Zeolite Encapsulation of Metal Ions for Antibacterial Surface Applications

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Zeolite Encapsulation Background and Objectives

Zeolite encapsulation of metal ions for antibacterial surface applications represents a cutting-edge approach in the field of materials science and antimicrobial technology. This innovative technique combines the unique properties of zeolites, crystalline aluminosilicate minerals known for their porous structure and ion-exchange capabilities, with the antimicrobial properties of metal ions. The development of this technology has been driven by the increasing need for effective and long-lasting antibacterial surfaces in various sectors, including healthcare, food processing, and consumer products.

The historical context of this technology can be traced back to the discovery of zeolites in the 18th century and the subsequent understanding of their molecular sieve properties in the mid-20th century. Concurrently, the antimicrobial properties of certain metal ions, such as silver, copper, and zinc, have been recognized and utilized for centuries. The convergence of these two fields has led to the emergence of zeolite encapsulation as a promising strategy for creating durable antibacterial surfaces.

The primary objective of zeolite encapsulation of metal ions is to develop surfaces that can effectively inhibit bacterial growth and proliferation over extended periods. This technology aims to address the limitations of traditional antibacterial coatings, which often suffer from rapid depletion of active agents or environmental degradation. By encapsulating metal ions within the zeolite framework, researchers seek to create a controlled release mechanism that maintains antimicrobial efficacy while minimizing the overall metal content required.

Key technological goals in this field include optimizing the ion exchange process to ensure efficient loading of metal ions into zeolite structures, developing methods to incorporate zeolite-metal complexes into various surface materials, and enhancing the durability and longevity of the antibacterial effects. Additionally, there is a focus on expanding the range of applicable metal ions and zeolite types to tailor the antimicrobial properties for specific applications and target organisms.

The evolution of this technology is closely tied to advancements in nanotechnology and materials engineering. Recent trends indicate a growing interest in combining zeolite encapsulation with other surface modification techniques to create multifunctional coatings that not only exhibit antibacterial properties but also possess self-cleaning, anti-fouling, or even self-healing capabilities.

As research in this area progresses, there is an increasing emphasis on understanding the mechanisms of action at the molecular level, optimizing the release kinetics of metal ions, and addressing potential environmental and health concerns associated with the use of metal-based antimicrobial agents. The ultimate aim is to develop sustainable, cost-effective, and highly efficient antibacterial surfaces that can significantly reduce the risk of pathogen transmission in various settings, contributing to improved public health and hygiene standards.

The historical context of this technology can be traced back to the discovery of zeolites in the 18th century and the subsequent understanding of their molecular sieve properties in the mid-20th century. Concurrently, the antimicrobial properties of certain metal ions, such as silver, copper, and zinc, have been recognized and utilized for centuries. The convergence of these two fields has led to the emergence of zeolite encapsulation as a promising strategy for creating durable antibacterial surfaces.

The primary objective of zeolite encapsulation of metal ions is to develop surfaces that can effectively inhibit bacterial growth and proliferation over extended periods. This technology aims to address the limitations of traditional antibacterial coatings, which often suffer from rapid depletion of active agents or environmental degradation. By encapsulating metal ions within the zeolite framework, researchers seek to create a controlled release mechanism that maintains antimicrobial efficacy while minimizing the overall metal content required.

Key technological goals in this field include optimizing the ion exchange process to ensure efficient loading of metal ions into zeolite structures, developing methods to incorporate zeolite-metal complexes into various surface materials, and enhancing the durability and longevity of the antibacterial effects. Additionally, there is a focus on expanding the range of applicable metal ions and zeolite types to tailor the antimicrobial properties for specific applications and target organisms.

The evolution of this technology is closely tied to advancements in nanotechnology and materials engineering. Recent trends indicate a growing interest in combining zeolite encapsulation with other surface modification techniques to create multifunctional coatings that not only exhibit antibacterial properties but also possess self-cleaning, anti-fouling, or even self-healing capabilities.

