Cellophane's Role in Zero-Waste Packaging Solutions

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Evolution

Cellophane, a transparent sheet made from regenerated cellulose, has undergone significant evolution since its invention in 1908 by Jacques E. Brandenberger. Initially developed as a waterproof tablecloth, cellophane quickly found its way into packaging applications due to its unique properties.

The early stages of cellophane's evolution focused on improving its moisture resistance and heat-sealability. In the 1920s, DuPont acquired the rights to produce cellophane in the United States and made substantial advancements in its manufacturing process. They developed moisture-proof cellophane, which greatly expanded its use in food packaging.

During the mid-20th century, cellophane experienced a surge in popularity as a packaging material. Its transparency, flexibility, and ability to preserve food freshness made it a preferred choice for various products. However, the rise of petroleum-based plastics in the 1960s and 1970s began to challenge cellophane's dominance in the packaging industry.

In recent decades, the evolution of cellophane has been driven by growing environmental concerns and the push for sustainable packaging solutions. Manufacturers have focused on improving cellophane's biodegradability and compostability, aligning it with the principles of zero-waste packaging.

Modern cellophane production processes have been refined to reduce environmental impact. Innovations in raw material sourcing, such as using wood pulp from sustainably managed forests, have enhanced cellophane's eco-friendly profile. Additionally, research into alternative cellulose sources, like agricultural waste, has opened new avenues for more sustainable cellophane production.

The latest developments in cellophane technology have centered on enhancing its barrier properties while maintaining its biodegradability. Advanced coatings and treatments have been developed to improve cellophane's resistance to moisture, gases, and UV light, making it more versatile for various packaging applications.

In the context of zero-waste packaging solutions, cellophane has re-emerged as a promising material. Its ability to biodegrade in both industrial composting facilities and home composting environments gives it a significant advantage over conventional plastics. Researchers are now exploring ways to further reduce the environmental footprint of cellophane production and improve its end-of-life characteristics.

The evolution of cellophane continues to be driven by the demand for sustainable packaging alternatives. As consumers and businesses increasingly prioritize eco-friendly options, cellophane is poised to play a crucial role in the transition towards zero-waste packaging solutions. Ongoing research and development efforts are focused on optimizing cellophane's properties to meet the diverse needs of modern packaging while minimizing environmental impact.

The early stages of cellophane's evolution focused on improving its moisture resistance and heat-sealability. In the 1920s, DuPont acquired the rights to produce cellophane in the United States and made substantial advancements in its manufacturing process. They developed moisture-proof cellophane, which greatly expanded its use in food packaging.

During the mid-20th century, cellophane experienced a surge in popularity as a packaging material. Its transparency, flexibility, and ability to preserve food freshness made it a preferred choice for various products. However, the rise of petroleum-based plastics in the 1960s and 1970s began to challenge cellophane's dominance in the packaging industry.

In recent decades, the evolution of cellophane has been driven by growing environmental concerns and the push for sustainable packaging solutions. Manufacturers have focused on improving cellophane's biodegradability and compostability, aligning it with the principles of zero-waste packaging.

Modern cellophane production processes have been refined to reduce environmental impact. Innovations in raw material sourcing, such as using wood pulp from sustainably managed forests, have enhanced cellophane's eco-friendly profile. Additionally, research into alternative cellulose sources, like agricultural waste, has opened new avenues for more sustainable cellophane production.

The latest developments in cellophane technology have centered on enhancing its barrier properties while maintaining its biodegradability. Advanced coatings and treatments have been developed to improve cellophane's resistance to moisture, gases, and UV light, making it more versatile for various packaging applications.

In the context of zero-waste packaging solutions, cellophane has re-emerged as a promising material. Its ability to biodegrade in both industrial composting facilities and home composting environments gives it a significant advantage over conventional plastics. Researchers are now exploring ways to further reduce the environmental footprint of cellophane production and improve its end-of-life characteristics.

