Cellophane: Addressing Challenges in Food Safety

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Evolution

Cellophane, a transparent sheet made from regenerated cellulose, has undergone significant evolution since its invention in 1908 by Jacques E. Brandenberger. Initially developed as a protective coating for tablecloths, cellophane quickly found its way into the food packaging industry due to its unique properties.

In the 1920s and 1930s, cellophane gained popularity as a moisture-proof packaging material for food products. This period marked the beginning of its widespread use in the food industry, revolutionizing food preservation and presentation. The 1940s saw further advancements in cellophane technology, with the development of heat-sealable coatings that enhanced its barrier properties and expanded its applications.

The 1950s and 1960s witnessed the rise of cellophane as the dominant flexible packaging material. During this time, improvements in manufacturing processes led to increased production efficiency and reduced costs. The introduction of colored and printed cellophane also expanded its use in marketing and branding food products.

In the 1970s and 1980s, cellophane faced competition from synthetic polymers like polyethylene and polypropylene. However, it maintained its position in certain niche markets due to its unique properties, such as high clarity and natural origin. This period also saw the development of more environmentally friendly production methods for cellophane.

The 1990s and early 2000s brought renewed interest in cellophane due to growing environmental concerns. Its biodegradability and renewable source material made it an attractive alternative to petroleum-based plastics. Research focused on improving its barrier properties and developing new grades for specific food applications.

In recent years, the evolution of cellophane has been driven by the demand for sustainable packaging solutions. Innovations have focused on enhancing its performance while maintaining its eco-friendly characteristics. These include the development of bio-based coatings to improve moisture and gas barrier properties, as well as the integration of active and intelligent packaging technologies.

The latest advancements in cellophane technology address specific food safety challenges. Antimicrobial cellophane films incorporating natural compounds have been developed to extend shelf life and reduce foodborne pathogens. Additionally, smart cellophane packaging with embedded sensors can now monitor food freshness and detect spoilage, providing real-time information to consumers and retailers.

As the food industry continues to prioritize safety and sustainability, cellophane's evolution is likely to persist. Future developments may include nanotechnology-enhanced cellophane with improved barrier properties and the integration of blockchain technology for enhanced traceability in the food supply chain.

In the 1920s and 1930s, cellophane gained popularity as a moisture-proof packaging material for food products. This period marked the beginning of its widespread use in the food industry, revolutionizing food preservation and presentation. The 1940s saw further advancements in cellophane technology, with the development of heat-sealable coatings that enhanced its barrier properties and expanded its applications.

The 1950s and 1960s witnessed the rise of cellophane as the dominant flexible packaging material. During this time, improvements in manufacturing processes led to increased production efficiency and reduced costs. The introduction of colored and printed cellophane also expanded its use in marketing and branding food products.

In the 1970s and 1980s, cellophane faced competition from synthetic polymers like polyethylene and polypropylene. However, it maintained its position in certain niche markets due to its unique properties, such as high clarity and natural origin. This period also saw the development of more environmentally friendly production methods for cellophane.

The 1990s and early 2000s brought renewed interest in cellophane due to growing environmental concerns. Its biodegradability and renewable source material made it an attractive alternative to petroleum-based plastics. Research focused on improving its barrier properties and developing new grades for specific food applications.

In recent years, the evolution of cellophane has been driven by the demand for sustainable packaging solutions. Innovations have focused on enhancing its performance while maintaining its eco-friendly characteristics. These include the development of bio-based coatings to improve moisture and gas barrier properties, as well as the integration of active and intelligent packaging technologies.

The latest advancements in cellophane technology address specific food safety challenges. Antimicrobial cellophane films incorporating natural compounds have been developed to extend shelf life and reduce foodborne pathogens. Additionally, smart cellophane packaging with embedded sensors can now monitor food freshness and detect spoilage, providing real-time information to consumers and retailers.

As the food industry continues to prioritize safety and sustainability, cellophane's evolution is likely to persist. Future developments may include nanotechnology-enhanced cellophane with improved barrier properties and the integration of blockchain technology for enhanced traceability in the food supply chain.

