Investigating Zeolites for Microbial Fuel Cell Efficiency

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Zeolite MFC Background

Microbial Fuel Cells (MFCs) have emerged as a promising technology for sustainable energy production and wastewater treatment. These bioelectrochemical systems harness the power of microorganisms to convert organic matter into electricity. The concept of MFCs dates back to the early 20th century, but significant advancements have been made in recent decades, particularly in improving their efficiency and practical applicability.

Zeolites, a class of aluminosilicate minerals, have recently gained attention in the field of MFC research due to their unique properties. These crystalline materials possess high surface area, uniform pore structure, and excellent ion-exchange capabilities. The integration of zeolites into MFC systems has shown potential to enhance various aspects of fuel cell performance, including power output, substrate utilization, and overall stability.

The use of zeolites in MFCs addresses several key challenges in the field. One of the primary limitations of MFCs has been their relatively low power density compared to conventional energy sources. Zeolites can potentially mitigate this issue by improving electron transfer processes and increasing the surface area available for microbial colonization. Additionally, the ion-exchange properties of zeolites may help in maintaining optimal conditions for microbial growth and activity within the fuel cell environment.

Research into zeolite-enhanced MFCs has explored various applications of these materials. Some studies have focused on using zeolites as electrode modifiers, creating more conducive surfaces for microbial attachment and electron transfer. Others have investigated the use of zeolites in membrane systems, aiming to improve proton exchange and reduce internal resistance. The versatility of zeolites allows for their integration at multiple points within the MFC architecture.

The development of zeolite-based MFCs intersects with broader trends in sustainable energy and environmental remediation. As global efforts to reduce carbon emissions intensify, technologies that can simultaneously generate clean energy and treat waste are becoming increasingly valuable. MFCs enhanced with zeolites have the potential to contribute to these goals by offering improved efficiency in both energy production and wastewater treatment processes.

Despite the promising results observed in laboratory settings, the application of zeolites in practical, large-scale MFC systems remains a challenge. Researchers are working to optimize zeolite formulations, develop cost-effective production methods, and address scalability issues. The ongoing investigation into zeolites for MFC efficiency represents a convergence of materials science, microbiology, and environmental engineering, highlighting the interdisciplinary nature of this field.

Zeolites, a class of aluminosilicate minerals, have recently gained attention in the field of MFC research due to their unique properties. These crystalline materials possess high surface area, uniform pore structure, and excellent ion-exchange capabilities. The integration of zeolites into MFC systems has shown potential to enhance various aspects of fuel cell performance, including power output, substrate utilization, and overall stability.

The use of zeolites in MFCs addresses several key challenges in the field. One of the primary limitations of MFCs has been their relatively low power density compared to conventional energy sources. Zeolites can potentially mitigate this issue by improving electron transfer processes and increasing the surface area available for microbial colonization. Additionally, the ion-exchange properties of zeolites may help in maintaining optimal conditions for microbial growth and activity within the fuel cell environment.

Research into zeolite-enhanced MFCs has explored various applications of these materials. Some studies have focused on using zeolites as electrode modifiers, creating more conducive surfaces for microbial attachment and electron transfer. Others have investigated the use of zeolites in membrane systems, aiming to improve proton exchange and reduce internal resistance. The versatility of zeolites allows for their integration at multiple points within the MFC architecture.

The development of zeolite-based MFCs intersects with broader trends in sustainable energy and environmental remediation. As global efforts to reduce carbon emissions intensify, technologies that can simultaneously generate clean energy and treat waste are becoming increasingly valuable. MFCs enhanced with zeolites have the potential to contribute to these goals by offering improved efficiency in both energy production and wastewater treatment processes.

Despite the promising results observed in laboratory settings, the application of zeolites in practical, large-scale MFC systems remains a challenge. Researchers are working to optimize zeolite formulations, develop cost-effective production methods, and address scalability issues. The ongoing investigation into zeolites for MFC efficiency represents a convergence of materials science, microbiology, and environmental engineering, highlighting the interdisciplinary nature of this field.

MFC Market Analysis

The microbial fuel cell (MFC) market has been experiencing significant growth in recent years, driven by increasing demand for sustainable energy solutions and wastewater treatment technologies. The global MFC market size was valued at approximately $10 million in 2020 and is projected to reach $20 million by 2025, growing at a CAGR of 15% during the forecast period.

The primary factors contributing to this market growth include rising environmental concerns, stringent government regulations on wastewater treatment, and the need for alternative energy sources. MFCs offer a unique advantage in simultaneously generating electricity and treating wastewater, making them attractive for various industries and municipalities.

