PTFE’s Contribution to Innovative Manufacturing Techniques

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Evolution & Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has undergone significant evolution since its accidental discovery by Roy Plunkett in 1938. Initially developed as a refrigerant, PTFE's unique properties quickly led to its application in various industries, revolutionizing manufacturing techniques over the decades.

The evolution of PTFE in manufacturing can be traced through several key phases. In the 1940s and 1950s, PTFE's non-stick and heat-resistant properties were first exploited in cookware and industrial coatings. The 1960s and 1970s saw an expansion into aerospace and automotive industries, where PTFE's low friction coefficient and chemical inertness proved invaluable. The 1980s and 1990s marked a period of refinement in PTFE production techniques, leading to more consistent and higher quality materials.

In recent years, the focus has shifted towards developing advanced PTFE composites and nanostructured materials. These innovations have opened up new possibilities in fields such as electronics, medical devices, and high-performance textiles. The ongoing evolution of PTFE continues to push the boundaries of what is possible in manufacturing, with a growing emphasis on sustainability and eco-friendly production methods.

The primary objectives in PTFE's contribution to innovative manufacturing techniques are multifaceted. Firstly, there is a drive to enhance the material's already impressive properties, such as further improving its non-stick capabilities, increasing its temperature resistance, and expanding its chemical compatibility range. This would enable PTFE to be used in even more extreme environments and applications.

Secondly, researchers aim to develop more efficient and cost-effective production methods for PTFE and its derivatives. This includes exploring new polymerization techniques and investigating ways to reduce the environmental impact of PTFE manufacturing. The goal is to make PTFE more accessible and sustainable for a wider range of industries.

Another key objective is to expand PTFE's role in advanced manufacturing processes. This includes its integration into 3D printing technologies, which could revolutionize the production of complex, custom components with unique properties. Additionally, there is a focus on developing PTFE-based smart materials that can respond to environmental stimuli, opening up new possibilities in fields such as adaptive manufacturing and self-healing materials.

Lastly, there is a growing interest in exploring PTFE's potential in emerging technologies such as nanotechnology and quantum computing. By manipulating PTFE at the molecular level, researchers hope to create novel materials with unprecedented properties, potentially leading to breakthroughs in fields ranging from energy storage to quantum information processing.

The evolution of PTFE in manufacturing can be traced through several key phases. In the 1940s and 1950s, PTFE's non-stick and heat-resistant properties were first exploited in cookware and industrial coatings. The 1960s and 1970s saw an expansion into aerospace and automotive industries, where PTFE's low friction coefficient and chemical inertness proved invaluable. The 1980s and 1990s marked a period of refinement in PTFE production techniques, leading to more consistent and higher quality materials.

In recent years, the focus has shifted towards developing advanced PTFE composites and nanostructured materials. These innovations have opened up new possibilities in fields such as electronics, medical devices, and high-performance textiles. The ongoing evolution of PTFE continues to push the boundaries of what is possible in manufacturing, with a growing emphasis on sustainability and eco-friendly production methods.

The primary objectives in PTFE's contribution to innovative manufacturing techniques are multifaceted. Firstly, there is a drive to enhance the material's already impressive properties, such as further improving its non-stick capabilities, increasing its temperature resistance, and expanding its chemical compatibility range. This would enable PTFE to be used in even more extreme environments and applications.

Secondly, researchers aim to develop more efficient and cost-effective production methods for PTFE and its derivatives. This includes exploring new polymerization techniques and investigating ways to reduce the environmental impact of PTFE manufacturing. The goal is to make PTFE more accessible and sustainable for a wider range of industries.

Another key objective is to expand PTFE's role in advanced manufacturing processes. This includes its integration into 3D printing technologies, which could revolutionize the production of complex, custom components with unique properties. Additionally, there is a focus on developing PTFE-based smart materials that can respond to environmental stimuli, opening up new possibilities in fields such as adaptive manufacturing and self-healing materials.

Lastly, there is a growing interest in exploring PTFE's potential in emerging technologies such as nanotechnology and quantum computing. By manipulating PTFE at the molecular level, researchers hope to create novel materials with unprecedented properties, potentially leading to breakthroughs in fields ranging from energy storage to quantum information processing.

