Electrospray Deposition Techniques for Zeolite Catalysts

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Zeolite Catalyst ESD Background and Objectives

Electrospray deposition (ESD) techniques for zeolite catalysts represent a cutting-edge approach in the field of catalyst synthesis and application. This technology has emerged as a promising method for creating highly efficient and selective catalytic systems, particularly in the realm of heterogeneous catalysis. The development of ESD for zeolite catalysts stems from the broader field of materials science and nanotechnology, where precise control over material deposition at the micro and nanoscale has become increasingly important.

The evolution of this technology can be traced back to the early applications of electrospray in mass spectrometry and thin film deposition. However, its adaptation for zeolite catalyst synthesis is a more recent development, driven by the need for more precise control over catalyst morphology, distribution, and performance. The convergence of zeolite science, which has been a cornerstone of industrial catalysis for decades, with advanced deposition techniques like ESD, marks a significant milestone in catalyst engineering.

The primary objective of employing ESD techniques for zeolite catalysts is to enhance catalyst efficiency and selectivity by achieving superior control over the deposition process. This includes aims such as improving the dispersion of active sites, optimizing pore structure, and tailoring the surface properties of the catalyst. By leveraging the unique capabilities of ESD, researchers and industry professionals seek to overcome limitations associated with traditional zeolite synthesis methods, such as poor control over crystal size and morphology.

Another key goal is to develop more sustainable and economical catalyst production methods. ESD offers the potential for reduced material waste, lower energy consumption, and the ability to create custom-designed catalysts for specific applications. This aligns with the broader industry trend towards more environmentally friendly and cost-effective manufacturing processes.

Furthermore, the application of ESD in zeolite catalyst preparation aims to bridge the gap between laboratory-scale synthesis and industrial-scale production. The scalability and reproducibility of ESD techniques are crucial factors in this regard, as they determine the feasibility of implementing this technology in large-scale catalyst manufacturing.

As the field progresses, researchers are also focusing on expanding the range of zeolite structures and compositions that can be effectively deposited using ESD. This includes exploring novel zeolite frameworks, hierarchical structures, and composite materials that combine zeolites with other catalytically active components. The ultimate aim is to create a new generation of high-performance catalysts capable of addressing complex chemical transformations in areas such as petrochemicals, fine chemicals, and environmental remediation.

The evolution of this technology can be traced back to the early applications of electrospray in mass spectrometry and thin film deposition. However, its adaptation for zeolite catalyst synthesis is a more recent development, driven by the need for more precise control over catalyst morphology, distribution, and performance. The convergence of zeolite science, which has been a cornerstone of industrial catalysis for decades, with advanced deposition techniques like ESD, marks a significant milestone in catalyst engineering.

The primary objective of employing ESD techniques for zeolite catalysts is to enhance catalyst efficiency and selectivity by achieving superior control over the deposition process. This includes aims such as improving the dispersion of active sites, optimizing pore structure, and tailoring the surface properties of the catalyst. By leveraging the unique capabilities of ESD, researchers and industry professionals seek to overcome limitations associated with traditional zeolite synthesis methods, such as poor control over crystal size and morphology.

Another key goal is to develop more sustainable and economical catalyst production methods. ESD offers the potential for reduced material waste, lower energy consumption, and the ability to create custom-designed catalysts for specific applications. This aligns with the broader industry trend towards more environmentally friendly and cost-effective manufacturing processes.

Furthermore, the application of ESD in zeolite catalyst preparation aims to bridge the gap between laboratory-scale synthesis and industrial-scale production. The scalability and reproducibility of ESD techniques are crucial factors in this regard, as they determine the feasibility of implementing this technology in large-scale catalyst manufacturing.

As the field progresses, researchers are also focusing on expanding the range of zeolite structures and compositions that can be effectively deposited using ESD. This includes exploring novel zeolite frameworks, hierarchical structures, and composite materials that combine zeolites with other catalytically active components. The ultimate aim is to create a new generation of high-performance catalysts capable of addressing complex chemical transformations in areas such as petrochemicals, fine chemicals, and environmental remediation.

