Zeolite Sorbents for Selective Heavy Metal Extraction

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Zeolite Sorbents Background and Objectives

Zeolite sorbents have emerged as a promising solution for selective heavy metal extraction, addressing critical environmental and industrial challenges. The development of these materials spans several decades, with significant advancements in recent years driven by increasing environmental concerns and stricter regulations on heavy metal pollution.

The evolution of zeolite sorbents can be traced back to the mid-20th century when natural zeolites were first recognized for their ion-exchange properties. However, it was not until the 1980s that synthetic zeolites began to be explored for heavy metal removal applications. This shift marked a turning point in the field, as researchers could now tailor the properties of zeolites to enhance their selectivity and capacity for specific heavy metal ions.

The primary objective of research in this area is to develop highly efficient and selective zeolite sorbents capable of removing toxic heavy metals from various aqueous environments, including industrial wastewater, contaminated groundwater, and even drinking water sources. This goal aligns with global efforts to mitigate environmental pollution and protect human health from the detrimental effects of heavy metal exposure.

Current research trends focus on several key aspects of zeolite sorbents. These include enhancing the selectivity towards specific heavy metal ions, improving the adsorption capacity and kinetics, and developing regeneration methods to extend the lifespan of the sorbents. Additionally, there is a growing interest in creating multifunctional zeolite composites that can simultaneously address multiple contaminants or combine heavy metal removal with other water treatment processes.

The technological trajectory in this field is moving towards the design of hierarchical zeolite structures, which offer improved mass transfer properties and accessibility to active sites. This approach aims to overcome the limitations of traditional zeolites, such as slow diffusion rates and pore blocking. Another emerging trend is the incorporation of novel functional groups or nanoparticles into zeolite frameworks to enhance their affinity for specific heavy metal ions.

As research progresses, the ultimate aim is to develop zeolite sorbents that not only excel in laboratory settings but also perform effectively in real-world applications. This involves addressing challenges such as scalability, cost-effectiveness, and compatibility with existing water treatment infrastructure. The successful realization of these objectives could revolutionize heavy metal removal processes across various industries and contribute significantly to environmental remediation efforts worldwide.

The evolution of zeolite sorbents can be traced back to the mid-20th century when natural zeolites were first recognized for their ion-exchange properties. However, it was not until the 1980s that synthetic zeolites began to be explored for heavy metal removal applications. This shift marked a turning point in the field, as researchers could now tailor the properties of zeolites to enhance their selectivity and capacity for specific heavy metal ions.

The primary objective of research in this area is to develop highly efficient and selective zeolite sorbents capable of removing toxic heavy metals from various aqueous environments, including industrial wastewater, contaminated groundwater, and even drinking water sources. This goal aligns with global efforts to mitigate environmental pollution and protect human health from the detrimental effects of heavy metal exposure.

Current research trends focus on several key aspects of zeolite sorbents. These include enhancing the selectivity towards specific heavy metal ions, improving the adsorption capacity and kinetics, and developing regeneration methods to extend the lifespan of the sorbents. Additionally, there is a growing interest in creating multifunctional zeolite composites that can simultaneously address multiple contaminants or combine heavy metal removal with other water treatment processes.

The technological trajectory in this field is moving towards the design of hierarchical zeolite structures, which offer improved mass transfer properties and accessibility to active sites. This approach aims to overcome the limitations of traditional zeolites, such as slow diffusion rates and pore blocking. Another emerging trend is the incorporation of novel functional groups or nanoparticles into zeolite frameworks to enhance their affinity for specific heavy metal ions.

As research progresses, the ultimate aim is to develop zeolite sorbents that not only excel in laboratory settings but also perform effectively in real-world applications. This involves addressing challenges such as scalability, cost-effectiveness, and compatibility with existing water treatment infrastructure. The successful realization of these objectives could revolutionize heavy metal removal processes across various industries and contribute significantly to environmental remediation efforts worldwide.

