Cellophane's Potential in the Food Preservation Market

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Evolution and Objectives

Cellophane, a transparent sheet made from regenerated cellulose, has a rich history in the food preservation market dating back to its invention in 1908 by Jacques E. Brandenberger. Initially developed as a waterproof tablecloth, cellophane's potential for food packaging was quickly recognized, leading to its widespread adoption in the 1920s and 1930s.

The evolution of cellophane in food preservation has been marked by continuous improvements in its properties and manufacturing processes. Early cellophane was moisture-permeable, limiting its effectiveness in preserving food. However, advancements in coating technologies in the 1940s led to the development of moisture-proof cellophane, significantly enhancing its food preservation capabilities.

Throughout the 20th century, cellophane remained a dominant packaging material due to its transparency, flexibility, and ability to protect food from moisture and contaminants. Its popularity, however, began to wane in the latter half of the century with the rise of petroleum-based plastics, which offered improved barrier properties and lower production costs.

In recent years, there has been a resurgence of interest in cellophane due to growing environmental concerns and the push for sustainable packaging solutions. Modern cellophane production focuses on improving its biodegradability and compostability while maintaining its excellent food preservation properties. Research is ongoing to enhance cellophane's barrier properties against oxygen and other gases, potentially expanding its applications in extended shelf-life packaging.

The primary objective of cellophane in the food preservation market is to provide an effective, eco-friendly alternative to conventional plastic packaging. This goal aligns with the global trend towards sustainable packaging solutions and the reduction of plastic waste. Cellophane aims to offer comparable or superior food preservation capabilities while addressing environmental concerns.

Key objectives for cellophane in the food preservation sector include improving its moisture barrier properties, enhancing its resistance to temperature fluctuations, and increasing its overall durability. Additionally, there is a focus on developing cellophane variants that are suitable for a wider range of food products, including those requiring high-barrier packaging.

Another critical objective is to optimize the production process of cellophane to make it more cost-effective and energy-efficient. This involves exploring new raw material sources, such as agricultural waste, to further reduce the environmental impact of cellophane production.

As the food industry increasingly prioritizes sustainability, cellophane's potential in the food preservation market lies in its ability to meet both environmental and functional requirements. The ongoing evolution of cellophane technology aims to position it as a leading sustainable packaging solution, capable of preserving food quality while minimizing ecological impact.

The evolution of cellophane in food preservation has been marked by continuous improvements in its properties and manufacturing processes. Early cellophane was moisture-permeable, limiting its effectiveness in preserving food. However, advancements in coating technologies in the 1940s led to the development of moisture-proof cellophane, significantly enhancing its food preservation capabilities.

Throughout the 20th century, cellophane remained a dominant packaging material due to its transparency, flexibility, and ability to protect food from moisture and contaminants. Its popularity, however, began to wane in the latter half of the century with the rise of petroleum-based plastics, which offered improved barrier properties and lower production costs.

In recent years, there has been a resurgence of interest in cellophane due to growing environmental concerns and the push for sustainable packaging solutions. Modern cellophane production focuses on improving its biodegradability and compostability while maintaining its excellent food preservation properties. Research is ongoing to enhance cellophane's barrier properties against oxygen and other gases, potentially expanding its applications in extended shelf-life packaging.

The primary objective of cellophane in the food preservation market is to provide an effective, eco-friendly alternative to conventional plastic packaging. This goal aligns with the global trend towards sustainable packaging solutions and the reduction of plastic waste. Cellophane aims to offer comparable or superior food preservation capabilities while addressing environmental concerns.

Key objectives for cellophane in the food preservation sector include improving its moisture barrier properties, enhancing its resistance to temperature fluctuations, and increasing its overall durability. Additionally, there is a focus on developing cellophane variants that are suitable for a wider range of food products, including those requiring high-barrier packaging.

Another critical objective is to optimize the production process of cellophane to make it more cost-effective and energy-efficient. This involves exploring new raw material sources, such as agricultural waste, to further reduce the environmental impact of cellophane production.

