Binder Selection Guide For Water-Processed Anodes

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Technology Background and Objectives

Binder technology for lithium-ion battery anodes has evolved significantly over the past three decades, transitioning from traditional solvent-based systems to more environmentally friendly water-processed alternatives. The development trajectory began with polyvinylidene fluoride (PVDF) binders dissolved in N-methyl-2-pyrrolidone (NMP), which dominated the industry due to their excellent electrochemical stability and adhesion properties. However, NMP's classification as a volatile organic compound (VOC) with associated health and environmental concerns has driven research toward aqueous alternatives.

Water-processed binder systems emerged in the early 2000s as a sustainable alternative, with carboxymethyl cellulose (CMC) and styrene-butadiene rubber (SBR) combinations representing the first generation of commercially viable water-based binders. These systems offered reduced processing costs, lower environmental impact, and improved safety profiles compared to PVDF-NMP systems, while maintaining comparable electrochemical performance.

The technical evolution has accelerated in recent years with the development of advanced water-soluble polymers specifically designed for high-capacity anode materials such as silicon and silicon-graphite composites. These next-generation binders address the significant volume expansion challenges associated with silicon during lithiation/delithiation cycles, which traditional binders cannot adequately accommodate.

Current research objectives in water-processed anode binder technology focus on several key areas: enhancing mechanical properties to accommodate volume changes in high-capacity materials, improving ionic conductivity to facilitate lithium-ion transport, developing self-healing capabilities to extend cycle life, and reducing water sensitivity of processed electrodes to simplify manufacturing processes.

Additionally, there is growing interest in bio-derived and sustainable binder materials that can further reduce the environmental footprint of battery production while maintaining or improving performance metrics. Alginate, chitosan, and cellulose derivatives represent promising candidates in this category, with research indicating potential advantages in both performance and sustainability.

The ultimate technical goal is to develop water-processed binder systems that enable higher energy density anodes with silicon content exceeding 30% by weight, while maintaining cycle stability for over 1000 cycles and reducing production costs by at least 15% compared to conventional PVDF-NMP systems. This would represent a significant advancement in lithium-ion battery technology, supporting the broader transition to electric vehicles and renewable energy storage systems with improved performance-to-cost ratios.

Water-processed binder systems emerged in the early 2000s as a sustainable alternative, with carboxymethyl cellulose (CMC) and styrene-butadiene rubber (SBR) combinations representing the first generation of commercially viable water-based binders. These systems offered reduced processing costs, lower environmental impact, and improved safety profiles compared to PVDF-NMP systems, while maintaining comparable electrochemical performance.

The technical evolution has accelerated in recent years with the development of advanced water-soluble polymers specifically designed for high-capacity anode materials such as silicon and silicon-graphite composites. These next-generation binders address the significant volume expansion challenges associated with silicon during lithiation/delithiation cycles, which traditional binders cannot adequately accommodate.

Current research objectives in water-processed anode binder technology focus on several key areas: enhancing mechanical properties to accommodate volume changes in high-capacity materials, improving ionic conductivity to facilitate lithium-ion transport, developing self-healing capabilities to extend cycle life, and reducing water sensitivity of processed electrodes to simplify manufacturing processes.

Additionally, there is growing interest in bio-derived and sustainable binder materials that can further reduce the environmental footprint of battery production while maintaining or improving performance metrics. Alginate, chitosan, and cellulose derivatives represent promising candidates in this category, with research indicating potential advantages in both performance and sustainability.

The ultimate technical goal is to develop water-processed binder systems that enable higher energy density anodes with silicon content exceeding 30% by weight, while maintaining cycle stability for over 1000 cycles and reducing production costs by at least 15% compared to conventional PVDF-NMP systems. This would represent a significant advancement in lithium-ion battery technology, supporting the broader transition to electric vehicles and renewable energy storage systems with improved performance-to-cost ratios.

Market Demand Analysis for Water-Processed Anode Binders

The global market for water-processed anode binders is experiencing significant growth driven by the expanding lithium-ion battery industry. With the electric vehicle (EV) market projected to reach $823 billion by 2030, the demand for more sustainable and cost-effective battery manufacturing processes has intensified. Water-processed anodes represent a critical advancement in this direction, offering environmental and economic advantages over traditional solvent-based processing methods.