The market for MFCs can be segmented based on application areas, including wastewater treatment, biosensors, and power generation. The wastewater treatment segment currently dominates the market, accounting for over 60% of the total market share. This is due to the increasing focus on water conservation and the need for cost-effective treatment solutions in both developed and developing countries.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States and Canada are the major contributors to the North American market, driven by substantial investments in research and development activities. Europe is witnessing rapid growth due to stringent environmental regulations and government initiatives promoting clean energy technologies.

The Asia-Pacific region is expected to exhibit the highest growth rate in the coming years, primarily due to rapid industrialization, urbanization, and increasing awareness about sustainable energy solutions in countries like China and India. These emerging economies are investing heavily in wastewater treatment infrastructure, creating significant opportunities for MFC technology adoption.

Key players in the MFC market include Cambrian Innovation, Emefcy, Microrganic Technologies, and Triqua International. These companies are focusing on technological advancements, strategic partnerships, and expanding their product portfolios to gain a competitive edge in the market.

The integration of zeolites in MFC technology is expected to create new growth opportunities in the market. Zeolites have the potential to enhance MFC efficiency by improving electron transfer and substrate utilization. This innovation could lead to increased power output and improved wastewater treatment capabilities, making MFCs more attractive for commercial applications.

However, challenges such as high initial costs, scalability issues, and limited awareness about MFC technology among end-users continue to hinder market growth. Overcoming these barriers through continued research, development, and demonstration projects will be crucial for widespread adoption of MFC technology in various industries and applications.

The primary factors contributing to this market growth include rising environmental concerns, stringent government regulations on wastewater treatment, and the need for alternative energy sources. MFCs offer a unique advantage in simultaneously generating electricity and treating wastewater, making them attractive for various industries and municipalities.

The market for MFCs can be segmented based on application areas, including wastewater treatment, biosensors, and power generation. The wastewater treatment segment currently dominates the market, accounting for over 60% of the total market share. This is due to the increasing focus on water conservation and the need for cost-effective treatment solutions in both developed and developing countries.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States and Canada are the major contributors to the North American market, driven by substantial investments in research and development activities. Europe is witnessing rapid growth due to stringent environmental regulations and government initiatives promoting clean energy technologies.

The Asia-Pacific region is expected to exhibit the highest growth rate in the coming years, primarily due to rapid industrialization, urbanization, and increasing awareness about sustainable energy solutions in countries like China and India. These emerging economies are investing heavily in wastewater treatment infrastructure, creating significant opportunities for MFC technology adoption.

Key players in the MFC market include Cambrian Innovation, Emefcy, Microrganic Technologies, and Triqua International. These companies are focusing on technological advancements, strategic partnerships, and expanding their product portfolios to gain a competitive edge in the market.

The integration of zeolites in MFC technology is expected to create new growth opportunities in the market. Zeolites have the potential to enhance MFC efficiency by improving electron transfer and substrate utilization. This innovation could lead to increased power output and improved wastewater treatment capabilities, making MFCs more attractive for commercial applications.

However, challenges such as high initial costs, scalability issues, and limited awareness about MFC technology among end-users continue to hinder market growth. Overcoming these barriers through continued research, development, and demonstration projects will be crucial for widespread adoption of MFC technology in various industries and applications.

Zeolite MFC Challenges

The integration of zeolites in microbial fuel cells (MFCs) presents several significant challenges that researchers and engineers must address to enhance overall system efficiency. One of the primary obstacles is optimizing the zeolite structure for effective ion exchange and catalytic activity within the MFC environment. The pore size and distribution of zeolites need to be carefully tailored to facilitate the movement of ions and substrates while preventing microbial fouling.

Another challenge lies in maintaining the long-term stability of zeolites under the harsh conditions typically found in MFCs. The acidic environment and presence of various metabolites can potentially degrade the zeolite structure over time, reducing its effectiveness. Researchers must develop strategies to enhance the chemical and mechanical stability of zeolites without compromising their beneficial properties.

The integration of zeolites into electrode materials poses additional challenges. Achieving a uniform distribution of zeolites within the electrode matrix while maintaining electrical conductivity is crucial for optimal performance. Furthermore, ensuring strong adhesion between zeolites and electrode surfaces to prevent detachment during operation remains a significant hurdle.