As the food industry increasingly prioritizes sustainability, cellophane's potential in the food preservation market lies in its ability to meet both environmental and functional requirements. The ongoing evolution of cellophane technology aims to position it as a leading sustainable packaging solution, capable of preserving food quality while minimizing ecological impact.

Food Preservation Market Analysis

The food preservation market has experienced significant growth in recent years, driven by increasing consumer demand for convenient, long-lasting food products and the need to reduce food waste. This market encompasses a wide range of technologies and products, including packaging materials, preservatives, and processing methods designed to extend the shelf life of food items.

Global market research indicates that the food preservation sector is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is attributed to several factors, including urbanization, changing lifestyles, and a growing awareness of food safety and quality among consumers.

In terms of market segmentation, the food preservation industry can be broadly divided into chemical preservatives, natural preservatives, and packaging solutions. Among these, packaging solutions have gained considerable traction due to their ability to provide a physical barrier against contaminants while maintaining food quality. Cellophane, as a packaging material, falls within this category and has the potential to play a significant role in the market's future.

The demand for eco-friendly and sustainable packaging solutions has become a major trend in the food preservation market. Consumers are increasingly conscious of environmental issues, leading to a shift away from traditional plastic packaging towards more biodegradable options. This trend presents both opportunities and challenges for cellophane, which is derived from renewable resources but faces competition from newer, more advanced materials.

Geographically, the food preservation market shows varying patterns of growth and adoption. Developed regions such as North America and Europe have mature markets with a focus on innovation and sustainability. In contrast, emerging economies in Asia-Pacific and Latin America are experiencing rapid growth due to increasing disposable incomes and changing food consumption patterns.

The competitive landscape of the food preservation market is characterized by the presence of both large multinational corporations and smaller, specialized companies. Key players in the packaging segment are investing heavily in research and development to create innovative solutions that address consumer demands for convenience, sustainability, and extended shelf life.

In the context of cellophane's potential, it is important to note that while the material has been in use for decades, recent advancements in its production and properties have renewed interest in its applications for food preservation. The market analysis suggests that there is room for cellophane to carve out a niche, particularly in segments where its unique properties align with consumer preferences and regulatory requirements.

Global market research indicates that the food preservation sector is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is attributed to several factors, including urbanization, changing lifestyles, and a growing awareness of food safety and quality among consumers.

In terms of market segmentation, the food preservation industry can be broadly divided into chemical preservatives, natural preservatives, and packaging solutions. Among these, packaging solutions have gained considerable traction due to their ability to provide a physical barrier against contaminants while maintaining food quality. Cellophane, as a packaging material, falls within this category and has the potential to play a significant role in the market's future.

The demand for eco-friendly and sustainable packaging solutions has become a major trend in the food preservation market. Consumers are increasingly conscious of environmental issues, leading to a shift away from traditional plastic packaging towards more biodegradable options. This trend presents both opportunities and challenges for cellophane, which is derived from renewable resources but faces competition from newer, more advanced materials.

Geographically, the food preservation market shows varying patterns of growth and adoption. Developed regions such as North America and Europe have mature markets with a focus on innovation and sustainability. In contrast, emerging economies in Asia-Pacific and Latin America are experiencing rapid growth due to increasing disposable incomes and changing food consumption patterns.

The competitive landscape of the food preservation market is characterized by the presence of both large multinational corporations and smaller, specialized companies. Key players in the packaging segment are investing heavily in research and development to create innovative solutions that address consumer demands for convenience, sustainability, and extended shelf life.

In the context of cellophane's potential, it is important to note that while the material has been in use for decades, recent advancements in its production and properties have renewed interest in its applications for food preservation. The market analysis suggests that there is room for cellophane to carve out a niche, particularly in segments where its unique properties align with consumer preferences and regulatory requirements.

Cellophane Technology Status

Cellophane, a transparent sheet made from regenerated cellulose, has been a significant player in the food preservation market for decades. Currently, the technology status of cellophane in this sector is characterized by both established applications and ongoing innovations.