Food Safety Demand

The global food safety market has witnessed significant growth in recent years, driven by increasing consumer awareness, stringent regulations, and the need for improved food quality assurance. The demand for cellophane as a food packaging material has surged due to its unique properties that address critical food safety challenges.

Consumer concerns about food contamination and foodborne illnesses have led to a heightened focus on food safety measures. This has resulted in a growing demand for packaging solutions that can effectively protect food products from external contaminants while maintaining freshness and quality. Cellophane, with its excellent barrier properties against moisture, gases, and microorganisms, has emerged as a preferred choice for food manufacturers and retailers.

The food industry has been experiencing a shift towards more sustainable and eco-friendly packaging options. Cellophane, being biodegradable and derived from renewable resources, aligns well with this trend. As consumers become more environmentally conscious, the demand for cellophane-based packaging solutions is expected to increase further.

The rise of e-commerce and food delivery services has created new challenges in maintaining food safety during transportation and storage. Cellophane's ability to provide a protective barrier against external factors while allowing for product visibility makes it an attractive option for these growing market segments.

Regulatory bodies worldwide have been implementing stricter food safety standards, requiring food manufacturers to adopt more effective packaging solutions. Cellophane's compliance with various food safety regulations and its ability to meet stringent quality standards have contributed to its increasing adoption in the food industry.

The COVID-19 pandemic has further accelerated the demand for food safety solutions, including cellophane-based packaging. Consumers have become more cautious about food handling and packaging, leading to a surge in demand for products that offer enhanced protection and hygiene.

Market research indicates that the global food packaging market is projected to reach substantial growth in the coming years, with a significant portion attributed to advanced packaging materials like cellophane. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid urbanization, changing consumer lifestyles, and increasing disposable incomes.

As food safety concerns continue to evolve, there is a growing need for innovative packaging solutions that can address emerging challenges. This presents opportunities for further research and development in cellophane technology to enhance its properties and expand its applications in the food industry.

Consumer concerns about food contamination and foodborne illnesses have led to a heightened focus on food safety measures. This has resulted in a growing demand for packaging solutions that can effectively protect food products from external contaminants while maintaining freshness and quality. Cellophane, with its excellent barrier properties against moisture, gases, and microorganisms, has emerged as a preferred choice for food manufacturers and retailers.

The food industry has been experiencing a shift towards more sustainable and eco-friendly packaging options. Cellophane, being biodegradable and derived from renewable resources, aligns well with this trend. As consumers become more environmentally conscious, the demand for cellophane-based packaging solutions is expected to increase further.

The rise of e-commerce and food delivery services has created new challenges in maintaining food safety during transportation and storage. Cellophane's ability to provide a protective barrier against external factors while allowing for product visibility makes it an attractive option for these growing market segments.

Regulatory bodies worldwide have been implementing stricter food safety standards, requiring food manufacturers to adopt more effective packaging solutions. Cellophane's compliance with various food safety regulations and its ability to meet stringent quality standards have contributed to its increasing adoption in the food industry.

The COVID-19 pandemic has further accelerated the demand for food safety solutions, including cellophane-based packaging. Consumers have become more cautious about food handling and packaging, leading to a surge in demand for products that offer enhanced protection and hygiene.

Market research indicates that the global food packaging market is projected to reach substantial growth in the coming years, with a significant portion attributed to advanced packaging materials like cellophane. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid urbanization, changing consumer lifestyles, and increasing disposable incomes.

As food safety concerns continue to evolve, there is a growing need for innovative packaging solutions that can address emerging challenges. This presents opportunities for further research and development in cellophane technology to enhance its properties and expand its applications in the food industry.

Cellophane Limitations

Despite its widespread use in food packaging, cellophane exhibits several limitations that impact its effectiveness in addressing food safety challenges. One of the primary concerns is its limited barrier properties against certain gases and moisture. While cellophane provides a good barrier against oxygen, it is relatively permeable to water vapor. This characteristic can lead to moisture loss or gain in packaged foods, potentially affecting their quality, texture, and shelf life.

Another significant limitation of cellophane is its susceptibility to temperature fluctuations. Extreme temperatures, both high and low, can compromise the structural integrity of cellophane, leading to potential breaches in the packaging. This vulnerability can expose food products to contamination or spoilage, particularly in environments with variable temperature conditions during storage or transportation.

