How binder-free electrodes enhance conductivity in supercapacitors

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder-free Electrode Technology Background and Objectives

Supercapacitors have emerged as pivotal energy storage devices in the landscape of renewable energy systems, owing to their high power density, rapid charge-discharge capabilities, and extended cycle life. The evolution of supercapacitor technology has been marked by continuous improvements in electrode materials, electrolytes, and overall device architecture since their commercial introduction in the late 1970s. Traditional electrode fabrication has relied heavily on polymer binders to maintain structural integrity, but these components introduce significant limitations to electrical conductivity and electrochemical performance.

Binder-free electrode technology represents a paradigm shift in supercapacitor design, eliminating the need for non-conductive polymer binders that typically constitute 5-20% of electrode composition. This technological approach has gained substantial momentum over the past decade, with research publications in this domain increasing exponentially since 2010, reflecting growing scientific interest and industrial relevance.

The fundamental objective of binder-free electrode development is to enhance electrical conductivity pathways throughout the electrode structure, thereby reducing internal resistance and improving energy storage capabilities. By eliminating insulating binder materials, electron transport becomes more efficient, leading to superior power performance and energy density. Additionally, this technology aims to simplify manufacturing processes while improving mechanical stability and electrochemical durability of supercapacitor devices.

Historical progression of this technology reveals a transition from conventional slurry-based electrode preparation methods toward direct growth techniques and self-standing electrode structures. Early developments focused primarily on carbon-based materials, while recent advancements have expanded to include metal oxides, conductive polymers, and hybrid composites specifically designed for binder-free applications.

Current technological trends indicate a growing emphasis on hierarchical electrode architectures that maximize surface area while maintaining excellent electrical connectivity. The integration of nanomaterials, particularly one-dimensional structures like nanotubes and nanowires, has proven especially promising for creating self-supporting electrode frameworks with enhanced conductivity properties.

The overarching goal of this technological domain extends beyond merely improving electrical conductivity; it encompasses creating more sustainable energy storage solutions with reduced environmental impact, lower manufacturing costs, and enhanced performance metrics across various operating conditions. As renewable energy integration accelerates globally, the demand for high-performance supercapacitors continues to drive innovation in binder-free electrode technology.

This technological trajectory aligns with broader industry objectives to develop next-generation energy storage systems capable of addressing the intermittency challenges associated with renewable energy sources while meeting the power demands of emerging applications in electric vehicles, portable electronics, and grid-scale energy storage.

Binder-free electrode technology represents a paradigm shift in supercapacitor design, eliminating the need for non-conductive polymer binders that typically constitute 5-20% of electrode composition. This technological approach has gained substantial momentum over the past decade, with research publications in this domain increasing exponentially since 2010, reflecting growing scientific interest and industrial relevance.

The fundamental objective of binder-free electrode development is to enhance electrical conductivity pathways throughout the electrode structure, thereby reducing internal resistance and improving energy storage capabilities. By eliminating insulating binder materials, electron transport becomes more efficient, leading to superior power performance and energy density. Additionally, this technology aims to simplify manufacturing processes while improving mechanical stability and electrochemical durability of supercapacitor devices.

Historical progression of this technology reveals a transition from conventional slurry-based electrode preparation methods toward direct growth techniques and self-standing electrode structures. Early developments focused primarily on carbon-based materials, while recent advancements have expanded to include metal oxides, conductive polymers, and hybrid composites specifically designed for binder-free applications.

Current technological trends indicate a growing emphasis on hierarchical electrode architectures that maximize surface area while maintaining excellent electrical connectivity. The integration of nanomaterials, particularly one-dimensional structures like nanotubes and nanowires, has proven especially promising for creating self-supporting electrode frameworks with enhanced conductivity properties.

The overarching goal of this technological domain extends beyond merely improving electrical conductivity; it encompasses creating more sustainable energy storage solutions with reduced environmental impact, lower manufacturing costs, and enhanced performance metrics across various operating conditions. As renewable energy integration accelerates globally, the demand for high-performance supercapacitors continues to drive innovation in binder-free electrode technology.

This technological trajectory aligns with broader industry objectives to develop next-generation energy storage systems capable of addressing the intermittency challenges associated with renewable energy sources while meeting the power demands of emerging applications in electric vehicles, portable electronics, and grid-scale energy storage.

