Charting PTFE’s Role in Automated Engineering

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE in Automation: Background and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has emerged as a crucial material in the realm of automated engineering. Its unique properties, including exceptional chemical resistance, low friction coefficient, and high thermal stability, have positioned PTFE at the forefront of technological advancements in automation.

The evolution of PTFE in automated engineering can be traced back to its accidental discovery by Roy Plunkett in 1938. Initially utilized in military and aerospace applications, PTFE's potential in industrial automation became apparent in the latter half of the 20th century. As manufacturing processes grew more sophisticated, the demand for materials capable of withstanding harsh environments and reducing maintenance requirements increased significantly.

In the context of automated engineering, PTFE's primary objective is to enhance the efficiency, reliability, and longevity of mechanical systems. Its non-stick properties make it ideal for applications where material buildup or adhesion could impede automated processes. Furthermore, PTFE's self-lubricating nature contributes to reduced wear and tear in moving parts, thereby extending the operational lifespan of automated equipment.

The integration of PTFE in automation has been driven by several key factors. Firstly, the push for increased productivity in manufacturing has necessitated materials that can withstand continuous operation under challenging conditions. Secondly, the growing emphasis on energy efficiency has led to the adoption of PTFE in applications where reducing friction can significantly lower power consumption.

As automation technologies continue to advance, the role of PTFE is expected to expand further. Current trends indicate a growing interest in PTFE composites, which combine the material's inherent properties with those of other substances to create tailored solutions for specific automated applications. These developments aim to address limitations in pure PTFE, such as its relatively low load-bearing capacity and tendency to cold flow under pressure.

The future objectives for PTFE in automated engineering are multifaceted. Researchers and engineers are focusing on developing PTFE-based materials with enhanced mechanical properties, improved wear resistance, and better thermal management capabilities. Additionally, there is a concerted effort to explore PTFE's potential in emerging fields such as robotics, where its properties could prove invaluable in designing more durable and efficient actuators and joints.

In conclusion, PTFE's journey in automated engineering reflects a broader trend of material science driving technological progress. As automation continues to reshape industries, the ongoing research and development in PTFE applications promise to yield innovative solutions that will further revolutionize automated systems across various sectors.

The evolution of PTFE in automated engineering can be traced back to its accidental discovery by Roy Plunkett in 1938. Initially utilized in military and aerospace applications, PTFE's potential in industrial automation became apparent in the latter half of the 20th century. As manufacturing processes grew more sophisticated, the demand for materials capable of withstanding harsh environments and reducing maintenance requirements increased significantly.

In the context of automated engineering, PTFE's primary objective is to enhance the efficiency, reliability, and longevity of mechanical systems. Its non-stick properties make it ideal for applications where material buildup or adhesion could impede automated processes. Furthermore, PTFE's self-lubricating nature contributes to reduced wear and tear in moving parts, thereby extending the operational lifespan of automated equipment.

The integration of PTFE in automation has been driven by several key factors. Firstly, the push for increased productivity in manufacturing has necessitated materials that can withstand continuous operation under challenging conditions. Secondly, the growing emphasis on energy efficiency has led to the adoption of PTFE in applications where reducing friction can significantly lower power consumption.

As automation technologies continue to advance, the role of PTFE is expected to expand further. Current trends indicate a growing interest in PTFE composites, which combine the material's inherent properties with those of other substances to create tailored solutions for specific automated applications. These developments aim to address limitations in pure PTFE, such as its relatively low load-bearing capacity and tendency to cold flow under pressure.

The future objectives for PTFE in automated engineering are multifaceted. Researchers and engineers are focusing on developing PTFE-based materials with enhanced mechanical properties, improved wear resistance, and better thermal management capabilities. Additionally, there is a concerted effort to explore PTFE's potential in emerging fields such as robotics, where its properties could prove invaluable in designing more durable and efficient actuators and joints.

In conclusion, PTFE's journey in automated engineering reflects a broader trend of material science driving technological progress. As automation continues to reshape industries, the ongoing research and development in PTFE applications promise to yield innovative solutions that will further revolutionize automated systems across various sectors.

Market Demand Analysis for PTFE in Automated Systems

The market demand for PTFE in automated systems has been experiencing significant growth, driven by the increasing adoption of automation across various industries. As manufacturing processes become more sophisticated and require higher precision, the unique properties of PTFE make it an invaluable material in automated engineering applications.

