Cellophane in Transparent OLED Displays: Current Trends

JUL 9, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Display Evolution

The evolution of OLED display technology has been a remarkable journey, spanning several decades of research and development. Initially conceived in the 1950s, organic electroluminescence laid the foundation for what would become OLED displays. However, it wasn't until the 1980s that significant progress was made in developing practical OLED devices.

The 1990s marked a crucial turning point with the invention of the first OLED display by Kodak researchers. This breakthrough paved the way for commercial applications, although early OLED displays were limited in size and efficiency. The early 2000s saw rapid advancements in OLED technology, with improvements in materials, manufacturing processes, and device structures.

As the technology matured, OLED displays began to find their way into consumer electronics. Mobile phones were among the first devices to adopt OLED screens, offering vibrant colors and energy efficiency. The mid-2000s witnessed the emergence of larger OLED panels, enabling their use in televisions and monitors.

Transparent OLED displays represent a more recent development in this evolutionary timeline. The concept of transparent displays has long been a goal for researchers and manufacturers, offering exciting possibilities for augmented reality applications and innovative product designs. The integration of cellophane in transparent OLED displays is a cutting-edge trend that aims to enhance transparency and flexibility while maintaining display performance.

The use of cellophane in OLED displays builds upon the inherent advantages of OLED technology, such as self-emissive pixels and the ability to create flexible displays. Cellophane, a thin, transparent film made from regenerated cellulose, offers unique properties that complement OLED structures. Its high optical clarity and potential for flexibility make it an attractive material for transparent display applications.

Current trends in cellophane-based transparent OLED displays focus on improving transparency levels, enhancing durability, and optimizing manufacturing processes. Researchers are exploring ways to integrate cellophane substrates with OLED components while maintaining electrical conductivity and light emission efficiency. This ongoing work represents the latest chapter in the OLED display evolution, pushing the boundaries of what's possible in display technology.

The 1990s marked a crucial turning point with the invention of the first OLED display by Kodak researchers. This breakthrough paved the way for commercial applications, although early OLED displays were limited in size and efficiency. The early 2000s saw rapid advancements in OLED technology, with improvements in materials, manufacturing processes, and device structures.

As the technology matured, OLED displays began to find their way into consumer electronics. Mobile phones were among the first devices to adopt OLED screens, offering vibrant colors and energy efficiency. The mid-2000s witnessed the emergence of larger OLED panels, enabling their use in televisions and monitors.

Transparent OLED displays represent a more recent development in this evolutionary timeline. The concept of transparent displays has long been a goal for researchers and manufacturers, offering exciting possibilities for augmented reality applications and innovative product designs. The integration of cellophane in transparent OLED displays is a cutting-edge trend that aims to enhance transparency and flexibility while maintaining display performance.

The use of cellophane in OLED displays builds upon the inherent advantages of OLED technology, such as self-emissive pixels and the ability to create flexible displays. Cellophane, a thin, transparent film made from regenerated cellulose, offers unique properties that complement OLED structures. Its high optical clarity and potential for flexibility make it an attractive material for transparent display applications.

Current trends in cellophane-based transparent OLED displays focus on improving transparency levels, enhancing durability, and optimizing manufacturing processes. Researchers are exploring ways to integrate cellophane substrates with OLED components while maintaining electrical conductivity and light emission efficiency. This ongoing work represents the latest chapter in the OLED display evolution, pushing the boundaries of what's possible in display technology.

Transparent OLED Market

The transparent OLED market has been experiencing significant growth and transformation in recent years, driven by the increasing demand for innovative display technologies across various industries. This market segment is characterized by its unique ability to offer see-through displays that can seamlessly integrate into environments while providing high-quality visual content.

The automotive sector has emerged as a key driver for transparent OLED adoption, with manufacturers incorporating these displays into windshields and windows for enhanced heads-up displays (HUDs) and infotainment systems. This integration allows for improved driver safety and a more immersive user experience. Additionally, the retail and hospitality industries have shown growing interest in transparent OLED technology for creating engaging and interactive storefront displays and digital signage.

Consumer electronics represent another significant market for transparent OLEDs, with applications in smartphones, smartwatches, and augmented reality (AR) devices. The technology's ability to provide high contrast ratios and true blacks while maintaining transparency makes it particularly attractive for these applications.