Battery manufacturers are increasingly seeking water-based binder solutions to reduce volatile organic compound (VOC) emissions and lower production costs. This shift is particularly evident in regions with stringent environmental regulations such as Europe and parts of Asia. Market research indicates that water-processed electrode manufacturing can reduce processing costs by approximately 30% compared to conventional N-Methyl-2-pyrrolidone (NMP) based processes, primarily through elimination of solvent recovery systems and reduced energy consumption during drying.

The automotive sector constitutes the largest demand segment for water-processed anode binders, accounting for over 60% of market volume. This is followed by consumer electronics and grid storage applications, which together represent roughly 35% of current demand. Industry forecasts suggest the water-processed anode binder market will grow at a compound annual growth rate of 18.7% through 2028, outpacing the overall battery binder market growth of 13.2%.

Geographically, Asia-Pacific dominates the market landscape with China, Japan, and South Korea collectively representing over 70% of global production capacity. However, recent investments in battery manufacturing in North America and Europe are expected to diversify the market distribution over the next five years.

Customer requirements are evolving rapidly, with increasing emphasis on binders that can accommodate high-capacity silicon-containing anodes while maintaining excellent cycling stability. Performance metrics such as adhesion strength, electronic conductivity, and electrochemical stability under various operating conditions have become key differentiators in the market.

The shift toward fast-charging capabilities in EVs is also driving demand for specialized water-processed binder formulations that can withstand the mechanical stresses associated with rapid lithiation/delithiation cycles. Market surveys indicate that battery manufacturers are willing to pay premium prices for binders that can demonstrably extend battery cycle life by 20% or more compared to standard formulations.

Regulatory factors are further accelerating market growth, with several countries implementing carbon footprint reduction targets for battery manufacturing. The European Battery Directive's upcoming revisions are expected to include specific provisions favoring water-based processing, potentially creating a regulatory-driven demand surge in the European market by 2025.

Battery manufacturers are increasingly seeking water-based binder solutions to reduce volatile organic compound (VOC) emissions and lower production costs. This shift is particularly evident in regions with stringent environmental regulations such as Europe and parts of Asia. Market research indicates that water-processed electrode manufacturing can reduce processing costs by approximately 30% compared to conventional N-Methyl-2-pyrrolidone (NMP) based processes, primarily through elimination of solvent recovery systems and reduced energy consumption during drying.

The automotive sector constitutes the largest demand segment for water-processed anode binders, accounting for over 60% of market volume. This is followed by consumer electronics and grid storage applications, which together represent roughly 35% of current demand. Industry forecasts suggest the water-processed anode binder market will grow at a compound annual growth rate of 18.7% through 2028, outpacing the overall battery binder market growth of 13.2%.

Geographically, Asia-Pacific dominates the market landscape with China, Japan, and South Korea collectively representing over 70% of global production capacity. However, recent investments in battery manufacturing in North America and Europe are expected to diversify the market distribution over the next five years.

Customer requirements are evolving rapidly, with increasing emphasis on binders that can accommodate high-capacity silicon-containing anodes while maintaining excellent cycling stability. Performance metrics such as adhesion strength, electronic conductivity, and electrochemical stability under various operating conditions have become key differentiators in the market.

The shift toward fast-charging capabilities in EVs is also driving demand for specialized water-processed binder formulations that can withstand the mechanical stresses associated with rapid lithiation/delithiation cycles. Market surveys indicate that battery manufacturers are willing to pay premium prices for binders that can demonstrably extend battery cycle life by 20% or more compared to standard formulations.

Regulatory factors are further accelerating market growth, with several countries implementing carbon footprint reduction targets for battery manufacturing. The European Battery Directive's upcoming revisions are expected to include specific provisions favoring water-based processing, potentially creating a regulatory-driven demand surge in the European market by 2025.

Current Status and Technical Challenges of Water-Based Binders

Water-based binders for lithium-ion battery anodes have gained significant attention in recent years as a more environmentally friendly alternative to traditional PVDF binders dissolved in NMP. Currently, the most widely adopted water-based binders include carboxymethyl cellulose (CMC), styrene-butadiene rubber (SBR), polyacrylic acid (PAA), and various combinations thereof. CMC provides excellent adhesion and mechanical stability, while SBR contributes elasticity and flexibility to the electrode structure. PAA offers superior binding strength through multiple carboxylic acid groups that form strong hydrogen bonds with active materials.