Scalability is another major concern when incorporating zeolites into MFCs. While zeolites may demonstrate promising results in laboratory-scale experiments, translating these benefits to larger, industrial-scale systems presents numerous engineering challenges. Issues such as uniform zeolite distribution, mass transfer limitations, and cost-effectiveness become more pronounced at larger scales.

The selection of appropriate zeolite types for specific MFC applications is also challenging. With numerous natural and synthetic zeolites available, each possessing unique properties, identifying the optimal zeolite composition for a given MFC setup requires extensive research and experimentation. Factors such as ion selectivity, surface area, and catalytic activity must be carefully balanced to maximize MFC performance.

Additionally, the potential environmental impact of zeolite use in MFCs must be considered. While zeolites are generally considered environmentally friendly, their large-scale application in MFCs may raise concerns about resource depletion and disposal of spent materials. Developing sustainable sourcing and recycling strategies for zeolites used in MFCs is essential for long-term viability.

Finally, the economic feasibility of incorporating zeolites into MFCs remains a significant challenge. The cost of zeolite production, modification, and integration must be balanced against the performance gains achieved. Researchers and engineers must work towards developing cost-effective methods for zeolite synthesis and modification to make their use in MFCs economically viable for widespread adoption.

Another challenge lies in maintaining the long-term stability of zeolites under the harsh conditions typically found in MFCs. The acidic environment and presence of various metabolites can potentially degrade the zeolite structure over time, reducing its effectiveness. Researchers must develop strategies to enhance the chemical and mechanical stability of zeolites without compromising their beneficial properties.

The integration of zeolites into electrode materials poses additional challenges. Achieving a uniform distribution of zeolites within the electrode matrix while maintaining electrical conductivity is crucial for optimal performance. Furthermore, ensuring strong adhesion between zeolites and electrode surfaces to prevent detachment during operation remains a significant hurdle.

Scalability is another major concern when incorporating zeolites into MFCs. While zeolites may demonstrate promising results in laboratory-scale experiments, translating these benefits to larger, industrial-scale systems presents numerous engineering challenges. Issues such as uniform zeolite distribution, mass transfer limitations, and cost-effectiveness become more pronounced at larger scales.

The selection of appropriate zeolite types for specific MFC applications is also challenging. With numerous natural and synthetic zeolites available, each possessing unique properties, identifying the optimal zeolite composition for a given MFC setup requires extensive research and experimentation. Factors such as ion selectivity, surface area, and catalytic activity must be carefully balanced to maximize MFC performance.

Additionally, the potential environmental impact of zeolite use in MFCs must be considered. While zeolites are generally considered environmentally friendly, their large-scale application in MFCs may raise concerns about resource depletion and disposal of spent materials. Developing sustainable sourcing and recycling strategies for zeolites used in MFCs is essential for long-term viability.

Finally, the economic feasibility of incorporating zeolites into MFCs remains a significant challenge. The cost of zeolite production, modification, and integration must be balanced against the performance gains achieved. Researchers and engineers must work towards developing cost-effective methods for zeolite synthesis and modification to make their use in MFCs economically viable for widespread adoption.

Current Zeolite MFC Solutions

01 Zeolite synthesis and modification

This category focuses on the development of new methods for synthesizing zeolites and modifying their properties to enhance efficiency. Techniques include novel synthesis routes, post-synthesis treatments, and incorporation of additional elements to tailor zeolite characteristics for specific applications.- Zeolite synthesis and modification: This category focuses on the development of new methods for synthesizing zeolites and modifying their structures to enhance efficiency. Techniques include novel synthesis routes, post-synthesis treatments, and incorporation of additional elements to improve catalytic activity and selectivity.

- Zeolites in catalytic processes: Zeolites are widely used as catalysts in various industrial processes. This point covers the application of zeolites in catalytic reactions, including hydrocarbon conversion, fine chemical synthesis, and environmental remediation. The efficiency of zeolites in these processes is explored and optimized.

- Zeolite membranes and separation technologies: This category addresses the use of zeolites in membrane technologies for efficient separation processes. It includes the development of zeolite-based membranes for gas separation, water purification, and molecular sieving applications, focusing on improving separation efficiency and selectivity.

- Zeolite characterization and performance evaluation: This point covers techniques and methodologies for characterizing zeolite properties and evaluating their performance in various applications. It includes advanced analytical methods, in-situ characterization techniques, and performance testing protocols to assess and optimize zeolite efficiency.

- Zeolites in environmental applications: This category focuses on the use of zeolites in environmental applications, such as wastewater treatment, air purification, and soil remediation. It explores the efficiency of zeolites in removing pollutants, heavy metals, and other contaminants from various environmental matrices.