The evolution of cellophane continues to be driven by the demand for sustainable packaging alternatives. As consumers and businesses increasingly prioritize eco-friendly options, cellophane is poised to play a crucial role in the transition towards zero-waste packaging solutions. Ongoing research and development efforts are focused on optimizing cellophane's properties to meet the diverse needs of modern packaging while minimizing environmental impact.

Sustainable Packaging

Sustainable packaging has emerged as a critical focus in the global effort to reduce waste and environmental impact. As industries and consumers alike become increasingly aware of the ecological consequences of traditional packaging methods, there is a growing demand for innovative solutions that minimize waste while maintaining product integrity. Cellophane, a biodegradable material derived from regenerated cellulose, has gained renewed interest in this context due to its potential to contribute to zero-waste packaging strategies.

The concept of sustainable packaging encompasses a range of principles aimed at reducing the environmental footprint of packaging throughout its lifecycle. These principles include the use of renewable or recycled materials, design for reusability or recyclability, minimization of packaging volume and weight, and the elimination of harmful substances in packaging materials. Cellophane aligns with several of these principles, offering a biodegradable alternative to conventional plastic films.

One of the key advantages of cellophane in sustainable packaging is its biodegradability. Unlike many synthetic plastics that persist in the environment for hundreds of years, cellophane can decompose naturally within a few months under proper conditions. This characteristic makes it an attractive option for single-use packaging applications where recycling may not be practical or economically viable. Additionally, cellophane's transparency and barrier properties against moisture and gases make it suitable for a wide range of food and non-food packaging applications.

However, the adoption of cellophane in zero-waste packaging solutions faces several challenges. The production process of cellophane, while based on renewable resources, can be energy-intensive and may involve the use of chemicals that require careful management to minimize environmental impact. Furthermore, the current recycling infrastructure is not well-equipped to handle cellophane, which can complicate end-of-life management in some regions.

To fully leverage cellophane's potential in sustainable packaging, ongoing research and development efforts are focusing on improving its production efficiency, enhancing its barrier properties, and exploring novel applications. Innovations in bio-based plasticizers and coatings are being pursued to expand cellophane's functionality while maintaining its biodegradability. Additionally, efforts are underway to develop more efficient recycling and composting systems that can effectively process cellophane alongside other biodegradable materials.

As the packaging industry continues to evolve towards more sustainable practices, cellophane represents a promising component in the broader spectrum of zero-waste solutions. Its role in sustainable packaging is likely to grow as technological advancements address current limitations and as consumer demand for environmentally friendly packaging options continues to rise. The integration of cellophane into comprehensive zero-waste strategies will require collaboration across the value chain, from material scientists and packaging designers to waste management systems and policymakers.

The concept of sustainable packaging encompasses a range of principles aimed at reducing the environmental footprint of packaging throughout its lifecycle. These principles include the use of renewable or recycled materials, design for reusability or recyclability, minimization of packaging volume and weight, and the elimination of harmful substances in packaging materials. Cellophane aligns with several of these principles, offering a biodegradable alternative to conventional plastic films.

One of the key advantages of cellophane in sustainable packaging is its biodegradability. Unlike many synthetic plastics that persist in the environment for hundreds of years, cellophane can decompose naturally within a few months under proper conditions. This characteristic makes it an attractive option for single-use packaging applications where recycling may not be practical or economically viable. Additionally, cellophane's transparency and barrier properties against moisture and gases make it suitable for a wide range of food and non-food packaging applications.

However, the adoption of cellophane in zero-waste packaging solutions faces several challenges. The production process of cellophane, while based on renewable resources, can be energy-intensive and may involve the use of chemicals that require careful management to minimize environmental impact. Furthermore, the current recycling infrastructure is not well-equipped to handle cellophane, which can complicate end-of-life management in some regions.

