Cellophane's Role in Global Efforts to Reduce Plastic Waste

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Evolution

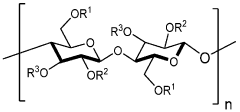

Cellophane, a transparent sheet made from regenerated cellulose, has undergone significant evolution since its invention in 1908 by Jacques E. Brandenberger. Initially developed as a waterproof tablecloth, cellophane quickly found its way into various applications due to its unique properties. The material's journey through the 20th century saw it become a staple in packaging and consumer goods industries.

In the early stages of its development, cellophane was primarily used for wrapping food products, providing a barrier against moisture and air while allowing visibility. This revolutionized food packaging, extending shelf life and improving product presentation. As manufacturing techniques improved, cellophane's applications expanded to include cigarette packaging, textile products, and even as a base for adhesive tapes.

The 1950s and 1960s marked a significant period in cellophane's evolution, with the introduction of heat-sealable coatings. This innovation greatly enhanced cellophane's utility in packaging, allowing for the creation of airtight seals and further extending its use in food preservation. During this time, cellophane also began to face competition from emerging plastic materials, particularly polyethylene and polypropylene.

As environmental concerns grew in the latter part of the 20th century, cellophane's biodegradable nature became increasingly relevant. Unlike many synthetic plastics, cellophane is derived from renewable resources and can decompose naturally, aligning with growing eco-friendly consumer preferences. This characteristic has led to a resurgence of interest in cellophane as a potential alternative to conventional plastics in recent years.

The 21st century has seen further advancements in cellophane technology, focusing on enhancing its properties and expanding its applications. Research has been conducted to improve cellophane's barrier properties, making it more resistant to gases and moisture while maintaining its biodegradability. Additionally, efforts have been made to develop cellophane variants with improved heat resistance and mechanical strength, broadening its potential uses in packaging and industrial applications.

In the context of global efforts to reduce plastic waste, cellophane has emerged as a promising material. Its biodegradable nature addresses one of the primary concerns associated with conventional plastics – their persistence in the environment. As such, there has been renewed interest in cellophane as a sustainable packaging solution, particularly in industries where transparency and barrier properties are crucial.

Recent developments have also focused on combining cellophane with other bio-based materials to create composite films with enhanced properties. These innovations aim to further improve cellophane's performance while maintaining its environmental benefits, positioning it as a viable alternative in the ongoing search for sustainable packaging solutions.

In the early stages of its development, cellophane was primarily used for wrapping food products, providing a barrier against moisture and air while allowing visibility. This revolutionized food packaging, extending shelf life and improving product presentation. As manufacturing techniques improved, cellophane's applications expanded to include cigarette packaging, textile products, and even as a base for adhesive tapes.

The 1950s and 1960s marked a significant period in cellophane's evolution, with the introduction of heat-sealable coatings. This innovation greatly enhanced cellophane's utility in packaging, allowing for the creation of airtight seals and further extending its use in food preservation. During this time, cellophane also began to face competition from emerging plastic materials, particularly polyethylene and polypropylene.

As environmental concerns grew in the latter part of the 20th century, cellophane's biodegradable nature became increasingly relevant. Unlike many synthetic plastics, cellophane is derived from renewable resources and can decompose naturally, aligning with growing eco-friendly consumer preferences. This characteristic has led to a resurgence of interest in cellophane as a potential alternative to conventional plastics in recent years.

The 21st century has seen further advancements in cellophane technology, focusing on enhancing its properties and expanding its applications. Research has been conducted to improve cellophane's barrier properties, making it more resistant to gases and moisture while maintaining its biodegradability. Additionally, efforts have been made to develop cellophane variants with improved heat resistance and mechanical strength, broadening its potential uses in packaging and industrial applications.

In the context of global efforts to reduce plastic waste, cellophane has emerged as a promising material. Its biodegradable nature addresses one of the primary concerns associated with conventional plastics – their persistence in the environment. As such, there has been renewed interest in cellophane as a sustainable packaging solution, particularly in industries where transparency and barrier properties are crucial.

Recent developments have also focused on combining cellophane with other bio-based materials to create composite films with enhanced properties. These innovations aim to further improve cellophane's performance while maintaining its environmental benefits, positioning it as a viable alternative in the ongoing search for sustainable packaging solutions.

Market Demand Analysis

The global market for sustainable packaging solutions has been experiencing significant growth in recent years, driven by increasing consumer awareness and regulatory pressures to reduce plastic waste. Cellophane, a biodegradable and compostable material derived from renewable resources, is emerging as a potential alternative to traditional plastic packaging in this context.