Market Demand Analysis

The market demand for PTFE (Polytetrafluoroethylene) in innovative manufacturing techniques has been steadily growing, driven by its unique properties and versatile applications across various industries. PTFE's exceptional chemical resistance, low friction coefficient, and high-temperature stability make it an invaluable material in advanced manufacturing processes.

In the automotive sector, PTFE is increasingly utilized in the production of high-performance engine components, gaskets, and seals. The material's ability to withstand extreme temperatures and chemical exposure has led to a surge in demand for PTFE-coated parts, enhancing engine efficiency and longevity. This trend is expected to continue as automotive manufacturers strive for more fuel-efficient and durable vehicles.

The aerospace industry has also become a significant consumer of PTFE-based products. The material's lightweight nature and resistance to wear make it ideal for aircraft components, including hydraulic systems, fuel lines, and electrical insulation. As the aerospace sector expands and focuses on developing more efficient and environmentally friendly aircraft, the demand for PTFE in innovative manufacturing techniques is projected to rise substantially.

In the electronics industry, PTFE's excellent dielectric properties have made it indispensable in the production of high-frequency circuit boards and semiconductor manufacturing equipment. The growing demand for smaller, faster, and more reliable electronic devices is driving the need for PTFE in advanced manufacturing processes, particularly in the development of 5G infrastructure and Internet of Things (IoT) devices.

The medical device industry has witnessed a significant increase in PTFE usage, particularly in the manufacturing of implantable devices and surgical instruments. PTFE's biocompatibility and non-stick properties make it an excellent choice for creating innovative medical products that improve patient outcomes and reduce the risk of complications. As the global population ages and healthcare technologies advance, the demand for PTFE in medical device manufacturing is expected to grow exponentially.

Industrial manufacturing has also embraced PTFE for its anti-corrosion and low-friction properties. The material is widely used in the production of chemical processing equipment, industrial coatings, and advanced filtration systems. As industries focus on improving efficiency and reducing maintenance costs, the demand for PTFE-based solutions in manufacturing processes continues to expand.

The global PTFE market is projected to experience substantial growth in the coming years, with a compound annual growth rate (CAGR) expected to remain strong. This growth is attributed to the increasing adoption of PTFE in emerging economies, ongoing technological advancements, and the material's expanding applications in various industries. The Asia-Pacific region, in particular, is anticipated to be a key driver of market growth, fueled by rapid industrialization and increasing investments in advanced manufacturing technologies.

In the automotive sector, PTFE is increasingly utilized in the production of high-performance engine components, gaskets, and seals. The material's ability to withstand extreme temperatures and chemical exposure has led to a surge in demand for PTFE-coated parts, enhancing engine efficiency and longevity. This trend is expected to continue as automotive manufacturers strive for more fuel-efficient and durable vehicles.

The aerospace industry has also become a significant consumer of PTFE-based products. The material's lightweight nature and resistance to wear make it ideal for aircraft components, including hydraulic systems, fuel lines, and electrical insulation. As the aerospace sector expands and focuses on developing more efficient and environmentally friendly aircraft, the demand for PTFE in innovative manufacturing techniques is projected to rise substantially.

In the electronics industry, PTFE's excellent dielectric properties have made it indispensable in the production of high-frequency circuit boards and semiconductor manufacturing equipment. The growing demand for smaller, faster, and more reliable electronic devices is driving the need for PTFE in advanced manufacturing processes, particularly in the development of 5G infrastructure and Internet of Things (IoT) devices.

The medical device industry has witnessed a significant increase in PTFE usage, particularly in the manufacturing of implantable devices and surgical instruments. PTFE's biocompatibility and non-stick properties make it an excellent choice for creating innovative medical products that improve patient outcomes and reduce the risk of complications. As the global population ages and healthcare technologies advance, the demand for PTFE in medical device manufacturing is expected to grow exponentially.

Industrial manufacturing has also embraced PTFE for its anti-corrosion and low-friction properties. The material is widely used in the production of chemical processing equipment, industrial coatings, and advanced filtration systems. As industries focus on improving efficiency and reducing maintenance costs, the demand for PTFE-based solutions in manufacturing processes continues to expand.