In the automotive sector, the demand for PTFE components in automated assembly lines has surged. PTFE's low friction coefficient and excellent wear resistance make it ideal for use in robotic arms, conveyor systems, and other moving parts that require smooth, continuous operation. This has led to improved efficiency and reduced maintenance costs in automotive manufacturing.

The electronics industry has also seen a rise in PTFE demand for automated production systems. As electronic devices become smaller and more complex, the need for precise, contamination-free manufacturing environments has increased. PTFE's non-stick properties and chemical inertness make it perfect for use in automated pick-and-place machines, PCB handling systems, and clean room equipment.

In the food and beverage industry, PTFE plays a crucial role in automated packaging and processing systems. Its FDA-approved status and resistance to high temperatures make it suitable for use in conveyor belts, seals, and gaskets in food processing equipment. The growing emphasis on food safety and hygiene has further boosted the demand for PTFE in this sector.

The aerospace industry has been another significant driver of PTFE demand in automated systems. As aircraft manufacturing becomes increasingly automated, PTFE is used in various applications, from automated drilling and fastening systems to robotic painting and coating equipment. Its ability to withstand extreme temperatures and harsh chemicals makes it indispensable in these high-performance environments.

The medical device manufacturing sector has also contributed to the growing demand for PTFE in automated systems. As the production of medical devices becomes more automated to ensure consistency and sterility, PTFE is used in various applications, including automated assembly lines for syringes, catheters, and implantable devices.

Market analysts predict that the global demand for PTFE in automated engineering applications will continue to grow at a steady pace. This growth is expected to be driven by ongoing technological advancements in automation, the expansion of smart manufacturing initiatives, and the increasing adoption of Industry 4.0 principles across various sectors.

However, it's important to note that the market demand for PTFE in automated systems is not without challenges. The high cost of PTFE compared to some alternative materials and environmental concerns related to its production and disposal may impact its adoption in certain applications. Nevertheless, the unique combination of properties offered by PTFE continues to make it a preferred choice in many automated engineering scenarios, ensuring its relevance in the evolving landscape of industrial automation.

In the automotive sector, the demand for PTFE components in automated assembly lines has surged. PTFE's low friction coefficient and excellent wear resistance make it ideal for use in robotic arms, conveyor systems, and other moving parts that require smooth, continuous operation. This has led to improved efficiency and reduced maintenance costs in automotive manufacturing.

The electronics industry has also seen a rise in PTFE demand for automated production systems. As electronic devices become smaller and more complex, the need for precise, contamination-free manufacturing environments has increased. PTFE's non-stick properties and chemical inertness make it perfect for use in automated pick-and-place machines, PCB handling systems, and clean room equipment.

In the food and beverage industry, PTFE plays a crucial role in automated packaging and processing systems. Its FDA-approved status and resistance to high temperatures make it suitable for use in conveyor belts, seals, and gaskets in food processing equipment. The growing emphasis on food safety and hygiene has further boosted the demand for PTFE in this sector.

The aerospace industry has been another significant driver of PTFE demand in automated systems. As aircraft manufacturing becomes increasingly automated, PTFE is used in various applications, from automated drilling and fastening systems to robotic painting and coating equipment. Its ability to withstand extreme temperatures and harsh chemicals makes it indispensable in these high-performance environments.

The medical device manufacturing sector has also contributed to the growing demand for PTFE in automated systems. As the production of medical devices becomes more automated to ensure consistency and sterility, PTFE is used in various applications, including automated assembly lines for syringes, catheters, and implantable devices.

Market analysts predict that the global demand for PTFE in automated engineering applications will continue to grow at a steady pace. This growth is expected to be driven by ongoing technological advancements in automation, the expansion of smart manufacturing initiatives, and the increasing adoption of Industry 4.0 principles across various sectors.

However, it's important to note that the market demand for PTFE in automated systems is not without challenges. The high cost of PTFE compared to some alternative materials and environmental concerns related to its production and disposal may impact its adoption in certain applications. Nevertheless, the unique combination of properties offered by PTFE continues to make it a preferred choice in many automated engineering scenarios, ensuring its relevance in the evolving landscape of industrial automation.

Current PTFE Applications and Challenges in Automation

Polytetrafluoroethylene (PTFE) has become an integral component in various automated engineering applications due to its unique properties. In the realm of automation, PTFE is widely used in seals, bearings, and conveyor belts, owing to its low friction coefficient, chemical inertness, and high temperature resistance. These characteristics make it ideal for environments where traditional materials would fail under extreme conditions.