Market Analysis for ESD Zeolite Catalysts

The market for electrospray deposition (ESD) techniques in zeolite catalyst production is experiencing significant growth, driven by the increasing demand for high-performance catalysts in various industries. Zeolite catalysts are widely used in petrochemical processing, environmental remediation, and fine chemical synthesis due to their unique porous structure and catalytic properties.

The global zeolite catalyst market is projected to expand at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2026, reaching a value of $5.9 billion by the end of the forecast period. Within this market, the segment utilizing ESD techniques is expected to grow at an even faster rate, owing to the advantages offered by this deposition method.

ESD techniques for zeolite catalysts are particularly attractive in applications requiring precise control over catalyst morphology and distribution. The automotive industry, for instance, is a key driver of market growth, as stringent emission regulations necessitate more efficient catalytic converters. The ability of ESD to create uniform, thin films of zeolite catalysts on various substrates makes it ideal for producing high-performance catalytic converters.

Another significant market segment for ESD zeolite catalysts is the petrochemical industry. The demand for cleaner fuels and more efficient refining processes has led to increased adoption of advanced zeolite catalysts. ESD techniques allow for the creation of tailored catalyst structures that can enhance selectivity and yield in complex chemical reactions.

The environmental sector also presents substantial opportunities for ESD zeolite catalysts. Water and air purification systems increasingly rely on advanced catalytic materials to remove pollutants effectively. The precise control over catalyst deposition offered by ESD techniques enables the development of more efficient and durable purification systems.

Geographically, North America and Europe currently dominate the market for ESD zeolite catalysts, owing to their well-established automotive and petrochemical industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing environmental concerns in countries like China and India.

Despite the promising market outlook, challenges remain in the widespread adoption of ESD techniques for zeolite catalyst production. The high initial investment required for ESD equipment and the need for specialized expertise can be barriers for smaller manufacturers. Additionally, competition from alternative deposition methods and the ongoing development of novel catalyst materials may impact market growth.

In conclusion, the market for ESD zeolite catalysts shows strong potential for growth, driven by increasing demand across multiple industries and the unique advantages offered by electrospray deposition techniques. As research and development efforts continue to improve the efficiency and cost-effectiveness of ESD processes, the market is expected to expand further, offering significant opportunities for both established players and innovative startups in the catalyst industry.

The global zeolite catalyst market is projected to expand at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2026, reaching a value of $5.9 billion by the end of the forecast period. Within this market, the segment utilizing ESD techniques is expected to grow at an even faster rate, owing to the advantages offered by this deposition method.

ESD techniques for zeolite catalysts are particularly attractive in applications requiring precise control over catalyst morphology and distribution. The automotive industry, for instance, is a key driver of market growth, as stringent emission regulations necessitate more efficient catalytic converters. The ability of ESD to create uniform, thin films of zeolite catalysts on various substrates makes it ideal for producing high-performance catalytic converters.

Another significant market segment for ESD zeolite catalysts is the petrochemical industry. The demand for cleaner fuels and more efficient refining processes has led to increased adoption of advanced zeolite catalysts. ESD techniques allow for the creation of tailored catalyst structures that can enhance selectivity and yield in complex chemical reactions.

The environmental sector also presents substantial opportunities for ESD zeolite catalysts. Water and air purification systems increasingly rely on advanced catalytic materials to remove pollutants effectively. The precise control over catalyst deposition offered by ESD techniques enables the development of more efficient and durable purification systems.

Geographically, North America and Europe currently dominate the market for ESD zeolite catalysts, owing to their well-established automotive and petrochemical industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing environmental concerns in countries like China and India.

Despite the promising market outlook, challenges remain in the widespread adoption of ESD techniques for zeolite catalyst production. The high initial investment required for ESD equipment and the need for specialized expertise can be barriers for smaller manufacturers. Additionally, competition from alternative deposition methods and the ongoing development of novel catalyst materials may impact market growth.