Market research indicates a growing demand for eco-friendly packaging materials across various industries, including food and beverage, personal care, and consumer goods. The global biodegradable packaging market, which includes cellophane, is projected to expand at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is primarily attributed to the shift in consumer preferences towards sustainable products and the implementation of stringent environmental regulations in many countries.

In the food packaging sector, which accounts for a significant portion of plastic waste, cellophane is gaining traction due to its transparency, barrier properties, and biodegradability. Major food manufacturers and retailers are increasingly exploring cellophane as an alternative to conventional plastic films for wrapping fresh produce, bakery items, and confectionery products.

The personal care and cosmetics industry is another key market segment showing interest in cellophane packaging. As consumers become more environmentally conscious, brands are seeking sustainable packaging solutions that align with their eco-friendly product formulations. Cellophane's ability to provide an attractive, clear packaging option while being biodegradable makes it an appealing choice for this sector.

E-commerce and retail sectors are also contributing to the growing demand for cellophane packaging. With the rise of online shopping, there is an increased need for protective packaging materials that are both effective and environmentally friendly. Cellophane's versatility and compostability make it a potential solution for reducing the environmental impact of shipping and packaging materials.

However, it is important to note that the market for cellophane faces competition from other sustainable packaging alternatives, such as bioplastics and recycled materials. The relative cost of cellophane compared to these alternatives and traditional plastics remains a factor influencing market adoption. As production scales up and technology improves, the cost-competitiveness of cellophane is expected to increase, potentially driving further market growth.

Geographically, Europe and North America are currently leading the adoption of sustainable packaging solutions, including cellophane, due to stringent regulations and high consumer awareness. However, emerging economies in Asia-Pacific and Latin America are expected to present significant growth opportunities as environmental concerns gain prominence in these regions.

Market research indicates a growing demand for eco-friendly packaging materials across various industries, including food and beverage, personal care, and consumer goods. The global biodegradable packaging market, which includes cellophane, is projected to expand at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is primarily attributed to the shift in consumer preferences towards sustainable products and the implementation of stringent environmental regulations in many countries.

In the food packaging sector, which accounts for a significant portion of plastic waste, cellophane is gaining traction due to its transparency, barrier properties, and biodegradability. Major food manufacturers and retailers are increasingly exploring cellophane as an alternative to conventional plastic films for wrapping fresh produce, bakery items, and confectionery products.

The personal care and cosmetics industry is another key market segment showing interest in cellophane packaging. As consumers become more environmentally conscious, brands are seeking sustainable packaging solutions that align with their eco-friendly product formulations. Cellophane's ability to provide an attractive, clear packaging option while being biodegradable makes it an appealing choice for this sector.

E-commerce and retail sectors are also contributing to the growing demand for cellophane packaging. With the rise of online shopping, there is an increased need for protective packaging materials that are both effective and environmentally friendly. Cellophane's versatility and compostability make it a potential solution for reducing the environmental impact of shipping and packaging materials.

However, it is important to note that the market for cellophane faces competition from other sustainable packaging alternatives, such as bioplastics and recycled materials. The relative cost of cellophane compared to these alternatives and traditional plastics remains a factor influencing market adoption. As production scales up and technology improves, the cost-competitiveness of cellophane is expected to increase, potentially driving further market growth.

Geographically, Europe and North America are currently leading the adoption of sustainable packaging solutions, including cellophane, due to stringent regulations and high consumer awareness. However, emerging economies in Asia-Pacific and Latin America are expected to present significant growth opportunities as environmental concerns gain prominence in these regions.

Technical Challenges

Cellophane, despite its potential as a biodegradable alternative to traditional plastics, faces several technical challenges in its widespread adoption for reducing global plastic waste. One of the primary obstacles is the material's limited barrier properties, particularly its high permeability to water vapor and gases. This characteristic restricts cellophane's use in packaging applications that require extended shelf life or protection against moisture and oxygen.

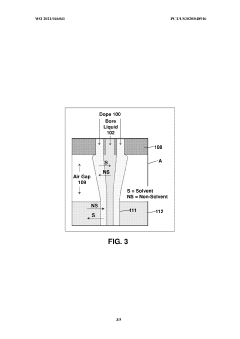

The production process of cellophane also presents significant hurdles. The traditional viscose process, which involves the use of carbon disulfide, poses environmental and health risks. While alternative production methods, such as the lyocell process, offer more environmentally friendly options, they are currently less economically viable on a large scale. This economic barrier hinders the widespread adoption of cellophane as a sustainable packaging material.