To fully leverage cellophane's potential in sustainable packaging, ongoing research and development efforts are focusing on improving its production efficiency, enhancing its barrier properties, and exploring novel applications. Innovations in bio-based plasticizers and coatings are being pursued to expand cellophane's functionality while maintaining its biodegradability. Additionally, efforts are underway to develop more efficient recycling and composting systems that can effectively process cellophane alongside other biodegradable materials.

As the packaging industry continues to evolve towards more sustainable practices, cellophane represents a promising component in the broader spectrum of zero-waste solutions. Its role in sustainable packaging is likely to grow as technological advancements address current limitations and as consumer demand for environmentally friendly packaging options continues to rise. The integration of cellophane into comprehensive zero-waste strategies will require collaboration across the value chain, from material scientists and packaging designers to waste management systems and policymakers.

Cellophane Challenges

Despite its potential as a biodegradable packaging material, cellophane faces several significant challenges in its adoption for zero-waste packaging solutions. One of the primary obstacles is its cost-effectiveness compared to conventional plastic alternatives. The production process of cellophane remains more expensive, making it less attractive for widespread commercial use, especially in industries with tight profit margins.

Another challenge lies in the material's performance characteristics. While cellophane offers excellent transparency and barrier properties against oxygen and moisture, it falls short in terms of heat resistance and durability compared to some synthetic plastics. This limitation restricts its application in certain packaging scenarios, particularly those involving hot foods or products requiring extended shelf life.

The scalability of cellophane production presents another hurdle. Current manufacturing processes are not as efficient or scalable as those for synthetic plastics, leading to supply chain constraints and potential difficulties in meeting large-scale demand. This issue is compounded by the limited number of manufacturers specializing in cellophane production, which can lead to supply bottlenecks and price volatility.

Environmental concerns, while less pronounced than with traditional plastics, still exist for cellophane. Although biodegradable, the material often requires specific conditions to decompose efficiently. In many waste management systems, cellophane may not break down as quickly as desired, potentially contributing to short-term waste accumulation. Additionally, the production of cellophane involves chemical processes that, while less harmful than those used for synthetic plastics, still have environmental impacts that need to be addressed.

The regulatory landscape also poses challenges for cellophane adoption. Inconsistent standards and regulations regarding biodegradable materials across different regions can complicate the use of cellophane in global supply chains. Manufacturers and brands may hesitate to invest in cellophane packaging solutions due to uncertainty about future regulatory requirements and potential compliance issues.

Consumer perception and education represent another significant challenge. While there is growing awareness of the need for sustainable packaging, many consumers are unfamiliar with cellophane and its properties. Misconceptions about its environmental impact or confusion with non-biodegradable plastic look-alikes can hinder its acceptance in the market. Educating consumers about the benefits and proper disposal of cellophane packaging requires substantial effort and resources.

Lastly, the integration of cellophane into existing recycling and composting infrastructures presents logistical challenges. Many current waste management systems are not optimized for handling biodegradable materials like cellophane, potentially leading to improper disposal or contamination of recycling streams. Overcoming these infrastructure limitations requires significant investment and coordination among various stakeholders in the waste management ecosystem.

Another challenge lies in the material's performance characteristics. While cellophane offers excellent transparency and barrier properties against oxygen and moisture, it falls short in terms of heat resistance and durability compared to some synthetic plastics. This limitation restricts its application in certain packaging scenarios, particularly those involving hot foods or products requiring extended shelf life.

The scalability of cellophane production presents another hurdle. Current manufacturing processes are not as efficient or scalable as those for synthetic plastics, leading to supply chain constraints and potential difficulties in meeting large-scale demand. This issue is compounded by the limited number of manufacturers specializing in cellophane production, which can lead to supply bottlenecks and price volatility.

Environmental concerns, while less pronounced than with traditional plastics, still exist for cellophane. Although biodegradable, the material often requires specific conditions to decompose efficiently. In many waste management systems, cellophane may not break down as quickly as desired, potentially contributing to short-term waste accumulation. Additionally, the production of cellophane involves chemical processes that, while less harmful than those used for synthetic plastics, still have environmental impacts that need to be addressed.

