Catalytic Removal of Gaseous Pollutants Using Zeolite Supported Catalysts

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Zeolite Catalysis Background and Objectives

Zeolite catalysis has emerged as a pivotal technology in addressing the pressing issue of gaseous pollutant removal. The development of this field can be traced back to the mid-20th century when the unique properties of zeolites were first recognized. These microporous aluminosilicate minerals possess exceptional catalytic capabilities due to their high surface area, uniform pore structure, and ion-exchange properties.

The evolution of zeolite catalysis has been driven by the increasing global concern over air pollution and its detrimental effects on human health and the environment. As industrial activities and vehicular emissions continue to rise, the need for efficient and cost-effective methods to remove gaseous pollutants has become more urgent. Zeolite-supported catalysts have shown remarkable potential in addressing this challenge, offering a versatile and sustainable solution for various pollutant removal applications.

The primary objective of research in this field is to develop highly efficient, stable, and economically viable zeolite-supported catalysts for the removal of a wide range of gaseous pollutants. These pollutants include nitrogen oxides (NOx), sulfur oxides (SOx), volatile organic compounds (VOCs), and carbon monoxide (CO). The ultimate goal is to achieve near-complete conversion of these harmful substances into environmentally benign products under realistic operating conditions.

Researchers are focusing on several key aspects to advance zeolite catalysis technology. One major area of interest is the modification and tailoring of zeolite structures to enhance their catalytic performance. This includes the development of hierarchical zeolites with improved mass transfer properties and the incorporation of various metal species to create multifunctional catalysts.

Another critical objective is to improve the thermal and hydrothermal stability of zeolite-supported catalysts, ensuring their long-term effectiveness in harsh industrial environments. Additionally, efforts are being made to broaden the temperature window of catalytic activity, allowing for more flexible and efficient operation across diverse applications.

The field of zeolite catalysis for gaseous pollutant removal is also exploring the integration of advanced characterization techniques and computational modeling. These tools provide deeper insights into the catalytic mechanisms and guide the rational design of next-generation catalysts. Furthermore, researchers are investigating the potential of combining zeolite catalysis with other technologies, such as plasma-assisted catalysis or photocatalysis, to achieve synergistic effects and overcome existing limitations.

As the technology continues to evolve, there is a growing emphasis on developing sustainable and eco-friendly zeolite catalysts. This includes the use of renewable resources for zeolite synthesis and the exploration of bio-inspired catalytic systems. The ultimate vision is to create a new generation of zeolite-supported catalysts that not only effectively remove gaseous pollutants but also contribute to the broader goals of environmental protection and sustainable development.

The evolution of zeolite catalysis has been driven by the increasing global concern over air pollution and its detrimental effects on human health and the environment. As industrial activities and vehicular emissions continue to rise, the need for efficient and cost-effective methods to remove gaseous pollutants has become more urgent. Zeolite-supported catalysts have shown remarkable potential in addressing this challenge, offering a versatile and sustainable solution for various pollutant removal applications.

The primary objective of research in this field is to develop highly efficient, stable, and economically viable zeolite-supported catalysts for the removal of a wide range of gaseous pollutants. These pollutants include nitrogen oxides (NOx), sulfur oxides (SOx), volatile organic compounds (VOCs), and carbon monoxide (CO). The ultimate goal is to achieve near-complete conversion of these harmful substances into environmentally benign products under realistic operating conditions.

Researchers are focusing on several key aspects to advance zeolite catalysis technology. One major area of interest is the modification and tailoring of zeolite structures to enhance their catalytic performance. This includes the development of hierarchical zeolites with improved mass transfer properties and the incorporation of various metal species to create multifunctional catalysts.

Another critical objective is to improve the thermal and hydrothermal stability of zeolite-supported catalysts, ensuring their long-term effectiveness in harsh industrial environments. Additionally, efforts are being made to broaden the temperature window of catalytic activity, allowing for more flexible and efficient operation across diverse applications.