The market has also seen increased adoption in architectural and interior design, where transparent OLED panels are being used to create dynamic and customizable spaces in both commercial and residential settings. This trend is expected to continue as the technology becomes more cost-effective and energy-efficient.

Geographically, Asia-Pacific leads the transparent OLED market, with South Korea and China at the forefront of production and innovation. However, North America and Europe are also significant markets, particularly in terms of adoption and application development.

Despite its growth, the transparent OLED market faces challenges, including high production costs and technical limitations in achieving higher transparency levels. Ongoing research and development efforts are focused on addressing these issues, with particular emphasis on improving transparency, enhancing durability, and reducing manufacturing costs.

As the technology matures, new applications are continually emerging, such as in the healthcare sector for advanced medical imaging displays and in the aerospace industry for cockpit instrumentation. These developments are expected to further expand the market potential of transparent OLEDs in the coming years.

The automotive sector has emerged as a key driver for transparent OLED adoption, with manufacturers incorporating these displays into windshields and windows for enhanced heads-up displays (HUDs) and infotainment systems. This integration allows for improved driver safety and a more immersive user experience. Additionally, the retail and hospitality industries have shown growing interest in transparent OLED technology for creating engaging and interactive storefront displays and digital signage.

Consumer electronics represent another significant market for transparent OLEDs, with applications in smartphones, smartwatches, and augmented reality (AR) devices. The technology's ability to provide high contrast ratios and true blacks while maintaining transparency makes it particularly attractive for these applications.

The market has also seen increased adoption in architectural and interior design, where transparent OLED panels are being used to create dynamic and customizable spaces in both commercial and residential settings. This trend is expected to continue as the technology becomes more cost-effective and energy-efficient.

Geographically, Asia-Pacific leads the transparent OLED market, with South Korea and China at the forefront of production and innovation. However, North America and Europe are also significant markets, particularly in terms of adoption and application development.

Despite its growth, the transparent OLED market faces challenges, including high production costs and technical limitations in achieving higher transparency levels. Ongoing research and development efforts are focused on addressing these issues, with particular emphasis on improving transparency, enhancing durability, and reducing manufacturing costs.

As the technology matures, new applications are continually emerging, such as in the healthcare sector for advanced medical imaging displays and in the aerospace industry for cockpit instrumentation. These developments are expected to further expand the market potential of transparent OLEDs in the coming years.

Cellophane Integration

Cellophane integration in transparent OLED displays represents a significant advancement in display technology. This innovative approach leverages the unique properties of cellophane to enhance the performance and functionality of OLED screens. Cellophane, a thin, transparent film made from regenerated cellulose, offers several advantages when incorporated into OLED displays.

One of the primary benefits of cellophane integration is its ability to improve light transmission. The high transparency of cellophane allows for better light output from the OLED pixels, resulting in brighter and more vibrant displays. This characteristic is particularly valuable in applications where display visibility in various lighting conditions is crucial, such as automotive displays or outdoor signage.

Furthermore, cellophane's flexibility contributes to the development of more durable and potentially foldable OLED displays. The material's inherent flexibility allows for the creation of curved or bendable screens without compromising the display's integrity or performance. This property opens up new design possibilities for consumer electronics and wearable devices.

Cellophane integration also addresses some of the challenges associated with traditional OLED displays, such as moisture sensitivity. The material acts as an effective barrier against water vapor and oxygen, helping to protect the sensitive organic layers of the OLED structure. This enhanced protection can lead to improved longevity and reliability of transparent OLED displays, particularly in demanding environmental conditions.

The integration process typically involves incorporating cellophane as a substrate or encapsulation layer within the OLED stack. Advanced manufacturing techniques, such as roll-to-roll processing, are being explored to efficiently integrate cellophane into large-scale OLED production. This approach not only enhances the display's performance but also has the potential to reduce production costs and increase manufacturing efficiency.

Recent developments in cellophane integration have focused on optimizing the material's optical and mechanical properties for OLED applications. Researchers are exploring various surface treatments and modifications to enhance cellophane's compatibility with other OLED components and to further improve its barrier properties against environmental factors.