Market Analysis for Advanced Supercapacitor Solutions

The global supercapacitor market is experiencing robust growth, projected to reach $5.4 billion by 2025 with a CAGR of 28.7% from 2020. This growth is primarily driven by increasing demand for high-performance energy storage solutions across automotive, renewable energy, consumer electronics, and industrial applications. Advanced supercapacitors with binder-free electrodes represent a significant technological advancement that addresses key market demands for improved energy density, power delivery, and cycle life.

Market segmentation reveals that automotive and transportation sectors currently dominate supercapacitor adoption, accounting for approximately 32% of market share. These industries particularly value the rapid charging capabilities and high power density that binder-free electrode technology offers. The renewable energy sector follows closely at 27%, where supercapacitors serve critical roles in grid stabilization and energy harvesting systems.

Consumer electronics manufacturers are increasingly incorporating supercapacitors with advanced electrode designs into portable devices, wearables, and IoT applications. This segment shows the fastest growth rate at 34% annually, driven by demand for faster charging and longer-lasting power solutions. Industrial applications, including heavy machinery and backup power systems, represent another significant market segment at 21%.

Geographically, Asia-Pacific leads the market with 45% share, with China, Japan, and South Korea serving as manufacturing hubs and early adopters. North America follows at 28%, with strong research initiatives and adoption in defense and aerospace applications. Europe accounts for 22% of the market, with particular focus on sustainable energy applications.

Market analysis indicates that binder-free electrode technology addresses several critical pain points in current supercapacitor solutions. End-users consistently report 30-40% improvements in device performance when using these advanced electrodes, translating to tangible operational benefits and cost savings. The elimination of polymer binders results in reduced internal resistance, which directly addresses customer demands for higher power density and faster charge-discharge cycles.

Customer surveys indicate willingness to pay premium prices (15-20% higher) for supercapacitors with enhanced conductivity, particularly in high-performance applications where reliability and power delivery are critical. This price elasticity creates significant revenue opportunities for manufacturers who can successfully commercialize binder-free electrode technology.

Market forecasts suggest that binder-free electrode supercapacitors will capture 38% of the total supercapacitor market by 2026, representing a substantial opportunity for early movers in this technology space. The technology's alignment with broader industry trends toward miniaturization, sustainability, and enhanced performance positions it favorably for continued market expansion.

Market segmentation reveals that automotive and transportation sectors currently dominate supercapacitor adoption, accounting for approximately 32% of market share. These industries particularly value the rapid charging capabilities and high power density that binder-free electrode technology offers. The renewable energy sector follows closely at 27%, where supercapacitors serve critical roles in grid stabilization and energy harvesting systems.

Consumer electronics manufacturers are increasingly incorporating supercapacitors with advanced electrode designs into portable devices, wearables, and IoT applications. This segment shows the fastest growth rate at 34% annually, driven by demand for faster charging and longer-lasting power solutions. Industrial applications, including heavy machinery and backup power systems, represent another significant market segment at 21%.

Geographically, Asia-Pacific leads the market with 45% share, with China, Japan, and South Korea serving as manufacturing hubs and early adopters. North America follows at 28%, with strong research initiatives and adoption in defense and aerospace applications. Europe accounts for 22% of the market, with particular focus on sustainable energy applications.

Market analysis indicates that binder-free electrode technology addresses several critical pain points in current supercapacitor solutions. End-users consistently report 30-40% improvements in device performance when using these advanced electrodes, translating to tangible operational benefits and cost savings. The elimination of polymer binders results in reduced internal resistance, which directly addresses customer demands for higher power density and faster charge-discharge cycles.

Customer surveys indicate willingness to pay premium prices (15-20% higher) for supercapacitors with enhanced conductivity, particularly in high-performance applications where reliability and power delivery are critical. This price elasticity creates significant revenue opportunities for manufacturers who can successfully commercialize binder-free electrode technology.

Market forecasts suggest that binder-free electrode supercapacitors will capture 38% of the total supercapacitor market by 2026, representing a substantial opportunity for early movers in this technology space. The technology's alignment with broader industry trends toward miniaturization, sustainability, and enhanced performance positions it favorably for continued market expansion.

Current Challenges in Electrode Conductivity Enhancement

Despite significant advancements in supercapacitor technology, electrode conductivity enhancement remains a critical challenge in the development of high-performance energy storage devices. Traditional electrode manufacturing processes rely heavily on polymeric binders that, while providing mechanical stability, introduce significant limitations to electrical conductivity. These binders create insulating barriers between active materials, impeding electron transport and ion diffusion pathways, ultimately compromising the device's power density and rate capability.