The regulatory landscape also poses challenges for cellophane adoption. Inconsistent standards and regulations regarding biodegradable materials across different regions can complicate the use of cellophane in global supply chains. Manufacturers and brands may hesitate to invest in cellophane packaging solutions due to uncertainty about future regulatory requirements and potential compliance issues.

Consumer perception and education represent another significant challenge. While there is growing awareness of the need for sustainable packaging, many consumers are unfamiliar with cellophane and its properties. Misconceptions about its environmental impact or confusion with non-biodegradable plastic look-alikes can hinder its acceptance in the market. Educating consumers about the benefits and proper disposal of cellophane packaging requires substantial effort and resources.

Lastly, the integration of cellophane into existing recycling and composting infrastructures presents logistical challenges. Many current waste management systems are not optimized for handling biodegradable materials like cellophane, potentially leading to improper disposal or contamination of recycling streams. Overcoming these infrastructure limitations requires significant investment and coordination among various stakeholders in the waste management ecosystem.

Current Solutions

01 Recycling and reprocessing of cellophane waste

Methods for recycling and reprocessing cellophane waste involve collecting, sorting, and treating the waste material to create new products or raw materials. This process may include mechanical, chemical, or biological treatments to break down the cellophane and recover valuable components. Recycling cellophane waste helps reduce environmental impact and conserves resources.- Recycling and reprocessing of cellophane waste: This approach involves collecting and processing used cellophane materials to create new products or raw materials. The recycling process may include sorting, cleaning, and reprocessing the cellophane waste into usable forms, reducing the amount of waste sent to landfills and conserving resources.

- Biodegradable cellophane alternatives: Developing and using biodegradable alternatives to traditional cellophane can significantly reduce waste. These materials are designed to break down naturally in the environment, minimizing long-term environmental impact. Biodegradable options may include plant-based materials or modified cellulose products that maintain similar properties to conventional cellophane.

- Improved cellophane production processes: Enhancing the production processes of cellophane can lead to reduced waste generation. This may involve optimizing manufacturing techniques, implementing more efficient machinery, or developing new methods that minimize material loss during production. Such improvements can result in less waste at the source and more efficient use of raw materials.

- Cellophane waste management systems: Implementing comprehensive waste management systems specifically designed for cellophane can help reduce overall waste. These systems may include specialized collection methods, sorting technologies, and treatment processes tailored to cellophane materials. Effective management can increase the recovery and reuse of cellophane waste while minimizing environmental impact.

- Upcycling cellophane waste into new products: Upcycling involves transforming cellophane waste into new, higher-value products. This approach can include using cellophane waste as a raw material for creating innovative items or incorporating it into composite materials. Upcycling not only reduces waste but also adds value to what would otherwise be discarded materials.

02 Biodegradable cellophane alternatives

Development of biodegradable alternatives to traditional cellophane can significantly reduce waste. These materials are designed to break down naturally in the environment, reducing long-term pollution. Biodegradable cellophane alternatives may be made from plant-based materials or engineered to degrade under specific conditions, offering a more sustainable packaging solution.Expand Specific Solutions03 Improved cellophane production processes

Advancements in cellophane production processes aim to reduce waste generation during manufacturing. These improvements may include optimizing raw material usage, implementing closed-loop systems, and developing more efficient production techniques. By minimizing waste at the source, these processes contribute to overall waste reduction in the cellophane industry.Expand Specific Solutions04 Cellophane waste management systems

Integrated waste management systems for cellophane focus on collection, sorting, and proper disposal or recycling of waste materials. These systems may involve specialized equipment, sorting technologies, and logistics to efficiently handle cellophane waste. Effective waste management systems help reduce the amount of cellophane ending up in landfills or the environment.Expand Specific Solutions05 Upcycling cellophane waste into new products