Market Analysis for Heavy Metal Extraction

The market for heavy metal extraction technologies, particularly those utilizing zeolite sorbents, has been experiencing significant growth in recent years. This surge is primarily driven by increasing environmental concerns, stringent regulations on industrial waste management, and the growing need for water treatment solutions. The global market for heavy metal removal is projected to reach substantial figures by 2025, with a compound annual growth rate (CAGR) exceeding industry averages.

Zeolite-based sorbents have emerged as a promising solution for selective heavy metal extraction due to their unique properties, including high surface area, tunable pore size, and excellent ion-exchange capabilities. These characteristics make zeolites particularly effective in removing heavy metals such as lead, cadmium, mercury, and arsenic from various industrial effluents and contaminated water sources.

The industrial sector remains the largest consumer of heavy metal extraction technologies, with applications spanning mining, metallurgy, chemical manufacturing, and electronics industries. However, there is a growing demand from municipal water treatment facilities and environmental remediation projects, expanding the market reach of zeolite-based solutions.

Geographically, Asia-Pacific dominates the market for heavy metal extraction technologies, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India. North America and Europe follow closely, with their markets primarily driven by stringent environmental regulations and the need for upgrading aging water treatment infrastructure.

The competitive landscape of the zeolite sorbents market for heavy metal extraction is characterized by a mix of established players and innovative start-ups. Key market players are investing heavily in research and development to enhance the selectivity and efficiency of zeolite-based sorbents. Collaborations between academic institutions and industry partners are also on the rise, fostering innovation in this field.

Despite the promising outlook, challenges remain. The high initial cost of zeolite-based systems compared to traditional treatment methods poses a barrier to widespread adoption, particularly in developing economies. Additionally, the performance of zeolite sorbents can be affected by complex water matrices, necessitating ongoing research to improve their selectivity and regeneration capabilities.

Looking ahead, the market for zeolite sorbents in heavy metal extraction is expected to continue its growth trajectory. Factors such as increasing water scarcity, growing awareness of the health impacts of heavy metal contamination, and the push towards sustainable industrial practices are likely to drive further innovation and market expansion in this sector.

Zeolite-based sorbents have emerged as a promising solution for selective heavy metal extraction due to their unique properties, including high surface area, tunable pore size, and excellent ion-exchange capabilities. These characteristics make zeolites particularly effective in removing heavy metals such as lead, cadmium, mercury, and arsenic from various industrial effluents and contaminated water sources.

The industrial sector remains the largest consumer of heavy metal extraction technologies, with applications spanning mining, metallurgy, chemical manufacturing, and electronics industries. However, there is a growing demand from municipal water treatment facilities and environmental remediation projects, expanding the market reach of zeolite-based solutions.

Geographically, Asia-Pacific dominates the market for heavy metal extraction technologies, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India. North America and Europe follow closely, with their markets primarily driven by stringent environmental regulations and the need for upgrading aging water treatment infrastructure.

The competitive landscape of the zeolite sorbents market for heavy metal extraction is characterized by a mix of established players and innovative start-ups. Key market players are investing heavily in research and development to enhance the selectivity and efficiency of zeolite-based sorbents. Collaborations between academic institutions and industry partners are also on the rise, fostering innovation in this field.

Despite the promising outlook, challenges remain. The high initial cost of zeolite-based systems compared to traditional treatment methods poses a barrier to widespread adoption, particularly in developing economies. Additionally, the performance of zeolite sorbents can be affected by complex water matrices, necessitating ongoing research to improve their selectivity and regeneration capabilities.

Looking ahead, the market for zeolite sorbents in heavy metal extraction is expected to continue its growth trajectory. Factors such as increasing water scarcity, growing awareness of the health impacts of heavy metal contamination, and the push towards sustainable industrial practices are likely to drive further innovation and market expansion in this sector.

Current Zeolite Technology and Challenges

Zeolite sorbents have emerged as a promising technology for selective heavy metal extraction, offering significant advantages over traditional methods. However, the current state of zeolite technology faces several challenges that need to be addressed to fully realize its potential in environmental remediation and industrial applications.