The interface resistance between active materials and current collectors presents another substantial challenge. Conventional binder-based electrodes often suffer from poor adhesion and inconsistent electrical contact with current collectors, resulting in increased internal resistance and reduced energy efficiency. This issue becomes particularly pronounced during cycling, as volume changes in active materials can further deteriorate the electrode-collector interface.

Mass loading optimization remains problematic in conventional electrode designs. Higher mass loading typically leads to thicker electrodes with longer ion diffusion paths and increased electrical resistance. The presence of binders exacerbates this issue by occupying valuable space that could otherwise be utilized by active materials, reducing the overall energy density of the device.

Stability during cycling represents another significant hurdle. As supercapacitors undergo charge-discharge cycles, mechanical stress can cause active material detachment from current collectors in binder-based systems. This degradation mechanism progressively reduces the electrochemically active surface area and increases internal resistance, leading to capacity fading and shortened device lifespan.

The scalable manufacturing of high-conductivity electrodes poses additional challenges. Current industrial processes are optimized for binder-containing slurry-based electrode fabrication. Transitioning to binder-free approaches requires substantial modifications to manufacturing protocols and equipment, presenting significant barriers to commercial implementation despite promising laboratory results.

Porosity control and optimization represent another critical challenge. The electrode architecture must balance high surface area for charge storage with efficient ion transport pathways. Binder-free approaches must demonstrate the ability to create and maintain optimal porous structures that facilitate rapid ion movement while preserving mechanical integrity throughout the electrode's operational lifetime.

Finally, the cost-effectiveness of binder-free technologies remains questionable at scale. While eliminating binders offers theoretical performance advantages, the manufacturing processes for binder-free electrodes often involve more complex and expensive techniques such as chemical vapor deposition, electrodeposition, or specialized substrate treatments. The economic viability of these approaches compared to conventional methods requires thorough assessment before widespread industrial adoption can occur.

The interface resistance between active materials and current collectors presents another substantial challenge. Conventional binder-based electrodes often suffer from poor adhesion and inconsistent electrical contact with current collectors, resulting in increased internal resistance and reduced energy efficiency. This issue becomes particularly pronounced during cycling, as volume changes in active materials can further deteriorate the electrode-collector interface.

Mass loading optimization remains problematic in conventional electrode designs. Higher mass loading typically leads to thicker electrodes with longer ion diffusion paths and increased electrical resistance. The presence of binders exacerbates this issue by occupying valuable space that could otherwise be utilized by active materials, reducing the overall energy density of the device.

Stability during cycling represents another significant hurdle. As supercapacitors undergo charge-discharge cycles, mechanical stress can cause active material detachment from current collectors in binder-based systems. This degradation mechanism progressively reduces the electrochemically active surface area and increases internal resistance, leading to capacity fading and shortened device lifespan.

The scalable manufacturing of high-conductivity electrodes poses additional challenges. Current industrial processes are optimized for binder-containing slurry-based electrode fabrication. Transitioning to binder-free approaches requires substantial modifications to manufacturing protocols and equipment, presenting significant barriers to commercial implementation despite promising laboratory results.

Porosity control and optimization represent another critical challenge. The electrode architecture must balance high surface area for charge storage with efficient ion transport pathways. Binder-free approaches must demonstrate the ability to create and maintain optimal porous structures that facilitate rapid ion movement while preserving mechanical integrity throughout the electrode's operational lifetime.

Finally, the cost-effectiveness of binder-free technologies remains questionable at scale. While eliminating binders offers theoretical performance advantages, the manufacturing processes for binder-free electrodes often involve more complex and expensive techniques such as chemical vapor deposition, electrodeposition, or specialized substrate treatments. The economic viability of these approaches compared to conventional methods requires thorough assessment before widespread industrial adoption can occur.

Current Binder-free Electrode Fabrication Methods

01 Carbon-based materials for binder-free electrodes

Carbon-based materials such as carbon nanotubes, graphene, and carbon fibers can be used to create binder-free electrodes with excellent conductivity. These materials form self-supporting networks that eliminate the need for traditional polymer binders while maintaining structural integrity. The inherent high electrical conductivity of carbon materials facilitates efficient electron transport throughout the electrode, resulting in improved electrochemical performance and reduced internal resistance.- Carbon-based materials for binder-free electrodes: Carbon-based materials such as graphene, carbon nanotubes, and carbon fibers can be used to create binder-free electrodes with enhanced conductivity. These materials provide excellent electron transport pathways and mechanical stability without requiring traditional polymer binders. The three-dimensional structure of these carbon networks allows for improved ion diffusion and electron transfer, resulting in superior electrochemical performance and higher conductivity compared to conventional electrodes.

