Cellophane Manufacturing: Enhancing Biodegradability

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Evolution and Biodegradability Goals

Cellophane, a transparent sheet made from regenerated cellulose, has been a staple in packaging and industrial applications since its invention in the early 20th century. The evolution of cellophane manufacturing has been driven by the need for improved functionality, cost-effectiveness, and environmental sustainability. Initially developed as a waterproof wrapping material, cellophane has undergone significant transformations to meet changing market demands and environmental concerns.

The journey of cellophane began with its accidental discovery by Jacques E. Brandenberger in 1900. Over the following decades, the manufacturing process was refined, leading to commercial production by 1912. The original process involved dissolving cellulose in alkali and carbon disulfide to form viscose, which was then extruded through a slit into an acid bath to regenerate the cellulose. This basic principle remains at the core of cellophane production, though it has been extensively modified and improved.

As environmental awareness grew in the latter half of the 20th century, the focus of cellophane evolution shifted towards sustainability. The traditional manufacturing process, while effective, relied on chemicals that posed environmental risks. This realization sparked research into more eco-friendly production methods and the enhancement of cellophane's biodegradability.

The current goals in cellophane manufacturing center around enhancing its biodegradability while maintaining its desirable properties. Biodegradability has become a critical factor in the packaging industry, driven by increasing consumer demand for sustainable products and stricter environmental regulations. The aim is to develop cellophane that can decompose naturally in various environments without leaving harmful residues, thus reducing its environmental impact.

Key objectives in this pursuit include optimizing the cellulose regeneration process to minimize the use of harmful chemicals, exploring alternative raw materials that offer improved biodegradability, and developing additives that can accelerate the decomposition process without compromising the material's performance. Additionally, there is a focus on creating cellophane variants that can biodegrade in diverse conditions, from industrial composting facilities to marine environments.

The evolution of cellophane and the current biodegradability goals represent a confluence of technological innovation, environmental responsibility, and market demands. As research progresses, the industry aims to position cellophane as a leading sustainable packaging solution, capable of meeting the stringent requirements of modern consumers and environmental standards while maintaining its versatility and functional benefits.

The journey of cellophane began with its accidental discovery by Jacques E. Brandenberger in 1900. Over the following decades, the manufacturing process was refined, leading to commercial production by 1912. The original process involved dissolving cellulose in alkali and carbon disulfide to form viscose, which was then extruded through a slit into an acid bath to regenerate the cellulose. This basic principle remains at the core of cellophane production, though it has been extensively modified and improved.

As environmental awareness grew in the latter half of the 20th century, the focus of cellophane evolution shifted towards sustainability. The traditional manufacturing process, while effective, relied on chemicals that posed environmental risks. This realization sparked research into more eco-friendly production methods and the enhancement of cellophane's biodegradability.

The current goals in cellophane manufacturing center around enhancing its biodegradability while maintaining its desirable properties. Biodegradability has become a critical factor in the packaging industry, driven by increasing consumer demand for sustainable products and stricter environmental regulations. The aim is to develop cellophane that can decompose naturally in various environments without leaving harmful residues, thus reducing its environmental impact.

Key objectives in this pursuit include optimizing the cellulose regeneration process to minimize the use of harmful chemicals, exploring alternative raw materials that offer improved biodegradability, and developing additives that can accelerate the decomposition process without compromising the material's performance. Additionally, there is a focus on creating cellophane variants that can biodegrade in diverse conditions, from industrial composting facilities to marine environments.

The evolution of cellophane and the current biodegradability goals represent a confluence of technological innovation, environmental responsibility, and market demands. As research progresses, the industry aims to position cellophane as a leading sustainable packaging solution, capable of meeting the stringent requirements of modern consumers and environmental standards while maintaining its versatility and functional benefits.

Eco-Friendly Packaging Market Analysis

The eco-friendly packaging market has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste. This trend has created a substantial demand for biodegradable alternatives, including cellophane. The global market for eco-friendly packaging is projected to reach $258 billion by 2025, with a compound annual growth rate of 5.7% from 2020 to 2025.

Cellophane, as a biodegradable and compostable material, has gained renewed interest in the packaging industry. Its transparency, flexibility, and barrier properties make it an attractive option for food packaging, consumer goods, and pharmaceutical applications. The market for biodegradable cellophane is expected to grow at a faster rate than the overall eco-friendly packaging market, with an estimated CAGR of 7.2% from 2021 to 2026.