As the demand for transparent and flexible displays continues to grow, cellophane integration in OLED technology is likely to play an increasingly important role. The ongoing research and development in this area promise to deliver next-generation displays with superior visual quality, durability, and form factor flexibility, catering to diverse applications across consumer electronics, automotive, and industrial sectors.

One of the primary benefits of cellophane integration is its ability to improve light transmission. The high transparency of cellophane allows for better light output from the OLED pixels, resulting in brighter and more vibrant displays. This characteristic is particularly valuable in applications where display visibility in various lighting conditions is crucial, such as automotive displays or outdoor signage.

Furthermore, cellophane's flexibility contributes to the development of more durable and potentially foldable OLED displays. The material's inherent flexibility allows for the creation of curved or bendable screens without compromising the display's integrity or performance. This property opens up new design possibilities for consumer electronics and wearable devices.

Cellophane integration also addresses some of the challenges associated with traditional OLED displays, such as moisture sensitivity. The material acts as an effective barrier against water vapor and oxygen, helping to protect the sensitive organic layers of the OLED structure. This enhanced protection can lead to improved longevity and reliability of transparent OLED displays, particularly in demanding environmental conditions.

The integration process typically involves incorporating cellophane as a substrate or encapsulation layer within the OLED stack. Advanced manufacturing techniques, such as roll-to-roll processing, are being explored to efficiently integrate cellophane into large-scale OLED production. This approach not only enhances the display's performance but also has the potential to reduce production costs and increase manufacturing efficiency.

Recent developments in cellophane integration have focused on optimizing the material's optical and mechanical properties for OLED applications. Researchers are exploring various surface treatments and modifications to enhance cellophane's compatibility with other OLED components and to further improve its barrier properties against environmental factors.

As the demand for transparent and flexible displays continues to grow, cellophane integration in OLED technology is likely to play an increasingly important role. The ongoing research and development in this area promise to deliver next-generation displays with superior visual quality, durability, and form factor flexibility, catering to diverse applications across consumer electronics, automotive, and industrial sectors.

Cellophane-OLED Solutions

01 Improving transparency of cellophane films

Various methods are employed to enhance the transparency of cellophane films. These include modifying the chemical composition, adjusting the manufacturing process, and applying surface treatments. Improved transparency is crucial for applications requiring clear visibility through the film.- Improving transparency of cellophane films: Various methods are employed to enhance the transparency of cellophane films. These include modifying the manufacturing process, adding specific additives, or treating the surface of the film. Improved transparency allows for better visibility of packaged contents and enhances the overall appearance of the product.

- Cellophane-based packaging solutions: Cellophane is widely used in packaging applications due to its transparency and other beneficial properties. Innovations in this area focus on developing new packaging designs, improving barrier properties, and enhancing the overall functionality of cellophane-based packaging materials.

- Modifying cellophane for specific applications: Researchers are exploring ways to modify cellophane to suit specific applications. This includes incorporating additional materials or treatments to enhance properties such as strength, flexibility, or resistance to environmental factors, while maintaining or improving transparency.

- Cellophane in optical and display technologies: Cellophane's transparency makes it suitable for use in various optical and display applications. Innovations in this area focus on utilizing cellophane's unique properties to create novel display technologies or improve existing ones, such as in projection systems or transparent screens.

- Environmental considerations in cellophane production: As environmental concerns grow, efforts are being made to develop more sustainable methods for producing transparent cellophane. This includes using eco-friendly raw materials, optimizing production processes to reduce energy consumption, and improving the biodegradability of cellophane products without compromising their transparency.

02 Cellophane packaging for food products

Cellophane is widely used in food packaging due to its transparency and barrier properties. Innovations focus on improving its performance for specific food applications, such as extending shelf life, maintaining product freshness, and enhancing visual appeal.Expand Specific Solutions03 Biodegradable cellophane alternatives

Research is ongoing to develop biodegradable alternatives to traditional cellophane. These new materials aim to maintain the transparency and functional properties of cellophane while offering improved environmental sustainability.Expand Specific Solutions04 Cellophane in optical applications

Cellophane's transparency makes it suitable for various optical applications. Innovations in this area include using cellophane in display technologies, optical filters, and light-modulating devices, leveraging its unique optical properties.Expand Specific Solutions05 Surface treatments for cellophane