The global PTFE market is projected to experience substantial growth in the coming years, with a compound annual growth rate (CAGR) expected to remain strong. This growth is attributed to the increasing adoption of PTFE in emerging economies, ongoing technological advancements, and the material's expanding applications in various industries. The Asia-Pacific region, in particular, is anticipated to be a key driver of market growth, fueled by rapid industrialization and increasing investments in advanced manufacturing technologies.

PTFE Tech Challenges

Polytetrafluoroethylene (PTFE) has revolutionized manufacturing techniques, but its unique properties also present significant challenges in processing and application. One of the primary obstacles is PTFE's high melting point and melt viscosity, which make traditional thermoplastic processing methods ineffective. This necessitates specialized techniques such as ram extrusion and sintering, limiting production efficiency and increasing manufacturing costs.

The material's extreme chemical inertness, while beneficial in many applications, poses difficulties in bonding and adhesion. This characteristic complicates the integration of PTFE components with other materials in complex manufacturing processes. Engineers must develop innovative surface treatment methods or utilize specialized adhesives to overcome this challenge, often resulting in additional production steps and increased complexity.

PTFE's low coefficient of friction, although advantageous in many scenarios, can be problematic in certain manufacturing contexts. It can lead to issues with material handling and positioning during production processes, requiring the development of specialized equipment and techniques to maintain precision and control.

The material's tendency to creep under load presents challenges in applications where dimensional stability is critical. This property necessitates careful design considerations and may limit PTFE's use in certain high-stress or high-precision components without additional reinforcement or modification.

Environmental concerns associated with PTFE production and disposal also pose challenges. The use of perfluorooctanoic acid (PFOA) in traditional PTFE manufacturing has raised health and environmental issues, prompting the need for alternative production methods and materials. This shift requires significant research and development efforts to maintain PTFE's desirable properties while addressing sustainability concerns.

The high cost of PTFE compared to other polymers can be a limiting factor in its widespread adoption in manufacturing. This economic challenge drives the need for more cost-effective production methods and the development of PTFE composites that can offer similar properties at a lower price point.

Lastly, the difficulty in recycling PTFE products presents a challenge in the context of increasing emphasis on circular economy principles in manufacturing. Developing effective recycling methods for PTFE waste and incorporating recycled PTFE into new products without compromising performance remains an ongoing technical challenge for the industry.

The material's extreme chemical inertness, while beneficial in many applications, poses difficulties in bonding and adhesion. This characteristic complicates the integration of PTFE components with other materials in complex manufacturing processes. Engineers must develop innovative surface treatment methods or utilize specialized adhesives to overcome this challenge, often resulting in additional production steps and increased complexity.

PTFE's low coefficient of friction, although advantageous in many scenarios, can be problematic in certain manufacturing contexts. It can lead to issues with material handling and positioning during production processes, requiring the development of specialized equipment and techniques to maintain precision and control.

The material's tendency to creep under load presents challenges in applications where dimensional stability is critical. This property necessitates careful design considerations and may limit PTFE's use in certain high-stress or high-precision components without additional reinforcement or modification.

Environmental concerns associated with PTFE production and disposal also pose challenges. The use of perfluorooctanoic acid (PFOA) in traditional PTFE manufacturing has raised health and environmental issues, prompting the need for alternative production methods and materials. This shift requires significant research and development efforts to maintain PTFE's desirable properties while addressing sustainability concerns.

The high cost of PTFE compared to other polymers can be a limiting factor in its widespread adoption in manufacturing. This economic challenge drives the need for more cost-effective production methods and the development of PTFE composites that can offer similar properties at a lower price point.

Lastly, the difficulty in recycling PTFE products presents a challenge in the context of increasing emphasis on circular economy principles in manufacturing. Developing effective recycling methods for PTFE waste and incorporating recycled PTFE into new products without compromising performance remains an ongoing technical challenge for the industry.

Current PTFE Solutions

01 PTFE manufacturing processes

Various methods for producing PTFE are described, including polymerization techniques, extrusion processes, and molding methods. These processes aim to improve the quality, consistency, and properties of PTFE products for different applications.- PTFE manufacturing processes: Various methods for producing PTFE are described, including polymerization techniques, extrusion processes, and molding methods. These processes aim to improve the quality, consistency, and properties of PTFE products for different applications.

- PTFE composites and blends: The development of PTFE composites and blends with other materials to enhance specific properties such as wear resistance, thermal conductivity, or mechanical strength. These combinations aim to create materials with improved performance for specialized applications.