Upcycling initiatives transform cellophane waste into new, higher-value products. This approach involves creative reuse of waste materials to create items such as decorative objects, packaging materials, or even construction materials. Upcycling not only reduces waste but also adds value to discarded cellophane, promoting a circular economy approach.Expand Specific Solutions

Industry Leaders

The cellophane market for zero-waste packaging solutions is in a growth phase, driven by increasing environmental concerns and sustainability initiatives. The market size is expanding as more companies adopt eco-friendly packaging alternatives. Technologically, cellophane is relatively mature, but innovations in biodegradability and performance are ongoing. Key players like Mitsubishi Polyester Film GmbH, Lenzing AG, and Toyobo Co., Ltd. are investing in research and development to enhance cellophane's properties and applications. Emerging companies such as World Centric and FiberLean Technologies Ltd. are also contributing to market innovation, focusing on compostable and fiber-based solutions. The competitive landscape is characterized by a mix of established manufacturers and innovative startups, all striving to meet the growing demand for sustainable packaging materials.

Lenzing AG

Technical Solution: Lenzing AG has pioneered the development of LENZING™ Cellophane, a wood-based, biodegradable cellophane film that serves as a sustainable alternative to fossil-based plastics in packaging. This innovative material is produced using Lenzing's eco-responsible wood sourcing practices and closed-loop production process, which recovers up to 99% of production chemicals[3]. LENZING™ Cellophane offers excellent transparency, high gloss, and strong barrier properties against gases, aromas, and microorganisms. The company has successfully applied this technology to create packaging solutions for various industries, including food, cosmetics, and consumer goods, with a focus on reducing plastic waste and promoting circular economy principles[4].

Strengths: Biodegradable, excellent barrier properties, versatile applications. Weaknesses: May have limitations in certain high-moisture environments, potentially higher production costs.

Société des Produits Nestlé SA

Technical Solution: Nestlé has incorporated cellophane into its sustainable packaging strategy as part of its commitment to making 100% of its packaging recyclable or reusable by 2025[7]. The company has developed a range of cellophane-based packaging solutions, focusing on its confectionery and snack products. Nestlé's approach involves using a combination of recyclable paper and biodegradable cellophane to create wrappers that maintain product freshness while reducing environmental impact. For instance, they have implemented this technology in the packaging of certain chocolate bar brands, replacing the traditional plastic flow wrap with a paper-cellophane composite that can be recycled in paper streams[8]. Nestlé's cellophane solutions are designed to meet food safety standards while aligning with circular economy principles.

Strengths: Large-scale implementation potential, integration with existing recycling streams. Weaknesses: Challenges in maintaining barrier properties for all product types, potential increased packaging costs.

Cellophane Innovations

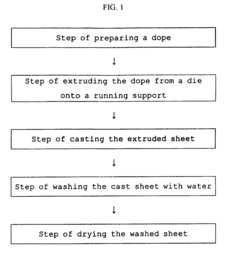

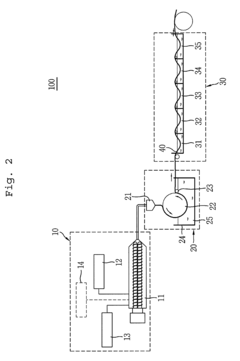

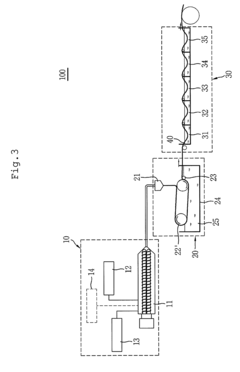

Method for preparing cellulose-based film and cellulose-based film

PatentActiveUS8883056B2

Innovation

- A method involving the preparation of a dope from alpha-cellulose pulp and an aqueous N-methylmorpholine-N-oxide solution, extrusion, casting, washing, and drying, which omits the use of NaOH or H2SO4 and avoids the use of CS2, allowing for the production of an environmentally friendly cellulose-based film with excellent properties.