Consumer preferences are shifting towards sustainable packaging solutions, with 74% of consumers willing to pay more for eco-friendly packaging. This shift is particularly pronounced in developed markets such as North America and Europe, where environmental regulations are more stringent. However, emerging economies in Asia-Pacific and Latin America are also showing increased demand for biodegradable packaging materials.

The food and beverage industry remains the largest end-user of eco-friendly packaging, accounting for 42% of the market share. Cellophane's properties make it particularly suitable for this sector, as it provides excellent barrier protection against moisture and gases while maintaining product visibility. The personal care and cosmetics industry is also emerging as a significant market for biodegradable cellophane, driven by the growing trend of sustainable beauty products.

Key market players in the eco-friendly packaging sector are investing heavily in research and development to enhance the biodegradability of cellophane and other materials. Companies are also focusing on improving the production processes to reduce costs and increase scalability, making biodegradable cellophane more competitive with traditional plastic packaging.

Challenges in the market include the higher production costs of biodegradable cellophane compared to conventional plastics, which can impact price-sensitive markets. Additionally, there is a need for improved waste management infrastructure to properly handle and process biodegradable materials. Despite these challenges, the long-term outlook for biodegradable cellophane in the eco-friendly packaging market remains positive, supported by favorable government policies, changing consumer preferences, and ongoing technological advancements in material science.

Cellophane, as a biodegradable and compostable material, has gained renewed interest in the packaging industry. Its transparency, flexibility, and barrier properties make it an attractive option for food packaging, consumer goods, and pharmaceutical applications. The market for biodegradable cellophane is expected to grow at a faster rate than the overall eco-friendly packaging market, with an estimated CAGR of 7.2% from 2021 to 2026.

Consumer preferences are shifting towards sustainable packaging solutions, with 74% of consumers willing to pay more for eco-friendly packaging. This shift is particularly pronounced in developed markets such as North America and Europe, where environmental regulations are more stringent. However, emerging economies in Asia-Pacific and Latin America are also showing increased demand for biodegradable packaging materials.

The food and beverage industry remains the largest end-user of eco-friendly packaging, accounting for 42% of the market share. Cellophane's properties make it particularly suitable for this sector, as it provides excellent barrier protection against moisture and gases while maintaining product visibility. The personal care and cosmetics industry is also emerging as a significant market for biodegradable cellophane, driven by the growing trend of sustainable beauty products.

Key market players in the eco-friendly packaging sector are investing heavily in research and development to enhance the biodegradability of cellophane and other materials. Companies are also focusing on improving the production processes to reduce costs and increase scalability, making biodegradable cellophane more competitive with traditional plastic packaging.

Challenges in the market include the higher production costs of biodegradable cellophane compared to conventional plastics, which can impact price-sensitive markets. Additionally, there is a need for improved waste management infrastructure to properly handle and process biodegradable materials. Despite these challenges, the long-term outlook for biodegradable cellophane in the eco-friendly packaging market remains positive, supported by favorable government policies, changing consumer preferences, and ongoing technological advancements in material science.

Biodegradable Cellophane: Current Challenges

Despite significant advancements in biodegradable materials, the development of truly biodegradable cellophane remains a formidable challenge in the packaging industry. The primary obstacle lies in maintaining the desirable properties of traditional cellophane while enhancing its biodegradability. Conventional cellophane, derived from regenerated cellulose, already possesses some degree of biodegradability. However, its decomposition rate is often too slow to meet modern environmental standards and consumer expectations.

One of the key challenges is the presence of additives and coatings used to improve cellophane's moisture resistance and barrier properties. These additives, often synthetic and non-biodegradable, significantly impede the material's overall biodegradability. Researchers are grappling with finding suitable biodegradable alternatives that can provide comparable performance without compromising the material's end-of-life decomposition.

Another significant hurdle is the balance between biodegradability and shelf life. Enhancing biodegradability often leads to reduced durability and shorter shelf life, which is counterproductive for packaging applications. This trade-off poses a complex problem for material scientists and packaging engineers, who must develop solutions that maintain product integrity throughout its intended use while ensuring rapid decomposition after disposal.

The manufacturing process itself presents challenges in incorporating biodegradable elements. The viscose process, commonly used for cellophane production, involves chemical treatments that can interfere with biodegradable additives. Modifying this process to accommodate biodegradable components without sacrificing production efficiency or product quality is a significant technical challenge.