One of the primary applications of PTFE in automation is in the manufacturing of high-performance seals and gaskets. These components are crucial in maintaining the integrity of automated systems, preventing leaks and contamination in hydraulic and pneumatic systems. PTFE's ability to maintain its properties across a wide temperature range (-200°C to +260°C) makes it particularly valuable in industrial automation where temperature fluctuations are common.

In the field of robotics, PTFE-coated components are increasingly being utilized to enhance the performance and longevity of moving parts. The material's self-lubricating properties reduce wear and tear, leading to decreased maintenance requirements and improved operational efficiency. This is particularly beneficial in high-precision automation tasks where smooth, consistent movement is essential.

Despite its numerous advantages, PTFE faces several challenges in automated engineering applications. One significant issue is its relatively poor wear resistance compared to some other engineering plastics. In high-speed or high-load applications, PTFE components may experience accelerated wear, necessitating more frequent replacements. This limitation has led to ongoing research into PTFE composites that aim to enhance its durability while maintaining its beneficial properties.

Another challenge lies in PTFE's inherent difficulty in bonding with other materials. This can complicate the integration of PTFE components into complex automated systems, often requiring specialized bonding techniques or mechanical fastening methods. The development of surface treatment technologies to improve PTFE's adhesion properties is an active area of research in the field.

The electrical insulating properties of PTFE, while advantageous in many applications, can pose challenges in environments where static discharge is a concern. In automated manufacturing processes involving sensitive electronic components, the accumulation of static charge on PTFE surfaces can potentially lead to equipment damage or product defects. This has spurred the development of conductive PTFE variants and anti-static treatments to mitigate these risks.

As automation technologies continue to advance, there is a growing demand for materials that can withstand increasingly extreme conditions while maintaining precision and reliability. This has led to ongoing efforts to expand PTFE's capabilities through the development of new formulations and processing techniques. Researchers are exploring ways to enhance PTFE's wear resistance, improve its thermal conductivity, and expand its range of operating temperatures to meet the evolving needs of automated engineering systems.

One of the primary applications of PTFE in automation is in the manufacturing of high-performance seals and gaskets. These components are crucial in maintaining the integrity of automated systems, preventing leaks and contamination in hydraulic and pneumatic systems. PTFE's ability to maintain its properties across a wide temperature range (-200°C to +260°C) makes it particularly valuable in industrial automation where temperature fluctuations are common.

In the field of robotics, PTFE-coated components are increasingly being utilized to enhance the performance and longevity of moving parts. The material's self-lubricating properties reduce wear and tear, leading to decreased maintenance requirements and improved operational efficiency. This is particularly beneficial in high-precision automation tasks where smooth, consistent movement is essential.

Despite its numerous advantages, PTFE faces several challenges in automated engineering applications. One significant issue is its relatively poor wear resistance compared to some other engineering plastics. In high-speed or high-load applications, PTFE components may experience accelerated wear, necessitating more frequent replacements. This limitation has led to ongoing research into PTFE composites that aim to enhance its durability while maintaining its beneficial properties.

Another challenge lies in PTFE's inherent difficulty in bonding with other materials. This can complicate the integration of PTFE components into complex automated systems, often requiring specialized bonding techniques or mechanical fastening methods. The development of surface treatment technologies to improve PTFE's adhesion properties is an active area of research in the field.

The electrical insulating properties of PTFE, while advantageous in many applications, can pose challenges in environments where static discharge is a concern. In automated manufacturing processes involving sensitive electronic components, the accumulation of static charge on PTFE surfaces can potentially lead to equipment damage or product defects. This has spurred the development of conductive PTFE variants and anti-static treatments to mitigate these risks.

As automation technologies continue to advance, there is a growing demand for materials that can withstand increasingly extreme conditions while maintaining precision and reliability. This has led to ongoing efforts to expand PTFE's capabilities through the development of new formulations and processing techniques. Researchers are exploring ways to enhance PTFE's wear resistance, improve its thermal conductivity, and expand its range of operating temperatures to meet the evolving needs of automated engineering systems.

Existing PTFE Solutions in Automated Engineering

01 PTFE manufacturing processes

Various methods for producing PTFE are described, including polymerization techniques, extrusion processes, and molding procedures. These processes aim to improve the quality, consistency, and properties of PTFE products for different applications.- PTFE manufacturing and processing methods: Various techniques for manufacturing and processing PTFE, including molding, extrusion, and sintering. These methods aim to improve the material's properties and tailor it for specific applications. Innovations in processing techniques can enhance PTFE's performance characteristics such as tensile strength, elongation, and thermal stability.