- Surface modification of PTFE: Techniques for modifying the surface of PTFE to improve its adhesion, wettability, or compatibility with other materials. These modifications can include chemical treatments, plasma treatments, or the application of coatings to enhance PTFE's functionality in various applications.

- PTFE in membrane technology: The use of PTFE in the development of advanced membrane technologies for applications such as water treatment, gas separation, and filtration. These membranes leverage PTFE's unique properties to achieve high performance and durability in challenging environments.

- PTFE in medical and biomedical applications: The application of PTFE in medical devices, implants, and biomedical engineering. This includes the development of PTFE-based materials with enhanced biocompatibility, reduced friction, and improved durability for use in various medical procedures and devices.

02 PTFE composites and blends

The development of PTFE composites and blends with other materials to enhance specific properties such as wear resistance, thermal conductivity, or mechanical strength. These combinations create new materials with improved performance for specialized applications.Expand Specific Solutions03 Surface modification of PTFE

Techniques for modifying the surface of PTFE to improve its adhesion, wettability, or compatibility with other materials. These modifications can include chemical treatments, plasma treatments, or the application of coatings to enhance PTFE's functionality in various applications.Expand Specific Solutions04 PTFE in membrane technology

The use of PTFE in the development of advanced membrane technologies for applications such as water treatment, gas separation, and fuel cells. These membranes leverage PTFE's unique properties to achieve high performance in filtration and separation processes.Expand Specific Solutions05 PTFE recycling and sustainability

Methods for recycling PTFE products and improving the sustainability of PTFE production and use. This includes techniques for reprocessing PTFE waste, reducing environmental impact, and developing more eco-friendly PTFE alternatives.Expand Specific Solutions

Key Industry Players

The PTFE market is in a mature growth stage, with a global market size estimated to reach $4.1 billion by 2026. The technology's maturity is evident in its widespread adoption across various industries, including manufacturing, electronics, and automotive. Key players like DAIKIN INDUSTRIES Ltd., DuPont de Nemours, Inc., and The Chemours Co. are driving innovation in PTFE applications, particularly in advanced manufacturing techniques. These companies are focusing on developing high-performance PTFE variants with enhanced properties for specialized industrial uses. The competitive landscape is characterized by ongoing research and development efforts to improve PTFE's performance characteristics and expand its applications in emerging technologies, such as 5G infrastructure and renewable energy systems.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has developed several innovative manufacturing techniques leveraging PTFE's properties. They have pioneered a unique PTFE granulation process that produces spherical PTFE particles with improved flowability and moldability[5]. This technique enables the production of high-quality PTFE components with complex shapes. Daikin has also developed advanced PTFE dispersion technologies, allowing for the creation of ultra-thin PTFE coatings with enhanced adhesion properties[6]. Furthermore, they have innovated in the field of PTFE compound manufacturing, creating specialized blends that combine PTFE with other materials to achieve specific performance characteristics for various industrial applications.

Strengths: Strong focus on PTFE innovations, diverse product portfolio, and global market presence. Weaknesses: Potential challenges in adapting to stricter environmental regulations related to fluoropolymer production.

3M Innovative Properties Co.

Technical Solution: 3M has contributed significantly to PTFE manufacturing innovations, leveraging their expertise in material science. They have developed advanced PTFE film extrusion techniques that allow for the production of ultra-thin, uniform PTFE films with exceptional properties[9]. 3M has also pioneered methods for creating PTFE-based composite materials, combining PTFE with other polymers or additives to enhance specific characteristics. Their innovations in PTFE foam manufacturing have led to the development of low-density PTFE materials with unique insulating and cushioning properties[10]. Furthermore, 3M has made advancements in PTFE surface modification techniques, enabling improved adhesion and printability of PTFE substrates for various applications.

Strengths: Diverse technological expertise, strong R&D capabilities, and a wide range of PTFE-based product applications. Weaknesses: Potential regulatory challenges and public scrutiny related to PFAS compounds.