The primary production method for cellophane remains the viscose process, which involves dissolving cellulose in alkali and carbon disulfide, followed by extrusion and regeneration. This process, while effective, has faced environmental scrutiny due to the use of toxic chemicals. As a result, research into more sustainable production methods is ongoing, with some companies exploring bio-based alternatives and greener chemical processes.

In terms of food preservation capabilities, cellophane continues to demonstrate excellent barrier properties against moisture, gases, and microorganisms. Its permeability can be tailored through coatings or laminations, allowing for customized solutions for different food products. Recent advancements have focused on enhancing these properties, with some manufacturers developing cellophane films with improved oxygen and moisture barriers.

The integration of nanotechnology has opened new avenues for cellophane development. Nanocomposite cellophane films incorporating materials such as nanocellulose or metal nanoparticles have shown promise in enhancing mechanical strength, barrier properties, and even antimicrobial activity. These innovations are particularly relevant for extending the shelf life of perishable foods.

Smart packaging concepts are also being explored with cellophane as a base material. Researchers are investigating the incorporation of sensors and indicators into cellophane films to provide real-time information on food freshness and quality. This includes color-changing indicators for temperature exposure and gas sensors for detecting spoilage.

Biodegradability remains a key advantage of cellophane in the current market landscape. With increasing consumer demand for sustainable packaging solutions, cellophane's natural biodegradability positions it favorably against synthetic plastic alternatives. However, the challenge lies in maintaining this biodegradability while enhancing performance characteristics to match or exceed those of conventional plastics.

The technology status of cellophane also reflects ongoing efforts to reduce production costs and improve scalability. While cellophane has been in use for over a century, its production process is still more expensive than that of many synthetic plastics. Research into more efficient production methods and the use of alternative raw materials aims to address this challenge.

In the context of food safety regulations, cellophane continues to meet stringent requirements. Its inertness and low migration of substances into food products make it a preferred choice for direct food contact applications. Ongoing research focuses on further reducing any potential migration and ensuring compliance with evolving food safety standards globally.

The primary production method for cellophane remains the viscose process, which involves dissolving cellulose in alkali and carbon disulfide, followed by extrusion and regeneration. This process, while effective, has faced environmental scrutiny due to the use of toxic chemicals. As a result, research into more sustainable production methods is ongoing, with some companies exploring bio-based alternatives and greener chemical processes.

In terms of food preservation capabilities, cellophane continues to demonstrate excellent barrier properties against moisture, gases, and microorganisms. Its permeability can be tailored through coatings or laminations, allowing for customized solutions for different food products. Recent advancements have focused on enhancing these properties, with some manufacturers developing cellophane films with improved oxygen and moisture barriers.

The integration of nanotechnology has opened new avenues for cellophane development. Nanocomposite cellophane films incorporating materials such as nanocellulose or metal nanoparticles have shown promise in enhancing mechanical strength, barrier properties, and even antimicrobial activity. These innovations are particularly relevant for extending the shelf life of perishable foods.

Smart packaging concepts are also being explored with cellophane as a base material. Researchers are investigating the incorporation of sensors and indicators into cellophane films to provide real-time information on food freshness and quality. This includes color-changing indicators for temperature exposure and gas sensors for detecting spoilage.

Biodegradability remains a key advantage of cellophane in the current market landscape. With increasing consumer demand for sustainable packaging solutions, cellophane's natural biodegradability positions it favorably against synthetic plastic alternatives. However, the challenge lies in maintaining this biodegradability while enhancing performance characteristics to match or exceed those of conventional plastics.

The technology status of cellophane also reflects ongoing efforts to reduce production costs and improve scalability. While cellophane has been in use for over a century, its production process is still more expensive than that of many synthetic plastics. Research into more efficient production methods and the use of alternative raw materials aims to address this challenge.