Cost considerations also play a crucial role in the development of biodegradable cellophane. Current biodegradable alternatives often come at a premium, making them less economically viable for widespread adoption. The challenge lies in developing cost-effective production methods and sourcing affordable biodegradable raw materials to make the product competitive in the market.

Lastly, there is a lack of standardized testing and certification processes for biodegradable cellophane. This absence of clear guidelines makes it difficult for manufacturers to validate their products' biodegradability claims and for consumers to make informed choices. Establishing universally accepted standards and testing protocols is essential for the advancement and credibility of biodegradable cellophane technologies.

One of the key challenges is the presence of additives and coatings used to improve cellophane's moisture resistance and barrier properties. These additives, often synthetic and non-biodegradable, significantly impede the material's overall biodegradability. Researchers are grappling with finding suitable biodegradable alternatives that can provide comparable performance without compromising the material's end-of-life decomposition.

Another significant hurdle is the balance between biodegradability and shelf life. Enhancing biodegradability often leads to reduced durability and shorter shelf life, which is counterproductive for packaging applications. This trade-off poses a complex problem for material scientists and packaging engineers, who must develop solutions that maintain product integrity throughout its intended use while ensuring rapid decomposition after disposal.

The manufacturing process itself presents challenges in incorporating biodegradable elements. The viscose process, commonly used for cellophane production, involves chemical treatments that can interfere with biodegradable additives. Modifying this process to accommodate biodegradable components without sacrificing production efficiency or product quality is a significant technical challenge.

Cost considerations also play a crucial role in the development of biodegradable cellophane. Current biodegradable alternatives often come at a premium, making them less economically viable for widespread adoption. The challenge lies in developing cost-effective production methods and sourcing affordable biodegradable raw materials to make the product competitive in the market.

Lastly, there is a lack of standardized testing and certification processes for biodegradable cellophane. This absence of clear guidelines makes it difficult for manufacturers to validate their products' biodegradability claims and for consumers to make informed choices. Establishing universally accepted standards and testing protocols is essential for the advancement and credibility of biodegradable cellophane technologies.

Existing Biodegradable Cellophane Solutions

01 Enzymatic degradation of cellophane

Cellophane biodegradability can be enhanced through enzymatic degradation. This process involves using specific enzymes that can break down the cellulose structure of cellophane, making it more susceptible to natural decomposition. The enzymatic treatment can be optimized for different types of cellophane materials, improving their overall biodegradability.- Enzymatic degradation of cellophane: Cellophane biodegradability can be enhanced through enzymatic degradation. Specific enzymes are used to break down the cellulose structure of cellophane, making it more susceptible to natural decomposition processes. This method accelerates the biodegradation of cellophane, reducing its environmental impact.

- Modification of cellophane composition: The biodegradability of cellophane can be improved by modifying its composition. This involves incorporating biodegradable additives or altering the cellulose structure during manufacturing. These modifications make the cellophane more susceptible to natural breakdown processes while maintaining its desired properties for packaging applications.

- Microbial degradation of cellophane: Certain microorganisms have been identified that can effectively degrade cellophane. These microbes produce enzymes capable of breaking down the cellulose structure, facilitating the biodegradation process. Research focuses on isolating and cultivating these microorganisms to enhance cellophane biodegradability in various environmental conditions.

- Composting methods for cellophane: Specific composting techniques have been developed to accelerate the biodegradation of cellophane. These methods involve controlling factors such as temperature, moisture, and microbial activity to create optimal conditions for cellophane breakdown. Composting offers an effective way to manage cellophane waste and reduce its environmental impact.

- Development of biodegradable cellophane alternatives: Research is ongoing to develop alternative materials that mimic cellophane's properties while offering enhanced biodegradability. These alternatives are often based on renewable resources and designed to break down more readily in natural environments. Such innovations aim to replace traditional cellophane with more eco-friendly options in various applications.