Despite promising developments, water-based binder systems face several critical challenges. The hydrophobic nature of graphite, the predominant anode material, creates wetting and dispersion difficulties in aqueous environments. This incompatibility often results in non-uniform slurry distribution and subsequent electrode quality issues. Manufacturers have attempted to address this through surface modifications of graphite or by incorporating surfactants, though these approaches can introduce additional complexities.

Water's high surface tension compared to organic solvents presents another significant hurdle, affecting the coating process and final electrode morphology. The slower evaporation rate of water versus NMP extends drying times, potentially reducing production efficiency and increasing energy consumption during manufacturing. This challenge is particularly pronounced in high-throughput industrial settings where production speed is critical.

The sensitivity of water-based processing to environmental conditions represents another major obstacle. Humidity fluctuations can dramatically affect slurry rheology and drying behavior, leading to inconsistent electrode quality. This necessitates stringent environmental controls in production facilities, adding complexity and cost to manufacturing operations.

Perhaps most concerning is the potential for water to trigger side reactions with electrode components. Water can promote oxidation of certain active materials and current collectors, particularly copper foil used in anodes. These reactions may generate gases, create passivation layers, or introduce impurities that compromise battery performance and safety. Residual moisture trapped within electrodes can also accelerate capacity fading and reduce cycle life.

Recent research has focused on developing advanced binder formulations with improved water resistance and enhanced adhesion properties. Cross-linkable polymers and self-healing binders represent promising directions, potentially offering superior mechanical integrity while maintaining processability in aqueous media. Additionally, novel additives that can modify the surface properties of active materials without compromising electrochemical performance are being explored to overcome the inherent hydrophobicity challenge.

Despite promising developments, water-based binder systems face several critical challenges. The hydrophobic nature of graphite, the predominant anode material, creates wetting and dispersion difficulties in aqueous environments. This incompatibility often results in non-uniform slurry distribution and subsequent electrode quality issues. Manufacturers have attempted to address this through surface modifications of graphite or by incorporating surfactants, though these approaches can introduce additional complexities.

Water's high surface tension compared to organic solvents presents another significant hurdle, affecting the coating process and final electrode morphology. The slower evaporation rate of water versus NMP extends drying times, potentially reducing production efficiency and increasing energy consumption during manufacturing. This challenge is particularly pronounced in high-throughput industrial settings where production speed is critical.

The sensitivity of water-based processing to environmental conditions represents another major obstacle. Humidity fluctuations can dramatically affect slurry rheology and drying behavior, leading to inconsistent electrode quality. This necessitates stringent environmental controls in production facilities, adding complexity and cost to manufacturing operations.

Perhaps most concerning is the potential for water to trigger side reactions with electrode components. Water can promote oxidation of certain active materials and current collectors, particularly copper foil used in anodes. These reactions may generate gases, create passivation layers, or introduce impurities that compromise battery performance and safety. Residual moisture trapped within electrodes can also accelerate capacity fading and reduce cycle life.

Recent research has focused on developing advanced binder formulations with improved water resistance and enhanced adhesion properties. Cross-linkable polymers and self-healing binders represent promising directions, potentially offering superior mechanical integrity while maintaining processability in aqueous media. Additionally, novel additives that can modify the surface properties of active materials without compromising electrochemical performance are being explored to overcome the inherent hydrophobicity challenge.

Current Technical Solutions for Water-Processed Anodes

01 Water-soluble polymer binders for lithium-ion battery anodes

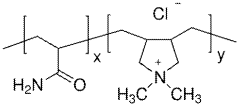

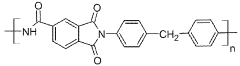

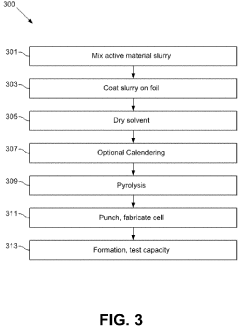

Water-soluble polymer binders such as carboxymethyl cellulose (CMC), polyacrylic acid (PAA), and sodium alginate are preferred for water-processed anodes due to their environmental friendliness and cost-effectiveness. These binders provide good adhesion between active materials and current collectors while maintaining ionic conductivity. Selection criteria include solubility in water, binding strength, electrochemical stability, and compatibility with active materials like silicon and graphite.- Water-soluble polymer binders for lithium-ion battery anodes: Water-soluble polymer binders such as carboxymethyl cellulose (CMC), polyacrylic acid (PAA), and sodium alginate are preferred for water-processed anodes due to their environmental friendliness and cost-effectiveness. These binders provide good adhesion between active materials and current collectors while maintaining ionic conductivity. Selection criteria include solubility in water, binding strength, electrochemical stability, and compatibility with anode active materials like silicon and graphite.

