Forecasting integration of PTFE in foldable antenna substrates

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Antenna Evolution

The integration of Polytetrafluoroethylene (PTFE) in antenna substrates has undergone significant evolution over the past decades. Initially, PTFE was primarily used in rigid antenna designs due to its excellent dielectric properties and low loss tangent. As the demand for more compact and versatile antennas grew, researchers began exploring ways to incorporate PTFE into flexible and foldable antenna structures.

In the early stages of PTFE antenna evolution, the material was mainly utilized in microstrip patch antennas for its ability to maintain consistent electrical properties across a wide range of frequencies. This characteristic made PTFE an ideal choice for applications requiring high-frequency performance and stability. However, the rigid nature of traditional PTFE substrates limited their use in applications that demanded flexibility or conformality.

The next phase of evolution saw the development of PTFE-based composite materials that offered improved flexibility while retaining the desirable electrical properties of PTFE. These composites typically combined PTFE with other polymers or reinforcing materials, resulting in substrates that could be bent or flexed to a certain degree. This advancement opened up new possibilities for antenna designs that could conform to non-planar surfaces or be integrated into curved structures.

As the demand for foldable and deployable antennas increased, particularly in aerospace and satellite communications, researchers began focusing on creating ultra-thin PTFE substrates. These substrates, often reinforced with glass fibers or other materials, offered a balance between flexibility and electrical performance. The development of such materials enabled the creation of antennas that could be folded for compact storage and then deployed to their full size when needed.

Recent advancements in PTFE antenna evolution have centered around the creation of highly flexible and stretchable PTFE-based substrates. These materials incorporate novel manufacturing techniques, such as electrospinning or the use of nanoparticles, to create PTFE films that can undergo significant deformation without compromising their electrical properties. This breakthrough has paved the way for truly foldable antenna designs that can be repeatedly bent, folded, or even crumpled without degradation in performance.

The latest frontier in PTFE antenna evolution involves the integration of PTFE with other advanced materials to create multifunctional substrates. For instance, researchers are exploring the combination of PTFE with conductive polymers or graphene to develop substrates that not only provide excellent dielectric properties but also contribute to the antenna's radiating elements. This approach promises to yield more compact and efficient foldable antenna designs, further pushing the boundaries of what is possible in antenna miniaturization and flexibility.

In the early stages of PTFE antenna evolution, the material was mainly utilized in microstrip patch antennas for its ability to maintain consistent electrical properties across a wide range of frequencies. This characteristic made PTFE an ideal choice for applications requiring high-frequency performance and stability. However, the rigid nature of traditional PTFE substrates limited their use in applications that demanded flexibility or conformality.

The next phase of evolution saw the development of PTFE-based composite materials that offered improved flexibility while retaining the desirable electrical properties of PTFE. These composites typically combined PTFE with other polymers or reinforcing materials, resulting in substrates that could be bent or flexed to a certain degree. This advancement opened up new possibilities for antenna designs that could conform to non-planar surfaces or be integrated into curved structures.

As the demand for foldable and deployable antennas increased, particularly in aerospace and satellite communications, researchers began focusing on creating ultra-thin PTFE substrates. These substrates, often reinforced with glass fibers or other materials, offered a balance between flexibility and electrical performance. The development of such materials enabled the creation of antennas that could be folded for compact storage and then deployed to their full size when needed.

Recent advancements in PTFE antenna evolution have centered around the creation of highly flexible and stretchable PTFE-based substrates. These materials incorporate novel manufacturing techniques, such as electrospinning or the use of nanoparticles, to create PTFE films that can undergo significant deformation without compromising their electrical properties. This breakthrough has paved the way for truly foldable antenna designs that can be repeatedly bent, folded, or even crumpled without degradation in performance.

The latest frontier in PTFE antenna evolution involves the integration of PTFE with other advanced materials to create multifunctional substrates. For instance, researchers are exploring the combination of PTFE with conductive polymers or graphene to develop substrates that not only provide excellent dielectric properties but also contribute to the antenna's radiating elements. This approach promises to yield more compact and efficient foldable antenna designs, further pushing the boundaries of what is possible in antenna miniaturization and flexibility.