One of the primary challenges is the selectivity of zeolites for specific heavy metals. While zeolites have shown remarkable capacity for metal ion adsorption, achieving high selectivity for target metals in complex mixtures remains a significant hurdle. This is particularly crucial in real-world applications where multiple contaminants are present simultaneously.

The stability of zeolite structures under various environmental conditions poses another challenge. Zeolites may undergo structural changes or degradation when exposed to extreme pH levels, high temperatures, or certain chemical species. Enhancing the stability of zeolite sorbents across a wide range of conditions is essential for their practical implementation in diverse industrial and environmental scenarios.

Scalability and cost-effectiveness present additional obstacles in the widespread adoption of zeolite technology. While zeolites have shown promise in laboratory-scale experiments, translating these results to large-scale industrial applications requires further research and development. The synthesis of zeolites with tailored properties on a commercial scale, while maintaining cost-effectiveness, remains a significant challenge.

The regeneration and reusability of zeolite sorbents are critical factors affecting their long-term viability. Developing efficient and economical methods for regenerating spent zeolites without compromising their adsorption capacity or selectivity is an ongoing area of research. This aspect is crucial for reducing operational costs and minimizing waste generation in industrial applications.

Another technical challenge lies in the modification and functionalization of zeolites to enhance their performance. While various modification techniques have been explored, optimizing these processes to achieve desired properties without compromising the zeolite's structural integrity or increasing production costs remains a complex task.

The development of novel zeolite structures with improved properties for heavy metal extraction is an active area of research. This includes the synthesis of hierarchical zeolites, composite materials, and zeolite-based membranes. However, controlling the formation of these advanced structures and understanding their structure-property relationships present significant scientific and engineering challenges.

In conclusion, while zeolite technology shows great promise for selective heavy metal extraction, addressing these challenges requires interdisciplinary research efforts. Overcoming these obstacles will pave the way for more efficient, cost-effective, and environmentally friendly solutions for heavy metal remediation across various industries and environmental applications.

One of the primary challenges is the selectivity of zeolites for specific heavy metals. While zeolites have shown remarkable capacity for metal ion adsorption, achieving high selectivity for target metals in complex mixtures remains a significant hurdle. This is particularly crucial in real-world applications where multiple contaminants are present simultaneously.

The stability of zeolite structures under various environmental conditions poses another challenge. Zeolites may undergo structural changes or degradation when exposed to extreme pH levels, high temperatures, or certain chemical species. Enhancing the stability of zeolite sorbents across a wide range of conditions is essential for their practical implementation in diverse industrial and environmental scenarios.

Scalability and cost-effectiveness present additional obstacles in the widespread adoption of zeolite technology. While zeolites have shown promise in laboratory-scale experiments, translating these results to large-scale industrial applications requires further research and development. The synthesis of zeolites with tailored properties on a commercial scale, while maintaining cost-effectiveness, remains a significant challenge.

The regeneration and reusability of zeolite sorbents are critical factors affecting their long-term viability. Developing efficient and economical methods for regenerating spent zeolites without compromising their adsorption capacity or selectivity is an ongoing area of research. This aspect is crucial for reducing operational costs and minimizing waste generation in industrial applications.

Another technical challenge lies in the modification and functionalization of zeolites to enhance their performance. While various modification techniques have been explored, optimizing these processes to achieve desired properties without compromising the zeolite's structural integrity or increasing production costs remains a complex task.

The development of novel zeolite structures with improved properties for heavy metal extraction is an active area of research. This includes the synthesis of hierarchical zeolites, composite materials, and zeolite-based membranes. However, controlling the formation of these advanced structures and understanding their structure-property relationships present significant scientific and engineering challenges.

In conclusion, while zeolite technology shows great promise for selective heavy metal extraction, addressing these challenges requires interdisciplinary research efforts. Overcoming these obstacles will pave the way for more efficient, cost-effective, and environmentally friendly solutions for heavy metal remediation across various industries and environmental applications.