In the context of food safety regulations, cellophane continues to meet stringent requirements. Its inertness and low migration of substances into food products make it a preferred choice for direct food contact applications. Ongoing research focuses on further reducing any potential migration and ensuring compliance with evolving food safety standards globally.

Current Cellophane Applications

01 Cellophane production and modification

Various methods and processes for producing and modifying cellophane are described. These include techniques for improving the properties of cellophane, such as its strength, flexibility, and barrier characteristics. The modifications may involve chemical treatments or the incorporation of additives to enhance the material's performance for specific applications.- Cellophane in packaging applications: Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is employed in food packaging, gift wrapping, and industrial packaging solutions. The material's ability to protect products while allowing visibility makes it popular in various industries.

- Biodegradable cellophane alternatives: Research is ongoing to develop biodegradable alternatives to traditional cellophane. These eco-friendly options aim to maintain the desirable properties of cellophane while reducing environmental impact. Innovations in this area focus on using renewable resources and improving the material's end-of-life characteristics.

- Cellophane in medical and pharmaceutical applications: Cellophane finds applications in the medical and pharmaceutical industries. It is used in wound dressings, drug delivery systems, and as a barrier material in various medical devices. The material's biocompatibility and ability to be sterilized contribute to its suitability for these applications.

- Modifications and improvements to cellophane: Ongoing research focuses on modifying and improving cellophane properties. This includes enhancing its barrier properties, increasing its strength, and improving its heat resistance. Various coating techniques and chemical treatments are explored to achieve these improvements while maintaining the material's core characteristics.

- Cellophane in textile and fiber applications: Cellophane is utilized in textile and fiber applications. It can be processed into fibers or used as a coating for fabrics. These applications take advantage of cellophane's unique properties to create innovative textiles with specific characteristics such as moisture resistance or enhanced durability.

02 Packaging applications of cellophane

Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. The patents describe various packaging solutions utilizing cellophane, including food packaging, consumer product packaging, and industrial packaging. Some innovations focus on improving the sealing properties and extending the shelf life of packaged products.Expand Specific Solutions03 Biodegradable and eco-friendly cellophane

Developments in biodegradable and environmentally friendly cellophane materials are presented. These innovations aim to address sustainability concerns by creating cellophane-like materials that can decompose naturally or be recycled more easily. Some approaches involve incorporating natural additives or modifying the cellulose structure to enhance biodegradability.Expand Specific Solutions04 Cellophane-based composite materials

Inventions related to composite materials incorporating cellophane are described. These composites may combine cellophane with other materials to create products with enhanced properties, such as improved strength, flexibility, or functionality. Applications of these composites range from packaging to industrial uses.Expand Specific Solutions05 Cellophane in medical and pharmaceutical applications

The use of cellophane in medical and pharmaceutical applications is explored. This includes the development of cellophane-based materials for drug delivery systems, wound dressings, and other medical devices. Some innovations focus on modifying cellophane to improve its biocompatibility and controlled release properties for these specialized applications.Expand Specific Solutions

Key Players in Cellophane Industry

The cellophane market in food preservation is experiencing dynamic growth, driven by increasing demand for sustainable packaging solutions. The industry is in a transitional phase, moving from early adoption to mainstream acceptance. Market size is expanding rapidly, with projections indicating significant growth potential. Technologically, cellophane is evolving, with companies like Zoono Group and Chr. Hansen A/S leading innovations in antimicrobial properties and biodegradability. Established players such as Stora Enso Oyj and Mars, Inc. are investing in research and development to enhance cellophane's functionality and eco-friendliness. This competitive landscape is fostering advancements in cellophane technology, positioning it as a promising solution for future food packaging needs.

Stora Enso Oyj

Technical Solution: Stora Enso has developed a novel approach to cellophane-based food preservation by focusing on nanocellulose-reinforced cellophane films. Their technology involves incorporating cellulose nanofibrils (CNF) into the cellophane structure, significantly enhancing its mechanical strength and barrier properties[13]. This reinforced cellophane exhibits improved resistance to oxygen and water vapor transmission, extending the shelf life of packaged foods[15]. Stora Enso has also developed a bio-based, compostable coating for their cellophane that provides additional barrier properties while maintaining the material's biodegradability[17].