02 Zeolite-based catalysts

Zeolites are widely used as catalysts in various industrial processes. This category covers the development of zeolite-based catalysts with improved efficiency, selectivity, and stability. It includes research on optimizing catalyst composition, structure, and performance for specific reactions.Expand Specific Solutions03 Adsorption and separation applications

Zeolites are efficient adsorbents and molecular sieves. This category focuses on enhancing zeolite efficiency in adsorption and separation processes, including gas purification, water treatment, and molecular sieving. It covers the development of zeolite materials with improved selectivity and capacity for target molecules.Expand Specific Solutions04 Ion exchange and water softening

Zeolites are effective ion exchangers, particularly for water softening applications. This category addresses improvements in zeolite efficiency for ion exchange processes, including enhanced capacity, regeneration methods, and selectivity for specific ions.Expand Specific Solutions05 Zeolite membranes and thin films

This category focuses on the development of zeolite membranes and thin films for various applications, including gas separation, pervaporation, and membrane reactors. It covers techniques to improve membrane efficiency, such as reducing defects, enhancing permeability, and optimizing selectivity.Expand Specific Solutions

Key MFC Industry Players

The investigation of zeolites for microbial fuel cell efficiency is in an early developmental stage, with a growing market potential as renewable energy solutions gain traction. The technology's maturity is still evolving, with research institutions like Massachusetts Institute of Technology and Tsinghua University leading academic efforts. Companies such as Haldor Topsøe A/S and LG Chem Ltd. are exploring commercial applications, leveraging their expertise in catalysts and materials science. The competitive landscape is diverse, involving both established players and emerging startups, reflecting the interdisciplinary nature of this field. As the technology progresses, collaborations between academia and industry are likely to accelerate innovation and market adoption.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a novel approach to enhance microbial fuel cell (MFC) efficiency using zeolites. Their research focuses on utilizing zeolites as a support material for microbial biofilms, improving electron transfer and substrate diffusion. The team has engineered zeolite structures with optimized pore sizes and surface properties to enhance bacterial adhesion and metabolic activity[1]. Additionally, they have explored the use of metal-doped zeolites to catalyze redox reactions within the MFC, further increasing power output[3]. MIT's approach also includes the development of hierarchical zeolite structures that combine micro- and meso-porosity, allowing for better mass transport while maintaining high surface area[5].

Strengths: Cutting-edge research in zeolite engineering, multidisciplinary approach combining materials science and microbiology. Weaknesses: Potential scalability challenges, high cost of specialized zeolite materials.

Haldor Topsøe A/S

Technical Solution: Haldor Topsøe has developed a proprietary zeolite-based technology for enhancing MFC efficiency. Their approach involves the synthesis of tailored zeolite catalysts that facilitate both anodic and cathodic reactions in MFCs. The company has created a series of ion-exchanged zeolites that improve the conductivity of the electrode materials, leading to enhanced electron transfer rates[2]. Additionally, Haldor Topsøe has developed a method for incorporating redox-active metal centers within zeolite frameworks, which act as electron mediators between bacteria and electrodes[4]. Their technology also includes the use of zeolite membranes as proton exchange membranes, improving overall MFC performance by optimizing proton transfer[6].

Strengths: Strong industrial expertise in zeolite synthesis and catalysis, potential for large-scale production. Weaknesses: Primarily focused on chemical aspects, may lack in-depth microbiology expertise.

Zeolite MFC Innovations

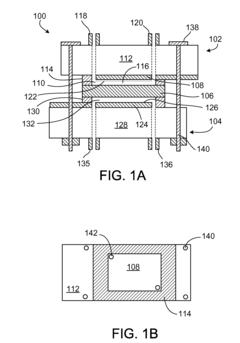

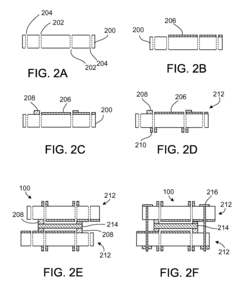

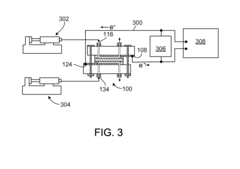

Micro-sized microbial fuel cell

PatentInactiveUS8734968B2

Innovation

- A micro-sized microbial fuel cell design featuring an anode and cathode portions separated by a cation exchange membrane, with a biofilm matrix supported on the anode and a high specific surface area, utilizing a process involving electron beam evaporation and spin-coating to form gaskets and electrodes, allowing for the creation of microfluidic chambers for anolyte and catholyte, achieving a Coulombic efficiency of at least 30% and a power density of 4.7 μW/cm².