The field of zeolite catalysis for gaseous pollutant removal is also exploring the integration of advanced characterization techniques and computational modeling. These tools provide deeper insights into the catalytic mechanisms and guide the rational design of next-generation catalysts. Furthermore, researchers are investigating the potential of combining zeolite catalysis with other technologies, such as plasma-assisted catalysis or photocatalysis, to achieve synergistic effects and overcome existing limitations.

As the technology continues to evolve, there is a growing emphasis on developing sustainable and eco-friendly zeolite catalysts. This includes the use of renewable resources for zeolite synthesis and the exploration of bio-inspired catalytic systems. The ultimate vision is to create a new generation of zeolite-supported catalysts that not only effectively remove gaseous pollutants but also contribute to the broader goals of environmental protection and sustainable development.

Market Analysis for Air Pollution Control

The market for air pollution control technologies, particularly those focusing on the catalytic removal of gaseous pollutants using zeolite supported catalysts, has been experiencing significant growth in recent years. This growth is primarily driven by increasing environmental concerns, stringent government regulations, and a growing awareness of the health impacts of air pollution.

The global air quality control systems market, which encompasses technologies like zeolite-supported catalysts, was valued at approximately $74 billion in 2020 and is projected to reach $92 billion by 2025, growing at a CAGR of 4.3%. Within this market, the segment for gaseous pollutant removal is expected to witness the highest growth rate due to the rising focus on reducing harmful emissions from industrial processes and vehicles.

Key market drivers include the implementation of stricter emission standards across various industries, particularly in developed economies. For instance, the European Union's Industrial Emissions Directive and the United States Environmental Protection Agency's Clean Air Act have set increasingly stringent limits on emissions of nitrogen oxides (NOx), sulfur oxides (SOx), and volatile organic compounds (VOCs).

Developing economies, especially China and India, are also emerging as significant markets for air pollution control technologies. These countries are facing severe air quality issues and are implementing policies to combat pollution, creating substantial opportunities for zeolite-supported catalyst technologies.

The automotive sector represents a major end-user for zeolite-supported catalysts, particularly in catalytic converters. With the global automotive industry transitioning towards cleaner technologies and stricter emission norms, the demand for advanced catalytic systems is expected to surge.

Industrial applications, including power plants, chemical processing facilities, and manufacturing units, form another crucial market segment. These industries are increasingly adopting zeolite-supported catalysts to comply with environmental regulations and improve their sustainability profiles.

The market is characterized by intense competition among key players, including companies like BASF, Johnson Matthey, and Clariant. These companies are investing heavily in research and development to enhance the efficiency and cost-effectiveness of zeolite-supported catalysts.

Challenges in the market include the high initial cost of implementing advanced air pollution control systems and the need for continuous innovation to meet evolving regulatory standards. However, the long-term benefits of improved air quality and potential cost savings through energy efficiency are expected to drive continued market growth.

The global air quality control systems market, which encompasses technologies like zeolite-supported catalysts, was valued at approximately $74 billion in 2020 and is projected to reach $92 billion by 2025, growing at a CAGR of 4.3%. Within this market, the segment for gaseous pollutant removal is expected to witness the highest growth rate due to the rising focus on reducing harmful emissions from industrial processes and vehicles.

Key market drivers include the implementation of stricter emission standards across various industries, particularly in developed economies. For instance, the European Union's Industrial Emissions Directive and the United States Environmental Protection Agency's Clean Air Act have set increasingly stringent limits on emissions of nitrogen oxides (NOx), sulfur oxides (SOx), and volatile organic compounds (VOCs).

Developing economies, especially China and India, are also emerging as significant markets for air pollution control technologies. These countries are facing severe air quality issues and are implementing policies to combat pollution, creating substantial opportunities for zeolite-supported catalyst technologies.

The automotive sector represents a major end-user for zeolite-supported catalysts, particularly in catalytic converters. With the global automotive industry transitioning towards cleaner technologies and stricter emission norms, the demand for advanced catalytic systems is expected to surge.

Industrial applications, including power plants, chemical processing facilities, and manufacturing units, form another crucial market segment. These industries are increasingly adopting zeolite-supported catalysts to comply with environmental regulations and improve their sustainability profiles.