In conclusion, the market for ESD zeolite catalysts shows strong potential for growth, driven by increasing demand across multiple industries and the unique advantages offered by electrospray deposition techniques. As research and development efforts continue to improve the efficiency and cost-effectiveness of ESD processes, the market is expected to expand further, offering significant opportunities for both established players and innovative startups in the catalyst industry.

ESD Zeolite Catalyst Technology Status and Challenges

Electrospray deposition (ESD) techniques for zeolite catalysts have gained significant attention in recent years due to their potential to enhance catalyst performance and efficiency. The current status of this technology is characterized by a growing body of research and development efforts, but also by several challenges that need to be addressed for widespread industrial adoption.

One of the primary advantages of ESD for zeolite catalysts is its ability to create uniform and well-dispersed catalyst layers with precise control over thickness and morphology. This level of control is crucial for optimizing catalyst performance in various applications, including petrochemical processes and environmental remediation. However, the scalability of ESD techniques for large-scale industrial production remains a significant challenge, limiting its current application primarily to laboratory and small-scale production settings.

Another key aspect of the current technology status is the ongoing research into the optimization of ESD parameters for different types of zeolites. Factors such as solvent composition, applied voltage, and flow rate significantly influence the final catalyst structure and performance. While progress has been made in understanding these relationships, there is still a need for more comprehensive studies to establish standardized protocols for different zeolite types and applications.

The integration of ESD techniques with other advanced manufacturing processes, such as 3D printing and microfluidics, represents an emerging trend in the field. These hybrid approaches offer the potential for creating complex, hierarchical catalyst structures with enhanced mass transfer properties and catalytic activity. However, the development of such integrated systems poses technical challenges in terms of process control and reproducibility.

A significant challenge facing ESD zeolite catalyst technology is the limited understanding of the long-term stability and performance of ESD-deposited catalysts under real-world operating conditions. While initial studies have shown promising results in terms of catalyst activity and selectivity, more extensive durability testing and lifecycle analysis are needed to validate the technology for industrial applications.

The environmental and safety aspects of ESD techniques also present challenges that need to be addressed. The use of organic solvents and high voltages in the ESD process raises concerns about worker safety and environmental impact. Developing greener solvent systems and improving process safety measures are active areas of research aimed at overcoming these challenges.

In conclusion, while ESD techniques for zeolite catalysts show great promise, the technology is still in a developmental stage with several challenges to overcome. Addressing issues of scalability, process optimization, long-term stability, and environmental impact will be crucial for advancing this technology towards widespread industrial adoption.

One of the primary advantages of ESD for zeolite catalysts is its ability to create uniform and well-dispersed catalyst layers with precise control over thickness and morphology. This level of control is crucial for optimizing catalyst performance in various applications, including petrochemical processes and environmental remediation. However, the scalability of ESD techniques for large-scale industrial production remains a significant challenge, limiting its current application primarily to laboratory and small-scale production settings.

Another key aspect of the current technology status is the ongoing research into the optimization of ESD parameters for different types of zeolites. Factors such as solvent composition, applied voltage, and flow rate significantly influence the final catalyst structure and performance. While progress has been made in understanding these relationships, there is still a need for more comprehensive studies to establish standardized protocols for different zeolite types and applications.

The integration of ESD techniques with other advanced manufacturing processes, such as 3D printing and microfluidics, represents an emerging trend in the field. These hybrid approaches offer the potential for creating complex, hierarchical catalyst structures with enhanced mass transfer properties and catalytic activity. However, the development of such integrated systems poses technical challenges in terms of process control and reproducibility.

A significant challenge facing ESD zeolite catalyst technology is the limited understanding of the long-term stability and performance of ESD-deposited catalysts under real-world operating conditions. While initial studies have shown promising results in terms of catalyst activity and selectivity, more extensive durability testing and lifecycle analysis are needed to validate the technology for industrial applications.