- PTFE composites and blends: Development of PTFE composites and blends with other materials to enhance specific properties. These combinations can improve wear resistance, thermal conductivity, or electrical properties. Fillers such as carbon fibers, glass fibers, or metal particles are often incorporated to create specialized PTFE-based materials for various industrial applications.

- Surface modification of PTFE: Techniques for modifying the surface of PTFE to improve its adhesion properties or compatibility with other materials. This includes chemical treatments, plasma treatments, or the application of coatings. Surface modification can enhance PTFE's usefulness in applications where bonding or printing is required.

- PTFE in membrane technology: Application of PTFE in the development of high-performance membranes for filtration, separation, and other processes. PTFE membranes offer excellent chemical resistance and non-stick properties, making them suitable for use in challenging environments. Innovations focus on improving pore size control, membrane strength, and overall filtration efficiency.

- Recycling and sustainability of PTFE: Methods for recycling and reprocessing PTFE to improve its sustainability and reduce environmental impact. This includes techniques for breaking down PTFE into reusable components, as well as processes for incorporating recycled PTFE into new products. Efforts are also focused on developing more environmentally friendly production methods for PTFE.

02 PTFE composites and blends

The development of PTFE composites and blends with other materials to enhance specific properties such as wear resistance, thermal conductivity, or mechanical strength. These combinations create new materials with improved performance for specialized applications.Expand Specific Solutions03 Surface modification of PTFE

Techniques for modifying the surface of PTFE to improve its adhesion, wettability, or compatibility with other materials. These modifications can include chemical treatments, plasma treatments, or the application of coatings to enhance PTFE's functionality in various applications.Expand Specific Solutions04 PTFE in membrane technology

The use of PTFE in the development of high-performance membranes for applications such as water treatment, gas separation, and fuel cells. These membranes leverage PTFE's unique properties to achieve improved filtration, selectivity, and durability.Expand Specific Solutions05 PTFE in medical and biomedical applications

The utilization of PTFE in various medical and biomedical applications, including implants, prosthetics, and drug delivery systems. PTFE's biocompatibility and low friction properties make it suitable for use in medical devices and tissue engineering.Expand Specific Solutions

Key Players in PTFE and Automation Industries

The market for PTFE in automated engineering is experiencing significant growth, driven by increasing demand for high-performance materials in various industries. The technology is in a mature stage, with established players like DuPont de Nemours, Daikin Industries, and The Chemours Co. leading the market. These companies have extensive experience in PTFE production and application development. The market size is expanding due to PTFE's unique properties, including chemical resistance and low friction. Emerging players like AGC, Inc. and Nexans SA are also contributing to market dynamics by introducing innovative PTFE-based solutions for automated engineering applications, further intensifying competition and driving technological advancements in the field.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin Industries has developed advanced PTFE (polytetrafluoroethylene) materials and processing techniques for automated engineering applications. Their approach focuses on creating high-performance PTFE compounds with enhanced mechanical properties and chemical resistance. Daikin's PTFE materials are engineered for precision molding and extrusion processes, enabling the production of complex components with tight tolerances. They have also developed specialized PTFE coatings that can be applied robotically, improving efficiency in manufacturing processes[1]. Daikin's innovations in PTFE technology include the development of micro-powder PTFE for additive manufacturing applications, allowing for the creation of intricate parts with excellent non-stick and low friction properties[3].

Strengths: Superior material properties, precision manufacturing capabilities, and adaptability to various automated processes. Weaknesses: Higher cost compared to standard PTFE materials, potential limitations in extreme temperature applications.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered the development of PTFE-based materials tailored for automated engineering systems. Their approach includes the creation of modified PTFE resins with improved wear resistance and lower friction coefficients, ideal for high-speed automated machinery. DuPont's PTFE innovations extend to the development of composite materials that combine PTFE with other polymers or fillers, enhancing overall performance in automated systems. They have also introduced PTFE dispersions that can be applied through automated spray systems, providing uniform coatings on complex geometries[2]. DuPont's research has led to the development of PTFE materials with improved thermal stability, allowing for use in automated processes operating at higher temperatures[4].

Strengths: Extensive R&D capabilities, wide range of PTFE formulations for various applications, strong brand recognition. Weaknesses: Potential higher costs, may require specialized equipment for processing some advanced formulations.

Innovative PTFE Applications in Automation

Porous non-woven PTFE compositions and methods of forming

PatentWO2025106714A1

Innovation

- A tape comprising a machined matrix with oriented long-strand PTFE fibrils, nodes containing active particles and short-strand PTFE, and a plurality of through pores, which can be expanded to form an expanded tape with enhanced surface area and mechanical robustness.