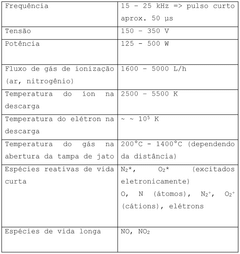

Base material for forming a cellulose packaging material and the use thereof

PatentWO2024164057A1

Innovation

- A base material composed of 98% to 99% cellulose and 1% to 2% inert silicon-based material, featuring a plasma-pre-treated cellulosic substrate, a nanofibrillated cellulose film layer for gas barrier, and an atmospheric plasma-coated inner layer for liquid barrier, ensuring waterproof and recyclable packaging.

Biodegradability

Cellophane, a transparent sheet made from regenerated cellulose, has gained attention in the zero-waste packaging industry due to its potential biodegradability. The biodegradation process of cellophane is influenced by various factors, including environmental conditions, microbial activity, and the presence of additives.

In ideal conditions, pure cellophane can biodegrade relatively quickly, typically within a few months to a year. This process occurs through the action of microorganisms that break down the cellulose molecules into simpler compounds. However, it is essential to note that the biodegradation rate can vary significantly depending on the specific environment and the presence of any additional substances in the cellophane.

One of the key advantages of cellophane in zero-waste packaging solutions is its ability to decompose without leaving harmful residues. When properly disposed of in composting facilities or natural environments, cellophane breaks down into carbon dioxide, water, and biomass, which can be assimilated back into the ecosystem.

However, it is crucial to consider that many commercial cellophane products contain additives or coatings that may impede the biodegradation process. These additives, such as plasticizers or moisture barriers, are often incorporated to enhance the material's performance characteristics but can significantly extend the time required for complete decomposition.

The biodegradability of cellophane also depends on the disposal environment. In industrial composting facilities, where temperature, moisture, and microbial activity are carefully controlled, cellophane can break down more efficiently. In contrast, biodegradation may be slower in home composting systems or natural environments with less optimal conditions.

Recent research has focused on improving the biodegradability of cellophane while maintaining its desirable properties for packaging applications. Some approaches include developing new cellulose-based materials with enhanced biodegradability or incorporating biodegradation-promoting additives that do not compromise the material's performance.

As the demand for sustainable packaging solutions continues to grow, the biodegradability of cellophane remains a critical factor in its adoption for zero-waste initiatives. Ongoing efforts to optimize its biodegradation properties while ensuring its functionality as a packaging material are essential for its continued relevance in environmentally conscious packaging solutions.

In ideal conditions, pure cellophane can biodegrade relatively quickly, typically within a few months to a year. This process occurs through the action of microorganisms that break down the cellulose molecules into simpler compounds. However, it is essential to note that the biodegradation rate can vary significantly depending on the specific environment and the presence of any additional substances in the cellophane.

One of the key advantages of cellophane in zero-waste packaging solutions is its ability to decompose without leaving harmful residues. When properly disposed of in composting facilities or natural environments, cellophane breaks down into carbon dioxide, water, and biomass, which can be assimilated back into the ecosystem.

However, it is crucial to consider that many commercial cellophane products contain additives or coatings that may impede the biodegradation process. These additives, such as plasticizers or moisture barriers, are often incorporated to enhance the material's performance characteristics but can significantly extend the time required for complete decomposition.

The biodegradability of cellophane also depends on the disposal environment. In industrial composting facilities, where temperature, moisture, and microbial activity are carefully controlled, cellophane can break down more efficiently. In contrast, biodegradation may be slower in home composting systems or natural environments with less optimal conditions.

Recent research has focused on improving the biodegradability of cellophane while maintaining its desirable properties for packaging applications. Some approaches include developing new cellulose-based materials with enhanced biodegradability or incorporating biodegradation-promoting additives that do not compromise the material's performance.