Cellophane's biodegradability, while often considered an environmental advantage, can pose challenges in long-term food preservation. The material's tendency to break down over time, especially in the presence of moisture, may limit its effectiveness for products requiring extended shelf life. This degradation process can potentially compromise the package's barrier properties, leading to increased risk of microbial contamination or oxidation of the food contents.

The material's limited heat-sealing capabilities present another constraint in food packaging applications. Cellophane typically requires additional coatings or laminations to achieve effective heat seals, which can complicate the manufacturing process and increase production costs. This limitation may restrict its use in certain packaging formats or for products that demand hermetic sealing for optimal safety and freshness.

Furthermore, cellophane's relatively low puncture resistance compared to some synthetic polymers can be problematic in maintaining package integrity throughout the supply chain. Sharp edges or rough handling during transportation and storage may compromise the packaging, potentially exposing food products to external contaminants or accelerating spoilage.

Lastly, the production of cellophane involves the use of chemicals and processes that may raise environmental and health concerns. The manufacturing process typically requires the use of carbon disulfide, a toxic and flammable compound. While efforts have been made to improve production methods, these environmental considerations may limit cellophane's adoption in certain markets or applications where sustainability is a primary concern.

Another significant limitation of cellophane is its susceptibility to temperature fluctuations. Extreme temperatures, both high and low, can compromise the structural integrity of cellophane, leading to potential breaches in the packaging. This vulnerability can expose food products to contamination or spoilage, particularly in environments with variable temperature conditions during storage or transportation.

Cellophane's biodegradability, while often considered an environmental advantage, can pose challenges in long-term food preservation. The material's tendency to break down over time, especially in the presence of moisture, may limit its effectiveness for products requiring extended shelf life. This degradation process can potentially compromise the package's barrier properties, leading to increased risk of microbial contamination or oxidation of the food contents.

The material's limited heat-sealing capabilities present another constraint in food packaging applications. Cellophane typically requires additional coatings or laminations to achieve effective heat seals, which can complicate the manufacturing process and increase production costs. This limitation may restrict its use in certain packaging formats or for products that demand hermetic sealing for optimal safety and freshness.

Furthermore, cellophane's relatively low puncture resistance compared to some synthetic polymers can be problematic in maintaining package integrity throughout the supply chain. Sharp edges or rough handling during transportation and storage may compromise the packaging, potentially exposing food products to external contaminants or accelerating spoilage.

Lastly, the production of cellophane involves the use of chemicals and processes that may raise environmental and health concerns. The manufacturing process typically requires the use of carbon disulfide, a toxic and flammable compound. While efforts have been made to improve production methods, these environmental considerations may limit cellophane's adoption in certain markets or applications where sustainability is a primary concern.

Current Solutions

01 Biodegradable cellophane for food packaging

Development of biodegradable cellophane materials for food packaging applications, focusing on improving environmental sustainability while maintaining food safety standards. These materials are designed to decompose naturally, reducing environmental impact without compromising the protective qualities required for food storage.- Biodegradable cellophane for food packaging: Development of biodegradable cellophane materials for food packaging applications, focusing on improving environmental sustainability while maintaining food safety standards. These materials are designed to break down naturally after use, reducing environmental impact.

- Antimicrobial cellophane for food preservation: Incorporation of antimicrobial agents into cellophane food packaging to enhance food safety by inhibiting the growth of harmful microorganisms. This technology helps extend the shelf life of packaged foods and reduces the risk of foodborne illnesses.

- Cellophane with improved barrier properties: Development of cellophane films with enhanced barrier properties to protect food from moisture, oxygen, and other external factors. These improvements help maintain food quality and safety during storage and transportation.

- Safety testing methods for cellophane food packaging: Advancements in testing methods to evaluate the safety of cellophane materials used in food packaging. These techniques assess potential chemical migration, toxicity, and overall compliance with food safety regulations.

- Eco-friendly coatings for cellophane food packaging: Development of environmentally friendly coatings for cellophane food packaging that enhance food safety without compromising recyclability or biodegradability. These coatings provide additional protection against contaminants and improve the overall performance of cellophane packaging.

