Zeolites in Battery Anodes for Enhanced Capacity

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Zeolite Anode Evolution

The evolution of zeolite anodes in battery technology represents a significant advancement in the quest for enhanced energy storage capacity. Initially, zeolites were primarily used in catalysis and molecular sieving applications. However, their unique porous structure and ion-exchange properties caught the attention of battery researchers in the early 2000s.

The first phase of zeolite anode development focused on using natural zeolites as additives in traditional graphite anodes. These early experiments showed modest improvements in capacity and cycle life, but the results were inconsistent due to variations in natural zeolite compositions. This led to a shift towards synthetic zeolites, which offered more controlled properties and reproducible results.

By the mid-2000s, researchers began exploring zeolites as standalone anode materials. The breakthrough came with the discovery that certain zeolite frameworks could reversibly intercalate lithium ions, potentially offering higher capacities than graphite. This sparked a wave of studies on different zeolite structures and their lithium storage mechanisms.

The next major milestone occurred in the early 2010s when scientists started modifying zeolites to enhance their electrical conductivity. Techniques such as carbon coating and metal doping were employed to address the inherently low conductivity of zeolites. These modifications significantly improved the rate capability and overall performance of zeolite anodes.

In recent years, the focus has shifted towards tailoring zeolite structures at the nanoscale. Researchers have developed methods to synthesize zeolite nanocrystals and hierarchical porous structures, which offer improved ion diffusion pathways and higher surface areas for lithium storage. This has led to zeolite anodes with capacities exceeding 1000 mAh/g, far surpassing the theoretical limit of graphite (372 mAh/g).

The latest developments in zeolite anode evolution involve composite materials. By combining zeolites with other high-capacity materials like silicon or metal oxides, researchers are creating hybrid anodes that leverage the strengths of multiple components. These composites aim to address issues such as volume expansion and capacity fading, which have been persistent challenges in high-capacity anode development.

Looking forward, the evolution of zeolite anodes is likely to continue along several paths. One promising direction is the development of zeolite-based solid electrolytes, which could enable the creation of all-solid-state batteries with enhanced safety and energy density. Additionally, researchers are exploring the potential of zeolites in sodium-ion and potassium-ion batteries, expanding their application beyond lithium-based systems.

The first phase of zeolite anode development focused on using natural zeolites as additives in traditional graphite anodes. These early experiments showed modest improvements in capacity and cycle life, but the results were inconsistent due to variations in natural zeolite compositions. This led to a shift towards synthetic zeolites, which offered more controlled properties and reproducible results.

By the mid-2000s, researchers began exploring zeolites as standalone anode materials. The breakthrough came with the discovery that certain zeolite frameworks could reversibly intercalate lithium ions, potentially offering higher capacities than graphite. This sparked a wave of studies on different zeolite structures and their lithium storage mechanisms.

The next major milestone occurred in the early 2010s when scientists started modifying zeolites to enhance their electrical conductivity. Techniques such as carbon coating and metal doping were employed to address the inherently low conductivity of zeolites. These modifications significantly improved the rate capability and overall performance of zeolite anodes.

In recent years, the focus has shifted towards tailoring zeolite structures at the nanoscale. Researchers have developed methods to synthesize zeolite nanocrystals and hierarchical porous structures, which offer improved ion diffusion pathways and higher surface areas for lithium storage. This has led to zeolite anodes with capacities exceeding 1000 mAh/g, far surpassing the theoretical limit of graphite (372 mAh/g).

The latest developments in zeolite anode evolution involve composite materials. By combining zeolites with other high-capacity materials like silicon or metal oxides, researchers are creating hybrid anodes that leverage the strengths of multiple components. These composites aim to address issues such as volume expansion and capacity fading, which have been persistent challenges in high-capacity anode development.

Looking forward, the evolution of zeolite anodes is likely to continue along several paths. One promising direction is the development of zeolite-based solid electrolytes, which could enable the creation of all-solid-state batteries with enhanced safety and energy density. Additionally, researchers are exploring the potential of zeolites in sodium-ion and potassium-ion batteries, expanding their application beyond lithium-based systems.

Battery Market Analysis

The global battery market has experienced significant growth in recent years, driven by the increasing demand for energy storage solutions across various sectors. This growth is particularly evident in the electric vehicle (EV) industry, consumer electronics, and renewable energy storage systems. The market size for batteries reached $108.4 billion in 2019 and is projected to expand at a compound annual growth rate (CAGR) of 14.1% from 2020 to 2027.