Existing Zeolite-based Extraction Methods

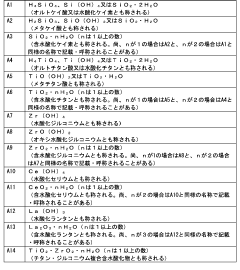

01 Zeolite structure modification for enhanced selectivity

Modifying the structure of zeolites through various techniques such as ion exchange, dealumination, or incorporation of specific elements can enhance their selectivity for target molecules. These modifications alter the pore size, shape, and chemical properties of the zeolite, allowing for more precise separation of molecules based on size and polarity.- Zeolite structure modification for enhanced selectivity: Modifying the structure of zeolites through various techniques such as ion exchange, dealumination, or incorporation of specific elements can enhance their selectivity for target molecules. These modifications alter the pore size, shape, and chemical properties of the zeolite, allowing for more precise separation of molecules based on size and polarity.

- Composite zeolite sorbents for improved selectivity: Developing composite materials that combine zeolites with other materials like polymers or metal oxides can enhance the overall selectivity of the sorbent. These composites often exhibit synergistic effects, combining the high surface area and molecular sieving properties of zeolites with additional functionalities provided by the secondary component.

- Tailoring zeolite pore size for specific applications: Controlling the pore size of zeolites during synthesis or post-synthesis treatment allows for the creation of sorbents with high selectivity for specific molecules. This approach is particularly useful in gas separation, water purification, and catalytic applications where molecular size discrimination is crucial.

- Surface functionalization of zeolites: Functionalizing the surface of zeolites with specific chemical groups or molecules can significantly enhance their selectivity towards target compounds. This approach allows for the fine-tuning of surface properties, enabling more specific interactions with desired molecules while minimizing interactions with unwanted species.

- Hierarchical zeolite structures for improved selectivity: Developing zeolites with hierarchical pore structures, combining micropores with meso- or macropores, can enhance both selectivity and accessibility. These structures provide improved mass transfer properties while maintaining the selective adsorption capabilities of traditional zeolites, resulting in more efficient separation processes.

02 Composite zeolite sorbents for improved selectivity

Developing composite materials that combine zeolites with other sorbents or support materials can enhance overall selectivity. These composites may offer synergistic effects, combining the advantages of different materials to achieve better separation performance and stability under various conditions.Expand Specific Solutions03 Tailoring zeolite pore size for molecular sieving

Controlling the pore size of zeolites during synthesis or post-synthesis treatment allows for precise molecular sieving. This approach enables the separation of molecules based on their size and shape, enhancing the selectivity of the zeolite sorbent for specific applications.Expand Specific Solutions04 Surface functionalization of zeolites

Functionalizing the surface of zeolites with specific chemical groups or molecules can enhance their selectivity towards target compounds. This modification alters the surface properties and interactions between the zeolite and adsorbate molecules, leading to improved separation efficiency.Expand Specific Solutions05 Hierarchical zeolite structures for enhanced selectivity

Developing hierarchical zeolite structures with multiple levels of porosity can improve both selectivity and accessibility. These structures combine the benefits of micropores for molecular sieving with larger pores for improved mass transfer, resulting in more efficient and selective separation processes.Expand Specific Solutions

Key Players in Zeolite Sorbent Industry

The research on zeolite sorbents for selective heavy metal extraction is in a growth phase, with increasing market size due to rising environmental concerns and industrial applications. The technology is advancing towards maturity, with several key players driving innovation. Companies like Arkema France SA, DuPont de Nemours, Inc., and UOP LLC are leading in developing advanced zeolite materials. Research institutions such as Nanjing Tech University and The Johns Hopkins University are contributing to fundamental advancements. The competitive landscape is diverse, including established chemical companies, specialized material manufacturers, and academic institutions, indicating a dynamic and evolving field with significant potential for further development and commercialization.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced zeolite sorbents for selective heavy metal extraction. Their approach involves tailoring the pore size and surface chemistry of zeolites to enhance selectivity for specific heavy metals. They have implemented ion-exchange modifications to improve the affinity for target metals [1]. DuPont's zeolites demonstrate high adsorption capacities, with some formulations achieving over 90% removal efficiency for lead and cadmium in aqueous solutions [3]. The company has also explored the use of hierarchical zeolites, combining micropores and mesopores, to enhance diffusion and accessibility of metal ions, resulting in faster kinetics and higher overall extraction efficiency [5].