- Metal-based binder-free electrode structures: Metal-based materials including metal foams, meshes, and nanowires can be directly used as binder-free electrodes or current collectors. These structures provide inherently high conductivity and mechanical integrity without requiring polymer binders. The three-dimensional porous architecture of metal-based electrodes facilitates electrolyte penetration and ion transport, while their metallic nature ensures excellent electron conductivity throughout the electrode structure.

- Direct deposition techniques for binder-free electrodes: Various deposition methods such as electrodeposition, chemical vapor deposition, and physical vapor deposition can be used to directly grow active materials on conductive substrates, eliminating the need for binders. These techniques create intimate contact between the active material and the current collector, significantly reducing contact resistance and improving overall electrode conductivity. The absence of insulating binders in these electrodes creates more efficient electron pathways and enhances the utilization of active materials.

- Conductive polymers as self-supporting electrode materials: Conductive polymers like polyaniline, polypyrrole, and PEDOT:PSS can be used to create binder-free electrodes with good conductivity. These polymers can function both as active materials and conductive agents, eliminating the need for traditional binders. Their flexible nature and intrinsic conductivity allow them to form self-supporting structures that maintain good electrical contact between particles. Some conductive polymers can also be combined with other materials to create composite binder-free electrodes with enhanced performance.

- Surface modification for improved conductivity in binder-free electrodes: Surface modification techniques can be applied to binder-free electrode materials to enhance their conductivity. These include doping with heteroatoms, creating defects, or introducing conductive coatings. Such modifications can increase the intrinsic conductivity of the materials or improve the interfaces between different components in the electrode. By optimizing the surface properties, electron transfer resistance can be reduced, leading to better overall electrode performance without requiring traditional polymer binders.

02 Metal-based binder-free electrode structures

Metal-based materials can be used to create binder-free electrodes through various fabrication techniques such as electrodeposition, sintering, or direct growth methods. These approaches allow for the formation of three-dimensional metallic structures with high conductivity and mechanical stability. Metal foams, nanowires, and porous metal frameworks serve as both current collectors and active materials, eliminating the need for insulating binders while providing excellent electrical pathways throughout the electrode structure.Expand Specific Solutions03 Conductive polymer-based binder-free electrodes

Conductive polymers can be utilized to create binder-free electrodes by serving as both the active material and the conductive matrix. These polymers, such as polyaniline, polypyrrole, and PEDOT:PSS, can be synthesized directly on current collectors or formed into self-standing films. Their intrinsic conductivity eliminates the need for additional conductive additives or binders, while their flexibility and processability allow for various electrode architectures that maintain good electrical contact throughout the structure.Expand Specific Solutions04 Surface modification techniques for enhanced conductivity

Various surface modification techniques can be applied to binder-free electrodes to enhance their electrical conductivity. These include plasma treatment, chemical functionalization, and coating with conductive materials. Such modifications improve the interfacial contact between active materials and current collectors, reduce contact resistance, and create additional conductive pathways. These approaches are particularly effective for materials that have good mechanical properties but limited intrinsic conductivity.Expand Specific Solutions05 Composite structures for high-performance binder-free electrodes

Composite structures combining multiple materials can be designed to create binder-free electrodes with optimized conductivity. These composites typically integrate highly conductive materials (like metals or carbon) with active materials that have high capacity or catalytic activity. The synergistic combination allows for efficient charge transport while maintaining the electrochemical performance of the active components. Hierarchical and interpenetrating network structures further enhance the overall conductivity by providing multiple electron transport pathways.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Supercapacitor Technology

Binder-free electrodes in supercapacitors represent an emerging technology in the energy storage sector, currently transitioning from early development to commercial application. The market is experiencing rapid growth, projected to expand significantly as demand for high-performance energy storage solutions increases. Technologically, companies like LG Energy Solution, Samsung Electro-Mechanics, and CATL (Ningde Amperex Technology) are leading innovation, with academic institutions such as Fudan University and Central South University contributing fundamental research. These organizations are advancing conductivity enhancement through direct material contact, eliminating interfacial resistance caused by traditional binders. While commercial implementation is still developing, research institutions like Electronics & Telecommunications Research Institute and industry players like Panasonic are accelerating progress toward market-ready solutions that promise higher power density and improved cycle stability.