The EV segment has emerged as a major driver of battery market growth, with sales of electric cars surpassing 10 million units globally in 2022. This surge in EV adoption has led to a corresponding increase in demand for high-performance batteries, particularly lithium-ion batteries. The push for longer driving ranges and faster charging times has intensified research efforts in battery technology, including the exploration of novel materials like zeolites for anode enhancement.

In the consumer electronics sector, the proliferation of smartphones, laptops, and wearable devices continues to fuel battery demand. The market for portable battery-powered devices is expected to grow steadily, with a focus on developing batteries that offer higher energy density and longer lifespan. This trend aligns well with research into zeolite-enhanced anodes, which promise improved capacity and cycle life.

The renewable energy sector presents another significant opportunity for battery market expansion. As countries worldwide transition towards cleaner energy sources, the need for efficient and large-scale energy storage solutions has become paramount. Grid-scale battery storage capacity is projected to increase from 9 GW in 2018 to 1,095 GW by 2040, highlighting the massive potential for advanced battery technologies.

Geographically, Asia-Pacific dominates the battery market, accounting for over 45% of global revenue in 2019. This dominance is attributed to the presence of major battery manufacturers in countries like China, Japan, and South Korea. However, North America and Europe are also witnessing substantial growth, driven by supportive government policies and increasing investments in electric mobility and renewable energy infrastructure.

The competitive landscape of the battery market is characterized by intense research and development activities, with major players investing heavily in next-generation battery technologies. The focus on enhancing battery performance, including capacity, charging speed, and lifespan, aligns well with the research on zeolites in battery anodes. As the market continues to evolve, innovations in materials science, such as the incorporation of zeolites, are likely to play a crucial role in shaping the future of battery technology and meeting the growing demand across various applications.

The EV segment has emerged as a major driver of battery market growth, with sales of electric cars surpassing 10 million units globally in 2022. This surge in EV adoption has led to a corresponding increase in demand for high-performance batteries, particularly lithium-ion batteries. The push for longer driving ranges and faster charging times has intensified research efforts in battery technology, including the exploration of novel materials like zeolites for anode enhancement.

In the consumer electronics sector, the proliferation of smartphones, laptops, and wearable devices continues to fuel battery demand. The market for portable battery-powered devices is expected to grow steadily, with a focus on developing batteries that offer higher energy density and longer lifespan. This trend aligns well with research into zeolite-enhanced anodes, which promise improved capacity and cycle life.

The renewable energy sector presents another significant opportunity for battery market expansion. As countries worldwide transition towards cleaner energy sources, the need for efficient and large-scale energy storage solutions has become paramount. Grid-scale battery storage capacity is projected to increase from 9 GW in 2018 to 1,095 GW by 2040, highlighting the massive potential for advanced battery technologies.

Geographically, Asia-Pacific dominates the battery market, accounting for over 45% of global revenue in 2019. This dominance is attributed to the presence of major battery manufacturers in countries like China, Japan, and South Korea. However, North America and Europe are also witnessing substantial growth, driven by supportive government policies and increasing investments in electric mobility and renewable energy infrastructure.

The competitive landscape of the battery market is characterized by intense research and development activities, with major players investing heavily in next-generation battery technologies. The focus on enhancing battery performance, including capacity, charging speed, and lifespan, aligns well with the research on zeolites in battery anodes. As the market continues to evolve, innovations in materials science, such as the incorporation of zeolites, are likely to play a crucial role in shaping the future of battery technology and meeting the growing demand across various applications.

Zeolite Anode Challenges

Despite the promising potential of zeolites in battery anodes for enhanced capacity, several significant challenges hinder their widespread adoption and optimal performance. One of the primary obstacles is the inherent low electrical conductivity of zeolites, which can impede electron transfer and limit overall battery efficiency. This issue necessitates the development of innovative strategies to improve conductivity without compromising the zeolite's beneficial properties.

Another critical challenge lies in the structural stability of zeolites during repeated charge-discharge cycles. The expansion and contraction of the anode material can lead to structural degradation over time, potentially resulting in capacity fade and reduced battery lifespan. Researchers must address this issue by exploring ways to enhance the mechanical robustness of zeolite-based anodes while maintaining their high capacity characteristics.

The integration of zeolites into existing battery manufacturing processes presents additional hurdles. Current production methods may not be directly compatible with zeolite incorporation, requiring modifications to established techniques or the development of entirely new fabrication processes. This adaptation can be both time-consuming and costly, potentially slowing down the commercialization of zeolite-enhanced battery technologies.