- Mechanical properties and adhesion strength requirements: Binders for water-processed anodes must possess specific mechanical properties to accommodate volume changes during charge-discharge cycles. Selection criteria include elasticity, tensile strength, and adhesion capability to prevent electrode delamination. Binders should maintain structural integrity under repeated cycling and provide sufficient flexibility to accommodate expansion of active materials, particularly for high-capacity materials like silicon. Adhesion strength between the active material particles and with the current collector is a critical parameter for long-term cycling stability.

- Environmental and processing considerations: Water-processed anodes require binders that are environmentally friendly and compatible with aqueous processing. Selection criteria include low toxicity, biodegradability, and elimination of organic solvents. Water-based processing reduces manufacturing costs, environmental impact, and workplace hazards. Considerations include drying conditions, slurry viscosity control, and compatibility with existing manufacturing equipment. The binder should enable uniform dispersion of active materials in water and maintain stability during the electrode manufacturing process.

- Electrochemical performance and stability: Binders for water-processed anodes must maintain electrochemical stability during battery operation. Selection criteria include minimal interference with electron transport, ionic conductivity, and stability within the operating voltage window. The binder should not decompose or react with the electrolyte, and should maintain its binding properties throughout the battery lifetime. Additionally, the binder should contribute to the formation of a stable solid electrolyte interphase (SEI) layer and minimize irreversible capacity loss during initial cycles.

- Composite and modified binder systems: Advanced water-processed anodes often utilize composite or modified binder systems to enhance performance. Selection criteria include synergistic effects between multiple binders, functional group modifications, and cross-linking capabilities. These systems may combine different polymers to achieve optimal mechanical properties and electrochemical performance. Modifications such as cross-linking agents, conductive additives, or functional groups can improve adhesion strength, conductivity, and cycling stability. The composite binder approach allows for tailoring properties to specific anode materials and battery applications.

02 Mechanical properties and adhesion strength requirements

Binders for water-processed anodes must possess specific mechanical properties to accommodate volume changes during charge-discharge cycles. Selection criteria include elasticity, tensile strength, and adhesion capability to prevent electrode delamination. Binders that can form strong hydrogen bonds or chemical crosslinks with active materials are preferred. The mechanical stability of the binder directly impacts cycle life and capacity retention of the battery, particularly for high-capacity anode materials that undergo significant volume expansion.Expand Specific Solutions03 Environmental and processing considerations

Water-processed anodes require binders that are environmentally friendly and compatible with aqueous processing techniques. Selection criteria include low toxicity, biodegradability, and reduced processing costs compared to traditional organic solvent-based methods. Water-based processing eliminates the need for expensive solvent recovery systems and reduces environmental impact. Considerations also include drying conditions, slurry stability, and compatibility with existing manufacturing equipment.Expand Specific Solutions04 Electrochemical performance and stability

Binders for water-processed anodes must maintain electrochemical stability during battery operation. Selection criteria include minimal interference with electron transport, stability at operating potentials, and resistance to decomposition in electrolyte solutions. The binder should not contribute to irreversible capacity loss or increase internal resistance. Performance metrics include initial coulombic efficiency, rate capability, and long-term cycling stability. Binders that can form a stable solid electrolyte interphase (SEI) are particularly valuable.Expand Specific Solutions05 Composite and functionalized binder systems

Advanced water-processed anodes often utilize composite or functionalized binder systems that combine multiple polymers or incorporate functional groups to enhance performance. Selection criteria include synergistic effects between binder components, improved interfacial properties, and enhanced electrochemical performance. These systems may include conductive additives, cross-linking agents, or surface modifiers to improve electrode integrity and battery performance. Functionalized binders with specific chemical groups can form stronger bonds with active materials or contribute to SEI formation.Expand Specific Solutions