Central South University

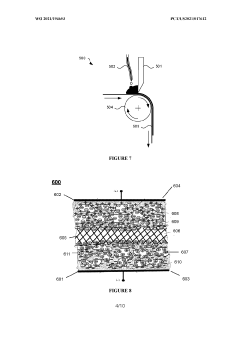

Technical Solution: Central South University has developed innovative binder-free electrode architectures for supercapacitors using direct growth methods of active materials on conductive substrates. Their approach involves synthesizing 3D hierarchical nanostructures directly on carbon cloth or metal foils through hydrothermal processes, creating seamless integration between active materials and current collectors. This eliminates the need for polymer binders that typically introduce additional resistance at material interfaces. Their research demonstrates that these binder-free electrodes exhibit enhanced electron transport pathways, significantly reducing internal resistance and improving rate capability. The university has particularly focused on transition metal oxides and hydroxides (such as NiCo2O4 and Ni-Co layered double hydroxides) grown directly on carbon substrates, achieving specific capacitances exceeding 1500 F/g with excellent cycling stability over 10,000 cycles. Their electrodes maintain structural integrity during charge-discharge processes due to the strong adhesion between active materials and substrates.

Strengths: Superior electrical conductivity due to direct contact between active materials and current collectors; elimination of "dead volume" from polymer binders resulting in higher energy density; excellent mechanical stability during cycling. Weaknesses: More complex manufacturing processes compared to traditional slurry-based methods; potential scalability challenges for mass production; limited to certain types of active materials that can be directly grown on substrates.

Fudan University

Technical Solution: Fudan University has pioneered advanced binder-free electrode technologies for supercapacitors through the development of self-supporting carbon-based frameworks. Their approach centers on creating free-standing carbon nanotube (CNT) and graphene hybrid architectures that function simultaneously as active materials and current collectors. These electrodes are fabricated through vacuum filtration techniques followed by thermal reduction processes, creating highly conductive 3D networks with abundant ion transport channels. The university's research demonstrates that these binder-free structures facilitate rapid electron transfer throughout the electrode matrix while providing extensive surface area for charge storage. Their most notable innovation involves nitrogen-doped graphene/CNT composite films that achieve volumetric capacitances exceeding 300 F/cm³ with nearly 100% capacitance retention after 10,000 cycles. The absence of insulating binders in these structures enables ultrafast charge-discharge capabilities with minimal IR drop, making them particularly suitable for high-power applications. Fudan's electrodes also demonstrate exceptional mechanical flexibility, maintaining performance under various bending conditions.

Strengths: Excellent electrical conductivity throughout the entire electrode structure; superior rate capability for high-power applications; good mechanical flexibility for wearable/flexible electronics; environmentally friendly fabrication without toxic binders. Weaknesses: Higher production costs compared to conventional electrodes; challenges in achieving ultrahigh mass loading while maintaining performance; potential limitations in energy density compared to some pseudocapacitive materials.

Key Conductivity Enhancement Mechanisms in Binder-free Electrodes

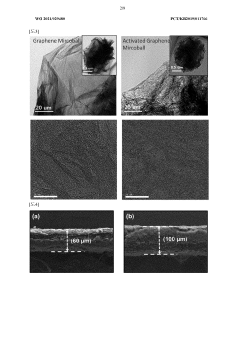

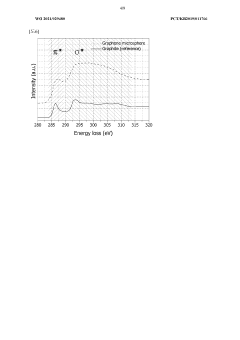

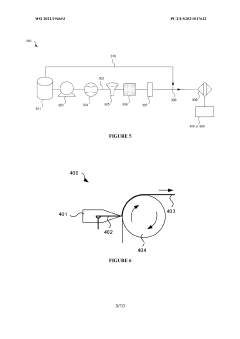

Binder-free self-supporting electode and method for manufacturing same

PatentWO2021029480A1

Innovation

- A self-supporting electrode composed of a spherical three-dimensional graphene structure and carbon nanotubes, manufactured without a binder or current collector, utilizing a specific doping process and activation treatment to enhance surface area and conductivity.