Another technical challenge lies in cellophane's mechanical properties. Although it possesses good tensile strength, its brittleness and low tear resistance limit its applicability in certain packaging scenarios. This necessitates the development of composite materials or surface treatments to enhance cellophane's durability and flexibility without compromising its biodegradability.

The disposal and recycling of cellophane also present technical difficulties. While cellophane is biodegradable, the rate of degradation can vary significantly depending on environmental conditions. In industrial composting facilities, cellophane may not break down as quickly as other organic materials, potentially disrupting the composting process. Additionally, the presence of coatings or additives used to enhance cellophane's properties can complicate its biodegradation and recycling processes.

Scalability remains a critical challenge in cellophane production. Current manufacturing processes are not optimized for the large-scale production necessary to compete with conventional plastics. This limitation is exacerbated by the higher production costs associated with cellophane, making it less economically attractive for manufacturers and consumers alike.

The development of cellophane-based materials with enhanced functionality, such as improved barrier properties or antimicrobial characteristics, is an ongoing challenge. Researchers are exploring various approaches, including nanocomposites and surface modifications, to address these limitations. However, these enhancements must be achieved without compromising cellophane's biodegradability or increasing its environmental footprint.

Lastly, the lack of standardized testing and certification processes for biodegradable materials like cellophane poses challenges in assessing and comparing their environmental impact. This absence of uniform standards makes it difficult for manufacturers to validate claims about biodegradability and compostability, potentially hindering consumer acceptance and regulatory approval.

The production process of cellophane also presents significant hurdles. The traditional viscose process, which involves the use of carbon disulfide, poses environmental and health risks. While alternative production methods, such as the lyocell process, offer more environmentally friendly options, they are currently less economically viable on a large scale. This economic barrier hinders the widespread adoption of cellophane as a sustainable packaging material.

Another technical challenge lies in cellophane's mechanical properties. Although it possesses good tensile strength, its brittleness and low tear resistance limit its applicability in certain packaging scenarios. This necessitates the development of composite materials or surface treatments to enhance cellophane's durability and flexibility without compromising its biodegradability.

The disposal and recycling of cellophane also present technical difficulties. While cellophane is biodegradable, the rate of degradation can vary significantly depending on environmental conditions. In industrial composting facilities, cellophane may not break down as quickly as other organic materials, potentially disrupting the composting process. Additionally, the presence of coatings or additives used to enhance cellophane's properties can complicate its biodegradation and recycling processes.

Scalability remains a critical challenge in cellophane production. Current manufacturing processes are not optimized for the large-scale production necessary to compete with conventional plastics. This limitation is exacerbated by the higher production costs associated with cellophane, making it less economically attractive for manufacturers and consumers alike.

The development of cellophane-based materials with enhanced functionality, such as improved barrier properties or antimicrobial characteristics, is an ongoing challenge. Researchers are exploring various approaches, including nanocomposites and surface modifications, to address these limitations. However, these enhancements must be achieved without compromising cellophane's biodegradability or increasing its environmental footprint.

Lastly, the lack of standardized testing and certification processes for biodegradable materials like cellophane poses challenges in assessing and comparing their environmental impact. This absence of uniform standards makes it difficult for manufacturers to validate claims about biodegradability and compostability, potentially hindering consumer acceptance and regulatory approval.

Current Solutions

01 Biodegradable cellophane alternatives

Development of biodegradable materials that can replace traditional cellophane plastic. These alternatives are designed to break down naturally in the environment, reducing long-term plastic waste. Materials may include plant-based polymers or modified cellulose that maintain similar properties to cellophane but with improved environmental impact.- Biodegradable cellophane alternatives: Development of biodegradable alternatives to traditional cellophane plastic, using materials such as plant-based polymers or modified cellulose. These alternatives offer similar properties to conventional cellophane but can decompose naturally, reducing long-term plastic waste accumulation.

- Recycling and upcycling cellophane waste: Implementation of advanced recycling technologies specifically designed for cellophane plastic waste. This includes chemical recycling processes to break down cellophane into its base components for reuse, as well as upcycling techniques to transform waste cellophane into higher-value products.