Furthermore, the scalability of zeolite production for large-scale battery applications remains a concern. While zeolites are abundant in nature, synthesizing specific types with desired properties in sufficient quantities for mass production can be challenging. Researchers must optimize synthesis methods to ensure consistent quality and cost-effectiveness at industrial scales.

The environmental impact and sustainability of zeolite-based anodes also warrant careful consideration. While zeolites are generally considered environmentally friendly, their extraction and processing methods may have ecological implications. Developing green synthesis routes and ensuring the recyclability of zeolite-containing batteries are crucial aspects that need to be addressed to align with global sustainability goals.

Lastly, the long-term stability and performance of zeolite anodes in various operating conditions require extensive testing and validation. Factors such as temperature fluctuations, humidity, and exposure to different electrolytes can significantly impact the zeolite's behavior and overall battery performance. Comprehensive studies are needed to fully understand and mitigate potential degradation mechanisms under real-world usage scenarios.

Another critical challenge lies in the structural stability of zeolites during repeated charge-discharge cycles. The expansion and contraction of the anode material can lead to structural degradation over time, potentially resulting in capacity fade and reduced battery lifespan. Researchers must address this issue by exploring ways to enhance the mechanical robustness of zeolite-based anodes while maintaining their high capacity characteristics.

The integration of zeolites into existing battery manufacturing processes presents additional hurdles. Current production methods may not be directly compatible with zeolite incorporation, requiring modifications to established techniques or the development of entirely new fabrication processes. This adaptation can be both time-consuming and costly, potentially slowing down the commercialization of zeolite-enhanced battery technologies.

Furthermore, the scalability of zeolite production for large-scale battery applications remains a concern. While zeolites are abundant in nature, synthesizing specific types with desired properties in sufficient quantities for mass production can be challenging. Researchers must optimize synthesis methods to ensure consistent quality and cost-effectiveness at industrial scales.

The environmental impact and sustainability of zeolite-based anodes also warrant careful consideration. While zeolites are generally considered environmentally friendly, their extraction and processing methods may have ecological implications. Developing green synthesis routes and ensuring the recyclability of zeolite-containing batteries are crucial aspects that need to be addressed to align with global sustainability goals.

Lastly, the long-term stability and performance of zeolite anodes in various operating conditions require extensive testing and validation. Factors such as temperature fluctuations, humidity, and exposure to different electrolytes can significantly impact the zeolite's behavior and overall battery performance. Comprehensive studies are needed to fully understand and mitigate potential degradation mechanisms under real-world usage scenarios.

Current Zeolite Solutions

01 Adsorption capacity of zeolites

Zeolites exhibit high adsorption capacity due to their porous structure and large surface area. This property makes them effective for various applications such as gas separation, water purification, and molecular sieving. The adsorption capacity can be influenced by factors like pore size, Si/Al ratio, and cation exchange.- Adsorption capacity of zeolites: Zeolites have a high adsorption capacity due to their porous structure and large surface area. This property makes them effective for various applications such as gas separation, water purification, and molecular sieving. The adsorption capacity can be influenced by factors like pore size, Si/Al ratio, and cation exchange.

- Ion exchange capacity of zeolites: Zeolites possess excellent ion exchange capacity, allowing them to remove harmful ions from water and replace them with less harmful ones. This property is particularly useful in water softening, wastewater treatment, and soil remediation applications. The ion exchange capacity can be modified by altering the zeolite's chemical composition.

- Catalytic capacity of zeolites: Zeolites exhibit strong catalytic properties, making them valuable in various industrial processes, particularly in the petrochemical industry. Their catalytic capacity stems from their unique structure, which provides active sites for chemical reactions. This property can be enhanced through modifications such as metal impregnation or dealumination.

- Gas storage capacity of zeolites: Zeolites have a significant capacity for gas storage due to their microporous structure. This property makes them suitable for applications such as natural gas storage, carbon dioxide capture, and hydrogen storage. The gas storage capacity can be optimized by tailoring the pore size and chemical composition of the zeolite.

- Thermal capacity and stability of zeolites: Zeolites possess high thermal capacity and stability, allowing them to maintain their structure and properties at elevated temperatures. This characteristic makes them valuable in applications such as heat storage, thermal insulation, and high-temperature catalysis. The thermal properties can be further enhanced through various modification techniques.