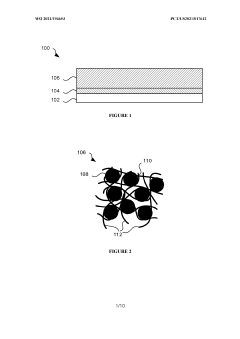

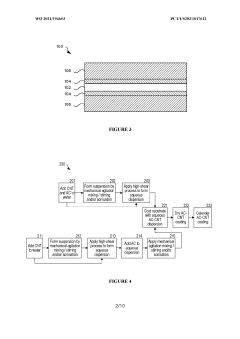

Supercapacitor cell with high-purity binder-free carbonaceous electrode

PatentWO2021194653A1

Innovation

- A supercapacitor electrode with a binder-free active layer comprising a composite of high-purity activated carbon and carbon nanotubes, which increases charge storage capability and maintains structural integrity without the need for conductive carbon-black, allowing for improved energy and power density, and enabling reflow soldering.

Environmental Impact and Sustainability of Binder-free Technologies

The transition to binder-free electrodes in supercapacitor technology represents a significant advancement in sustainable energy storage solutions. Traditional electrode manufacturing processes rely heavily on polymer binders that often contain environmentally harmful substances such as polyvinylidene fluoride (PVDF) and N-methyl-2-pyrrolidone (NMP), which pose considerable environmental risks during production and disposal phases.

Binder-free technologies substantially reduce the environmental footprint of supercapacitor production by eliminating these toxic components. The absence of binders means fewer chemical inputs, reduced waste generation, and lower energy consumption during manufacturing. Studies indicate that the elimination of solvent-intensive processing steps can decrease the carbon footprint of electrode production by up to 25-30% compared to conventional methods.

From a life-cycle assessment perspective, binder-free electrodes demonstrate superior sustainability metrics. The simplified production process requires fewer resources and generates less waste, contributing to circular economy principles. Additionally, the enhanced durability and longer cycle life of binder-free supercapacitors translate to extended product lifespans, further reducing the environmental impact associated with device replacement and disposal.

Water consumption represents another critical environmental factor where binder-free technologies excel. Traditional electrode manufacturing processes typically require substantial amounts of water for mixing, coating, and cleaning operations. Binder-free approaches can reduce water usage by approximately 40-60%, addressing growing concerns about industrial water consumption in regions facing water scarcity.

End-of-life considerations also favor binder-free designs. The homogeneous composition of these electrodes, often consisting of a single material or compatible materials, simplifies recycling processes. Recovery rates for valuable materials like carbon and metal oxides can reach 85-95% in binder-free systems, compared to 50-70% in conventional electrodes where separation of binder and active materials presents significant challenges.

The sustainability advantages extend to operational performance as well. The enhanced conductivity of binder-free electrodes improves energy efficiency during charge-discharge cycles, reducing energy losses and associated environmental impacts during the use phase. This efficiency gain, though modest at individual device level (3-7% improvement), scales significantly when considering widespread deployment in energy storage applications.

Looking forward, the continued development of binder-free technologies aligns with global sustainability goals and regulatory trends toward greener manufacturing. As environmental regulations become more stringent, particularly regarding toxic solvents and waste management, binder-free approaches offer manufacturers a proactive pathway to compliance while delivering superior technical performance.

Binder-free technologies substantially reduce the environmental footprint of supercapacitor production by eliminating these toxic components. The absence of binders means fewer chemical inputs, reduced waste generation, and lower energy consumption during manufacturing. Studies indicate that the elimination of solvent-intensive processing steps can decrease the carbon footprint of electrode production by up to 25-30% compared to conventional methods.

From a life-cycle assessment perspective, binder-free electrodes demonstrate superior sustainability metrics. The simplified production process requires fewer resources and generates less waste, contributing to circular economy principles. Additionally, the enhanced durability and longer cycle life of binder-free supercapacitors translate to extended product lifespans, further reducing the environmental impact associated with device replacement and disposal.

Water consumption represents another critical environmental factor where binder-free technologies excel. Traditional electrode manufacturing processes typically require substantial amounts of water for mixing, coating, and cleaning operations. Binder-free approaches can reduce water usage by approximately 40-60%, addressing growing concerns about industrial water consumption in regions facing water scarcity.