Strengths: Enhanced mechanical and barrier properties while maintaining biodegradability. Weaknesses: May have higher production costs and require specialized manufacturing processes.

Mars, Inc.

Technical Solution: Mars has developed a cellophane-based packaging system that focuses on sustainability and food preservation. Their approach involves using bio-based cellophane derived from renewable resources, such as wood pulp or corn starch[2]. This eco-friendly cellophane is then treated with a proprietary coating that enhances its barrier properties against oxygen, moisture, and UV light[4]. Mars has also incorporated smart indicators into the cellophane packaging that change color based on the freshness of the food inside, allowing consumers to visually assess product quality[6].

Strengths: Environmentally friendly approach with added consumer-facing features for freshness monitoring. Weaknesses: May have higher production costs and potentially limited applicability to certain food types.

Cellophane Innovations Review

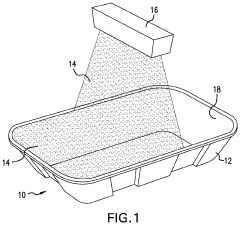

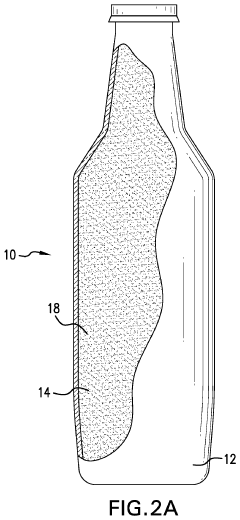

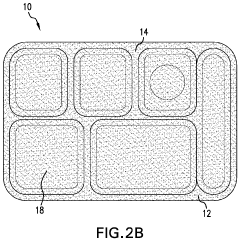

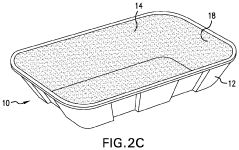

Methods and articles for keeping food fresher for longer and shelf-life extension to enhance food security and safety

PatentPendingUS20230097707A1

Innovation

- A composition comprising benzalkonium chloride, hydrogen peroxide, 3-(tri-methoxysilyl)propyldimethyl octadecyl ammonium chloride, and deionized water is applied to food packaging surfaces, forming a long-lasting, broad-spectrum antimicrobial coating that reduces microbial populations by up to 90% and maintains effectiveness across various substrates.

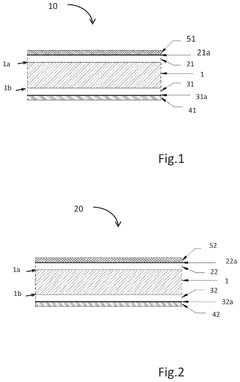

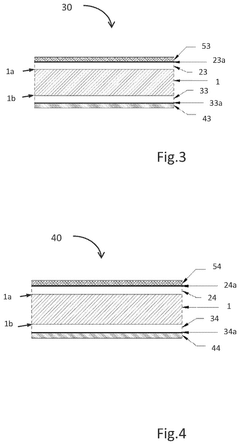

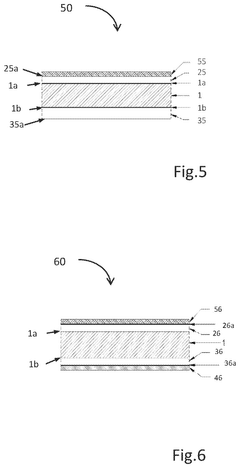

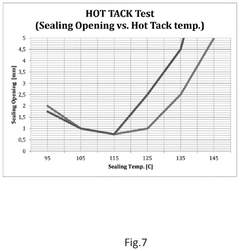

Polymeric Structures for Packagings

PatentPendingUS20250153468A1

Innovation

- The use of nitrous flame treatment (NFT) on polyolefinic surfaces, specifically BOPP, eliminates the need for primers by activating the substrates and introducing nitrogen-based functional groups, enhancing adhesion without delamination.