- Improved cellophane production processes: Innovations in cellophane manufacturing processes to reduce waste generation during production. This includes optimizing material usage, implementing closed-loop systems, and developing more efficient production techniques that minimize scrap and off-spec material.

- Cellophane waste collection and sorting systems: Development of specialized collection and sorting systems for cellophane plastic waste. This includes automated sorting technologies using artificial intelligence and machine vision to efficiently separate cellophane from other plastic waste streams, facilitating more effective recycling.

- Cellophane reduction in packaging: Strategies and technologies to reduce the use of cellophane in packaging applications. This includes the development of alternative packaging materials, design innovations to minimize cellophane usage, and the promotion of reusable packaging systems to decrease overall cellophane consumption.

02 Recycling and upcycling cellophane waste

Implementation of processes to recycle or upcycle cellophane plastic waste. This includes developing new methods for collecting, sorting, and processing used cellophane materials. The recycled cellophane can be transformed into new products or used as raw material for other industries, reducing the overall waste sent to landfills.Expand Specific Solutions03 Improved cellophane production techniques

Advancements in cellophane manufacturing processes to reduce waste during production. This involves optimizing material usage, minimizing off-cuts, and developing more efficient production methods. These improvements aim to decrease the amount of waste generated before the cellophane even reaches consumers.Expand Specific Solutions04 Cellophane alternatives from waste materials

Creation of cellophane-like materials using waste products from other industries. This approach repurposes materials that would otherwise be discarded, such as agricultural byproducts or industrial waste streams, to create functional alternatives to traditional cellophane. This not only reduces cellophane waste but also addresses waste from other sources.Expand Specific Solutions05 Reduction of cellophane usage through innovative packaging

Development of innovative packaging solutions that minimize or eliminate the need for cellophane. This includes designing new packaging structures, using alternative materials, or creating reusable packaging systems. The goal is to reduce the overall demand for cellophane in packaging applications, thereby decreasing waste generation.Expand Specific Solutions

Key Industry Players

The global effort to reduce plastic waste through cellophane technology is in a transitional phase, with the market showing significant growth potential. The industry is moving from early-stage research to commercial applications, driven by increasing environmental concerns and regulatory pressures. Major players like Braskem SA, Unilever Global IP Ltd., and Procter & Gamble Co. are investing in sustainable packaging solutions, including cellophane-based alternatives. The technology's maturity varies, with companies like Futamura Chemical Co., Ltd. and Eastman Chemical Co. leading in cellulose-based film production. However, challenges remain in scalability and cost-effectiveness, indicating that the technology is still evolving. The market is expected to expand as more companies adopt eco-friendly packaging strategies, aligning with global sustainability goals.

Unilever Global IP Ltd.

Technical Solution: Unilever has pioneered the use of cellophane in their "Less Plastic. Better Plastic. No Plastic." initiative to combat global plastic waste. Their approach involves a multi-faceted strategy that includes the development of cellophane-based packaging with enhanced biodegradability and recyclability[1]. Unilever's cellophane innovation focuses on creating thin, flexible films that maintain product freshness while significantly reducing the overall plastic content in their packaging[2]. The company has also invested in research to improve the moisture barrier properties of cellophane, making it suitable for a wider range of products, including those with high moisture content[3]. Additionally, Unilever has partnered with waste management companies to establish collection and recycling systems specifically designed for cellophane-based packaging, ensuring a closed-loop system for their materials[4].

Strengths: Comprehensive approach to plastic reduction; Improved cellophane properties for wider application; Established recycling partnerships. Weaknesses: Potential challenges in scaling up production; Consumer education needed for proper disposal.

Procter & Gamble Co.

Technical Solution: Procter & Gamble has developed a recyclable and compostable cellophane-based packaging solution as part of their global efforts to reduce plastic waste. Their approach involves using a modified cellulose film that maintains the barrier properties and transparency of traditional cellophane while improving its end-of-life recyclability and compostability[1]. The company has also invested in chemical recycling technologies to break down cellophane and other cellulose-based materials into their basic building blocks, which can then be used to create new packaging materials[2]. P&G's cellophane innovation includes the incorporation of bio-based additives that enhance the material's biodegradability in both industrial and home composting environments, addressing the growing demand for sustainable packaging solutions[3].

Strengths: Leverages existing cellophane properties while improving sustainability; Addresses both recyclability and compostability; Aligns with circular economy principles. Weaknesses: May require specialized recycling infrastructure; Potential higher production costs compared to conventional plastics.