The market is characterized by intense competition among key players, including companies like BASF, Johnson Matthey, and Clariant. These companies are investing heavily in research and development to enhance the efficiency and cost-effectiveness of zeolite-supported catalysts.

Challenges in the market include the high initial cost of implementing advanced air pollution control systems and the need for continuous innovation to meet evolving regulatory standards. However, the long-term benefits of improved air quality and potential cost savings through energy efficiency are expected to drive continued market growth.

Current Challenges in Gaseous Pollutant Removal

The catalytic removal of gaseous pollutants using zeolite-supported catalysts faces several significant challenges that hinder its widespread implementation and efficiency. One of the primary obstacles is the deactivation of catalysts due to various factors such as poisoning, fouling, and thermal degradation. Sulfur compounds and heavy metals present in the gas streams can irreversibly bind to active sites, reducing catalyst performance over time.

Another major challenge is the need for high-temperature operation, which increases energy consumption and operational costs. While higher temperatures generally improve reaction kinetics, they also accelerate catalyst degradation and may lead to undesired side reactions. Balancing temperature requirements with catalyst longevity and selectivity remains a complex issue.

The presence of moisture in gas streams poses additional difficulties. Water vapor can compete with pollutants for adsorption sites on zeolites, reducing overall removal efficiency. Moreover, it can cause structural changes in the zeolite framework, potentially altering its catalytic properties.

Selectivity is another critical challenge, particularly in complex gas mixtures containing multiple pollutants. Achieving high removal rates for target compounds while minimizing the conversion of non-target species requires careful catalyst design and process optimization.

The development of catalysts capable of simultaneously removing multiple pollutants, such as NOx, SOx, and volatile organic compounds (VOCs), remains an ongoing challenge. Current systems often require separate treatment stages for different pollutants, increasing complexity and costs.

Mass transfer limitations within zeolite pores can significantly impact catalyst effectiveness. Diffusion constraints may prevent pollutants from reaching active sites, particularly for larger molecules. Overcoming these limitations without compromising the zeolite's structural integrity and stability is a persistent challenge.

Scalability and cost-effectiveness present additional hurdles. While zeolite-supported catalysts show promise in laboratory settings, translating these results to industrial-scale applications while maintaining performance and economic viability is complex. The high cost of some zeolites and noble metal catalysts can make large-scale implementation prohibitively expensive.

Lastly, catalyst regeneration and disposal pose environmental and economic challenges. Developing efficient, cost-effective methods for in-situ regeneration or environmentally friendly disposal of spent catalysts is crucial for the long-term sustainability of this technology.

Another major challenge is the need for high-temperature operation, which increases energy consumption and operational costs. While higher temperatures generally improve reaction kinetics, they also accelerate catalyst degradation and may lead to undesired side reactions. Balancing temperature requirements with catalyst longevity and selectivity remains a complex issue.

The presence of moisture in gas streams poses additional difficulties. Water vapor can compete with pollutants for adsorption sites on zeolites, reducing overall removal efficiency. Moreover, it can cause structural changes in the zeolite framework, potentially altering its catalytic properties.

Selectivity is another critical challenge, particularly in complex gas mixtures containing multiple pollutants. Achieving high removal rates for target compounds while minimizing the conversion of non-target species requires careful catalyst design and process optimization.

The development of catalysts capable of simultaneously removing multiple pollutants, such as NOx, SOx, and volatile organic compounds (VOCs), remains an ongoing challenge. Current systems often require separate treatment stages for different pollutants, increasing complexity and costs.

Mass transfer limitations within zeolite pores can significantly impact catalyst effectiveness. Diffusion constraints may prevent pollutants from reaching active sites, particularly for larger molecules. Overcoming these limitations without compromising the zeolite's structural integrity and stability is a persistent challenge.

Scalability and cost-effectiveness present additional hurdles. While zeolite-supported catalysts show promise in laboratory settings, translating these results to industrial-scale applications while maintaining performance and economic viability is complex. The high cost of some zeolites and noble metal catalysts can make large-scale implementation prohibitively expensive.