Environmental Impact Assessment

The environmental impact of cellophane in the food preservation market is a critical consideration for its potential widespread adoption. Cellophane, being a biodegradable material derived from renewable resources, offers several environmental advantages over traditional plastic packaging materials.

Firstly, cellophane's production process has a lower carbon footprint compared to petroleum-based plastics. The primary raw material for cellophane, wood pulp, is a renewable resource that can be sustainably managed. This reduces the reliance on fossil fuels and helps mitigate greenhouse gas emissions associated with packaging production.

In terms of waste management, cellophane's biodegradability is a significant environmental benefit. Unlike conventional plastics that persist in the environment for hundreds of years, cellophane can decompose naturally within a few months to a few years, depending on environmental conditions. This characteristic greatly reduces the long-term environmental impact of food packaging waste.

However, it is important to note that the environmental benefits of cellophane are not without caveats. The production process involves the use of chemicals, such as carbon disulfide, which can have negative environmental impacts if not properly managed. Manufacturers must implement stringent controls and treatment processes to minimize the release of these chemicals into the environment.

Water usage is another environmental consideration in cellophane production. The manufacturing process requires substantial amounts of water, which necessitates efficient water management and recycling systems to minimize the overall environmental footprint.

When considering the entire lifecycle of cellophane in food preservation, its impact on food waste reduction should also be factored into the environmental assessment. By effectively preserving food and extending shelf life, cellophane can contribute to reducing food waste, which is a significant source of greenhouse gas emissions and resource depletion.

The end-of-life disposal of cellophane presents both opportunities and challenges. While its biodegradability is advantageous, proper disposal infrastructure is crucial to realize these benefits. Composting facilities capable of handling cellophane waste need to be more widely available to ensure that the material's environmental advantages are fully realized.

In conclusion, the environmental impact assessment of cellophane in the food preservation market reveals a complex picture. While offering significant advantages in terms of biodegradability and renewable resource use, challenges remain in production processes and end-of-life management. As the food industry increasingly prioritizes sustainable packaging solutions, ongoing research and development efforts are likely to further improve cellophane's environmental profile, potentially solidifying its position as a key player in eco-friendly food preservation.

Firstly, cellophane's production process has a lower carbon footprint compared to petroleum-based plastics. The primary raw material for cellophane, wood pulp, is a renewable resource that can be sustainably managed. This reduces the reliance on fossil fuels and helps mitigate greenhouse gas emissions associated with packaging production.

In terms of waste management, cellophane's biodegradability is a significant environmental benefit. Unlike conventional plastics that persist in the environment for hundreds of years, cellophane can decompose naturally within a few months to a few years, depending on environmental conditions. This characteristic greatly reduces the long-term environmental impact of food packaging waste.

However, it is important to note that the environmental benefits of cellophane are not without caveats. The production process involves the use of chemicals, such as carbon disulfide, which can have negative environmental impacts if not properly managed. Manufacturers must implement stringent controls and treatment processes to minimize the release of these chemicals into the environment.

Water usage is another environmental consideration in cellophane production. The manufacturing process requires substantial amounts of water, which necessitates efficient water management and recycling systems to minimize the overall environmental footprint.

When considering the entire lifecycle of cellophane in food preservation, its impact on food waste reduction should also be factored into the environmental assessment. By effectively preserving food and extending shelf life, cellophane can contribute to reducing food waste, which is a significant source of greenhouse gas emissions and resource depletion.

The end-of-life disposal of cellophane presents both opportunities and challenges. While its biodegradability is advantageous, proper disposal infrastructure is crucial to realize these benefits. Composting facilities capable of handling cellophane waste need to be more widely available to ensure that the material's environmental advantages are fully realized.

In conclusion, the environmental impact assessment of cellophane in the food preservation market reveals a complex picture. While offering significant advantages in terms of biodegradability and renewable resource use, challenges remain in production processes and end-of-life management. As the food industry increasingly prioritizes sustainable packaging solutions, ongoing research and development efforts are likely to further improve cellophane's environmental profile, potentially solidifying its position as a key player in eco-friendly food preservation.