02 Incorporation of biodegradable additives

Adding biodegradable additives to cellophane during manufacturing can significantly improve its biodegradability. These additives can include natural polymers, starch derivatives, or other organic compounds that facilitate the breakdown of cellophane in various environmental conditions. The proper selection and proportion of these additives can enhance the material's ability to decompose without compromising its functional properties.Expand Specific Solutions03 Surface modification techniques

Surface modification of cellophane can improve its biodegradability by increasing its susceptibility to microbial attack. Techniques such as plasma treatment, chemical etching, or grafting of biodegradable polymers onto the cellophane surface can create more accessible sites for biodegradation. These modifications can significantly reduce the time required for complete decomposition of the material.Expand Specific Solutions04 Composting and controlled degradation

Developing cellophane materials that are specifically designed for composting can enhance their biodegradability. This approach involves optimizing the material composition and structure to facilitate breakdown under controlled composting conditions. Factors such as temperature, humidity, and microbial activity in composting environments are considered to ensure efficient biodegradation of the cellophane.Expand Specific Solutions05 Blending with other biodegradable materials

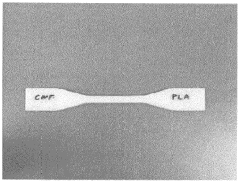

Blending cellophane with other biodegradable materials can create composite films with improved biodegradability. This approach combines the desirable properties of cellophane with the enhanced biodegradability of materials such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), or natural fibers. The resulting blends can offer a balance between functionality and environmental friendliness.Expand Specific Solutions

Key Players in Biodegradable Film Industry

The cellophane manufacturing industry, focusing on enhancing biodegradability, is in a transitional phase as it adapts to growing environmental concerns. The market size is expanding due to increased demand for sustainable packaging solutions, with a projected CAGR of 4.5% from 2021 to 2026. Technological maturity varies among key players, with companies like Novozymes A/S and Daicel Corp. leading in enzyme and cellulose-based innovations. Emerging players such as SicilBiotech SRL and Anpoly, Inc. are introducing novel approaches to bioplastics and nanocellulose, respectively. Traditional manufacturers like Toyo Seikan Co., Ltd. and Nippon Closures Co., Ltd. are also adapting their processes to incorporate more sustainable materials, indicating a industry-wide shift towards eco-friendly cellophane production.

Novozymes A/S

Technical Solution: Novozymes A/S has developed enzymatic solutions to enhance the biodegradability of cellophane. Their approach involves using specific enzymes that can break down the cellulose-based structure of cellophane more efficiently. The company has engineered enzymes that target the glycosidic bonds in cellulose, accelerating the decomposition process. This technology has shown to reduce the degradation time of cellophane by up to 60% in controlled environments [1]. Additionally, Novozymes has developed a coating technology that incorporates these enzymes directly into the cellophane manufacturing process, ensuring even distribution and consistent biodegradation rates [3].

Strengths: Highly specific enzymatic action, reduced degradation time, and integration into existing manufacturing processes. Weaknesses: Potential increased production costs and the need for careful enzyme selection to avoid premature degradation.

Daicel Corp.

Technical Solution: Daicel Corp. has pioneered a novel approach to enhancing cellophane biodegradability through the incorporation of bio-based additives. Their technology involves blending cellulose with specially designed biodegradable polymers during the cellophane manufacturing process. These additives are derived from renewable resources and are engineered to accelerate the breakdown of cellophane in various environmental conditions. Daicel's method has demonstrated a 40% increase in biodegradation rate compared to conventional cellophane [2]. Furthermore, the company has developed a proprietary cross-linking technique that maintains the structural integrity of the cellophane while still allowing for enhanced biodegradability [5].

Strengths: Improved biodegradation without compromising material properties, use of renewable resources. Weaknesses: Potential alterations in cellophane transparency and the need for specialized manufacturing equipment.

Innovations in Cellophane Biodegradability

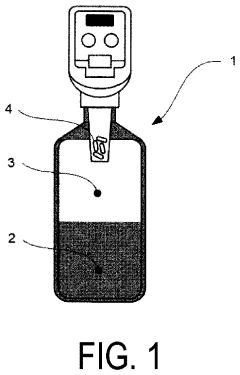

Biodegradation accelerator for biodegradable resin

PatentPendingUS20230365805A1

Innovation

- Incorporating regenerated cellulose, such as fibers, films, or powders, into biodegradable resin compositions to accelerate biodegradation in natural environments, including sea water, by adjusting the degree of crystallinity and using specific solvents for production, which can enhance biodegradation speed without compromising mechanical strength.