PTFE Patent Landscape

Melt-fabricable polytetrafluoroethylene

PatentInactiveEP1077230B1

Innovation

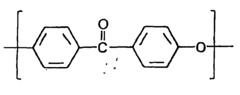

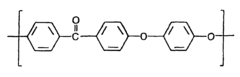

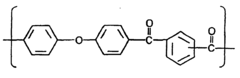

- A composition comprising at least 50 wt% PTFE with a melt viscosity of at least 10^8 Pa·s, combined with 20-80 wt% PTFE micropowder and 20-50 wt% polyaryleneetherketone, allowing for melt fabricability through extrusion and injection molding by dispersing polyaryleneetherketone as fine particles within a PTFE matrix.

Method of making synthetic melt spun fibers with polytetrafluoroethylene

PatentInactiveHK1085425A

Innovation

- Incorporation of dispersible PTFE powder with low micron or submicron particle size into synthetic melt spun fibers, resulting in improved properties such as lower coefficient of friction and reduced wettability.

- The method improves the overall melt spinning process by increasing lubricity, resulting in lower production times, increased processing speeds, and overall production rates.

- The PTFE-enhanced fibers exhibit multiple improved properties, including stain resistance, UV protection, and reduced gas permeability, making them suitable for various applications such as industrial filtration and sportswear.

Environmental Impact

The environmental impact of PTFE's contribution to innovative manufacturing techniques is a critical aspect that requires careful consideration. PTFE, or polytetrafluoroethylene, has revolutionized various manufacturing processes due to its unique properties, but its environmental footprint is complex and multifaceted.

One of the primary environmental concerns associated with PTFE manufacturing is the production and emission of perfluorooctanoic acid (PFOA), a persistent organic pollutant. Historically, PFOA was used in the production of PTFE, leading to environmental contamination and potential health risks. However, the industry has made significant strides in developing PFOA-free manufacturing processes, greatly reducing this environmental burden.

The durability and chemical resistance of PTFE contribute to its long lifespan in manufacturing applications, which can be viewed as an environmental advantage. Products and components made with PTFE often require less frequent replacement, potentially reducing waste and resource consumption over time. Additionally, PTFE's non-stick properties can lead to more efficient manufacturing processes, reducing the need for lubricants and cleaning agents, which can have positive environmental implications.

However, the end-of-life management of PTFE products presents challenges. PTFE is not biodegradable and can persist in the environment for extended periods. While recycling technologies for PTFE exist, they are not yet widely implemented, leading to concerns about the accumulation of PTFE waste in landfills or incineration facilities.

In terms of energy consumption, the production of PTFE is generally energy-intensive, contributing to its carbon footprint. However, when considering the entire lifecycle of PTFE products, the energy savings achieved through improved efficiency in manufacturing processes and extended product lifespans may offset some of these initial energy costs.

The use of PTFE in innovative manufacturing techniques has also led to advancements in clean energy technologies. For instance, PTFE membranes are crucial components in fuel cells and certain types of solar panels, contributing to the development of more sustainable energy solutions. This indirect environmental benefit should be weighed against the direct impacts of PTFE production and use.

As environmental regulations become more stringent, manufacturers are increasingly focusing on developing more sustainable PTFE production methods and exploring bio-based alternatives. These efforts aim to reduce the environmental impact of PTFE while maintaining its beneficial properties for innovative manufacturing techniques.

One of the primary environmental concerns associated with PTFE manufacturing is the production and emission of perfluorooctanoic acid (PFOA), a persistent organic pollutant. Historically, PFOA was used in the production of PTFE, leading to environmental contamination and potential health risks. However, the industry has made significant strides in developing PFOA-free manufacturing processes, greatly reducing this environmental burden.

The durability and chemical resistance of PTFE contribute to its long lifespan in manufacturing applications, which can be viewed as an environmental advantage. Products and components made with PTFE often require less frequent replacement, potentially reducing waste and resource consumption over time. Additionally, PTFE's non-stick properties can lead to more efficient manufacturing processes, reducing the need for lubricants and cleaning agents, which can have positive environmental implications.

However, the end-of-life management of PTFE products presents challenges. PTFE is not biodegradable and can persist in the environment for extended periods. While recycling technologies for PTFE exist, they are not yet widely implemented, leading to concerns about the accumulation of PTFE waste in landfills or incineration facilities.

In terms of energy consumption, the production of PTFE is generally energy-intensive, contributing to its carbon footprint. However, when considering the entire lifecycle of PTFE products, the energy savings achieved through improved efficiency in manufacturing processes and extended product lifespans may offset some of these initial energy costs.