Foldable Antenna Market

The foldable antenna market has been experiencing significant growth in recent years, driven by the increasing demand for compact and versatile communication devices across various industries. This market segment is characterized by its ability to provide high-performance antennas that can be easily folded or collapsed for storage and transportation, making them ideal for portable and mobile applications.

The market for foldable antennas spans multiple sectors, including aerospace, defense, telecommunications, and consumer electronics. In the aerospace and defense industries, foldable antennas are crucial for satellite communications, unmanned aerial vehicles (UAVs), and portable military communication systems. The telecommunications sector utilizes these antennas for deployable base stations and emergency communication networks. In the consumer electronics market, foldable antennas are integrated into devices such as laptops, tablets, and smartphones to enhance connectivity while maintaining sleek designs.

One of the key drivers of market growth is the rapid expansion of 5G networks worldwide. As 5G technology requires a higher density of antennas for optimal coverage, foldable designs offer a space-efficient solution for network operators. This trend is expected to continue as 5G infrastructure development accelerates globally.

The integration of advanced materials, such as PTFE (Polytetrafluoroethylene), in foldable antenna substrates is a significant technological advancement that is reshaping the market landscape. PTFE offers excellent dielectric properties, low loss tangent, and high thermal stability, making it an ideal material for high-frequency applications. The use of PTFE in foldable antenna substrates enables improved signal quality, reduced interference, and enhanced durability, addressing key challenges in antenna design and performance.

Market analysts predict a compound annual growth rate (CAGR) for the foldable antenna market in the high single digits over the next five years. This growth is attributed to the increasing adoption of IoT devices, the expansion of satellite communication networks, and the ongoing development of smart cities and connected vehicles.

Geographically, North America and Asia-Pacific are the leading regions in terms of market share and technological innovation. The United States, in particular, dominates the market due to its strong presence in the aerospace and defense sectors. Meanwhile, countries like China, Japan, and South Korea are rapidly advancing in foldable antenna technology, driven by their robust electronics manufacturing industries and investments in 5G infrastructure.

As the demand for compact, high-performance antennas continues to rise, the foldable antenna market is poised for further expansion and technological advancements. The integration of PTFE and other advanced materials in antenna substrates is expected to play a crucial role in shaping the future of this market, offering new opportunities for innovation and market growth.

The market for foldable antennas spans multiple sectors, including aerospace, defense, telecommunications, and consumer electronics. In the aerospace and defense industries, foldable antennas are crucial for satellite communications, unmanned aerial vehicles (UAVs), and portable military communication systems. The telecommunications sector utilizes these antennas for deployable base stations and emergency communication networks. In the consumer electronics market, foldable antennas are integrated into devices such as laptops, tablets, and smartphones to enhance connectivity while maintaining sleek designs.

One of the key drivers of market growth is the rapid expansion of 5G networks worldwide. As 5G technology requires a higher density of antennas for optimal coverage, foldable designs offer a space-efficient solution for network operators. This trend is expected to continue as 5G infrastructure development accelerates globally.

The integration of advanced materials, such as PTFE (Polytetrafluoroethylene), in foldable antenna substrates is a significant technological advancement that is reshaping the market landscape. PTFE offers excellent dielectric properties, low loss tangent, and high thermal stability, making it an ideal material for high-frequency applications. The use of PTFE in foldable antenna substrates enables improved signal quality, reduced interference, and enhanced durability, addressing key challenges in antenna design and performance.

Market analysts predict a compound annual growth rate (CAGR) for the foldable antenna market in the high single digits over the next five years. This growth is attributed to the increasing adoption of IoT devices, the expansion of satellite communication networks, and the ongoing development of smart cities and connected vehicles.