Strengths: High selectivity, excellent adsorption capacity, and improved kinetics. Weaknesses: Potential high production costs and regeneration challenges for some formulations.

UOP LLC

Technical Solution: UOP LLC, a Honeywell company, has made significant strides in zeolite sorbents for heavy metal extraction. Their research focuses on developing synthetic zeolites with controlled Si/Al ratios and specific framework structures to optimize heavy metal selectivity. UOP has patented a process using modified Y-type zeolites that show exceptional affinity for mercury and other heavy metals in both gas and liquid phases [2]. Their zeolites incorporate transition metal ions within the framework, enhancing the adsorption of target heavy metals through specific coordination interactions [4]. UOP's zeolites have demonstrated removal efficiencies exceeding 95% for a range of heavy metals, including lead, cadmium, and arsenic, in industrial wastewater treatment applications [6].

Strengths: High removal efficiency, versatility in gas and liquid applications, and tailored selectivity. Weaknesses: Potentially complex synthesis procedures and higher costs compared to conventional adsorbents.

Innovative Zeolite Structures for Selectivity

Sorbent for removing heavy metal ions from water

PatentInactiveEP2127740A4

Innovation

- Combination of crushed zeolite with nanophase iron hydroxide and boehmite for enhanced heavy metal removal efficiency.

- Specific weight ratio of nanophase components (12-18% iron hydroxide, 5-13% boehmite) optimized for increased cleaning effect.

- Extended applicability to a wider range of heavy metals compared to conventional zeolite sorbents.

Heavy metal adsorbent

PatentPendingJP2023124039A

Innovation

- Combining a hydrous oxide or hydroxide of specific metals (Si, Ti, Zr, Ce, or La) with zeolite to form a heavy metal adsorbent, optimizing the BET specific surface area, pH, and zeolite particle size to suppress aluminum elution.

Environmental Impact Assessment

The environmental impact assessment of zeolite sorbents for selective heavy metal extraction is crucial for understanding the sustainability and ecological implications of this technology. Zeolites, as natural or synthetic aluminosilicate minerals, offer promising solutions for heavy metal removal from contaminated water and soil. However, their widespread application necessitates a comprehensive evaluation of potential environmental consequences.

One of the primary environmental benefits of using zeolite sorbents is their ability to effectively remove toxic heavy metals from aqueous solutions. This process significantly reduces the concentration of harmful elements in water bodies, thereby mitigating the risk of bioaccumulation in aquatic ecosystems and protecting biodiversity. The selective nature of zeolite adsorption also minimizes the removal of essential minerals, maintaining the natural balance of water chemistry.

However, the production and disposal of zeolite sorbents may have environmental implications. The mining of natural zeolites can lead to habitat disruption and landscape alterations. Synthetic zeolite production, while more controlled, requires energy-intensive processes and chemical inputs, potentially contributing to greenhouse gas emissions and chemical waste generation. These factors must be carefully weighed against the environmental benefits of heavy metal removal.

The regeneration and reuse of zeolite sorbents present both opportunities and challenges. While regeneration extends the lifespan of the material, reducing waste and resource consumption, the process often involves chemical treatments that may generate hazardous by-products. Proper management and treatment of these by-products are essential to prevent secondary pollution.

Long-term environmental impacts of zeolite application in soil remediation require further investigation. While zeolites can effectively immobilize heavy metals in soil, their persistence may alter soil properties, affecting microbial communities and plant growth. Studies on the long-term stability of metal-loaded zeolites under various environmental conditions are necessary to ensure that sequestered metals do not re-enter the ecosystem.