As research in this area progresses, there is an increasing emphasis on understanding the mechanisms of action at the molecular level, optimizing the release kinetics of metal ions, and addressing potential environmental and health concerns associated with the use of metal-based antimicrobial agents. The ultimate aim is to develop sustainable, cost-effective, and highly efficient antibacterial surfaces that can significantly reduce the risk of pathogen transmission in various settings, contributing to improved public health and hygiene standards.

Market Analysis for Antibacterial Surfaces

The market for antibacterial surfaces has experienced significant growth in recent years, driven by increasing awareness of hygiene and the need for infection control across various sectors. The global antibacterial coatings market is expected to reach substantial value by 2025, with a compound annual growth rate (CAGR) exceeding 10% during the forecast period. This growth is primarily attributed to the rising demand in healthcare facilities, food processing industries, and public spaces.

Healthcare sector remains the largest consumer of antibacterial surfaces, accounting for a significant portion of the market share. Hospitals, clinics, and other medical facilities are increasingly adopting these surfaces to reduce the risk of hospital-acquired infections (HAIs) and improve patient safety. The COVID-19 pandemic has further accelerated this trend, with heightened focus on surface disinfection and long-lasting antimicrobial protection.

The food and beverage industry is another key market for antibacterial surfaces, driven by stringent regulations on food safety and hygiene. Manufacturers are incorporating these surfaces in food processing equipment, packaging materials, and storage facilities to prevent bacterial contamination and extend product shelf life. This sector is expected to witness robust growth in the coming years as food safety concerns continue to rise globally.

Consumer goods and home appliances represent an emerging market for antibacterial surfaces. With increasing health consciousness among consumers, there is a growing demand for household items with built-in antimicrobial properties. This includes kitchen appliances, bathroom fixtures, and electronic devices with touch surfaces.

Geographically, North America and Europe currently dominate the antibacterial surfaces market, owing to advanced healthcare infrastructure and stringent regulations. However, Asia-Pacific is projected to be the fastest-growing region, driven by rapid urbanization, increasing healthcare expenditure, and growing awareness of hygiene practices in countries like China and India.

The market is characterized by intense competition among key players, with continuous innovation in product development. Major companies are investing heavily in research and development to create more effective and durable antibacterial surfaces. The integration of nanotechnology and advanced materials science is opening new avenues for product innovation, with a focus on developing surfaces that can provide long-lasting protection against a broad spectrum of microorganisms.

Healthcare sector remains the largest consumer of antibacterial surfaces, accounting for a significant portion of the market share. Hospitals, clinics, and other medical facilities are increasingly adopting these surfaces to reduce the risk of hospital-acquired infections (HAIs) and improve patient safety. The COVID-19 pandemic has further accelerated this trend, with heightened focus on surface disinfection and long-lasting antimicrobial protection.

The food and beverage industry is another key market for antibacterial surfaces, driven by stringent regulations on food safety and hygiene. Manufacturers are incorporating these surfaces in food processing equipment, packaging materials, and storage facilities to prevent bacterial contamination and extend product shelf life. This sector is expected to witness robust growth in the coming years as food safety concerns continue to rise globally.

Consumer goods and home appliances represent an emerging market for antibacterial surfaces. With increasing health consciousness among consumers, there is a growing demand for household items with built-in antimicrobial properties. This includes kitchen appliances, bathroom fixtures, and electronic devices with touch surfaces.

Geographically, North America and Europe currently dominate the antibacterial surfaces market, owing to advanced healthcare infrastructure and stringent regulations. However, Asia-Pacific is projected to be the fastest-growing region, driven by rapid urbanization, increasing healthcare expenditure, and growing awareness of hygiene practices in countries like China and India.

The market is characterized by intense competition among key players, with continuous innovation in product development. Major companies are investing heavily in research and development to create more effective and durable antibacterial surfaces. The integration of nanotechnology and advanced materials science is opening new avenues for product innovation, with a focus on developing surfaces that can provide long-lasting protection against a broad spectrum of microorganisms.