Various surface treatments are applied to cellophane to modify its properties. These treatments can enhance transparency, improve adhesion, increase moisture resistance, or add functionality such as anti-fog properties, expanding the range of applications for cellophane films.Expand Specific Solutions

Industry Leaders

The transparent OLED display market is in a growth phase, with increasing adoption across consumer electronics and automotive sectors. The global market size is projected to expand significantly in the coming years, driven by demand for innovative display technologies. Technologically, transparent OLED displays are advancing rapidly, with key players like LG Display, BOE Technology, and Samsung Display leading development efforts. These companies are focusing on improving transparency, flexibility, and energy efficiency. While the technology is maturing, challenges remain in scaling production and reducing costs. Collaboration between display manufacturers, materials suppliers like Corning, and research institutions is accelerating progress towards commercial viability and wider application of transparent OLED displays.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has made significant strides in transparent OLED technology, incorporating cellophane-inspired materials. Their approach focuses on ultra-thin film transistors (TFTs) and organic light-emitting layers deposited on transparent substrates. BOE's technology allows for a transparency of up to 70% in their displays, surpassing many competitors[4]. The company has developed a proprietary encapsulation technique that protects the organic materials from moisture and oxygen, extending the lifespan of their transparent OLEDs[5]. BOE has also introduced flexible transparent OLED displays, combining transparency with bendability for innovative applications in wearable technology and curved architectural displays[6].

Strengths: High transparency, advanced encapsulation technology, and flexibility. Weaknesses: Higher production costs and potential limitations in color reproduction compared to non-transparent OLEDs.

Corning, Inc.

Technical Solution: Corning has leveraged its expertise in glass technology to develop advanced substrates for transparent OLED displays. While not directly manufacturing OLEDs, Corning's contributions to the field are significant. They have created ultra-thin, flexible glass substrates that serve as an ideal base for transparent OLED displays. These substrates offer superior barrier properties against moisture and oxygen compared to plastic alternatives, crucial for OLED longevity[9]. Corning's glass also provides excellent thermal stability, allowing for higher processing temperatures during OLED fabrication. The company has developed specialized coatings that enhance light transmission and reduce reflections, further improving the performance of transparent OLEDs[10].

Strengths: Superior barrier properties, thermal stability, and optical performance of glass substrates. Weaknesses: Potential limitations in flexibility compared to plastic substrates and higher material costs.

Key Cellophane Patents

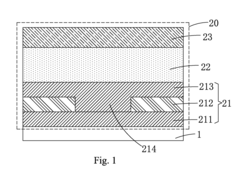

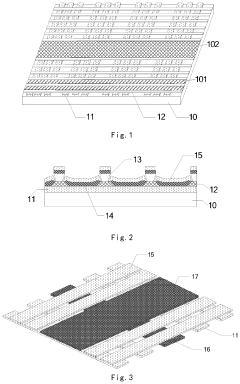

Transparent OLED display panel and manufacturing method thereof

PatentActiveUS20180366678A1

Innovation

- A transparent OLED display panel design featuring a substrate with sub-pixels comprising a first transparent electrode, a reflective electrode with a hollow center, and a second transparent electrode, allowing light to pass through while maintaining reflectivity, using ITO for the electrodes and silver for the reflective layer.