The disposal of spent zeolite sorbents poses another environmental concern. If not properly managed, these materials could become a source of concentrated heavy metals, potentially leading to soil and groundwater contamination. Developing safe disposal methods or innovative recycling techniques for metal-laden zeolites is crucial for minimizing environmental risks and promoting circular economy principles.

In conclusion, while zeolite sorbents offer significant potential for heavy metal remediation, their environmental impact must be carefully assessed and managed throughout their lifecycle. Balancing the benefits of contaminant removal against the environmental costs of production, use, and disposal is essential for ensuring the overall sustainability of this technology. Continued research and development in eco-friendly zeolite synthesis, regeneration methods, and end-of-life management will be key to optimizing the environmental performance of zeolite-based heavy metal extraction systems.

One of the primary environmental benefits of using zeolite sorbents is their ability to effectively remove toxic heavy metals from aqueous solutions. This process significantly reduces the concentration of harmful elements in water bodies, thereby mitigating the risk of bioaccumulation in aquatic ecosystems and protecting biodiversity. The selective nature of zeolite adsorption also minimizes the removal of essential minerals, maintaining the natural balance of water chemistry.

However, the production and disposal of zeolite sorbents may have environmental implications. The mining of natural zeolites can lead to habitat disruption and landscape alterations. Synthetic zeolite production, while more controlled, requires energy-intensive processes and chemical inputs, potentially contributing to greenhouse gas emissions and chemical waste generation. These factors must be carefully weighed against the environmental benefits of heavy metal removal.

The regeneration and reuse of zeolite sorbents present both opportunities and challenges. While regeneration extends the lifespan of the material, reducing waste and resource consumption, the process often involves chemical treatments that may generate hazardous by-products. Proper management and treatment of these by-products are essential to prevent secondary pollution.

Long-term environmental impacts of zeolite application in soil remediation require further investigation. While zeolites can effectively immobilize heavy metals in soil, their persistence may alter soil properties, affecting microbial communities and plant growth. Studies on the long-term stability of metal-loaded zeolites under various environmental conditions are necessary to ensure that sequestered metals do not re-enter the ecosystem.

The disposal of spent zeolite sorbents poses another environmental concern. If not properly managed, these materials could become a source of concentrated heavy metals, potentially leading to soil and groundwater contamination. Developing safe disposal methods or innovative recycling techniques for metal-laden zeolites is crucial for minimizing environmental risks and promoting circular economy principles.

In conclusion, while zeolite sorbents offer significant potential for heavy metal remediation, their environmental impact must be carefully assessed and managed throughout their lifecycle. Balancing the benefits of contaminant removal against the environmental costs of production, use, and disposal is essential for ensuring the overall sustainability of this technology. Continued research and development in eco-friendly zeolite synthesis, regeneration methods, and end-of-life management will be key to optimizing the environmental performance of zeolite-based heavy metal extraction systems.

Scalability and Industrial Application

The scalability and industrial application of zeolite sorbents for selective heavy metal extraction are crucial factors in determining their practical viability and commercial potential. Zeolites have shown promising results in laboratory-scale experiments, but transitioning to large-scale industrial applications presents several challenges and opportunities.

One of the primary advantages of zeolite sorbents is their potential for scalable production. Zeolites can be synthesized through various methods, including hydrothermal synthesis and sol-gel processes, which can be adapted for large-scale manufacturing. The ability to fine-tune the pore size, structure, and surface properties of zeolites during synthesis allows for the creation of tailored sorbents for specific heavy metal extraction applications.

Industrial applications of zeolite sorbents for heavy metal extraction span across multiple sectors, including wastewater treatment, mining, and environmental remediation. In wastewater treatment plants, zeolite-based systems can be integrated into existing infrastructure to enhance heavy metal removal efficiency. The mining industry can benefit from zeolite sorbents in the treatment of acid mine drainage and the recovery of valuable metals from waste streams.