Environmental Impact of MFCs

Microbial Fuel Cells (MFCs) have emerged as a promising technology for sustainable energy production and waste treatment. As research into MFCs continues to advance, it is crucial to consider their environmental impact. The integration of zeolites in MFCs has shown potential for enhancing efficiency, but it also raises questions about the overall environmental footprint of these systems.

One of the primary environmental benefits of MFCs is their ability to treat wastewater while simultaneously generating electricity. This dual functionality reduces the energy requirements for conventional wastewater treatment processes, potentially leading to significant reductions in greenhouse gas emissions. The incorporation of zeolites into MFCs may further improve this aspect by enhancing the removal of contaminants and increasing power output.

Zeolites, being naturally occurring aluminosilicate minerals, are generally considered environmentally friendly. Their use in MFCs could potentially reduce the need for synthetic materials, which often have higher environmental costs associated with their production. However, the mining and processing of zeolites do have some environmental impacts, including land disturbance and energy consumption, which must be factored into the overall assessment.

The longevity and stability of zeolite-enhanced MFCs could contribute to reduced waste generation. If zeolites can improve the durability of MFC components or extend the operational lifespan of these systems, it would result in less frequent replacement and disposal of materials. This aspect is particularly important when considering the life cycle analysis of MFC technology.

Water conservation is another potential environmental benefit of zeolite-enhanced MFCs. By improving the efficiency of wastewater treatment, these systems may reduce the overall water footprint associated with energy production and waste management. This is especially significant in water-stressed regions where sustainable water use is a critical concern.

The scalability of MFCs with zeolite integration could have implications for their environmental impact. If zeolites enable the development of more compact and efficient MFC designs, it could lead to reduced land use requirements for large-scale implementations. This could be particularly beneficial in urban environments where space is at a premium.

However, it is important to consider potential negative environmental impacts as well. The production and transportation of zeolites for MFC applications could contribute to carbon emissions, depending on the sourcing and manufacturing processes involved. Additionally, the disposal or recycling of zeolite materials at the end of their useful life in MFCs must be carefully managed to prevent environmental contamination.

In conclusion, while the integration of zeolites in MFCs shows promise for enhancing efficiency and environmental performance, a comprehensive life cycle assessment is necessary to fully understand the net environmental impact of this technology. Future research should focus on optimizing the environmental benefits while minimizing potential drawbacks to ensure that zeolite-enhanced MFCs contribute positively to sustainable energy and waste management solutions.

One of the primary environmental benefits of MFCs is their ability to treat wastewater while simultaneously generating electricity. This dual functionality reduces the energy requirements for conventional wastewater treatment processes, potentially leading to significant reductions in greenhouse gas emissions. The incorporation of zeolites into MFCs may further improve this aspect by enhancing the removal of contaminants and increasing power output.

Zeolites, being naturally occurring aluminosilicate minerals, are generally considered environmentally friendly. Their use in MFCs could potentially reduce the need for synthetic materials, which often have higher environmental costs associated with their production. However, the mining and processing of zeolites do have some environmental impacts, including land disturbance and energy consumption, which must be factored into the overall assessment.

The longevity and stability of zeolite-enhanced MFCs could contribute to reduced waste generation. If zeolites can improve the durability of MFC components or extend the operational lifespan of these systems, it would result in less frequent replacement and disposal of materials. This aspect is particularly important when considering the life cycle analysis of MFC technology.

Water conservation is another potential environmental benefit of zeolite-enhanced MFCs. By improving the efficiency of wastewater treatment, these systems may reduce the overall water footprint associated with energy production and waste management. This is especially significant in water-stressed regions where sustainable water use is a critical concern.

The scalability of MFCs with zeolite integration could have implications for their environmental impact. If zeolites enable the development of more compact and efficient MFC designs, it could lead to reduced land use requirements for large-scale implementations. This could be particularly beneficial in urban environments where space is at a premium.

However, it is important to consider potential negative environmental impacts as well. The production and transportation of zeolites for MFC applications could contribute to carbon emissions, depending on the sourcing and manufacturing processes involved. Additionally, the disposal or recycling of zeolite materials at the end of their useful life in MFCs must be carefully managed to prevent environmental contamination.