02 Antimicrobial cellophane for food preservation

Incorporation of antimicrobial agents into cellophane to enhance food safety by inhibiting the growth of harmful microorganisms. This technology extends the shelf life of packaged foods and reduces the risk of foodborne illnesses, making cellophane a safer option for food packaging.Expand Specific Solutions03 Cellophane with improved barrier properties

Development of cellophane with enhanced barrier properties to protect food from moisture, oxygen, and other external factors that could compromise food safety. These improvements help maintain food quality and extend shelf life, ensuring better protection against contamination and spoilage.Expand Specific Solutions04 Safety testing methods for cellophane food packaging

Advancement in testing methods to evaluate the safety of cellophane used in food packaging. These methods assess factors such as chemical migration, toxicity, and compliance with food safety regulations to ensure that cellophane packaging meets stringent safety standards for food contact materials.Expand Specific Solutions05 Eco-friendly coatings for cellophane in food applications

Development of environmentally friendly coatings for cellophane used in food packaging. These coatings enhance the material's properties while ensuring food safety, focusing on using non-toxic, sustainable ingredients that do not compromise the recyclability or biodegradability of the cellophane.Expand Specific Solutions

Industry Leaders

The cellophane market for food safety applications is in a mature growth stage, with a global market size estimated to exceed $600 million by 2025. The technology has reached a high level of maturity, with established players like Cargill, Dow Global Technologies, and Asahi Kasei dominating the market. These companies have developed advanced cellophane formulations with enhanced barrier properties and antimicrobial features. Emerging players such as Codexis and Zhejiang Hengchuan New Material are focusing on bio-based and sustainable cellophane alternatives to address environmental concerns. The competitive landscape is characterized by ongoing R&D efforts to improve cellophane's functionality and cost-effectiveness for food packaging applications.

Cargill, Inc.

Technical Solution: Cargill has developed an innovative cellophane-based packaging solution that addresses food safety challenges. Their approach involves incorporating antimicrobial agents into the cellophane film, creating an active packaging system that inhibits the growth of harmful microorganisms[1]. The company has also implemented nanotechnology to enhance the barrier properties of cellophane, reducing oxygen and moisture permeability[2]. This technology extends the shelf life of packaged foods while maintaining product quality. Additionally, Cargill has introduced a bio-based cellophane variant derived from renewable resources, aligning with sustainability goals while ensuring food safety[3].

Strengths: Enhanced antimicrobial properties, improved barrier function, and sustainable sourcing. Weaknesses: Potentially higher production costs and limited applicability to certain food types.

Dow Global Technologies LLC

Technical Solution: Dow has developed a cutting-edge cellophane technology called "SafeGuard" that addresses food safety concerns. This technology incorporates a proprietary blend of food-grade additives into the cellophane structure, creating an active barrier against pathogens and contaminants[4]. SafeGuard cellophane also features enhanced oxygen and moisture barrier properties, significantly extending the shelf life of packaged foods[5]. Dow's innovation includes a smart indicator system integrated into the cellophane, which changes color when food spoilage begins, providing visual cues to consumers[6]. The company has also focused on improving the heat-sealing properties of cellophane, ensuring better package integrity and reducing the risk of contamination during transportation and storage.

Strengths: Advanced pathogen resistance, smart indicator system, and improved package integrity. Weaknesses: Higher production costs and potential limitations in recycling due to added components.

Key Innovations

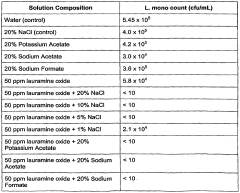

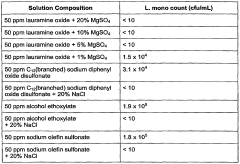

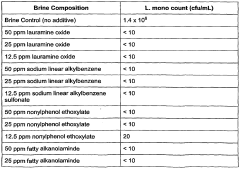

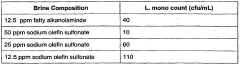

Antimicrobial salt solutions for cheese processing applications

PatentWO2007139722A1

Innovation

- A food-safe antimicrobial solution combining surfactants and salts, such as sodium chloride, which maintains antibacterial effectiveness even at low temperatures and neutral pH, effectively killing pathogens like L. monocytogenes without toxic byproducts.