The environmental and safety aspects of ESD techniques also present challenges that need to be addressed. The use of organic solvents and high voltages in the ESD process raises concerns about worker safety and environmental impact. Developing greener solvent systems and improving process safety measures are active areas of research aimed at overcoming these challenges.

In conclusion, while ESD techniques for zeolite catalysts show great promise, the technology is still in a developmental stage with several challenges to overcome. Addressing issues of scalability, process optimization, long-term stability, and environmental impact will be crucial for advancing this technology towards widespread industrial adoption.

Current ESD Techniques for Zeolite Catalysts

01 Electrospray ionization techniques

Electrospray ionization is a key technique in electrospray deposition, involving the use of high voltage to create charged droplets. This method is widely used in mass spectrometry and can be applied to various materials for thin film deposition. The process allows for precise control over particle size and distribution, making it suitable for creating uniform coatings.- Electrospray ionization techniques: Electrospray ionization is a key technique in electrospray deposition, involving the use of high voltage to create charged droplets. This method is widely used in mass spectrometry and can be applied to various materials for thin film deposition. The process allows for precise control over particle size and distribution, making it suitable for creating uniform coatings.

- Nanoparticle deposition using electrospray: Electrospray deposition is particularly effective for depositing nanoparticles onto surfaces. This technique enables the creation of nanostructured coatings with controlled morphology and composition. It's useful in various applications, including the fabrication of sensors, catalysts, and advanced electronic devices.

- Electrospray in thin film production: The electrospray method is utilized in the production of thin films for various applications. This technique allows for the deposition of uniform, high-quality films with precise thickness control. It's particularly useful in the manufacturing of organic electronics, solar cells, and protective coatings.

- Electrospray deposition for biomedical applications: Electrospray deposition techniques are increasingly used in biomedical applications. This method allows for the controlled deposition of biomolecules, drugs, and biocompatible materials onto surfaces. It's particularly useful in creating drug delivery systems, biosensors, and tissue engineering scaffolds.

- Advancements in electrospray equipment and processes: Ongoing research focuses on improving electrospray deposition equipment and processes. This includes developing new nozzle designs, optimizing spray parameters, and enhancing the control over the deposition process. These advancements aim to increase efficiency, improve coating quality, and expand the range of materials that can be deposited using this technique.

02 Nanoparticle deposition using electrospray

Electrospray deposition is effective for creating nanoparticle coatings on various substrates. This technique allows for the controlled deposition of nanoparticles, enabling the creation of functional surfaces with specific properties. The method is particularly useful in fields such as electronics, sensors, and biomedical applications where precise nanostructure control is crucial.Expand Specific Solutions03 Electrospray in thin film fabrication

Electrospray deposition is utilized in the fabrication of thin films for various applications. This technique allows for the creation of uniform and conformal coatings on different substrates. It is particularly useful in producing thin films for electronic devices, optical coatings, and protective layers. The process offers advantages in terms of film quality and the ability to deposit a wide range of materials.Expand Specific Solutions04 Electrospray mass spectrometry applications

Electrospray ionization is extensively used in mass spectrometry for analyzing various compounds. This technique allows for the ionization of large, non-volatile molecules, making it particularly useful in biochemical and pharmaceutical research. The method enables the analysis of complex mixtures and provides high sensitivity for detecting trace amounts of substances.Expand Specific Solutions05 Advancements in electrospray equipment and control

Recent developments in electrospray deposition focus on improving equipment design and process control. These advancements include enhanced nozzle designs, better voltage control systems, and improved substrate manipulation techniques. Such innovations aim to increase deposition precision, expand the range of depositable materials, and improve overall process efficiency and reproducibility.Expand Specific Solutions

Key Players in ESD Zeolite Catalyst Industry

The electrospray deposition of zeolite catalysts is an emerging technology in the early stages of development, with a growing market potential in catalyst manufacturing and materials science. The global zeolite catalyst market is projected to reach several billion dollars by 2025, driven by increasing demand in petrochemical and environmental applications. While the technology is still maturing, several key players are advancing its development. Companies like 3M Innovative Properties, ExxonMobil Chemical Patents, and Dow Global Technologies are actively researching and patenting electrospray techniques for zeolite catalysts. Academic institutions such as Rutgers University and University of South Carolina are also contributing to fundamental research in this area, indicating a collaborative ecosystem between industry and academia to drive innovation and commercialization.