As the demand for sustainable packaging solutions continues to grow, the biodegradability of cellophane remains a critical factor in its adoption for zero-waste initiatives. Ongoing efforts to optimize its biodegradation properties while ensuring its functionality as a packaging material are essential for its continued relevance in environmentally conscious packaging solutions.

Regulatory Framework

The regulatory framework surrounding cellophane's use in zero-waste packaging solutions is complex and evolving, reflecting the growing global emphasis on sustainability and environmental protection. At the international level, organizations such as the United Nations Environment Programme (UNEP) have established guidelines and initiatives to promote sustainable packaging practices, which indirectly influence the use of cellophane in zero-waste solutions.

In the European Union, the Packaging and Packaging Waste Directive (94/62/EC) sets standards for packaging materials, including cellophane, to ensure they are recyclable, reusable, or biodegradable. The EU's Circular Economy Action Plan further reinforces these requirements, pushing for more sustainable packaging solutions and potentially favoring cellophane's biodegradable properties.

The United States Food and Drug Administration (FDA) regulates cellophane as a food contact substance, ensuring its safety for use in food packaging. The FDA's regulations on food packaging materials indirectly impact the adoption of cellophane in zero-waste solutions by setting standards for material safety and performance.

Many countries have implemented or are considering implementing extended producer responsibility (EPR) laws, which hold manufacturers accountable for the entire lifecycle of their products, including packaging. These regulations can incentivize the use of biodegradable materials like cellophane in packaging solutions.

Local and regional governments are increasingly enacting bans or restrictions on single-use plastics, which can create opportunities for alternative materials such as cellophane. For instance, California's SB 54 law mandates that all packaging in the state be recyclable or compostable by 2032, potentially boosting the adoption of cellophane-based solutions.

Certification systems and standards, such as the Biodegradable Products Institute (BPI) certification in North America and the EN 13432 standard in Europe, provide frameworks for assessing the biodegradability and compostability of packaging materials. These standards can influence the acceptance and marketability of cellophane-based zero-waste packaging solutions.

As environmental concerns continue to grow, it is likely that regulatory frameworks will evolve to further promote sustainable packaging solutions. This may include more stringent requirements for material recyclability, biodegradability, and overall environmental impact, potentially creating both opportunities and challenges for cellophane's role in zero-waste packaging solutions.

In the European Union, the Packaging and Packaging Waste Directive (94/62/EC) sets standards for packaging materials, including cellophane, to ensure they are recyclable, reusable, or biodegradable. The EU's Circular Economy Action Plan further reinforces these requirements, pushing for more sustainable packaging solutions and potentially favoring cellophane's biodegradable properties.

The United States Food and Drug Administration (FDA) regulates cellophane as a food contact substance, ensuring its safety for use in food packaging. The FDA's regulations on food packaging materials indirectly impact the adoption of cellophane in zero-waste solutions by setting standards for material safety and performance.

Many countries have implemented or are considering implementing extended producer responsibility (EPR) laws, which hold manufacturers accountable for the entire lifecycle of their products, including packaging. These regulations can incentivize the use of biodegradable materials like cellophane in packaging solutions.

Local and regional governments are increasingly enacting bans or restrictions on single-use plastics, which can create opportunities for alternative materials such as cellophane. For instance, California's SB 54 law mandates that all packaging in the state be recyclable or compostable by 2032, potentially boosting the adoption of cellophane-based solutions.

Certification systems and standards, such as the Biodegradable Products Institute (BPI) certification in North America and the EN 13432 standard in Europe, provide frameworks for assessing the biodegradability and compostability of packaging materials. These standards can influence the acceptance and marketability of cellophane-based zero-waste packaging solutions.

As environmental concerns continue to grow, it is likely that regulatory frameworks will evolve to further promote sustainable packaging solutions. This may include more stringent requirements for material recyclability, biodegradability, and overall environmental impact, potentially creating both opportunities and challenges for cellophane's role in zero-waste packaging solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!