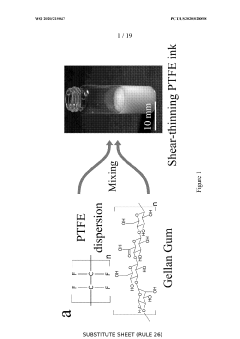

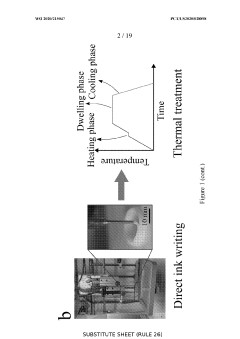

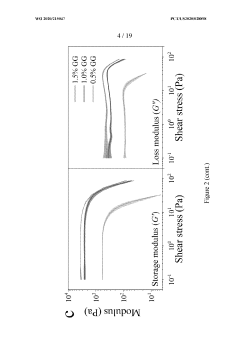

Fluoropolymer shear-thinning INKS and methods of making and using same

PatentWO2020215047A1

Innovation

- Development of shear-thinning inks comprising PTFE particles, a medium, and a shear-thinning agent like gellan gum, combined with a multistage thermal treatment process for direct ink writing, allowing for the creation of complex PTFE structures with tunable mechanical properties.

Environmental Impact of PTFE in Automation

The environmental impact of PTFE in automation is a critical consideration as the material's usage continues to expand in various industrial applications. PTFE, known for its exceptional chemical resistance and low friction properties, has become integral to many automated systems. However, its environmental footprint raises concerns that warrant careful examination.

PTFE production involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. While efforts have been made to phase out PFOA, the environmental legacy of its historical use remains a challenge. The manufacturing process also contributes to greenhouse gas emissions, particularly through the release of fluorinated compounds.

In automated systems, PTFE's durability and longevity can be viewed as environmentally beneficial, as it reduces the need for frequent replacements and associated waste. However, the material's resistance to degradation becomes problematic at the end of its lifecycle. PTFE does not biodegrade and can persist in the environment for extended periods, potentially accumulating in ecosystems.

The disposal of PTFE-containing components from automated systems presents another environmental challenge. Incineration of PTFE can release harmful substances, including hydrofluoric acid and perfluoroisobutylene, necessitating specialized disposal methods. Recycling PTFE is technically feasible but not widely practiced due to economic and logistical constraints.

On the positive side, PTFE's use in automation can contribute to improved energy efficiency in industrial processes. Its low friction properties reduce wear and energy consumption in moving parts, potentially leading to lower overall energy use and associated emissions. Additionally, PTFE's chemical inertness can prevent contamination and reduce the need for harsh cleaning chemicals in certain applications.

The automation industry is increasingly focusing on developing more sustainable alternatives to traditional PTFE. Research into bio-based fluoropolymers and PTFE recycling technologies shows promise for reducing the material's environmental impact. Some companies are exploring PTFE-free solutions for certain applications, balancing performance requirements with environmental considerations.

As automation continues to advance, the industry faces the challenge of optimizing PTFE use while minimizing its environmental footprint. This involves improving production processes, enhancing end-of-life management, and developing more sustainable alternatives. The future of PTFE in automation will likely be shaped by a growing emphasis on circular economy principles and stricter environmental regulations.

PTFE production involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. While efforts have been made to phase out PFOA, the environmental legacy of its historical use remains a challenge. The manufacturing process also contributes to greenhouse gas emissions, particularly through the release of fluorinated compounds.

In automated systems, PTFE's durability and longevity can be viewed as environmentally beneficial, as it reduces the need for frequent replacements and associated waste. However, the material's resistance to degradation becomes problematic at the end of its lifecycle. PTFE does not biodegrade and can persist in the environment for extended periods, potentially accumulating in ecosystems.

The disposal of PTFE-containing components from automated systems presents another environmental challenge. Incineration of PTFE can release harmful substances, including hydrofluoric acid and perfluoroisobutylene, necessitating specialized disposal methods. Recycling PTFE is technically feasible but not widely practiced due to economic and logistical constraints.

On the positive side, PTFE's use in automation can contribute to improved energy efficiency in industrial processes. Its low friction properties reduce wear and energy consumption in moving parts, potentially leading to lower overall energy use and associated emissions. Additionally, PTFE's chemical inertness can prevent contamination and reduce the need for harsh cleaning chemicals in certain applications.