Lastly, catalyst regeneration and disposal pose environmental and economic challenges. Developing efficient, cost-effective methods for in-situ regeneration or environmentally friendly disposal of spent catalysts is crucial for the long-term sustainability of this technology.

Existing Zeolite Supported Catalyst Solutions

01 Regeneration of zeolite catalysts

Methods for regenerating spent zeolite catalysts involve removing contaminants and restoring catalytic activity. This can include thermal treatments, chemical treatments, or a combination of both to remove coke deposits and other impurities from the catalyst surface and pores.- Regeneration of zeolite catalysts: Methods for regenerating spent zeolite catalysts involve removing contaminants and restoring catalytic activity. This can include thermal treatments, chemical treatments, or a combination of both to remove coke deposits and other impurities from the catalyst surface and pores.

- Separation of zeolite catalysts from reaction mixtures: Techniques for separating zeolite catalysts from reaction mixtures after catalytic processes. This may involve filtration, centrifugation, or other physical separation methods to recover the catalyst for reuse or disposal.

- Deactivation and disposal of zeolite catalysts: Procedures for safely deactivating and disposing of spent zeolite catalysts that can no longer be regenerated. This may include chemical treatments to neutralize any remaining active sites or hazardous components before disposal in accordance with environmental regulations.

- Extraction of valuable metals from spent zeolite catalysts: Methods for recovering valuable metals, such as platinum or palladium, from spent zeolite catalysts. This can involve leaching processes, thermal treatments, or other extraction techniques to reclaim precious metals before catalyst disposal.

- In-situ removal of contaminants from zeolite catalysts: Techniques for removing contaminants from zeolite catalysts during the reaction process, without the need for separate regeneration steps. This can include continuous or periodic flushing with solvents or reactive gases to maintain catalyst activity and extend catalyst life.

02 Separation of zeolite catalysts from reaction mixtures

Techniques for separating zeolite catalysts from reaction mixtures after catalytic processes. This may involve filtration, centrifugation, or other physical separation methods to recover the catalyst for reuse or disposal.Expand Specific Solutions03 Deactivation and disposal of zeolite catalysts

Processes for safely deactivating and disposing of spent zeolite catalysts that can no longer be regenerated. This may include chemical treatments to neutralize any remaining active sites or hazardous components before disposal in accordance with environmental regulations.Expand Specific Solutions04 Extraction of valuable metals from spent zeolite catalysts

Methods for recovering valuable metals, such as platinum group metals, from spent zeolite catalysts. This can involve leaching processes, selective dissolution, or other extraction techniques to reclaim precious metals before catalyst disposal.Expand Specific Solutions05 In-situ removal of contaminants from zeolite catalysts

Techniques for removing contaminants from zeolite catalysts during the catalytic process, without the need for separate regeneration steps. This can include the use of scavenging agents or continuous regeneration processes to maintain catalyst activity.Expand Specific Solutions

Key Players in Catalytic Pollution Control

The catalytic removal of gaseous pollutants using zeolite-supported catalysts is a rapidly evolving field in environmental technology. The market is in a growth phase, driven by increasing environmental regulations and the need for cleaner air. The global market size for catalytic air purification is projected to reach several billion dollars by 2025. Technologically, the field is advancing, with companies like Johnson Matthey, Umicore, and BASF leading in catalyst development. Automotive manufacturers such as Toyota, Volkswagen, and Honda are also heavily invested in this technology for emission control. Research institutions like South China University of Technology are contributing to innovations in zeolite-based catalysts. The competition is intense, with a mix of established chemical companies and emerging environmental technology firms vying for market share.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corp. has made significant advancements in zeolite-supported catalysts for automotive emissions control. Their technology focuses on improving the performance of three-way catalysts (TWC) and lean NOx trap (LNT) systems using zeolite-based materials. Toyota has developed novel zeolite structures with optimized pore sizes and distributions to enhance the dispersion and stability of precious metal catalysts. Their catalysts demonstrate superior low-temperature activity, with some formulations achieving over 50% conversion of CO and hydrocarbons at temperatures as low as 150°C [8]. Toyota has also pioneered the use of copper-exchanged small-pore zeolites, such as Cu-CHA, in passive NOx adsorber (PNA) systems, which can effectively trap NOx emissions during cold starts and release them at higher temperatures for subsequent reduction [9].