Current Challenges in Metal Ion Encapsulation

The encapsulation of metal ions in zeolites for antibacterial surface applications faces several significant challenges. One of the primary issues is achieving uniform distribution and stable retention of metal ions within the zeolite framework. The complex porous structure of zeolites can lead to uneven distribution of metal ions, resulting in inconsistent antibacterial performance across the surface.

Another challenge lies in controlling the release rate of metal ions from the zeolite matrix. Rapid release may provide initial high antibacterial activity but can quickly diminish over time, while overly slow release may not achieve the desired antimicrobial effect. Striking the right balance for sustained, effective antibacterial action remains a key hurdle in this field.

The selection of appropriate zeolite types and metal ions for specific applications presents another obstacle. Different zeolite structures and compositions can significantly affect the encapsulation efficiency and release kinetics of metal ions. Similarly, various metal ions exhibit different antibacterial mechanisms and efficacies, necessitating careful consideration in their selection for target pathogens and environments.

Environmental factors pose additional challenges to the stability and performance of metal ion-encapsulated zeolites. Exposure to varying pH levels, temperatures, and ionic strengths in different application settings can alter the release behavior of metal ions and potentially compromise the zeolite structure itself. Ensuring robustness across diverse conditions is crucial for practical applications.

Scalability and cost-effectiveness in the production of metal ion-encapsulated zeolites remain significant hurdles. Current synthesis methods often involve complex procedures and expensive precursors, limiting large-scale industrial adoption. Developing more efficient and economical production techniques is essential for widespread implementation of this technology.

Potential toxicity and environmental impact of released metal ions are also concerns that need addressing. While the antibacterial properties are beneficial, uncontrolled release of certain metal ions may have adverse effects on human health and ecosystems. Balancing efficacy with safety is a critical challenge in the development of these materials.

Lastly, the long-term stability and durability of metal ion-encapsulated zeolites in various applications require further investigation. Factors such as mechanical wear, chemical degradation, and biofilm formation can affect the performance and lifespan of these antibacterial surfaces. Enhancing the longevity and maintaining consistent efficacy over extended periods remain important areas for improvement in this field.

Another challenge lies in controlling the release rate of metal ions from the zeolite matrix. Rapid release may provide initial high antibacterial activity but can quickly diminish over time, while overly slow release may not achieve the desired antimicrobial effect. Striking the right balance for sustained, effective antibacterial action remains a key hurdle in this field.

The selection of appropriate zeolite types and metal ions for specific applications presents another obstacle. Different zeolite structures and compositions can significantly affect the encapsulation efficiency and release kinetics of metal ions. Similarly, various metal ions exhibit different antibacterial mechanisms and efficacies, necessitating careful consideration in their selection for target pathogens and environments.

Environmental factors pose additional challenges to the stability and performance of metal ion-encapsulated zeolites. Exposure to varying pH levels, temperatures, and ionic strengths in different application settings can alter the release behavior of metal ions and potentially compromise the zeolite structure itself. Ensuring robustness across diverse conditions is crucial for practical applications.

Scalability and cost-effectiveness in the production of metal ion-encapsulated zeolites remain significant hurdles. Current synthesis methods often involve complex procedures and expensive precursors, limiting large-scale industrial adoption. Developing more efficient and economical production techniques is essential for widespread implementation of this technology.

Potential toxicity and environmental impact of released metal ions are also concerns that need addressing. While the antibacterial properties are beneficial, uncontrolled release of certain metal ions may have adverse effects on human health and ecosystems. Balancing efficacy with safety is a critical challenge in the development of these materials.

Lastly, the long-term stability and durability of metal ion-encapsulated zeolites in various applications require further investigation. Factors such as mechanical wear, chemical degradation, and biofilm formation can affect the performance and lifespan of these antibacterial surfaces. Enhancing the longevity and maintaining consistent efficacy over extended periods remain important areas for improvement in this field.