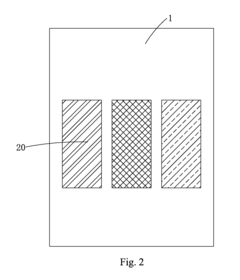

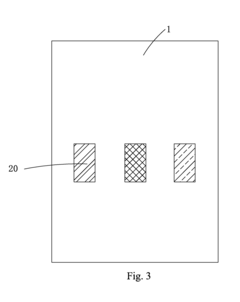

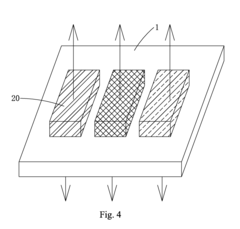

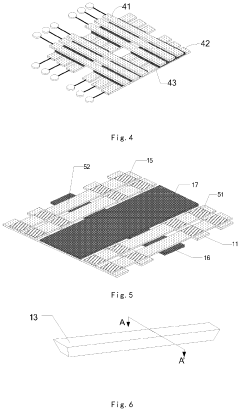

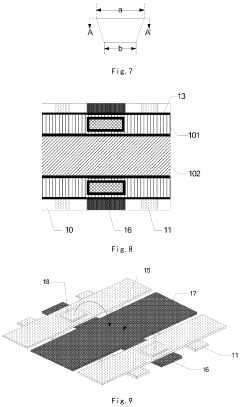

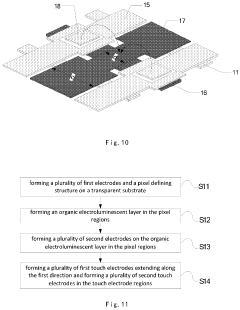

In-cell transparent touch display panel, manufacturing method and driving method thereof

PatentActiveUS20200004363A1

Innovation

- An in-cell transparent touch display panel is developed, comprising transparent electrodes and organic electroluminescent layers on a substrate, with a pixel defining structure and touch electrodes arranged in specific directions to enable both touch functionality and transparency, along with barriers and a silver material layer to enhance display performance.

Manufacturing Processes

The manufacturing processes for incorporating cellophane in transparent OLED displays involve several intricate steps and advanced techniques. The production typically begins with the preparation of the cellophane substrate, which undergoes rigorous cleaning and surface treatment to ensure optimal adhesion and performance.

One of the key processes is the deposition of transparent conductive layers onto the cellophane substrate. This is often achieved through techniques such as sputtering or chemical vapor deposition (CVD). These methods allow for the creation of ultra-thin, highly conductive layers that maintain the transparency of the cellophane while providing the necessary electrical properties for OLED functionality.

Following the conductive layer deposition, the organic light-emitting materials are applied. This step usually employs thermal evaporation or solution processing methods, depending on the specific OLED materials used. The precise control of layer thickness and uniformity is crucial for achieving high-quality displays.

Encapsulation is another critical stage in the manufacturing process. Given the sensitivity of OLED materials to moisture and oxygen, a robust barrier layer must be applied to protect the device. Advanced thin-film encapsulation techniques, such as atomic layer deposition (ALD), are often utilized to create ultra-thin, highly effective barrier layers that preserve the flexibility and transparency of the cellophane-based display.

The integration of the cellophane-based OLED with other display components, such as the backplane electronics and touch sensors, presents unique challenges. Manufacturers are developing specialized bonding and lamination techniques to ensure seamless integration while maintaining the display's flexibility and optical properties.

Quality control and testing are integral parts of the manufacturing process. Automated optical inspection systems are employed to detect defects in the transparent OLED layers, while electrical testing ensures the proper functioning of each pixel. Flexibility and durability tests are particularly important for cellophane-based displays to verify their performance under various bending and environmental conditions.

As the technology evolves, manufacturers are continually refining their processes to improve yield rates and reduce production costs. This includes the development of roll-to-roll manufacturing techniques, which hold promise for large-scale, cost-effective production of flexible transparent OLED displays using cellophane substrates.

One of the key processes is the deposition of transparent conductive layers onto the cellophane substrate. This is often achieved through techniques such as sputtering or chemical vapor deposition (CVD). These methods allow for the creation of ultra-thin, highly conductive layers that maintain the transparency of the cellophane while providing the necessary electrical properties for OLED functionality.

Following the conductive layer deposition, the organic light-emitting materials are applied. This step usually employs thermal evaporation or solution processing methods, depending on the specific OLED materials used. The precise control of layer thickness and uniformity is crucial for achieving high-quality displays.

Encapsulation is another critical stage in the manufacturing process. Given the sensitivity of OLED materials to moisture and oxygen, a robust barrier layer must be applied to protect the device. Advanced thin-film encapsulation techniques, such as atomic layer deposition (ALD), are often utilized to create ultra-thin, highly effective barrier layers that preserve the flexibility and transparency of the cellophane-based display.

The integration of the cellophane-based OLED with other display components, such as the backplane electronics and touch sensors, presents unique challenges. Manufacturers are developing specialized bonding and lamination techniques to ensure seamless integration while maintaining the display's flexibility and optical properties.