Regulatory Compliance in Food Packaging

Regulatory compliance in food packaging is a critical aspect of the cellophane industry, particularly as it relates to its potential in the food preservation market. The use of cellophane in food packaging is subject to stringent regulations set by various governmental bodies, including the Food and Drug Administration (FDA) in the United States and the European Food Safety Authority (EFSA) in the European Union.

These regulatory bodies have established specific guidelines for materials that come into direct contact with food, known as food contact materials (FCMs). Cellophane, as an FCM, must meet these requirements to ensure the safety of consumers and maintain the integrity of packaged food products. The regulations typically cover aspects such as migration limits of chemical substances, overall composition, and manufacturing processes.

One of the primary concerns in regulatory compliance for cellophane is the potential migration of chemicals from the packaging material into the food. Manufacturers must demonstrate that their cellophane products do not release harmful substances into food at levels that could pose a risk to human health. This often involves extensive testing and documentation to prove compliance with migration limits set by regulatory authorities.

Additionally, the production process of cellophane must adhere to Good Manufacturing Practices (GMP) as outlined by regulatory bodies. This includes maintaining proper hygiene standards, implementing quality control measures, and ensuring traceability throughout the production chain. Manufacturers are required to keep detailed records of their production processes and be prepared for potential audits by regulatory agencies.

Labeling requirements also form a significant part of regulatory compliance for cellophane food packaging. Manufacturers must provide accurate information about the composition of their packaging materials and any specific instructions for use or disposal. This transparency is crucial for both consumers and downstream users in the food industry.

As the food preservation market evolves, so do the regulations governing packaging materials. Manufacturers of cellophane must stay abreast of these changes and continuously adapt their products and processes to maintain compliance. This may involve reformulating products, upgrading manufacturing facilities, or investing in new testing methodologies.

The global nature of the food industry adds another layer of complexity to regulatory compliance. Cellophane manufacturers aiming to serve international markets must navigate a complex web of regulations that can vary significantly between countries and regions. This often necessitates obtaining multiple certifications and adapting packaging solutions to meet diverse regulatory requirements.

These regulatory bodies have established specific guidelines for materials that come into direct contact with food, known as food contact materials (FCMs). Cellophane, as an FCM, must meet these requirements to ensure the safety of consumers and maintain the integrity of packaged food products. The regulations typically cover aspects such as migration limits of chemical substances, overall composition, and manufacturing processes.

One of the primary concerns in regulatory compliance for cellophane is the potential migration of chemicals from the packaging material into the food. Manufacturers must demonstrate that their cellophane products do not release harmful substances into food at levels that could pose a risk to human health. This often involves extensive testing and documentation to prove compliance with migration limits set by regulatory authorities.

Additionally, the production process of cellophane must adhere to Good Manufacturing Practices (GMP) as outlined by regulatory bodies. This includes maintaining proper hygiene standards, implementing quality control measures, and ensuring traceability throughout the production chain. Manufacturers are required to keep detailed records of their production processes and be prepared for potential audits by regulatory agencies.

Labeling requirements also form a significant part of regulatory compliance for cellophane food packaging. Manufacturers must provide accurate information about the composition of their packaging materials and any specific instructions for use or disposal. This transparency is crucial for both consumers and downstream users in the food industry.

As the food preservation market evolves, so do the regulations governing packaging materials. Manufacturers of cellophane must stay abreast of these changes and continuously adapt their products and processes to maintain compliance. This may involve reformulating products, upgrading manufacturing facilities, or investing in new testing methodologies.

The global nature of the food industry adds another layer of complexity to regulatory compliance. Cellophane manufacturers aiming to serve international markets must navigate a complex web of regulations that can vary significantly between countries and regions. This often necessitates obtaining multiple certifications and adapting packaging solutions to meet diverse regulatory requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!