Existing Metal Ion Encapsulation Techniques

01 Zeolite encapsulation of metal ions for antibacterial properties

Zeolites can be used to encapsulate metal ions, such as silver, copper, or zinc, to create antibacterial materials. The porous structure of zeolites allows for controlled release of metal ions, providing long-lasting antimicrobial effects. This technique can be applied in various fields, including healthcare, textiles, and water treatment.- Zeolite encapsulation of metal ions for antibacterial properties: Zeolites can be used to encapsulate metal ions, such as silver, copper, or zinc, to create antibacterial materials. The porous structure of zeolites allows for controlled release of metal ions, providing long-lasting antibacterial effects. This method is effective for various applications, including water treatment, medical devices, and consumer products.

- Synthesis and modification of zeolites for improved metal ion encapsulation: Various methods are employed to synthesize and modify zeolites to enhance their metal ion encapsulation capabilities. These include hydrothermal synthesis, ion exchange, and surface modification techniques. The goal is to optimize the zeolite structure for better metal ion retention and controlled release, leading to more effective antibacterial properties.

- Applications of zeolite-encapsulated metal ions in water treatment: Zeolite-encapsulated metal ions are particularly useful in water treatment applications. They can be incorporated into filtration systems, membranes, or used as adsorbents to remove bacteria and other contaminants from water. This technology offers advantages such as high efficiency, reusability, and environmental friendliness compared to traditional water treatment methods.

- Incorporation of zeolite-encapsulated metal ions in medical devices and healthcare products: Zeolite-encapsulated metal ions are utilized in various medical devices and healthcare products to impart antibacterial properties. This includes wound dressings, catheters, implants, and dental materials. The controlled release of metal ions from zeolites provides sustained antimicrobial activity, reducing the risk of infections and improving patient outcomes.

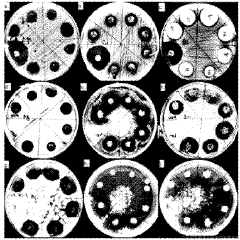

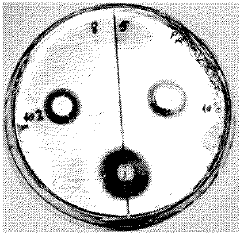

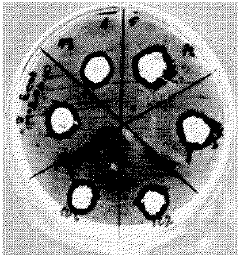

- Characterization and testing of zeolite-encapsulated metal ion antibacterial materials: Various analytical techniques and testing methods are employed to characterize and evaluate the performance of zeolite-encapsulated metal ion antibacterial materials. These include spectroscopic methods, microscopy, and microbiological assays to assess metal ion release kinetics, antibacterial efficacy, and long-term stability. Such characterization is crucial for optimizing formulations and ensuring product quality.

02 Synthesis methods for metal ion-loaded zeolites

Various methods can be employed to synthesize metal ion-loaded zeolites, including ion exchange, impregnation, and in-situ synthesis. These processes involve incorporating metal ions into the zeolite framework or pores, optimizing the antibacterial efficacy of the resulting material.Expand Specific Solutions03 Applications of antibacterial zeolites in consumer products

Metal ion-loaded zeolites can be incorporated into various consumer products to impart antibacterial properties. These applications include personal care items, household cleaning products, and food packaging materials, enhancing their ability to inhibit bacterial growth and improve hygiene.Expand Specific Solutions04 Environmental and medical applications of antibacterial zeolites

Zeolites with encapsulated metal ions find applications in environmental remediation and medical fields. They can be used for water purification, air filtration, and as antimicrobial coatings for medical devices and implants, leveraging their ability to release metal ions in a controlled manner.Expand Specific Solutions05 Characterization and performance evaluation of antibacterial zeolites

Various analytical techniques are employed to characterize metal ion-loaded zeolites and evaluate their antibacterial performance. These methods include spectroscopic analysis, microscopy, and microbiological assays to assess the efficacy and longevity of the antibacterial properties in different environmental conditions.Expand Specific Solutions