Strengths: Excellent low-temperature performance, effective NOx trapping during cold starts, improved precious metal utilization. Weaknesses: May require complex control strategies for optimal performance across various driving conditions, potential for increased system complexity.

Johnson Matthey Plc

Technical Solution: Johnson Matthey has pioneered the development of zeolite-supported catalysts for gaseous pollutant removal, particularly focusing on selective catalytic reduction (SCR) systems. Their technology employs copper and iron-exchanged zeolites, such as Cu-SSZ-13 and Fe-BEA, to effectively reduce NOx emissions from diesel engines and industrial sources. The company's catalysts exhibit exceptional low-temperature activity, with some formulations achieving over 80% NOx conversion at temperatures as low as 180°C [4]. Johnson Matthey has also developed innovative coating techniques to improve catalyst adhesion and durability on various substrate materials, including cordierite and silicon carbide [5]. Their catalysts are designed to maintain high performance even in the presence of sulfur and other potential poisons, ensuring long-term effectiveness in real-world applications.

Strengths: Excellent low-temperature performance, high resistance to poisoning, versatile substrate compatibility. Weaknesses: May require precise control of exhaust gas composition for optimal performance, potential for ammonia slip in SCR systems.

Innovations in Zeolite Catalyst Design

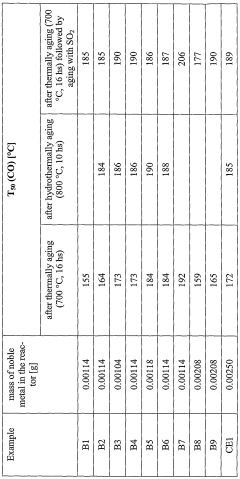

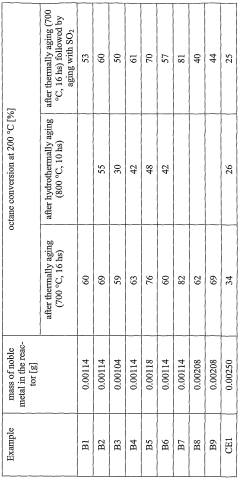

Zeolite catalyst for the simultaneous removal of carbon monoxide and hydrocarbons from oxygen-rich exhaust gases and processes for the manufacture thereof

PatentWO2006037610A1

Innovation

- A catalyst comprising tin oxide, palladium, and a zeolite as the carrier oxide, optionally with additional platinum group metals or promoters, is developed, which maintains efficiency after thermal aging and exhibits good sulfur resistance, reducing the need for high platinum content and associated costs.

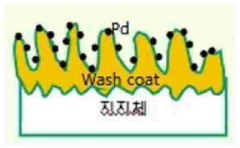

Catalyst for purifying discharging gas and method manufacturing the same

PatentInactiveKR1020130032417A

Innovation

- A catalyst is formed by electroless plating a noble metal layer, such as palladium, on a zeolite support, which is a ceramic material, to enhance VOC removal efficiency and reduce manufacturing costs and time, with the zeolite support being shaped to maintain mechanical integrity and large surface area.

Environmental Regulations and Compliance

Environmental regulations and compliance play a crucial role in shaping the development and implementation of catalytic technologies for gaseous pollutant removal. The increasing global focus on air quality and environmental protection has led to the establishment of stringent emission standards across various industries. These regulations have become a driving force for innovation in zeolite-supported catalysts for pollutant abatement.

In the United States, the Clean Air Act (CAA) and its amendments set the foundation for air quality standards and emission controls. The Environmental Protection Agency (EPA) enforces these regulations, which include National Ambient Air Quality Standards (NAAQS) for criteria pollutants such as nitrogen oxides (NOx), sulfur dioxide (SO2), and particulate matter. These standards have necessitated the development of advanced catalytic systems, with zeolite-supported catalysts emerging as a promising solution.