Innovative Approaches

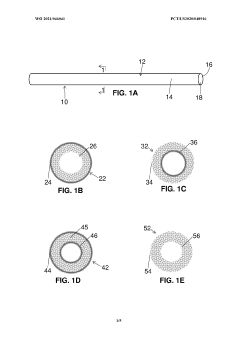

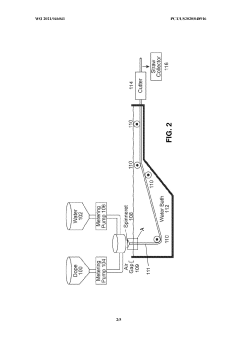

Biodegradable products and methods of production

PatentWO2021046041A1

Innovation

- Development of biodegradable products, specifically elongated tubular members made from cellulose esters with controlled porosity and acetyl degree of substitution, which are compostable under industrial and home conditions, and suitable for applications like drinking straws and packaging, using a solvent casting or extrusion process.

Reducing surface and bulk contamination in plastic

PatentActiveUS20240017188A1

Innovation

- A method involving packed leaching extraction stages using a leaching solvent at temperatures below the plastic's primary melting point, with a solvent-to-plastic mass ratio less than 5:1 and pressures between atmospheric and 1,000 atm, effectively reduces contaminant concentrations of alkyl phenols, bisphenols, dioxins, PCBs, and phthalates by at least 55% or to the limit of quantification.

Environmental Impact

Cellophane, a biodegradable and compostable material derived from renewable resources, has emerged as a potential alternative to traditional plastics in the global effort to reduce plastic waste. Its environmental impact is multifaceted, encompassing both positive and negative aspects that warrant careful consideration.

One of the primary environmental benefits of cellophane is its biodegradability. Unlike conventional plastics that can persist in the environment for hundreds of years, cellophane breaks down naturally within a few months to a few years, depending on environmental conditions. This characteristic significantly reduces the long-term accumulation of waste in landfills and natural ecosystems.

Furthermore, cellophane's production process relies on renewable resources, primarily wood pulp or cotton linters. This shift away from fossil fuel-based raw materials used in traditional plastic production helps to reduce the carbon footprint associated with packaging materials. The renewable nature of its source materials also contributes to a more sustainable production cycle.

However, the environmental impact of cellophane is not entirely positive. The production process involves the use of chemicals such as carbon disulfide and sulfuric acid, which can have harmful effects on the environment if not properly managed. Additionally, the energy-intensive nature of cellophane production contributes to greenhouse gas emissions, albeit potentially less than that of traditional plastic manufacturing.

Water consumption is another environmental concern associated with cellophane production. The process requires significant amounts of water, which can strain local water resources in areas where production facilities are located. Proper water management and recycling systems are crucial to mitigate this impact.

While cellophane is biodegradable, it is important to note that optimal decomposition often requires specific conditions, such as those found in industrial composting facilities. In natural environments or typical landfill conditions, the breakdown process may be slower, potentially leading to temporary accumulation before complete degradation occurs.

The end-of-life management of cellophane products also plays a crucial role in its overall environmental impact. Proper disposal and recycling infrastructure are necessary to ensure that cellophane items are processed correctly, maximizing their environmental benefits. Education and awareness campaigns are essential to inform consumers about the proper disposal methods for cellophane products.

In conclusion, while cellophane offers several environmental advantages over traditional plastics, particularly in terms of biodegradability and renewable sourcing, its production and disposal still present challenges that must be addressed. As the global community continues to seek solutions to plastic waste, the role of cellophane will likely evolve, with ongoing research and development aimed at further improving its environmental performance and addressing its current limitations.

One of the primary environmental benefits of cellophane is its biodegradability. Unlike conventional plastics that can persist in the environment for hundreds of years, cellophane breaks down naturally within a few months to a few years, depending on environmental conditions. This characteristic significantly reduces the long-term accumulation of waste in landfills and natural ecosystems.

Furthermore, cellophane's production process relies on renewable resources, primarily wood pulp or cotton linters. This shift away from fossil fuel-based raw materials used in traditional plastic production helps to reduce the carbon footprint associated with packaging materials. The renewable nature of its source materials also contributes to a more sustainable production cycle.

However, the environmental impact of cellophane is not entirely positive. The production process involves the use of chemicals such as carbon disulfide and sulfuric acid, which can have harmful effects on the environment if not properly managed. Additionally, the energy-intensive nature of cellophane production contributes to greenhouse gas emissions, albeit potentially less than that of traditional plastic manufacturing.