Key Players in Zeolite and Antibacterial Industries

The field of zeolite encapsulation of metal ions for antibacterial surface applications is in a growth phase, with increasing market potential due to rising demand for antimicrobial solutions across various industries. The global market size for antimicrobial coatings is projected to reach several billion dollars by 2025. Technologically, this area is advancing rapidly, with companies like Sinanen Zeomic Co., Ltd. and DiFusion Technologies, Inc. leading in innovation. Larger corporations such as Koninklijke Philips NV and FUJIFILM Corp. are also investing in this technology, indicating its growing importance. The involvement of academic institutions like The Hong Kong University of Science & Technology and National Central University suggests ongoing research and development efforts to improve the efficacy and applications of this technology.

Sinanen Zeomic Co., Ltd.

Technical Solution: Sinanen Zeomic has developed a proprietary zeolite-based antibacterial technology that encapsulates silver ions within the zeolite structure. This method allows for controlled release of silver ions, providing long-lasting antibacterial effects. The company's zeolite particles are typically 1-3 μm in size, ensuring even distribution and effectiveness when incorporated into various materials[1]. Their technology involves a unique ion-exchange process that allows for precise control of silver ion concentration, optimizing antibacterial efficacy while minimizing potential environmental impacts[2]. The zeolite encapsulation also protects the silver ions from degradation, extending the functional lifespan of the antibacterial properties[3].

Strengths: Controlled release of silver ions, long-lasting antibacterial effects, and protection of active ingredients. Weaknesses: Potential for higher production costs and limited compatibility with certain materials.

Sumitomo Seika Chemicals Co., Ltd.

Technical Solution: Sumitomo Seika Chemicals has developed a zeolite-based antibacterial technology that focuses on creating highly stable and efficient silver ion carriers. Their approach involves synthesizing custom zeolite structures with optimized pore sizes and distributions to enhance silver ion loading and release characteristics. The company's technology incorporates a unique surface treatment process that improves the zeolite particles' dispersibility in various matrices, including polymers and coatings[10]. Sumitomo Seika's zeolite encapsulation method also includes strategies to prevent agglomeration of silver ions, ensuring consistent antibacterial performance over extended periods[11]. Their technology has been successfully applied in a range of industrial and consumer products, demonstrating its versatility and effectiveness in diverse applications[12].

Strengths: Customized zeolite structures, improved dispersibility, and prevention of silver ion agglomeration. Weaknesses: Potentially complex manufacturing process and higher costs for specialized applications.

Innovative Zeolite Structures for Ion Retention

Antibacterial agent

PatentActiveJP2007131551A

Innovation

- The development of a tabular zeolite with specific size and shape parameters (0.05 to 1.0 μm diameter, 0.01 to 0.25 μm thickness, and a D/T ratio of 4 or more) containing metal ions like silver, copper, and zinc, with a specific surface area of 200-1000 m²/g, enhances adhesion, dispersibility, and maintains high antibacterial performance over time.

Antimicrobial material including metal ion filled in synthetic zeolite

PatentInactiveJP2018024633A

Innovation

- Development of zeolite-containing building materials with separately added silver, copper, and zinc metal ions to provide antifungal, anticandida, and antibacterial properties.

Environmental Impact of Zeolite-based Materials

The environmental impact of zeolite-based materials, particularly those used in antibacterial surface applications, is a crucial consideration in their development and deployment. Zeolites, as aluminosilicate minerals with a porous structure, have gained attention for their ability to encapsulate metal ions, which can impart antibacterial properties to surfaces. However, their widespread use raises important questions about their long-term effects on ecosystems and human health.

One of the primary environmental concerns associated with zeolite-based antibacterial materials is their potential for leaching. As these materials are exposed to various environmental conditions, there is a risk that the encapsulated metal ions may be released over time. This leaching process could lead to the accumulation of metal ions in soil and water systems, potentially affecting aquatic life and terrestrial ecosystems. The extent of this impact depends on factors such as the stability of the zeolite structure, the type and concentration of metal ions used, and the environmental conditions to which the materials are exposed.