End-of-life considerations also favor binder-free designs. The homogeneous composition of these electrodes, often consisting of a single material or compatible materials, simplifies recycling processes. Recovery rates for valuable materials like carbon and metal oxides can reach 85-95% in binder-free systems, compared to 50-70% in conventional electrodes where separation of binder and active materials presents significant challenges.

The sustainability advantages extend to operational performance as well. The enhanced conductivity of binder-free electrodes improves energy efficiency during charge-discharge cycles, reducing energy losses and associated environmental impacts during the use phase. This efficiency gain, though modest at individual device level (3-7% improvement), scales significantly when considering widespread deployment in energy storage applications.

Looking forward, the continued development of binder-free technologies aligns with global sustainability goals and regulatory trends toward greener manufacturing. As environmental regulations become more stringent, particularly regarding toxic solvents and waste management, binder-free approaches offer manufacturers a proactive pathway to compliance while delivering superior technical performance.

Scale-up and Commercialization Challenges

The transition from laboratory-scale prototypes to commercial production of binder-free supercapacitor electrodes presents significant challenges. Manufacturing processes must be adapted to handle delicate nanostructured materials while maintaining their enhanced conductivity properties. Current production methods for conventional electrodes rely heavily on established coating and calendering processes optimized for binder-containing systems, requiring substantial retooling for binder-free alternatives.

Cost considerations represent a major hurdle in commercialization efforts. While binder-free electrodes demonstrate superior conductivity and performance, their fabrication often involves specialized techniques such as chemical vapor deposition, electrodeposition, or hydrothermal synthesis that are more expensive than traditional slurry-based methods. The economic viability depends on achieving sufficient performance improvements to justify the increased production costs.

Quality control and consistency pose additional challenges in scaled production. Without binders that typically help ensure uniform electrode properties, manufacturers must develop new quality assurance protocols. Variations in substrate properties, deposition parameters, and post-processing conditions can significantly impact the final electrode conductivity and performance characteristics, requiring precise monitoring systems.

Durability and stability concerns also emerge during scale-up. Laboratory demonstrations often focus on performance metrics rather than long-term stability. Commercial applications demand thousands of charge-discharge cycles under varied environmental conditions. The mechanical integrity of binder-free electrodes during repeated cycling must be thoroughly evaluated, as the absence of polymeric binders may affect electrode cohesion over time.

Supply chain considerations further complicate commercialization. Many advanced binder-free electrode designs incorporate specialized nanomaterials or rare elements with limited availability and fluctuating costs. Establishing reliable supply chains for these materials at commercial scales requires strategic partnerships and potentially vertical integration.

Regulatory compliance and safety standards present the final barrier to market entry. New materials and manufacturing processes must undergo rigorous testing to meet industry standards. Environmental impact assessments are particularly important, as some nanomaterials used in advanced electrode designs may have unknown ecological effects, potentially requiring specialized handling and disposal protocols.

Cost considerations represent a major hurdle in commercialization efforts. While binder-free electrodes demonstrate superior conductivity and performance, their fabrication often involves specialized techniques such as chemical vapor deposition, electrodeposition, or hydrothermal synthesis that are more expensive than traditional slurry-based methods. The economic viability depends on achieving sufficient performance improvements to justify the increased production costs.

Quality control and consistency pose additional challenges in scaled production. Without binders that typically help ensure uniform electrode properties, manufacturers must develop new quality assurance protocols. Variations in substrate properties, deposition parameters, and post-processing conditions can significantly impact the final electrode conductivity and performance characteristics, requiring precise monitoring systems.

Durability and stability concerns also emerge during scale-up. Laboratory demonstrations often focus on performance metrics rather than long-term stability. Commercial applications demand thousands of charge-discharge cycles under varied environmental conditions. The mechanical integrity of binder-free electrodes during repeated cycling must be thoroughly evaluated, as the absence of polymeric binders may affect electrode cohesion over time.

Supply chain considerations further complicate commercialization. Many advanced binder-free electrode designs incorporate specialized nanomaterials or rare elements with limited availability and fluctuating costs. Establishing reliable supply chains for these materials at commercial scales requires strategic partnerships and potentially vertical integration.

Regulatory compliance and safety standards present the final barrier to market entry. New materials and manufacturing processes must undergo rigorous testing to meet industry standards. Environmental impact assessments are particularly important, as some nanomaterials used in advanced electrode designs may have unknown ecological effects, potentially requiring specialized handling and disposal protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!