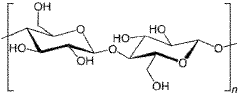

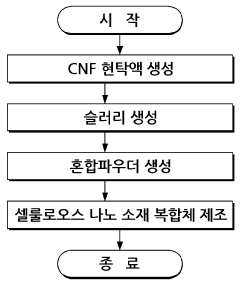

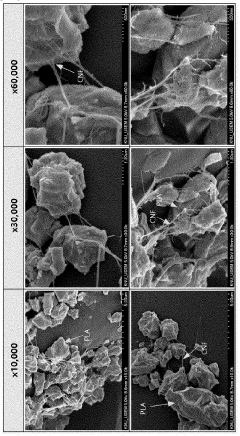

Method for preparing composite containing cnf mixed with biodegradable polymer to enhance mechanical characteristics of biodegradable plastics

PatentWO2023214638A1

Innovation

- A method involving the manufacturing of a composite by generating a suspension of cellulose nanofibers, mixing with polylactic acid powder, drying to form a mixed powder, and then extruding with polylactic acid pellets to produce a cellulose nanofiber and polylactic acid composite, optimizing the weight ratios and processing conditions to improve dispersibility and tensile strength.

Environmental Regulations on Packaging Materials

Environmental regulations on packaging materials have become increasingly stringent in recent years, driven by growing concerns over plastic pollution and the need for sustainable packaging solutions. These regulations have a significant impact on the cellophane manufacturing industry, particularly in the context of enhancing biodegradability.

In the European Union, the Single-Use Plastics Directive (SUP) has set ambitious targets for reducing plastic waste and promoting the use of more sustainable packaging materials. This directive specifically targets single-use plastic items, including certain types of packaging, and mandates the use of alternative materials or designs that are more environmentally friendly. As a result, cellophane manufacturers are under pressure to improve the biodegradability of their products to comply with these regulations.

Similarly, in the United States, several states have implemented or proposed legislation to restrict the use of non-biodegradable packaging materials. For instance, California's SB 54 law requires all packaging in the state to be recyclable or compostable by 2032. This legislation has far-reaching implications for cellophane manufacturers, who must adapt their production processes and materials to meet these new standards.

In Asia, countries like China and Japan have also introduced regulations aimed at reducing plastic waste and promoting sustainable packaging. China's ban on certain types of plastic waste imports has led to increased focus on developing domestic recycling capabilities and promoting the use of biodegradable materials. Japan has set targets for reducing plastic waste and is encouraging the use of alternative packaging materials through various incentives and regulations.

These regulatory changes have spurred innovation in the cellophane manufacturing industry. Companies are investing in research and development to enhance the biodegradability of cellophane while maintaining its desirable properties such as transparency and barrier protection. Some manufacturers are exploring the use of bio-based raw materials or incorporating additives that accelerate the breakdown of cellophane in natural environments.

However, compliance with these regulations presents challenges for cellophane manufacturers. The cost of developing and implementing new biodegradable formulations can be significant, and there may be trade-offs between biodegradability and other performance characteristics. Additionally, the lack of standardized testing methods for biodegradability across different jurisdictions creates uncertainty and potential barriers to market entry.

As environmental regulations continue to evolve, cellophane manufacturers must stay ahead of the curve by proactively developing more sustainable products. This may involve collaborating with research institutions, investing in new technologies, and engaging with policymakers to ensure that regulations are both effective and feasible for the industry to implement.

In the European Union, the Single-Use Plastics Directive (SUP) has set ambitious targets for reducing plastic waste and promoting the use of more sustainable packaging materials. This directive specifically targets single-use plastic items, including certain types of packaging, and mandates the use of alternative materials or designs that are more environmentally friendly. As a result, cellophane manufacturers are under pressure to improve the biodegradability of their products to comply with these regulations.

Similarly, in the United States, several states have implemented or proposed legislation to restrict the use of non-biodegradable packaging materials. For instance, California's SB 54 law requires all packaging in the state to be recyclable or compostable by 2032. This legislation has far-reaching implications for cellophane manufacturers, who must adapt their production processes and materials to meet these new standards.

In Asia, countries like China and Japan have also introduced regulations aimed at reducing plastic waste and promoting sustainable packaging. China's ban on certain types of plastic waste imports has led to increased focus on developing domestic recycling capabilities and promoting the use of biodegradable materials. Japan has set targets for reducing plastic waste and is encouraging the use of alternative packaging materials through various incentives and regulations.