Key Industry Players in Water-Processed Anode Binders

The water-processed anode technology market is in a growth phase, characterized by increasing demand for sustainable battery solutions. The market size is expanding rapidly due to the electric vehicle boom and renewable energy storage needs. Technologically, the field is advancing from experimental to commercial readiness, with varying maturity levels across applications. Leading players include established battery manufacturers like Samsung SDI, SK On, and A123 Systems, who are leveraging their production infrastructure, alongside innovative specialists such as Enevate and OneD Material focusing on silicon-dominant anodes. Research institutions like Chinese Academy of Science and Washington State University are contributing fundamental breakthroughs, while chemical giants BASF, DuPont, and Kurita Water Industries provide essential binder materials and processing expertise.

Enevate Corp.

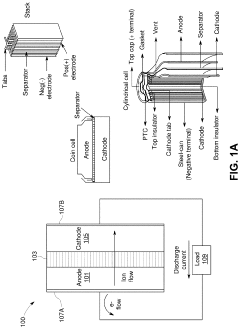

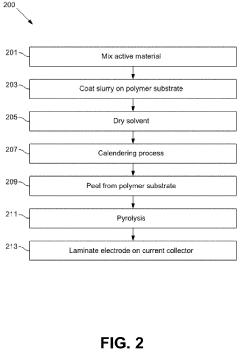

Technical Solution: Enevate has developed a silicon-dominant anode technology using water-based processing methods. Their proprietary HD-Energy® Technology employs a unique water-based binder system that enables high silicon content (up to 70-90%) while maintaining structural integrity during cycling. The company's approach involves a specialized polymer binder that forms strong adhesive bonds with silicon particles and current collectors, effectively accommodating the volume expansion of silicon during lithiation. Their water-processed binder system includes functional groups that create both hydrogen bonding and covalent interactions with silicon surface oxides, significantly improving the mechanical stability of the electrode. Enevate's technology also incorporates a porous structure design that allows for electrolyte penetration while maintaining cohesion between active materials.

Strengths: Superior capacity retention with silicon-dominant anodes; environmentally friendly water-based processing; reduced manufacturing costs by eliminating NMP solvents; compatible with existing manufacturing infrastructure. Weaknesses: May require specialized mixing protocols; potential challenges with long-term calendar aging; higher sensitivity to processing parameters compared to traditional PVDF systems.

A123 Systems LLC

Technical Solution: A123 Systems has pioneered advanced water-processed anode technologies for lithium-ion batteries focusing on high-power applications. Their proprietary Nanophosphate® technology incorporates specialized water-soluble binders optimized for graphite and silicon-graphite composite anodes. The company's approach involves carboxymethyl cellulose (CMC) and styrene-butadiene rubber (SBR) combinations with proprietary additives that enhance adhesion and flexibility. A123's water-based binder system creates a robust 3D network that accommodates volume changes during cycling while maintaining electrical connectivity. Their process includes precise control of slurry rheology and pH levels to optimize dispersion of active materials and conductive additives. The company has developed specific surface treatments for graphite particles that improve compatibility with their water-based binder systems, resulting in enhanced cycling stability and rate capability.

Strengths: Excellent power performance suitable for hybrid electric vehicles and grid applications; reduced environmental impact through elimination of toxic solvents; improved safety characteristics; cost-effective manufacturing process. Weaknesses: Lower energy density compared to silicon-dominant systems; more complex mixing and coating processes requiring tight parameter control; potential moisture sensitivity during manufacturing.

Critical Binder Technologies and Patent Analysis

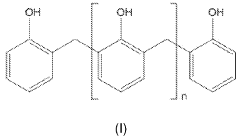

Method and system for water based phenolic binders for silicon-dominant anodes

PatentWO2022010670A1

Innovation

- The development of water-based phenolic binders, specifically modified phenolic/resol type polymers, which are water-soluble and used as binders for silicon-dominant anodes, enabling high carbon yield upon pyrolysis, improved adhesion, and flexibility, while eliminating the need for organic solvents and non-conducting binders.