However, scaling up zeolite sorbent production and application faces several challenges. The cost-effectiveness of large-scale zeolite synthesis needs to be carefully evaluated, considering factors such as raw material availability, energy consumption, and process optimization. Additionally, the long-term stability and regeneration of zeolite sorbents in industrial settings must be addressed to ensure their economic viability.

The development of innovative reactor designs and process engineering solutions is essential for the successful implementation of zeolite sorbents in industrial-scale heavy metal extraction. Continuous flow systems, fluidized bed reactors, and membrane-based separation technologies are being explored to enhance the efficiency and throughput of zeolite-based extraction processes.

Environmental and regulatory considerations also play a crucial role in the scalability and industrial application of zeolite sorbents. The disposal or regeneration of spent zeolites containing heavy metals must comply with environmental regulations and waste management protocols. Research into sustainable regeneration methods and the potential for metal recovery from spent zeolites is ongoing to address these concerns.

Collaboration between academic institutions, research organizations, and industrial partners is vital for accelerating the transition of zeolite sorbents from laboratory-scale studies to full-scale industrial applications. Pilot-scale demonstrations and field trials are essential steps in validating the performance and reliability of zeolite-based heavy metal extraction systems under real-world conditions.

As the demand for efficient and sustainable heavy metal removal technologies continues to grow, the scalability and industrial application of zeolite sorbents present significant opportunities for innovation and commercialization. Ongoing research and development efforts are focused on overcoming the challenges associated with large-scale implementation, paving the way for the widespread adoption of zeolite-based solutions in heavy metal extraction across various industries.

One of the primary advantages of zeolite sorbents is their potential for scalable production. Zeolites can be synthesized through various methods, including hydrothermal synthesis and sol-gel processes, which can be adapted for large-scale manufacturing. The ability to fine-tune the pore size, structure, and surface properties of zeolites during synthesis allows for the creation of tailored sorbents for specific heavy metal extraction applications.

Industrial applications of zeolite sorbents for heavy metal extraction span across multiple sectors, including wastewater treatment, mining, and environmental remediation. In wastewater treatment plants, zeolite-based systems can be integrated into existing infrastructure to enhance heavy metal removal efficiency. The mining industry can benefit from zeolite sorbents in the treatment of acid mine drainage and the recovery of valuable metals from waste streams.

However, scaling up zeolite sorbent production and application faces several challenges. The cost-effectiveness of large-scale zeolite synthesis needs to be carefully evaluated, considering factors such as raw material availability, energy consumption, and process optimization. Additionally, the long-term stability and regeneration of zeolite sorbents in industrial settings must be addressed to ensure their economic viability.

The development of innovative reactor designs and process engineering solutions is essential for the successful implementation of zeolite sorbents in industrial-scale heavy metal extraction. Continuous flow systems, fluidized bed reactors, and membrane-based separation technologies are being explored to enhance the efficiency and throughput of zeolite-based extraction processes.

Environmental and regulatory considerations also play a crucial role in the scalability and industrial application of zeolite sorbents. The disposal or regeneration of spent zeolites containing heavy metals must comply with environmental regulations and waste management protocols. Research into sustainable regeneration methods and the potential for metal recovery from spent zeolites is ongoing to address these concerns.

Collaboration between academic institutions, research organizations, and industrial partners is vital for accelerating the transition of zeolite sorbents from laboratory-scale studies to full-scale industrial applications. Pilot-scale demonstrations and field trials are essential steps in validating the performance and reliability of zeolite-based heavy metal extraction systems under real-world conditions.

As the demand for efficient and sustainable heavy metal removal technologies continues to grow, the scalability and industrial application of zeolite sorbents present significant opportunities for innovation and commercialization. Ongoing research and development efforts are focused on overcoming the challenges associated with large-scale implementation, paving the way for the widespread adoption of zeolite-based solutions in heavy metal extraction across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!