3M Innovative Properties Co.

Technical Solution: 3M has developed a unique electrospray deposition technique for zeolite catalysts that leverages their expertise in materials science and thin film technology. Their approach focuses on creating ultra-thin, uniform zeolite coatings with exceptional control over film thickness and morphology [15]. 3M's method incorporates a proprietary nozzle design that allows for the generation of highly monodisperse droplets, resulting in more uniform deposition and improved catalyst performance [17]. The company has also developed a specialized substrate pre-treatment process that enhances the adhesion and growth of zeolite crystals during electrospray deposition [19]. Additionally, 3M has implemented advanced electrostatic field shaping techniques to achieve precise control over the deposition pattern and catalyst distribution, enabling the creation of patterned zeolite catalyst arrays for specific applications [21].

Strengths: Exceptional control over film thickness and uniformity, ability to create patterned catalyst arrays, and improved adhesion to substrates. Weaknesses: Potentially limited to thin film applications and may require specialized equipment for implementation.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed an innovative electrospray deposition technique for zeolite catalysts that focuses on large-scale production and industrial applicability. Their approach utilizes a multi-nozzle array system that allows for simultaneous deposition of zeolite particles over large surface areas [7]. Dow's method incorporates in-situ heating during the electrospray process, which promotes rapid crystallization and improves the adhesion of the zeolite layer to the substrate [9]. The company has also implemented a continuous feed system that enables the production of zeolite catalysts with consistent properties in a more efficient manner compared to batch processes [11]. Additionally, Dow has developed specialized post-deposition treatments to fine-tune the catalytic properties of the electrosprayed zeolites, such as ion-exchange processes and controlled dealumination [13].

Strengths: Scalability for industrial production, improved efficiency, and consistent catalyst quality. Weaknesses: Potentially higher initial equipment costs and complexity in maintaining uniform deposition across large areas.

Innovations in ESD for Zeolite Synthesis

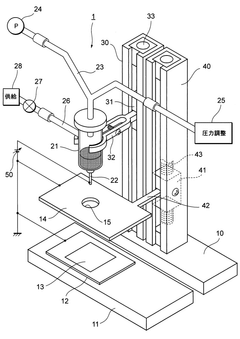

Method for the uniform nanostructured deposition of catalytic particles by means of electrospray

PatentWO2013144390A1

Innovation

- A procedure involving an electrospray process with a catalytic ink comprising colloidal suspensions of catalytic nanoparticles in a dilute solution, using a polymeric dispersant and applying a negative potential to the collector plate, ensuring the particles are dry upon impact by maintaining a sufficient distance between the needle and collector to exceed the solvent evaporation time, and utilizing a dielectric mask to focus field lines and enhance edge deposition.

Method and device for forming electrode catalyst layer by electrospray method

PatentWO2018135611A1

Innovation

- The electrospray method is improved by using a catalyst ink with low viscosity, containing a mixture of electrode catalysts, a polymer electrolyte binder, and volatile organic compounds or water, which is sprayed onto a polymer electrolyte membrane under controlled negative pressure, allowing for uniform deposition and reduced Pt usage, with the binder coating the catalyst particles effectively.

Environmental Impact of ESD Zeolite Catalysts

The environmental impact of Electrospray Deposition (ESD) techniques for zeolite catalysts is a crucial consideration in their development and application. These catalysts, when produced using ESD methods, offer several environmental advantages over traditional manufacturing processes.