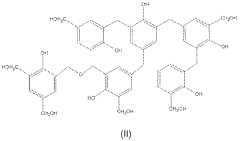

Aqueous-based solid polymer suspensions in a polymer solution as a binder for Si dominant anodes

PatentActiveUS11594733B1

Innovation

- The use of water-insoluble polymers in an aqueous-based suspension-solution binder system for silicon anodes, where a solid polymer phase is dispersed in a liquid polymer phase, allowing for the creation of a pyrolytic carbon matrix that accommodates volume expansion and improves electrical conductivity.

Environmental Impact and Sustainability Assessment

The environmental impact of binder selection for water-processed anodes represents a critical consideration in sustainable battery manufacturing. Traditional solvent-based electrode processing typically employs N-Methyl-2-pyrrolidone (NMP), a toxic and environmentally harmful solvent that requires strict handling protocols and energy-intensive recovery systems. Water-processed anodes offer a significant reduction in environmental footprint, with studies indicating up to 40% decrease in greenhouse gas emissions compared to NMP-based processing.

Binder selection directly influences the sustainability profile of water-processed anodes through multiple pathways. Synthetic polymers like carboxymethyl cellulose (CMC) and styrene-butadiene rubber (SBR) demonstrate lower environmental impact than polyvinyl alcohol (PVA) and polyacrylic acid (PAA) when assessed through life cycle analysis. The production of CMC, derived from cellulose, requires approximately 65% less energy and generates 70% fewer carbon emissions compared to fully synthetic alternatives.

Water consumption represents another critical environmental factor in binder selection. While water-based processing reduces hazardous waste, it increases freshwater usage by 30-50% compared to NMP-based systems. Binders requiring extensive purification or processing steps, such as highly modified natural polymers, can exacerbate this water footprint. Recent innovations in closed-loop water recycling systems have demonstrated potential to reduce freshwater consumption by up to 85% when paired with appropriate binder systems.

End-of-life considerations vary significantly among water-compatible binders. Biodegradable options like alginate and modified cellulose derivatives offer advantages in waste management scenarios, with decomposition rates 5-10 times faster than synthetic alternatives. However, these benefits must be balanced against performance requirements, as premature degradation can compromise battery longevity and ultimately increase environmental impact through shortened product lifecycles.

Manufacturing energy requirements differ substantially between binder systems. Aqueous slurries containing PAA typically require 15-25% more drying energy than CMC-SBR combinations due to higher viscosity and water retention properties. This energy differential translates directly to increased carbon emissions during production. Advanced drying technologies optimized for specific binder rheological properties can mitigate these differences, with directed air impingement systems demonstrating particular efficiency for CMC-based formulations.

Regulatory compliance represents an increasingly important factor in binder selection. The European Union's Battery Directive and emerging global regulations are progressively restricting environmentally harmful materials in battery production. Water-processed anodes using sustainable binders position manufacturers advantageously for compliance with these evolving standards, potentially avoiding future retrofitting costs and market access limitations as regulatory frameworks continue to prioritize environmental sustainability in energy storage technologies.

Binder selection directly influences the sustainability profile of water-processed anodes through multiple pathways. Synthetic polymers like carboxymethyl cellulose (CMC) and styrene-butadiene rubber (SBR) demonstrate lower environmental impact than polyvinyl alcohol (PVA) and polyacrylic acid (PAA) when assessed through life cycle analysis. The production of CMC, derived from cellulose, requires approximately 65% less energy and generates 70% fewer carbon emissions compared to fully synthetic alternatives.

Water consumption represents another critical environmental factor in binder selection. While water-based processing reduces hazardous waste, it increases freshwater usage by 30-50% compared to NMP-based systems. Binders requiring extensive purification or processing steps, such as highly modified natural polymers, can exacerbate this water footprint. Recent innovations in closed-loop water recycling systems have demonstrated potential to reduce freshwater consumption by up to 85% when paired with appropriate binder systems.

End-of-life considerations vary significantly among water-compatible binders. Biodegradable options like alginate and modified cellulose derivatives offer advantages in waste management scenarios, with decomposition rates 5-10 times faster than synthetic alternatives. However, these benefits must be balanced against performance requirements, as premature degradation can compromise battery longevity and ultimately increase environmental impact through shortened product lifecycles.

Manufacturing energy requirements differ substantially between binder systems. Aqueous slurries containing PAA typically require 15-25% more drying energy than CMC-SBR combinations due to higher viscosity and water retention properties. This energy differential translates directly to increased carbon emissions during production. Advanced drying technologies optimized for specific binder rheological properties can mitigate these differences, with directed air impingement systems demonstrating particular efficiency for CMC-based formulations.