Method for treating food surfaces with bacteriophages

PatentWO2016010751A1

Innovation

- Applying a bacteriophage and a specific methylcellulose with anhydroglucose units joined by 1-4 linkages, where hydroxy groups are substituted with methyl groups in specific ratios, to food surfaces, preferably when they are warm, to inhibit bacterial growth and contamination.

Regulatory Compliance

Regulatory compliance is a critical aspect of the cellophane industry, particularly in its application for food safety. As cellophane continues to play a significant role in food packaging, manufacturers and distributors must navigate a complex landscape of regulations to ensure their products meet stringent safety standards.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of food contact materials, including cellophane. The FDA's Code of Federal Regulations Title 21, Part 177, Subpart B specifically addresses cellophane, outlining the permitted raw materials, production processes, and additives. Manufacturers must ensure their cellophane products comply with these regulations to be deemed safe for food contact.

The European Union has its own set of regulations governing food contact materials, including Regulation (EC) No 1935/2004. This framework regulation sets out general principles of safety and inertness for all food contact materials. Additionally, Commission Regulation (EU) No 10/2011 provides specific requirements for plastic materials and articles intended to come into contact with food, which may apply to certain cellophane products.

Globally, the food packaging industry must also adhere to Good Manufacturing Practices (GMPs) as outlined by various regulatory bodies. These practices ensure that food contact materials, including cellophane, are produced in a manner that prevents contamination and maintains product integrity.

Compliance with these regulations often requires extensive testing and documentation. Manufacturers must conduct migration tests to ensure that no harmful substances leach from the cellophane into the food. They must also provide detailed information on the composition of their products and demonstrate that all components are approved for food contact use.

The regulatory landscape is not static, and manufacturers must stay abreast of changes in regulations across different markets. For instance, there is an increasing focus on the environmental impact of packaging materials, leading to new regulations on biodegradability and recycling. This may affect the production and use of cellophane in food packaging.

Certification programs, such as those offered by the Global Food Safety Initiative (GFSI), can help manufacturers demonstrate compliance with international food safety standards. These certifications often go beyond regulatory requirements and can provide a competitive advantage in the market.

As the food industry continues to evolve, so do the regulations surrounding food packaging materials. Manufacturers of cellophane must maintain robust quality management systems and stay informed about regulatory changes to ensure ongoing compliance and maintain consumer trust in the safety of their products.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of food contact materials, including cellophane. The FDA's Code of Federal Regulations Title 21, Part 177, Subpart B specifically addresses cellophane, outlining the permitted raw materials, production processes, and additives. Manufacturers must ensure their cellophane products comply with these regulations to be deemed safe for food contact.

The European Union has its own set of regulations governing food contact materials, including Regulation (EC) No 1935/2004. This framework regulation sets out general principles of safety and inertness for all food contact materials. Additionally, Commission Regulation (EU) No 10/2011 provides specific requirements for plastic materials and articles intended to come into contact with food, which may apply to certain cellophane products.

Globally, the food packaging industry must also adhere to Good Manufacturing Practices (GMPs) as outlined by various regulatory bodies. These practices ensure that food contact materials, including cellophane, are produced in a manner that prevents contamination and maintains product integrity.

Compliance with these regulations often requires extensive testing and documentation. Manufacturers must conduct migration tests to ensure that no harmful substances leach from the cellophane into the food. They must also provide detailed information on the composition of their products and demonstrate that all components are approved for food contact use.

The regulatory landscape is not static, and manufacturers must stay abreast of changes in regulations across different markets. For instance, there is an increasing focus on the environmental impact of packaging materials, leading to new regulations on biodegradability and recycling. This may affect the production and use of cellophane in food packaging.

Certification programs, such as those offered by the Global Food Safety Initiative (GFSI), can help manufacturers demonstrate compliance with international food safety standards. These certifications often go beyond regulatory requirements and can provide a competitive advantage in the market.

As the food industry continues to evolve, so do the regulations surrounding food packaging materials. Manufacturers of cellophane must maintain robust quality management systems and stay informed about regulatory changes to ensure ongoing compliance and maintain consumer trust in the safety of their products.