One of the primary benefits is the reduction in waste generation. ESD techniques allow for precise control over the deposition of zeolite particles, resulting in more efficient use of materials. This precision minimizes excess material usage and reduces the amount of waste produced during the manufacturing process. Consequently, there is less need for disposal of unused or excess catalysts, which can have positive implications for landfill usage and overall waste management.

The energy efficiency of ESD techniques also contributes to their positive environmental profile. Compared to conventional methods of zeolite catalyst production, ESD typically requires lower temperatures and shorter processing times. This reduction in energy consumption translates to lower greenhouse gas emissions associated with the manufacturing process, aligning with global efforts to mitigate climate change.

Water usage is another area where ESD zeolite catalysts demonstrate environmental benefits. The process generally requires less water than traditional wet chemistry methods, contributing to water conservation efforts. This is particularly significant in regions where water scarcity is a concern, as it reduces the strain on local water resources.

In terms of air quality, ESD techniques for zeolite catalysts often result in reduced emissions of volatile organic compounds (VOCs) and other air pollutants. The controlled nature of the deposition process minimizes the release of particulate matter, which can be a concern in conventional powder-based catalyst production methods.

The longevity and efficiency of ESD-produced zeolite catalysts also have indirect environmental benefits. These catalysts often exhibit enhanced performance and durability, which can lead to longer operational lifetimes in their applications. This extended lifespan reduces the frequency of catalyst replacement, thereby decreasing the overall environmental footprint associated with production, transportation, and disposal of catalysts over time.

Furthermore, the improved catalytic performance of ESD zeolite catalysts can lead to more efficient chemical processes in various industries. This efficiency can result in reduced energy consumption and lower emissions in the end-use applications, extending the environmental benefits beyond the production phase.

However, it is important to note that the environmental impact of ESD zeolite catalysts is not uniformly positive. The process may involve the use of solvents or other chemicals that require careful handling and disposal. Additionally, the production of the precursor materials and the energy used in the electrospray process itself must be considered in a comprehensive environmental assessment.

One of the primary benefits is the reduction in waste generation. ESD techniques allow for precise control over the deposition of zeolite particles, resulting in more efficient use of materials. This precision minimizes excess material usage and reduces the amount of waste produced during the manufacturing process. Consequently, there is less need for disposal of unused or excess catalysts, which can have positive implications for landfill usage and overall waste management.

The energy efficiency of ESD techniques also contributes to their positive environmental profile. Compared to conventional methods of zeolite catalyst production, ESD typically requires lower temperatures and shorter processing times. This reduction in energy consumption translates to lower greenhouse gas emissions associated with the manufacturing process, aligning with global efforts to mitigate climate change.

Water usage is another area where ESD zeolite catalysts demonstrate environmental benefits. The process generally requires less water than traditional wet chemistry methods, contributing to water conservation efforts. This is particularly significant in regions where water scarcity is a concern, as it reduces the strain on local water resources.

In terms of air quality, ESD techniques for zeolite catalysts often result in reduced emissions of volatile organic compounds (VOCs) and other air pollutants. The controlled nature of the deposition process minimizes the release of particulate matter, which can be a concern in conventional powder-based catalyst production methods.

The longevity and efficiency of ESD-produced zeolite catalysts also have indirect environmental benefits. These catalysts often exhibit enhanced performance and durability, which can lead to longer operational lifetimes in their applications. This extended lifespan reduces the frequency of catalyst replacement, thereby decreasing the overall environmental footprint associated with production, transportation, and disposal of catalysts over time.

Furthermore, the improved catalytic performance of ESD zeolite catalysts can lead to more efficient chemical processes in various industries. This efficiency can result in reduced energy consumption and lower emissions in the end-use applications, extending the environmental benefits beyond the production phase.

However, it is important to note that the environmental impact of ESD zeolite catalysts is not uniformly positive. The process may involve the use of solvents or other chemicals that require careful handling and disposal. Additionally, the production of the precursor materials and the energy used in the electrospray process itself must be considered in a comprehensive environmental assessment.