In conclusion, while the integration of zeolites in MFCs shows promise for enhancing efficiency and environmental performance, a comprehensive life cycle assessment is necessary to fully understand the net environmental impact of this technology. Future research should focus on optimizing the environmental benefits while minimizing potential drawbacks to ensure that zeolite-enhanced MFCs contribute positively to sustainable energy and waste management solutions.

Zeolite MFC Scalability

The scalability of zeolite-enhanced microbial fuel cells (MFCs) presents both opportunities and challenges for large-scale implementation. As research progresses, the potential for scaling up these systems becomes increasingly apparent, with several key factors influencing their viability at industrial levels.

One of the primary advantages of zeolite-enhanced MFCs is their improved power density and efficiency compared to conventional MFCs. This enhancement is attributed to the unique properties of zeolites, including their high surface area, ion exchange capacity, and ability to immobilize microorganisms. These characteristics contribute to better electron transfer and substrate utilization, potentially reducing the overall footprint required for large-scale MFC installations.

However, scaling up zeolite-enhanced MFCs also faces several hurdles. The cost of zeolites, particularly synthetic varieties with tailored properties, can be significant when considering industrial-scale applications. This economic factor necessitates a careful balance between performance improvements and material costs. Additionally, the long-term stability of zeolite structures in MFC environments requires further investigation to ensure consistent performance over extended operational periods.

Another critical aspect of scalability is the design of MFC reactors that can effectively incorporate zeolites while maintaining optimal conditions for microbial growth and electron transfer. As the size of MFC systems increases, issues such as mass transfer limitations, pH gradients, and substrate distribution become more pronounced. Innovative reactor designs that address these challenges while maximizing the benefits of zeolites are essential for successful scaling.

The integration of zeolite-enhanced MFCs with existing wastewater treatment infrastructure presents an opportunity for large-scale implementation. By leveraging current treatment facilities, the adoption of this technology could be accelerated. However, this approach requires careful consideration of compatibility issues and potential modifications to existing systems.

Standardization of zeolite-enhanced MFC components and manufacturing processes is crucial for widespread adoption and scalability. Developing standardized modules or units that can be easily replicated and assembled could significantly reduce production costs and simplify maintenance procedures. This approach would also facilitate the integration of these systems into various applications beyond wastewater treatment, such as bioremediation or energy recovery from organic waste streams.

As research continues, addressing these scalability challenges will be crucial for realizing the full potential of zeolite-enhanced MFCs in industrial applications. Collaborative efforts between material scientists, microbiologists, and engineers will be essential in overcoming these obstacles and paving the way for large-scale implementation of this promising technology.

One of the primary advantages of zeolite-enhanced MFCs is their improved power density and efficiency compared to conventional MFCs. This enhancement is attributed to the unique properties of zeolites, including their high surface area, ion exchange capacity, and ability to immobilize microorganisms. These characteristics contribute to better electron transfer and substrate utilization, potentially reducing the overall footprint required for large-scale MFC installations.

However, scaling up zeolite-enhanced MFCs also faces several hurdles. The cost of zeolites, particularly synthetic varieties with tailored properties, can be significant when considering industrial-scale applications. This economic factor necessitates a careful balance between performance improvements and material costs. Additionally, the long-term stability of zeolite structures in MFC environments requires further investigation to ensure consistent performance over extended operational periods.

Another critical aspect of scalability is the design of MFC reactors that can effectively incorporate zeolites while maintaining optimal conditions for microbial growth and electron transfer. As the size of MFC systems increases, issues such as mass transfer limitations, pH gradients, and substrate distribution become more pronounced. Innovative reactor designs that address these challenges while maximizing the benefits of zeolites are essential for successful scaling.

The integration of zeolite-enhanced MFCs with existing wastewater treatment infrastructure presents an opportunity for large-scale implementation. By leveraging current treatment facilities, the adoption of this technology could be accelerated. However, this approach requires careful consideration of compatibility issues and potential modifications to existing systems.

Standardization of zeolite-enhanced MFC components and manufacturing processes is crucial for widespread adoption and scalability. Developing standardized modules or units that can be easily replicated and assembled could significantly reduce production costs and simplify maintenance procedures. This approach would also facilitate the integration of these systems into various applications beyond wastewater treatment, such as bioremediation or energy recovery from organic waste streams.

As research continues, addressing these scalability challenges will be crucial for realizing the full potential of zeolite-enhanced MFCs in industrial applications. Collaborative efforts between material scientists, microbiologists, and engineers will be essential in overcoming these obstacles and paving the way for large-scale implementation of this promising technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!