The automation industry is increasingly focusing on developing more sustainable alternatives to traditional PTFE. Research into bio-based fluoropolymers and PTFE recycling technologies shows promise for reducing the material's environmental impact. Some companies are exploring PTFE-free solutions for certain applications, balancing performance requirements with environmental considerations.

As automation continues to advance, the industry faces the challenge of optimizing PTFE use while minimizing its environmental footprint. This involves improving production processes, enhancing end-of-life management, and developing more sustainable alternatives. The future of PTFE in automation will likely be shaped by a growing emphasis on circular economy principles and stricter environmental regulations.

Regulatory Landscape for PTFE Use in Automation

The regulatory landscape for PTFE use in automation is complex and multifaceted, reflecting the material's widespread applications and potential environmental impacts. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating PTFE under the Toxic Substances Control Act (TSCA). The EPA has implemented stringent guidelines for the production, use, and disposal of PTFE, particularly focusing on the perfluorooctanoic acid (PFOA) used in its manufacturing process.

European regulations are equally stringent, with the European Chemicals Agency (ECHA) overseeing PTFE use under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework. REACH requires manufacturers and importers to register chemicals and provide safety data, ensuring transparency and accountability in the use of PTFE in automated systems.

In the context of automation, specific industry standards further govern PTFE application. The International Organization for Standardization (ISO) has developed standards such as ISO 13000-1 and ISO 13000-2, which specify the requirements for virgin and processed unfilled PTFE products. These standards are crucial for ensuring consistency and quality in automated manufacturing processes that utilize PTFE components.

The food and pharmaceutical industries have additional regulatory considerations. The U.S. Food and Drug Administration (FDA) has approved certain grades of PTFE for food contact applications, while the European Food Safety Authority (EFSA) provides similar guidance for the European market. These regulations are particularly relevant for automated food processing and packaging systems that incorporate PTFE components.

Occupational safety regulations also impact PTFE use in automation. The Occupational Safety and Health Administration (OSHA) in the U.S. has established exposure limits for PTFE particles and fumes, which must be considered in the design and operation of automated systems using PTFE materials.

As environmental concerns grow, regulations are evolving to address the long-term impacts of PTFE. The Stockholm Convention on Persistent Organic Pollutants has led to increased scrutiny of perfluorinated compounds, including those used in PTFE production. This has prompted research into alternative manufacturing processes and more environmentally friendly substitutes for traditional PTFE in certain automated applications.

Compliance with these diverse regulations presents both challenges and opportunities for companies involved in automated engineering. While adherence to standards ensures product safety and environmental responsibility, it also drives innovation in material science and manufacturing processes. As the regulatory landscape continues to evolve, companies must stay informed and adaptable to maintain compliance and competitive advantage in the use of PTFE in automated systems.

European regulations are equally stringent, with the European Chemicals Agency (ECHA) overseeing PTFE use under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework. REACH requires manufacturers and importers to register chemicals and provide safety data, ensuring transparency and accountability in the use of PTFE in automated systems.

In the context of automation, specific industry standards further govern PTFE application. The International Organization for Standardization (ISO) has developed standards such as ISO 13000-1 and ISO 13000-2, which specify the requirements for virgin and processed unfilled PTFE products. These standards are crucial for ensuring consistency and quality in automated manufacturing processes that utilize PTFE components.

The food and pharmaceutical industries have additional regulatory considerations. The U.S. Food and Drug Administration (FDA) has approved certain grades of PTFE for food contact applications, while the European Food Safety Authority (EFSA) provides similar guidance for the European market. These regulations are particularly relevant for automated food processing and packaging systems that incorporate PTFE components.

Occupational safety regulations also impact PTFE use in automation. The Occupational Safety and Health Administration (OSHA) in the U.S. has established exposure limits for PTFE particles and fumes, which must be considered in the design and operation of automated systems using PTFE materials.

As environmental concerns grow, regulations are evolving to address the long-term impacts of PTFE. The Stockholm Convention on Persistent Organic Pollutants has led to increased scrutiny of perfluorinated compounds, including those used in PTFE production. This has prompted research into alternative manufacturing processes and more environmentally friendly substitutes for traditional PTFE in certain automated applications.

Compliance with these diverse regulations presents both challenges and opportunities for companies involved in automated engineering. While adherence to standards ensures product safety and environmental responsibility, it also drives innovation in material science and manufacturing processes. As the regulatory landscape continues to evolve, companies must stay informed and adaptable to maintain compliance and competitive advantage in the use of PTFE in automated systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!