Scalability of ESD for Industrial Zeolite Production

The scalability of Electrospray Deposition (ESD) techniques for industrial zeolite production presents both opportunities and challenges. As the demand for zeolite catalysts continues to grow across various industries, the ability to scale up ESD processes becomes crucial for meeting production requirements.

One of the primary advantages of ESD for zeolite production is its potential for precise control over particle size and morphology. This level of control is particularly valuable in industrial settings where catalyst performance is closely tied to these parameters. However, maintaining this precision at larger scales requires careful engineering and process optimization.

The transition from laboratory-scale ESD to industrial-scale production involves several key considerations. Firstly, the design of larger electrospray systems must account for increased throughput without compromising the quality of the deposited zeolite layers. This often necessitates the development of multi-nozzle arrays or continuous flow systems to enhance production rates.

Another critical factor in scaling up ESD for zeolite production is the management of process parameters. Variables such as voltage, flow rate, and substrate-to-nozzle distance must be carefully controlled and adjusted to accommodate larger production volumes. Automated control systems and real-time monitoring technologies play a vital role in maintaining consistency across extended production runs.

The economic viability of large-scale ESD for zeolite catalysts depends on optimizing material utilization and energy efficiency. Industrial implementation requires the development of recycling systems for unused precursor solutions and the integration of energy-efficient power supplies to reduce operational costs.

Substrate handling and uniformity present additional challenges in scaling up ESD processes. Ensuring even deposition across larger substrate areas demands innovative approaches to substrate movement and positioning within the electrospray field. Continuous or semi-continuous processing methods may be necessary to achieve the required production volumes.

As ESD technology scales up, quality control and characterization methods must evolve in tandem. In-line monitoring techniques and rapid analysis tools become essential for maintaining product consistency and identifying process deviations in real-time. This may involve the integration of spectroscopic or imaging technologies directly into the production line.

The environmental impact of scaled-up ESD processes also warrants consideration. Implementing closed-loop systems for solvent recovery and minimizing waste generation are crucial steps in ensuring the sustainability of industrial-scale zeolite production via ESD.

One of the primary advantages of ESD for zeolite production is its potential for precise control over particle size and morphology. This level of control is particularly valuable in industrial settings where catalyst performance is closely tied to these parameters. However, maintaining this precision at larger scales requires careful engineering and process optimization.

The transition from laboratory-scale ESD to industrial-scale production involves several key considerations. Firstly, the design of larger electrospray systems must account for increased throughput without compromising the quality of the deposited zeolite layers. This often necessitates the development of multi-nozzle arrays or continuous flow systems to enhance production rates.

Another critical factor in scaling up ESD for zeolite production is the management of process parameters. Variables such as voltage, flow rate, and substrate-to-nozzle distance must be carefully controlled and adjusted to accommodate larger production volumes. Automated control systems and real-time monitoring technologies play a vital role in maintaining consistency across extended production runs.

The economic viability of large-scale ESD for zeolite catalysts depends on optimizing material utilization and energy efficiency. Industrial implementation requires the development of recycling systems for unused precursor solutions and the integration of energy-efficient power supplies to reduce operational costs.

Substrate handling and uniformity present additional challenges in scaling up ESD processes. Ensuring even deposition across larger substrate areas demands innovative approaches to substrate movement and positioning within the electrospray field. Continuous or semi-continuous processing methods may be necessary to achieve the required production volumes.

As ESD technology scales up, quality control and characterization methods must evolve in tandem. In-line monitoring techniques and rapid analysis tools become essential for maintaining product consistency and identifying process deviations in real-time. This may involve the integration of spectroscopic or imaging technologies directly into the production line.

The environmental impact of scaled-up ESD processes also warrants consideration. Implementing closed-loop systems for solvent recovery and minimizing waste generation are crucial steps in ensuring the sustainability of industrial-scale zeolite production via ESD.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!