Environmental Impact

The environmental impact of cellophane in food safety applications is a critical consideration in the broader context of sustainable packaging solutions. Cellophane, a biodegradable material derived from cellulose, offers several environmental advantages over traditional plastic packaging. Its production process, which involves the regeneration of cellulose from wood pulp or cotton linters, generally has a lower carbon footprint compared to petroleum-based plastics.

One of the key environmental benefits of cellophane is its biodegradability. Under proper conditions, cellophane can decompose within a few months to a few years, significantly reducing the long-term environmental burden associated with packaging waste. This characteristic aligns well with the growing global emphasis on reducing plastic pollution and promoting circular economy principles in the packaging industry.

However, the environmental impact of cellophane is not without complexities. The production of cellophane involves chemical processes that can generate pollutants if not properly managed. The use of carbon disulfide in the viscose process, a common method for producing cellophane, raises environmental concerns due to its toxicity and potential for air and water pollution. Advancements in production technologies have led to more environmentally friendly methods, such as the lyocell process, which uses less harmful solvents.

Water usage is another environmental factor to consider in cellophane production. The manufacturing process requires significant amounts of water, which can strain local water resources if not managed sustainably. However, modern production facilities often implement water recycling systems to mitigate this impact.

In terms of food safety applications, cellophane's environmental profile is further enhanced by its potential to reduce food waste. Its excellent barrier properties against moisture and gases can extend the shelf life of food products, potentially reducing the amount of food that spoils before consumption. This indirect environmental benefit is significant, considering the substantial environmental impact of food waste in terms of resource use and greenhouse gas emissions.

The end-of-life management of cellophane also contributes to its environmental impact. While biodegradable, the material's disposal still requires proper waste management infrastructure to ensure it decomposes under optimal conditions. In industrial composting facilities, cellophane can be effectively broken down, but it may not degrade as readily in home composting systems or if improperly disposed of in landfills.

As the food industry increasingly prioritizes sustainable packaging solutions, the environmental impact of cellophane continues to be a subject of research and development. Efforts are ongoing to further improve its production efficiency, reduce chemical use, and enhance its end-of-life management. These advancements aim to position cellophane as an environmentally responsible choice for food safety applications, balancing the need for effective packaging with the imperative of environmental stewardship.

One of the key environmental benefits of cellophane is its biodegradability. Under proper conditions, cellophane can decompose within a few months to a few years, significantly reducing the long-term environmental burden associated with packaging waste. This characteristic aligns well with the growing global emphasis on reducing plastic pollution and promoting circular economy principles in the packaging industry.

However, the environmental impact of cellophane is not without complexities. The production of cellophane involves chemical processes that can generate pollutants if not properly managed. The use of carbon disulfide in the viscose process, a common method for producing cellophane, raises environmental concerns due to its toxicity and potential for air and water pollution. Advancements in production technologies have led to more environmentally friendly methods, such as the lyocell process, which uses less harmful solvents.

Water usage is another environmental factor to consider in cellophane production. The manufacturing process requires significant amounts of water, which can strain local water resources if not managed sustainably. However, modern production facilities often implement water recycling systems to mitigate this impact.

In terms of food safety applications, cellophane's environmental profile is further enhanced by its potential to reduce food waste. Its excellent barrier properties against moisture and gases can extend the shelf life of food products, potentially reducing the amount of food that spoils before consumption. This indirect environmental benefit is significant, considering the substantial environmental impact of food waste in terms of resource use and greenhouse gas emissions.

The end-of-life management of cellophane also contributes to its environmental impact. While biodegradable, the material's disposal still requires proper waste management infrastructure to ensure it decomposes under optimal conditions. In industrial composting facilities, cellophane can be effectively broken down, but it may not degrade as readily in home composting systems or if improperly disposed of in landfills.

As the food industry increasingly prioritizes sustainable packaging solutions, the environmental impact of cellophane continues to be a subject of research and development. Efforts are ongoing to further improve its production efficiency, reduce chemical use, and enhance its end-of-life management. These advancements aim to position cellophane as an environmentally responsible choice for food safety applications, balancing the need for effective packaging with the imperative of environmental stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!