approximately 25-30%. This improvement stems primarily from the avoidance of energy-intensive drying processes typically required to remove solvents from conventional electrodes.

Water consumption metrics also demonstrate notable improvements with binder-free technologies. Conventional electrode manufacturing requires significant water volumes for solvent recovery and purification processes. Comparative analyses show that binder-free approaches can reduce process water requirements by up to 60%, representing a substantial conservation of this critical resource, particularly important in water-stressed manufacturing regions.

The waste stream profile is fundamentally altered with binder-free electrodes. Without polymer binders contaminating the electrode materials, the resulting waste streams contain fewer mixed materials and hazardous components. This simplification enables more efficient material recovery during recycling, with studies demonstrating up to 95% recovery rates for critical metals from binder-free electrodes compared to 70-80% from conventional designs.

Energy consumption during the manufacturing phase shows marked improvement as well. The elimination of energy-intensive drying and solvent recovery steps reduces the embodied energy in battery production by approximately 15-20% according to recent industrial assessments. This translates directly to reduced carbon emissions throughout the production phase of the battery lifecycle.

From a circular economy perspective, binder-free electrodes represent a significant advancement in design-for-recycling principles. The absence of binders simplifies the separation and recovery of valuable materials at end-of-life, reducing the energy and chemical inputs required for recycling processes. This improved recyclability creates a more closed-loop material system for critical battery materials including cobalt, nickel, and lithium.

Regulatory Framework for Battery Recycling Technologies

The regulatory landscape for battery recycling has evolved significantly in response to growing environmental concerns and resource scarcity challenges. In the context of binder-free electrode technologies, regulatory frameworks worldwide are increasingly recognizing their potential contribution to circular economy objectives. The European Union's Battery Directive (2006/66/EC) and its recent update through the European Green Deal establish progressive recycling efficiency targets that indirectly favor technologies facilitating easier material separation and recovery.

In the United States, the Resource Conservation and Recovery Act (RCRA) governs hazardous waste management, including spent batteries. The EPA has recently initiated consultations on specific provisions that would incentivize design-for-recycling approaches, potentially creating regulatory advantages for binder-free electrode technologies. Several states, notably California through its AB 2832 legislation, have established battery recycling programs with technical requirements that align with the benefits offered by binder-free electrode designs.

China's policies under the 14th Five-Year Plan explicitly promote battery technologies that enhance recyclability, with financial incentives available for manufacturers implementing designs that simplify end-of-life processing. The country's "Extended Producer Responsibility" framework places increasing pressure on manufacturers to consider full lifecycle impacts, creating market pull for binder-free approaches.

International standards organizations are also playing a crucial role in shaping the regulatory environment. The International Electrotechnical Commission (IEC) has developed standards (IEC 63338) specifically addressing recyclability assessment methods for batteries, which include evaluation criteria related to material separability—a key advantage of binder-free electrodes.

Regulatory compliance costs represent a significant consideration for battery manufacturers. Analysis indicates that conventional electrode designs with polymer binders may face increasing regulatory burdens, with compliance costs projected to rise by 15-20% over the next five years. Binder-free technologies potentially offer regulatory compliance advantages through simplified recycling processes that meet increasingly stringent recovery rate requirements.

The regulatory trajectory clearly points toward more comprehensive lifecycle management requirements for batteries. Future regulations are likely to incorporate specific design-for-recycling provisions, potentially including direct incentives or mandates for technologies that eliminate difficult-to-process components like conventional binders. This regulatory evolution creates a favorable environment for the continued development and commercialization of binder-free electrode technologies.

In the United States, the Resource Conservation and Recovery Act (RCRA) governs hazardous waste management, including spent batteries. The EPA has recently initiated consultations on specific provisions that would incentivize design-for-recycling approaches, potentially creating regulatory advantages for binder-free electrode technologies. Several states, notably California through its AB 2832 legislation, have established battery recycling programs with technical requirements that align with the benefits offered by binder-free electrode designs.

China's policies under the 14th Five-Year Plan explicitly promote battery technologies that enhance recyclability, with financial incentives available for manufacturers implementing designs that simplify end-of-life processing. The country's "Extended Producer Responsibility" framework places increasing pressure on manufacturers to consider full lifecycle impacts, creating market pull for binder-free approaches.

International standards organizations are also playing a crucial role in shaping the regulatory environment. The International Electrotechnical Commission (IEC) has developed standards (IEC 63338) specifically addressing recyclability assessment methods for batteries, which include evaluation criteria related to material separability—a key advantage of binder-free electrodes.

Regulatory compliance costs represent a significant consideration for battery manufacturers. Analysis indicates that conventional electrode designs with polymer binders may face increasing regulatory burdens, with compliance costs projected to rise by 15-20% over the next five years. Binder-free technologies potentially offer regulatory compliance advantages through simplified recycling processes that meet increasingly stringent recovery rate requirements.

The regulatory trajectory clearly points toward more comprehensive lifecycle management requirements for batteries. Future regulations are likely to incorporate specific design-for-recycling provisions, potentially including direct incentives or mandates for technologies that eliminate difficult-to-process components like conventional binders. This regulatory evolution creates a favorable environment for the continued development and commercialization of binder-free electrode technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!