The European Union has implemented similar regulations through directives such as the Industrial Emissions Directive (IED) and the Medium Combustion Plant Directive (MCPD). These directives establish emission limit values for various pollutants and require the use of Best Available Techniques (BAT) in industrial processes. Zeolite-supported catalysts have gained prominence as a BAT for gaseous pollutant removal, particularly in sectors such as power generation and chemical manufacturing.

In Asia, countries like China and India have also strengthened their environmental regulations in recent years. China's Air Pollution Prevention and Control Law and India's National Clean Air Programme have set ambitious targets for air quality improvement, driving the adoption of advanced catalytic technologies. The stringent emission standards in these rapidly industrializing nations have created a significant market opportunity for zeolite-supported catalysts.

Compliance with these regulations often requires continuous monitoring and reporting of emissions. This has led to the development of integrated systems that combine zeolite-supported catalysts with advanced monitoring technologies, ensuring real-time compliance and optimization of pollutant removal processes. The regulatory landscape has also influenced research priorities, with increased focus on enhancing catalyst durability, efficiency, and adaptability to various operating conditions.

The evolving nature of environmental regulations presents both challenges and opportunities for the field of zeolite-supported catalysts. As emission standards become more stringent, there is a constant need for innovation to meet these requirements cost-effectively. This regulatory pressure has accelerated research into novel zeolite structures, improved catalyst formulations, and more efficient reactor designs. Additionally, the global trend towards circular economy principles is influencing regulations, promoting the development of regenerable and recyclable zeolite catalysts to minimize waste and resource consumption.

In the United States, the Clean Air Act (CAA) and its amendments set the foundation for air quality standards and emission controls. The Environmental Protection Agency (EPA) enforces these regulations, which include National Ambient Air Quality Standards (NAAQS) for criteria pollutants such as nitrogen oxides (NOx), sulfur dioxide (SO2), and particulate matter. These standards have necessitated the development of advanced catalytic systems, with zeolite-supported catalysts emerging as a promising solution.

The European Union has implemented similar regulations through directives such as the Industrial Emissions Directive (IED) and the Medium Combustion Plant Directive (MCPD). These directives establish emission limit values for various pollutants and require the use of Best Available Techniques (BAT) in industrial processes. Zeolite-supported catalysts have gained prominence as a BAT for gaseous pollutant removal, particularly in sectors such as power generation and chemical manufacturing.

In Asia, countries like China and India have also strengthened their environmental regulations in recent years. China's Air Pollution Prevention and Control Law and India's National Clean Air Programme have set ambitious targets for air quality improvement, driving the adoption of advanced catalytic technologies. The stringent emission standards in these rapidly industrializing nations have created a significant market opportunity for zeolite-supported catalysts.

Compliance with these regulations often requires continuous monitoring and reporting of emissions. This has led to the development of integrated systems that combine zeolite-supported catalysts with advanced monitoring technologies, ensuring real-time compliance and optimization of pollutant removal processes. The regulatory landscape has also influenced research priorities, with increased focus on enhancing catalyst durability, efficiency, and adaptability to various operating conditions.

The evolving nature of environmental regulations presents both challenges and opportunities for the field of zeolite-supported catalysts. As emission standards become more stringent, there is a constant need for innovation to meet these requirements cost-effectively. This regulatory pressure has accelerated research into novel zeolite structures, improved catalyst formulations, and more efficient reactor designs. Additionally, the global trend towards circular economy principles is influencing regulations, promoting the development of regenerable and recyclable zeolite catalysts to minimize waste and resource consumption.

Economic Feasibility of Zeolite Catalysts

The economic feasibility of zeolite catalysts for the removal of gaseous pollutants is a critical factor in their widespread adoption and implementation. Zeolite-supported catalysts have shown promising results in laboratory settings, but their economic viability on an industrial scale requires careful consideration.