Quality control and testing are integral parts of the manufacturing process. Automated optical inspection systems are employed to detect defects in the transparent OLED layers, while electrical testing ensures the proper functioning of each pixel. Flexibility and durability tests are particularly important for cellophane-based displays to verify their performance under various bending and environmental conditions.

As the technology evolves, manufacturers are continually refining their processes to improve yield rates and reduce production costs. This includes the development of roll-to-roll manufacturing techniques, which hold promise for large-scale, cost-effective production of flexible transparent OLED displays using cellophane substrates.

Environmental Impact

The integration of cellophane in transparent OLED displays presents both opportunities and challenges from an environmental perspective. As the demand for transparent displays grows, it is crucial to consider the ecological implications of this technology.

Cellophane, a biodegradable material derived from cellulose, offers potential advantages in terms of sustainability compared to traditional plastic substrates. Its renewable source and ability to decompose naturally align with the increasing focus on environmentally friendly technologies. However, the production process of cellophane still requires energy and resources, which must be factored into its overall environmental impact.

The use of cellophane in OLED displays may contribute to reducing electronic waste, a significant environmental concern in the tech industry. As cellophane is biodegradable, it could potentially decrease the long-term environmental footprint of discarded displays. This aligns with the growing emphasis on circular economy principles and extended producer responsibility in electronics manufacturing.

Energy efficiency is another critical aspect to consider. Transparent OLED displays utilizing cellophane may offer improved light transmission properties, potentially reducing the energy consumption required for display brightness. This could lead to longer battery life in portable devices and lower overall energy usage, contributing to reduced carbon emissions over the product lifecycle.

However, the environmental impact of cellophane-based displays extends beyond the material itself. The manufacturing processes, including the production of OLED components and the integration of cellophane substrates, must be evaluated for their energy consumption and potential emissions. Additionally, the durability and lifespan of cellophane-based displays compared to traditional options will influence their overall environmental footprint.

The recyclability and end-of-life management of cellophane-based OLED displays also warrant consideration. While cellophane itself is biodegradable, the complex nature of electronic displays, including various metals and chemicals, may complicate recycling efforts. Developing effective recycling and disposal methods for these hybrid devices will be crucial to maximizing their environmental benefits.

As the technology evolves, ongoing research into the environmental impact of cellophane in transparent OLED displays is essential. This includes life cycle assessments, studies on biodegradation rates in different conditions, and investigations into potential ecological effects of widespread adoption. Such research will inform future developments and help guide the industry towards more sustainable practices in display technology.

Cellophane, a biodegradable material derived from cellulose, offers potential advantages in terms of sustainability compared to traditional plastic substrates. Its renewable source and ability to decompose naturally align with the increasing focus on environmentally friendly technologies. However, the production process of cellophane still requires energy and resources, which must be factored into its overall environmental impact.

The use of cellophane in OLED displays may contribute to reducing electronic waste, a significant environmental concern in the tech industry. As cellophane is biodegradable, it could potentially decrease the long-term environmental footprint of discarded displays. This aligns with the growing emphasis on circular economy principles and extended producer responsibility in electronics manufacturing.

Energy efficiency is another critical aspect to consider. Transparent OLED displays utilizing cellophane may offer improved light transmission properties, potentially reducing the energy consumption required for display brightness. This could lead to longer battery life in portable devices and lower overall energy usage, contributing to reduced carbon emissions over the product lifecycle.

However, the environmental impact of cellophane-based displays extends beyond the material itself. The manufacturing processes, including the production of OLED components and the integration of cellophane substrates, must be evaluated for their energy consumption and potential emissions. Additionally, the durability and lifespan of cellophane-based displays compared to traditional options will influence their overall environmental footprint.

The recyclability and end-of-life management of cellophane-based OLED displays also warrant consideration. While cellophane itself is biodegradable, the complex nature of electronic displays, including various metals and chemicals, may complicate recycling efforts. Developing effective recycling and disposal methods for these hybrid devices will be crucial to maximizing their environmental benefits.

As the technology evolves, ongoing research into the environmental impact of cellophane in transparent OLED displays is essential. This includes life cycle assessments, studies on biodegradation rates in different conditions, and investigations into potential ecological effects of widespread adoption. Such research will inform future developments and help guide the industry towards more sustainable practices in display technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!