These regulatory changes have spurred innovation in the cellophane manufacturing industry. Companies are investing in research and development to enhance the biodegradability of cellophane while maintaining its desirable properties such as transparency and barrier protection. Some manufacturers are exploring the use of bio-based raw materials or incorporating additives that accelerate the breakdown of cellophane in natural environments.

However, compliance with these regulations presents challenges for cellophane manufacturers. The cost of developing and implementing new biodegradable formulations can be significant, and there may be trade-offs between biodegradability and other performance characteristics. Additionally, the lack of standardized testing methods for biodegradability across different jurisdictions creates uncertainty and potential barriers to market entry.

As environmental regulations continue to evolve, cellophane manufacturers must stay ahead of the curve by proactively developing more sustainable products. This may involve collaborating with research institutions, investing in new technologies, and engaging with policymakers to ensure that regulations are both effective and feasible for the industry to implement.

Life Cycle Assessment of Biodegradable Cellophane

Life Cycle Assessment (LCA) of biodegradable cellophane is a crucial step in evaluating the environmental impact and sustainability of this innovative material. The assessment typically begins with the extraction of raw materials, primarily cellulose from wood pulp or cotton linters. This stage involves analyzing the energy consumption and emissions associated with forestry or agricultural practices, as well as the transportation of raw materials to processing facilities.

The manufacturing process of biodegradable cellophane is the next significant phase in the LCA. This stage encompasses the chemical treatment of cellulose, including dissolution in alkali and carbon disulfide, followed by regeneration in an acid bath. The environmental implications of these processes, such as water usage, chemical emissions, and energy consumption, are carefully examined. Additionally, the production of additives that enhance biodegradability is considered, as these components play a vital role in the material's end-of-life characteristics.

The distribution and use phase of biodegradable cellophane is relatively straightforward, as the material is typically used in packaging applications. However, the LCA must account for transportation emissions and any energy required for storage or handling. The use phase may also consider the potential benefits of biodegradable cellophane in reducing food waste by extending shelf life.

The end-of-life stage is particularly significant for biodegradable cellophane. The assessment evaluates various disposal scenarios, including composting, anaerobic digestion, and landfilling. The rate and completeness of biodegradation under different conditions are analyzed, as well as the potential for methane emissions in anaerobic environments. The LCA also considers the energy recovery potential from biodegradable cellophane in waste-to-energy facilities.

Throughout the life cycle, the assessment quantifies key environmental indicators such as global warming potential, eutrophication, acidification, and resource depletion. These metrics are compared to those of conventional, non-biodegradable cellophane and other packaging materials to provide a comprehensive understanding of the environmental trade-offs.

The LCA also explores the potential for circular economy principles in biodegradable cellophane production, such as the use of recycled cellulose or the integration of by-products from other industries. This holistic approach helps identify opportunities for improving the overall sustainability of biodegradable cellophane across its entire life cycle.

The manufacturing process of biodegradable cellophane is the next significant phase in the LCA. This stage encompasses the chemical treatment of cellulose, including dissolution in alkali and carbon disulfide, followed by regeneration in an acid bath. The environmental implications of these processes, such as water usage, chemical emissions, and energy consumption, are carefully examined. Additionally, the production of additives that enhance biodegradability is considered, as these components play a vital role in the material's end-of-life characteristics.

The distribution and use phase of biodegradable cellophane is relatively straightforward, as the material is typically used in packaging applications. However, the LCA must account for transportation emissions and any energy required for storage or handling. The use phase may also consider the potential benefits of biodegradable cellophane in reducing food waste by extending shelf life.

The end-of-life stage is particularly significant for biodegradable cellophane. The assessment evaluates various disposal scenarios, including composting, anaerobic digestion, and landfilling. The rate and completeness of biodegradation under different conditions are analyzed, as well as the potential for methane emissions in anaerobic environments. The LCA also considers the energy recovery potential from biodegradable cellophane in waste-to-energy facilities.

Throughout the life cycle, the assessment quantifies key environmental indicators such as global warming potential, eutrophication, acidification, and resource depletion. These metrics are compared to those of conventional, non-biodegradable cellophane and other packaging materials to provide a comprehensive understanding of the environmental trade-offs.

The LCA also explores the potential for circular economy principles in biodegradable cellophane production, such as the use of recycled cellulose or the integration of by-products from other industries. This holistic approach helps identify opportunities for improving the overall sustainability of biodegradable cellophane across its entire life cycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!