Water consumption is another environmental concern associated with cellophane production. The process requires significant amounts of water, which can strain local water resources in areas where production facilities are located. Proper water management and recycling systems are crucial to mitigate this impact.

While cellophane is biodegradable, it is important to note that optimal decomposition often requires specific conditions, such as those found in industrial composting facilities. In natural environments or typical landfill conditions, the breakdown process may be slower, potentially leading to temporary accumulation before complete degradation occurs.

The end-of-life management of cellophane products also plays a crucial role in its overall environmental impact. Proper disposal and recycling infrastructure are necessary to ensure that cellophane items are processed correctly, maximizing their environmental benefits. Education and awareness campaigns are essential to inform consumers about the proper disposal methods for cellophane products.

In conclusion, while cellophane offers several environmental advantages over traditional plastics, particularly in terms of biodegradability and renewable sourcing, its production and disposal still present challenges that must be addressed. As the global community continues to seek solutions to plastic waste, the role of cellophane will likely evolve, with ongoing research and development aimed at further improving its environmental performance and addressing its current limitations.

Regulatory Framework

The regulatory framework surrounding cellophane and its role in reducing plastic waste is complex and evolving. Governments worldwide are implementing various policies and regulations to address the growing concern of plastic pollution. These regulations often focus on single-use plastics, packaging materials, and waste management practices.

In the European Union, the Single-Use Plastics Directive, implemented in 2019, aims to reduce the impact of certain plastic products on the environment. While cellophane is not explicitly mentioned in this directive, it falls under the broader category of packaging materials. The directive encourages the use of sustainable alternatives and sets targets for recycling and waste reduction.

The United States has a more fragmented approach, with regulations varying at the state and local levels. Some states, such as California, have implemented comprehensive plastic reduction laws that may impact the use of cellophane in packaging. The Federal Trade Commission's Green Guides provide guidelines for environmental marketing claims, which can influence how cellophane products are marketed as eco-friendly alternatives.

In Asia, countries like Japan and South Korea have introduced regulations to promote the use of biodegradable materials in packaging. These regulations may create opportunities for cellophane, particularly if it can be produced from renewable sources and demonstrate biodegradability.

International agreements, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, have been amended to include plastic waste. This has implications for the global trade of plastic materials, including cellophane, and may influence its production and disposal practices.

Certification schemes and standards play a crucial role in the regulatory landscape. Organizations like the Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC) provide certifications for sustainably sourced cellulose, which is used in cellophane production. These certifications can help companies comply with regulations and meet consumer demands for environmentally responsible products.

As the global focus on plastic waste reduction intensifies, it is likely that regulations will continue to evolve. Future regulatory frameworks may include extended producer responsibility schemes, mandatory recycling targets, and stricter labeling requirements. These changes could significantly impact the cellophane industry, potentially driving innovation in production methods and end-of-life solutions.

In the European Union, the Single-Use Plastics Directive, implemented in 2019, aims to reduce the impact of certain plastic products on the environment. While cellophane is not explicitly mentioned in this directive, it falls under the broader category of packaging materials. The directive encourages the use of sustainable alternatives and sets targets for recycling and waste reduction.

The United States has a more fragmented approach, with regulations varying at the state and local levels. Some states, such as California, have implemented comprehensive plastic reduction laws that may impact the use of cellophane in packaging. The Federal Trade Commission's Green Guides provide guidelines for environmental marketing claims, which can influence how cellophane products are marketed as eco-friendly alternatives.

In Asia, countries like Japan and South Korea have introduced regulations to promote the use of biodegradable materials in packaging. These regulations may create opportunities for cellophane, particularly if it can be produced from renewable sources and demonstrate biodegradability.

International agreements, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, have been amended to include plastic waste. This has implications for the global trade of plastic materials, including cellophane, and may influence its production and disposal practices.

Certification schemes and standards play a crucial role in the regulatory landscape. Organizations like the Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC) provide certifications for sustainably sourced cellulose, which is used in cellophane production. These certifications can help companies comply with regulations and meet consumer demands for environmentally responsible products.

As the global focus on plastic waste reduction intensifies, it is likely that regulations will continue to evolve. Future regulatory frameworks may include extended producer responsibility schemes, mandatory recycling targets, and stricter labeling requirements. These changes could significantly impact the cellophane industry, potentially driving innovation in production methods and end-of-life solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!