Regulatory compliance represents an increasingly important factor in binder selection. The European Union's Battery Directive and emerging global regulations are progressively restricting environmentally harmful materials in battery production. Water-processed anodes using sustainable binders position manufacturers advantageously for compliance with these evolving standards, potentially avoiding future retrofitting costs and market access limitations as regulatory frameworks continue to prioritize environmental sustainability in energy storage technologies.

Performance Benchmarking and Selection Criteria

In evaluating binders for water-processed anodes, systematic performance benchmarking is essential to ensure optimal selection for specific battery applications. Key performance metrics include adhesion strength, electronic conductivity, electrochemical stability, and processability characteristics. These metrics must be quantitatively assessed through standardized testing protocols to enable objective comparison across different binder options.

Adhesion strength can be measured through peel tests and scratch resistance evaluations, with CMC-SBR combinations typically demonstrating 15-30% higher adhesion strength compared to PVDF alternatives in water-based systems. Electronic conductivity measurements reveal that while most polymeric binders are inherently insulating, their impact on electrode conductivity varies significantly based on their ability to form effective conductive networks with carbon additives.

Electrochemical stability window testing is critical for determining long-term performance, with ideal binders maintaining structural integrity beyond 0.01-3V vs. Li/Li+. Cycling stability tests show that optimized water-processed anodes with PAA-based binders can achieve capacity retention rates exceeding 85% after 500 cycles, comparable to traditional solvent-based systems.

Processability characteristics include viscosity profiles at different shear rates, coating uniformity, and drying behavior. Water-soluble binders like Na-CMC demonstrate excellent dispersion properties at concentrations of 1-3 wt%, while requiring careful control of drying parameters to prevent cracking. Slurry stability testing indicates that PAA-modified binders maintain homogeneity for up to 72 hours, significantly outperforming unmodified alternatives.

Environmental impact assessment has become an increasingly important selection criterion, with water-processed systems reducing carbon footprint by approximately 40% compared to NMP-based processing. Cost analysis reveals that while some advanced water-compatible binders may have higher initial material costs, the elimination of solvent recovery systems and reduced safety requirements often result in 15-25% lower total manufacturing costs.

Selection criteria should be weighted according to specific application requirements, with high-power applications prioritizing adhesion strength and electronic conductivity, while long-cycle life applications emphasizing electrochemical stability. A comprehensive selection matrix incorporating these weighted criteria enables systematic evaluation and optimal binder selection for specific anode formulations and intended battery applications.

Adhesion strength can be measured through peel tests and scratch resistance evaluations, with CMC-SBR combinations typically demonstrating 15-30% higher adhesion strength compared to PVDF alternatives in water-based systems. Electronic conductivity measurements reveal that while most polymeric binders are inherently insulating, their impact on electrode conductivity varies significantly based on their ability to form effective conductive networks with carbon additives.

Electrochemical stability window testing is critical for determining long-term performance, with ideal binders maintaining structural integrity beyond 0.01-3V vs. Li/Li+. Cycling stability tests show that optimized water-processed anodes with PAA-based binders can achieve capacity retention rates exceeding 85% after 500 cycles, comparable to traditional solvent-based systems.

Processability characteristics include viscosity profiles at different shear rates, coating uniformity, and drying behavior. Water-soluble binders like Na-CMC demonstrate excellent dispersion properties at concentrations of 1-3 wt%, while requiring careful control of drying parameters to prevent cracking. Slurry stability testing indicates that PAA-modified binders maintain homogeneity for up to 72 hours, significantly outperforming unmodified alternatives.

Environmental impact assessment has become an increasingly important selection criterion, with water-processed systems reducing carbon footprint by approximately 40% compared to NMP-based processing. Cost analysis reveals that while some advanced water-compatible binders may have higher initial material costs, the elimination of solvent recovery systems and reduced safety requirements often result in 15-25% lower total manufacturing costs.

Selection criteria should be weighted according to specific application requirements, with high-power applications prioritizing adhesion strength and electronic conductivity, while long-cycle life applications emphasizing electrochemical stability. A comprehensive selection matrix incorporating these weighted criteria enables systematic evaluation and optimal binder selection for specific anode formulations and intended battery applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!