Another aspect to consider is the biodegradability of zeolite-based materials. While natural zeolites are generally considered environmentally friendly due to their mineral origin, synthetic zeolites and modified zeolite composites may have different degradation profiles. The persistence of these materials in the environment could lead to long-term accumulation, particularly in aquatic sediments or soil. This raises questions about their potential to act as microplastic-like pollutants, especially when used in consumer products or industrial applications with high disposal rates.

The production process of zeolite-based antibacterial materials also warrants environmental scrutiny. The synthesis of zeolites and their modification with metal ions often involves energy-intensive processes and the use of chemicals that may have their own environmental footprints. Life cycle assessments are necessary to evaluate the overall environmental impact, from raw material extraction to disposal or recycling. This holistic approach helps in comparing zeolite-based solutions with alternative antibacterial technologies and materials.

On the positive side, the use of zeolite-encapsulated metal ions for antibacterial surfaces may offer environmental benefits by reducing the need for traditional chemical disinfectants. This could lead to a decrease in the release of harmful chemicals into the environment and potentially mitigate the development of antibiotic-resistant bacteria. Additionally, the controlled release of antibacterial agents from zeolites may result in more efficient use of these substances, reducing overall consumption and environmental exposure.

The potential for recycling and reuse of zeolite-based materials is another important environmental consideration. If these materials can be effectively recovered and regenerated, it could significantly reduce their environmental impact and promote a more circular economy approach. However, the feasibility and energy requirements of such recycling processes need to be carefully evaluated to ensure they provide a net environmental benefit.

One of the primary environmental concerns associated with zeolite-based antibacterial materials is their potential for leaching. As these materials are exposed to various environmental conditions, there is a risk that the encapsulated metal ions may be released over time. This leaching process could lead to the accumulation of metal ions in soil and water systems, potentially affecting aquatic life and terrestrial ecosystems. The extent of this impact depends on factors such as the stability of the zeolite structure, the type and concentration of metal ions used, and the environmental conditions to which the materials are exposed.

Another aspect to consider is the biodegradability of zeolite-based materials. While natural zeolites are generally considered environmentally friendly due to their mineral origin, synthetic zeolites and modified zeolite composites may have different degradation profiles. The persistence of these materials in the environment could lead to long-term accumulation, particularly in aquatic sediments or soil. This raises questions about their potential to act as microplastic-like pollutants, especially when used in consumer products or industrial applications with high disposal rates.

The production process of zeolite-based antibacterial materials also warrants environmental scrutiny. The synthesis of zeolites and their modification with metal ions often involves energy-intensive processes and the use of chemicals that may have their own environmental footprints. Life cycle assessments are necessary to evaluate the overall environmental impact, from raw material extraction to disposal or recycling. This holistic approach helps in comparing zeolite-based solutions with alternative antibacterial technologies and materials.

On the positive side, the use of zeolite-encapsulated metal ions for antibacterial surfaces may offer environmental benefits by reducing the need for traditional chemical disinfectants. This could lead to a decrease in the release of harmful chemicals into the environment and potentially mitigate the development of antibiotic-resistant bacteria. Additionally, the controlled release of antibacterial agents from zeolites may result in more efficient use of these substances, reducing overall consumption and environmental exposure.

The potential for recycling and reuse of zeolite-based materials is another important environmental consideration. If these materials can be effectively recovered and regenerated, it could significantly reduce their environmental impact and promote a more circular economy approach. However, the feasibility and energy requirements of such recycling processes need to be carefully evaluated to ensure they provide a net environmental benefit.

Regulatory Framework for Antimicrobial Surfaces

The regulatory framework for antimicrobial surfaces, particularly those utilizing zeolite encapsulation of metal ions, is a complex and evolving landscape. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating antimicrobial products under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). Products containing zeolites with encapsulated metal ions for antibacterial purposes are typically classified as pesticides and must undergo rigorous testing and registration processes.