02 Ion exchange capacity of zeolites

Zeolites possess excellent ion exchange capacity, allowing them to remove harmful ions from water and replace them with beneficial ones. This property is particularly useful in water softening, wastewater treatment, and soil remediation applications. The ion exchange capacity can be tailored by modifying the zeolite's chemical composition and structure.Expand Specific Solutions03 Catalytic capacity of zeolites

Zeolites demonstrate remarkable catalytic capacity, making them valuable in various industrial processes, including petroleum refining and petrochemical production. Their unique pore structure and acidity allow for shape-selective catalysis, enhancing reaction rates and product selectivity. The catalytic capacity can be optimized by controlling the zeolite's composition and structure.Expand Specific Solutions04 Gas storage capacity of zeolites

Zeolites exhibit significant gas storage capacity, making them suitable for applications such as natural gas storage, carbon dioxide capture, and hydrogen storage. Their ability to selectively adsorb and store gases is attributed to their uniform pore size distribution and high internal surface area. The gas storage capacity can be enhanced through various modification techniques.Expand Specific Solutions05 Thermal storage capacity of zeolites

Zeolites possess notable thermal storage capacity, making them useful in energy storage and heat exchange applications. Their ability to absorb and release heat during hydration and dehydration cycles allows for efficient thermal energy storage. This property can be optimized by selecting appropriate zeolite types and modifying their structure and composition.Expand Specific Solutions

Key Battery Innovators

The research on zeolites in battery anodes for enhanced capacity is in an early development stage, with significant potential for growth. The market size is expanding as the demand for high-performance batteries increases across various industries. While the technology is still maturing, several key players are actively involved in advancing this field. Companies like Sony Group Corp., Murata Manufacturing Co. Ltd., and TDK Corp. are leveraging their expertise in electronics and materials to explore zeolite applications in battery anodes. Additionally, specialized firms such as Sila Nanotechnologies, Inc. and Enovix Operations, Inc. are focusing on innovative battery technologies, potentially incorporating zeolites to enhance capacity. The competitive landscape is diverse, with both established electronics giants and emerging startups contributing to the development of this promising technology.

Sony Group Corp.

Technical Solution: Sony, a leader in consumer electronics and battery technology, has likely investigated the use of zeolites in battery anodes as part of their ongoing research into high-capacity energy storage solutions. Their approach may involve incorporating zeolite materials into their existing lithium-ion battery designs to enhance anode performance. Sony's research could focus on using zeolites as a host material for silicon or other high-capacity anode materials, leveraging the zeolites' porous structure to manage volume expansion and improve cycle life [9]. Additionally, they might be exploring zeolite-based coatings or additives to enhance the solid electrolyte interphase (SEI) formation and stability in their next-generation battery anodes [10].

Strengths: Extensive experience in battery manufacturing and commercialization, strong R&D capabilities. Weaknesses: May face challenges in integrating new zeolite-based materials into existing production lines.

Sila Nanotechnologies, Inc.

Technical Solution: Sila Nanotechnologies has developed a silicon-based anode material that incorporates nanocomposite structures, potentially including zeolites, to enhance battery capacity. Their approach involves creating a nanostructured silicon material that can accommodate the volume expansion during lithiation, a common challenge with silicon anodes. The company's technology reportedly enables up to 20% increase in energy density compared to conventional graphite anodes [1]. Sila's method likely utilizes zeolites as a scaffold or protective matrix for silicon nanoparticles, leveraging the zeolites' porous structure to manage electrolyte access and mitigate silicon degradation over multiple charge cycles [2].

Strengths: High energy density, potential for significant capacity improvement, and better cycle life compared to pure silicon anodes. Weaknesses: Potentially higher production costs and complexity in large-scale manufacturing.

Zeolite Anode Advances

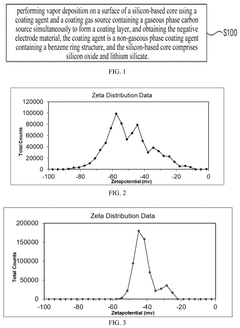

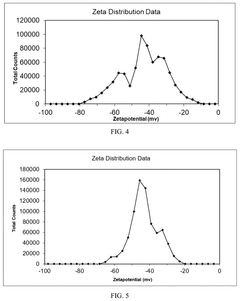

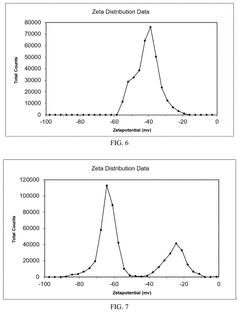

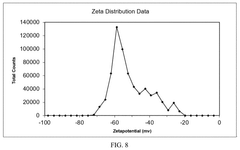

Anode material and preparation method thereof, and lithium ion battery

PatentPendingUS20250158042A1

Innovation

- A silicon-based anode material with a core composed of silicon oxide and lithium silicate, coated with a carbon material layer, is developed. The coating layer is formed through vapor deposition using a gaseous phase carbon source and a non-gaseous phase coating agent with a benzene ring structure, optimizing the surface composition and interface reactions.