The use of PTFE in innovative manufacturing techniques has also led to advancements in clean energy technologies. For instance, PTFE membranes are crucial components in fuel cells and certain types of solar panels, contributing to the development of more sustainable energy solutions. This indirect environmental benefit should be weighed against the direct impacts of PTFE production and use.

As environmental regulations become more stringent, manufacturers are increasingly focusing on developing more sustainable PTFE production methods and exploring bio-based alternatives. These efforts aim to reduce the environmental impact of PTFE while maintaining its beneficial properties for innovative manufacturing techniques.

PTFE Safety Regulations

The safety regulations surrounding PTFE (Polytetrafluoroethylene) play a crucial role in its application within innovative manufacturing techniques. As PTFE's use expands across various industries, regulatory bodies have established comprehensive guidelines to ensure its safe handling, processing, and implementation.

One of the primary safety concerns with PTFE is the potential release of harmful fumes when heated to high temperatures. Regulatory agencies, such as the Occupational Safety and Health Administration (OSHA) in the United States, have set strict exposure limits for PTFE-related compounds. These regulations mandate proper ventilation systems and personal protective equipment for workers involved in PTFE manufacturing and processing.

In the context of innovative manufacturing techniques, safety regulations often focus on the thermal decomposition of PTFE. When heated above 260°C (500°F), PTFE can release toxic gases, including perfluoroisobutylene (PFIB) and hydrogen fluoride (HF). As a result, manufacturing processes utilizing PTFE must adhere to temperature control protocols and implement fail-safe mechanisms to prevent overheating.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has also impacted PTFE usage in manufacturing. REACH requires manufacturers and importers to assess and manage the risks associated with PTFE and its related substances, ensuring their safe use throughout the supply chain.

Safety regulations extend to the disposal and recycling of PTFE products as well. Many countries have implemented specific guidelines for the proper disposal of PTFE waste to prevent environmental contamination. These regulations often require specialized recycling processes or controlled incineration to minimize the release of harmful byproducts.

In the medical and food industries, where PTFE is widely used due to its non-stick and biocompatible properties, additional safety regulations apply. The U.S. Food and Drug Administration (FDA) has established guidelines for PTFE use in food contact materials and medical devices, ensuring its safety for human exposure.

As innovative manufacturing techniques continue to evolve, safety regulations surrounding PTFE are likely to adapt. Emerging technologies, such as 3D printing with PTFE-based materials, may require new safety protocols and regulatory frameworks. Manufacturers and researchers must stay informed about these evolving regulations to ensure compliance and maintain safe working environments.

One of the primary safety concerns with PTFE is the potential release of harmful fumes when heated to high temperatures. Regulatory agencies, such as the Occupational Safety and Health Administration (OSHA) in the United States, have set strict exposure limits for PTFE-related compounds. These regulations mandate proper ventilation systems and personal protective equipment for workers involved in PTFE manufacturing and processing.

In the context of innovative manufacturing techniques, safety regulations often focus on the thermal decomposition of PTFE. When heated above 260°C (500°F), PTFE can release toxic gases, including perfluoroisobutylene (PFIB) and hydrogen fluoride (HF). As a result, manufacturing processes utilizing PTFE must adhere to temperature control protocols and implement fail-safe mechanisms to prevent overheating.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has also impacted PTFE usage in manufacturing. REACH requires manufacturers and importers to assess and manage the risks associated with PTFE and its related substances, ensuring their safe use throughout the supply chain.

Safety regulations extend to the disposal and recycling of PTFE products as well. Many countries have implemented specific guidelines for the proper disposal of PTFE waste to prevent environmental contamination. These regulations often require specialized recycling processes or controlled incineration to minimize the release of harmful byproducts.

In the medical and food industries, where PTFE is widely used due to its non-stick and biocompatible properties, additional safety regulations apply. The U.S. Food and Drug Administration (FDA) has established guidelines for PTFE use in food contact materials and medical devices, ensuring its safety for human exposure.

As innovative manufacturing techniques continue to evolve, safety regulations surrounding PTFE are likely to adapt. Emerging technologies, such as 3D printing with PTFE-based materials, may require new safety protocols and regulatory frameworks. Manufacturers and researchers must stay informed about these evolving regulations to ensure compliance and maintain safe working environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!