The EPA requires manufacturers to demonstrate the efficacy and safety of their antimicrobial products through extensive laboratory testing and field trials. This includes evaluating the product's effectiveness against specific microorganisms, its potential environmental impact, and any risks to human health. The registration process also involves submitting detailed information about the product's composition, manufacturing process, and intended use.

In the European Union, the Biocidal Products Regulation (BPR) governs the use of antimicrobial substances. Under this regulation, zeolite-encapsulated metal ions used for antibacterial purposes would likely be classified as active substances in biocidal products. The European Chemicals Agency (ECHA) oversees the approval process for these substances, which involves a comprehensive assessment of their safety and efficacy.

Japan has its own regulatory framework for antimicrobial products, administered by the Ministry of Health, Labour and Welfare. The Japanese system places a strong emphasis on product safety and requires manufacturers to provide extensive documentation on the antimicrobial properties and potential risks associated with their products.

Globally, there is a growing trend towards harmonization of regulatory standards for antimicrobial surfaces. The International Organization for Standardization (ISO) has developed several standards related to the testing and evaluation of antimicrobial products, which are increasingly being adopted by regulatory bodies worldwide. These standards help ensure consistency in product performance and safety across different markets.

One of the key challenges in regulating zeolite-encapsulated metal ion antimicrobial surfaces is the need to balance their potential benefits with any potential risks. Regulators must consider factors such as the long-term stability of the encapsulated ions, the potential for leaching into the environment, and the development of antimicrobial resistance. As a result, manufacturers are often required to conduct ongoing monitoring and reporting on the performance and safety of their products even after they have been approved for use.

As the technology behind zeolite encapsulation of metal ions continues to advance, regulatory frameworks are likely to evolve to address new challenges and opportunities. This may include the development of more specific guidelines for nanotechnology-based antimicrobial surfaces and increased focus on sustainable and environmentally friendly antimicrobial solutions.

The EPA requires manufacturers to demonstrate the efficacy and safety of their antimicrobial products through extensive laboratory testing and field trials. This includes evaluating the product's effectiveness against specific microorganisms, its potential environmental impact, and any risks to human health. The registration process also involves submitting detailed information about the product's composition, manufacturing process, and intended use.

In the European Union, the Biocidal Products Regulation (BPR) governs the use of antimicrobial substances. Under this regulation, zeolite-encapsulated metal ions used for antibacterial purposes would likely be classified as active substances in biocidal products. The European Chemicals Agency (ECHA) oversees the approval process for these substances, which involves a comprehensive assessment of their safety and efficacy.

Japan has its own regulatory framework for antimicrobial products, administered by the Ministry of Health, Labour and Welfare. The Japanese system places a strong emphasis on product safety and requires manufacturers to provide extensive documentation on the antimicrobial properties and potential risks associated with their products.

Globally, there is a growing trend towards harmonization of regulatory standards for antimicrobial surfaces. The International Organization for Standardization (ISO) has developed several standards related to the testing and evaluation of antimicrobial products, which are increasingly being adopted by regulatory bodies worldwide. These standards help ensure consistency in product performance and safety across different markets.

One of the key challenges in regulating zeolite-encapsulated metal ion antimicrobial surfaces is the need to balance their potential benefits with any potential risks. Regulators must consider factors such as the long-term stability of the encapsulated ions, the potential for leaching into the environment, and the development of antimicrobial resistance. As a result, manufacturers are often required to conduct ongoing monitoring and reporting on the performance and safety of their products even after they have been approved for use.

As the technology behind zeolite encapsulation of metal ions continues to advance, regulatory frameworks are likely to evolve to address new challenges and opportunities. This may include the development of more specific guidelines for nanotechnology-based antimicrobial surfaces and increased focus on sustainable and environmentally friendly antimicrobial solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!