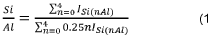

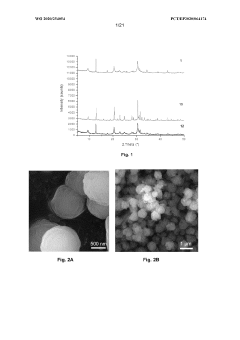

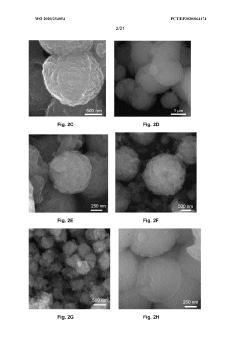

Zeolite, precursors thereof, methods for making the same and use of the zeolite as sorbent for co 2

PatentWO2020254054A1

Innovation

- Development of zeolites without organic templates, specifically those with caesium and a low Si/Al molar ratio, which form nanoparticles with enhanced specific surface area and cation content, allowing selective sorption of carbon dioxide over methane and nitrogen.

Environmental Impact

The integration of zeolites in battery anodes for enhanced capacity has significant environmental implications that warrant careful consideration. Zeolites, as naturally occurring aluminosilicate minerals, offer a more sustainable alternative to traditional anode materials. Their porous structure and high surface area contribute to improved battery performance while potentially reducing the environmental footprint of battery production.

One of the primary environmental benefits of using zeolites in battery anodes is the reduction of reliance on rare earth elements and heavy metals. This shift can lead to decreased mining activities and associated environmental degradation. Zeolites are abundant and can be sourced from various geological locations, minimizing the geopolitical and environmental risks associated with the extraction of more scarce materials.

The production process of zeolite-based anodes generally requires less energy compared to the synthesis of conventional anode materials. This energy efficiency translates to lower greenhouse gas emissions during manufacturing, aligning with global efforts to combat climate change. Additionally, the use of zeolites can potentially extend battery life cycles, reducing the frequency of battery replacements and subsequently decreasing electronic waste.

However, the environmental impact of zeolite mining and processing must be carefully managed. While less harmful than rare earth element extraction, zeolite mining can still lead to habitat disruption and soil erosion if not conducted responsibly. Implementing sustainable mining practices and reclamation efforts is crucial to mitigate these potential negative impacts.

The recyclability of zeolite-based anodes presents another environmental advantage. The relatively simple chemical composition of zeolites compared to complex metal alloys used in traditional anodes may facilitate easier and more efficient recycling processes. This could contribute to a more circular economy in battery production and reduce the overall environmental burden of battery disposal.

Water usage in zeolite synthesis and battery production is an area that requires attention. While zeolites have the potential to improve water purification processes, their production may involve significant water consumption. Developing water-efficient manufacturing techniques and implementing closed-loop water systems in production facilities are essential steps in minimizing the water footprint of zeolite-based battery technologies.

As research on zeolites in battery anodes progresses, it is imperative to conduct comprehensive life cycle assessments to fully understand their environmental impact from cradle to grave. This holistic approach will help identify areas for further improvement and ensure that the environmental benefits of zeolite integration outweigh any potential drawbacks throughout the entire battery lifecycle.

One of the primary environmental benefits of using zeolites in battery anodes is the reduction of reliance on rare earth elements and heavy metals. This shift can lead to decreased mining activities and associated environmental degradation. Zeolites are abundant and can be sourced from various geological locations, minimizing the geopolitical and environmental risks associated with the extraction of more scarce materials.

The production process of zeolite-based anodes generally requires less energy compared to the synthesis of conventional anode materials. This energy efficiency translates to lower greenhouse gas emissions during manufacturing, aligning with global efforts to combat climate change. Additionally, the use of zeolites can potentially extend battery life cycles, reducing the frequency of battery replacements and subsequently decreasing electronic waste.