One of the primary advantages of zeolite catalysts is their relatively low cost compared to other catalytic materials. Zeolites are naturally occurring aluminosilicate minerals, and synthetic zeolites can be produced at scale with reasonable expenses. This cost-effectiveness is particularly important when considering large-scale applications in industrial settings or for air pollution control in urban areas.

The longevity and durability of zeolite catalysts contribute significantly to their economic feasibility. These catalysts often demonstrate high thermal stability and resistance to deactivation, which translates to longer operational lifetimes. This extended usability reduces the frequency of catalyst replacement, thereby lowering long-term operational costs for pollution control systems.

Another economic advantage of zeolite catalysts is their versatility. A single type of zeolite catalyst can often be effective against multiple gaseous pollutants, reducing the need for separate treatment systems. This multi-functionality can lead to significant cost savings in terms of equipment and operational complexity.

The regeneration capability of zeolite catalysts further enhances their economic appeal. Many zeolite-based systems can be regenerated in-situ or through simple processes, allowing for repeated use without significant loss of catalytic activity. This regeneration potential substantially reduces the overall catalyst consumption and associated costs over time.

However, the economic feasibility of zeolite catalysts also faces challenges. The initial investment for implementing zeolite-based pollution control systems can be substantial, particularly for large-scale industrial applications. This upfront cost may be a barrier for some organizations, especially smaller enterprises or those in developing economies.

The performance of zeolite catalysts can be affected by the presence of moisture or certain chemical species in the gas stream, which may necessitate additional pretreatment steps. These requirements can increase the overall system complexity and operational costs, potentially impacting the economic viability in certain applications.

In conclusion, while zeolite catalysts offer several economic advantages in terms of cost-effectiveness, durability, and versatility, their overall economic feasibility depends on the specific application context, scale of operation, and local regulatory requirements. A comprehensive cost-benefit analysis, considering both short-term implementation costs and long-term operational savings, is essential for accurately assessing the economic viability of zeolite-supported catalysts in gaseous pollutant removal systems.

One of the primary advantages of zeolite catalysts is their relatively low cost compared to other catalytic materials. Zeolites are naturally occurring aluminosilicate minerals, and synthetic zeolites can be produced at scale with reasonable expenses. This cost-effectiveness is particularly important when considering large-scale applications in industrial settings or for air pollution control in urban areas.

The longevity and durability of zeolite catalysts contribute significantly to their economic feasibility. These catalysts often demonstrate high thermal stability and resistance to deactivation, which translates to longer operational lifetimes. This extended usability reduces the frequency of catalyst replacement, thereby lowering long-term operational costs for pollution control systems.

Another economic advantage of zeolite catalysts is their versatility. A single type of zeolite catalyst can often be effective against multiple gaseous pollutants, reducing the need for separate treatment systems. This multi-functionality can lead to significant cost savings in terms of equipment and operational complexity.

The regeneration capability of zeolite catalysts further enhances their economic appeal. Many zeolite-based systems can be regenerated in-situ or through simple processes, allowing for repeated use without significant loss of catalytic activity. This regeneration potential substantially reduces the overall catalyst consumption and associated costs over time.

However, the economic feasibility of zeolite catalysts also faces challenges. The initial investment for implementing zeolite-based pollution control systems can be substantial, particularly for large-scale industrial applications. This upfront cost may be a barrier for some organizations, especially smaller enterprises or those in developing economies.

The performance of zeolite catalysts can be affected by the presence of moisture or certain chemical species in the gas stream, which may necessitate additional pretreatment steps. These requirements can increase the overall system complexity and operational costs, potentially impacting the economic viability in certain applications.

In conclusion, while zeolite catalysts offer several economic advantages in terms of cost-effectiveness, durability, and versatility, their overall economic feasibility depends on the specific application context, scale of operation, and local regulatory requirements. A comprehensive cost-benefit analysis, considering both short-term implementation costs and long-term operational savings, is essential for accurately assessing the economic viability of zeolite-supported catalysts in gaseous pollutant removal systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!