However, the environmental impact of zeolite mining and processing must be carefully managed. While less harmful than rare earth element extraction, zeolite mining can still lead to habitat disruption and soil erosion if not conducted responsibly. Implementing sustainable mining practices and reclamation efforts is crucial to mitigate these potential negative impacts.

The recyclability of zeolite-based anodes presents another environmental advantage. The relatively simple chemical composition of zeolites compared to complex metal alloys used in traditional anodes may facilitate easier and more efficient recycling processes. This could contribute to a more circular economy in battery production and reduce the overall environmental burden of battery disposal.

Water usage in zeolite synthesis and battery production is an area that requires attention. While zeolites have the potential to improve water purification processes, their production may involve significant water consumption. Developing water-efficient manufacturing techniques and implementing closed-loop water systems in production facilities are essential steps in minimizing the water footprint of zeolite-based battery technologies.

As research on zeolites in battery anodes progresses, it is imperative to conduct comprehensive life cycle assessments to fully understand their environmental impact from cradle to grave. This holistic approach will help identify areas for further improvement and ensure that the environmental benefits of zeolite integration outweigh any potential drawbacks throughout the entire battery lifecycle.

Zeolite Supply Chain

The zeolite supply chain for battery anode applications involves a complex network of stakeholders, from raw material extraction to final product integration. The process begins with mining operations, primarily located in regions rich in volcanic rocks and ash deposits. China, South Korea, and the United States are among the leading producers of natural zeolites, while synthetic zeolites are manufactured globally in specialized chemical facilities.

Raw zeolite materials undergo several processing stages to meet the specific requirements for battery anode applications. This includes crushing, grinding, and purification to remove impurities and enhance the desired properties. Specialized companies focus on modifying zeolites through ion exchange, dealumination, or surface functionalization to optimize their performance in battery systems.

The supply chain faces challenges in ensuring consistent quality and purity of zeolites, as variations can significantly impact battery performance. Stringent quality control measures are implemented throughout the production process, often requiring advanced analytical techniques and expertise.

Distribution networks play a crucial role in connecting zeolite producers with battery manufacturers. These networks must be efficient and reliable to meet the growing demand in the energy storage sector. The increasing interest in zeolite-enhanced battery anodes has led to the emergence of specialized suppliers and distributors focusing on this niche market.

Battery manufacturers integrate zeolites into their anode production processes, which may involve blending with other materials such as graphite or silicon. This integration step requires careful optimization to achieve the desired capacity enhancement without compromising other battery characteristics.

The zeolite supply chain is influenced by factors such as geopolitical considerations, environmental regulations, and technological advancements. As research continues to demonstrate the benefits of zeolites in battery anodes, there is a growing need for scaling up production and establishing more robust supply chains to meet potential future demand.

Sustainability considerations are becoming increasingly important in the zeolite supply chain. Efforts are being made to develop more environmentally friendly extraction and processing methods, as well as to explore recycling options for zeolites used in batteries at the end of their life cycle.

Raw zeolite materials undergo several processing stages to meet the specific requirements for battery anode applications. This includes crushing, grinding, and purification to remove impurities and enhance the desired properties. Specialized companies focus on modifying zeolites through ion exchange, dealumination, or surface functionalization to optimize their performance in battery systems.

The supply chain faces challenges in ensuring consistent quality and purity of zeolites, as variations can significantly impact battery performance. Stringent quality control measures are implemented throughout the production process, often requiring advanced analytical techniques and expertise.

Distribution networks play a crucial role in connecting zeolite producers with battery manufacturers. These networks must be efficient and reliable to meet the growing demand in the energy storage sector. The increasing interest in zeolite-enhanced battery anodes has led to the emergence of specialized suppliers and distributors focusing on this niche market.

Battery manufacturers integrate zeolites into their anode production processes, which may involve blending with other materials such as graphite or silicon. This integration step requires careful optimization to achieve the desired capacity enhancement without compromising other battery characteristics.

The zeolite supply chain is influenced by factors such as geopolitical considerations, environmental regulations, and technological advancements. As research continues to demonstrate the benefits of zeolites in battery anodes, there is a growing need for scaling up production and establishing more robust supply chains to meet potential future demand.

Sustainability considerations are becoming increasingly important in the zeolite supply chain. Efforts are being made to develop more environmentally friendly extraction and processing methods, as well as to explore recycling options for zeolites used in batteries at the end of their life cycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!