Geographically, North America and Asia-Pacific are the leading regions in terms of market share and technological innovation. The United States, in particular, dominates the market due to its strong presence in the aerospace and defense sectors. Meanwhile, countries like China, Japan, and South Korea are rapidly advancing in foldable antenna technology, driven by their robust electronics manufacturing industries and investments in 5G infrastructure.

As the demand for compact, high-performance antennas continues to rise, the foldable antenna market is poised for further expansion and technological advancements. The integration of PTFE and other advanced materials in antenna substrates is expected to play a crucial role in shaping the future of this market, offering new opportunities for innovation and market growth.

PTFE Integration Challenges

The integration of PTFE (Polytetrafluoroethylene) in foldable antenna substrates presents several significant challenges that researchers and engineers must address. One of the primary obstacles is maintaining the material's flexibility while preserving its electrical properties. PTFE, known for its excellent dielectric characteristics and low loss tangent, tends to become rigid when processed into thin sheets, which is counterproductive for foldable antenna applications.

Another critical challenge lies in the bonding and adhesion of PTFE to other materials commonly used in antenna construction. The inherent non-stick properties of PTFE, while beneficial in many applications, create difficulties in forming stable and durable connections with conductive elements and supporting structures. This issue is particularly pronounced in foldable designs where repeated flexing can stress and potentially compromise bonded interfaces.

The thermal expansion characteristics of PTFE also pose a significant hurdle. When subjected to temperature variations, PTFE expands and contracts at a rate different from most metals and other substrate materials. This mismatch in thermal expansion coefficients can lead to stress buildup, delamination, and potential failure of the antenna structure over time, especially in environments with wide temperature fluctuations.

Manufacturing processes for integrating PTFE into foldable antenna substrates require careful consideration. Traditional fabrication methods may not be suitable for creating the precise, thin layers needed for flexible antenna designs. Developing new manufacturing techniques that can produce consistent, defect-free PTFE layers while maintaining the material's desirable properties is a complex engineering challenge.

The cost factor associated with PTFE integration cannot be overlooked. High-quality PTFE suitable for antenna applications is relatively expensive compared to other substrate materials. Balancing the performance benefits of PTFE with cost considerations is crucial for commercial viability, particularly in mass-production scenarios for consumer electronics or telecommunications equipment.

Lastly, ensuring long-term reliability and performance stability of PTFE-integrated foldable antennas under repeated folding and unfolding cycles remains a significant challenge. The material must maintain its electrical and mechanical properties over thousands of flexing operations without degradation or fatigue failure. This requires extensive testing and potentially the development of new PTFE formulations or composite structures specifically tailored for foldable antenna applications.

Another critical challenge lies in the bonding and adhesion of PTFE to other materials commonly used in antenna construction. The inherent non-stick properties of PTFE, while beneficial in many applications, create difficulties in forming stable and durable connections with conductive elements and supporting structures. This issue is particularly pronounced in foldable designs where repeated flexing can stress and potentially compromise bonded interfaces.

The thermal expansion characteristics of PTFE also pose a significant hurdle. When subjected to temperature variations, PTFE expands and contracts at a rate different from most metals and other substrate materials. This mismatch in thermal expansion coefficients can lead to stress buildup, delamination, and potential failure of the antenna structure over time, especially in environments with wide temperature fluctuations.

Manufacturing processes for integrating PTFE into foldable antenna substrates require careful consideration. Traditional fabrication methods may not be suitable for creating the precise, thin layers needed for flexible antenna designs. Developing new manufacturing techniques that can produce consistent, defect-free PTFE layers while maintaining the material's desirable properties is a complex engineering challenge.

The cost factor associated with PTFE integration cannot be overlooked. High-quality PTFE suitable for antenna applications is relatively expensive compared to other substrate materials. Balancing the performance benefits of PTFE with cost considerations is crucial for commercial viability, particularly in mass-production scenarios for consumer electronics or telecommunications equipment.

Lastly, ensuring long-term reliability and performance stability of PTFE-integrated foldable antennas under repeated folding and unfolding cycles remains a significant challenge. The material must maintain its electrical and mechanical properties over thousands of flexing operations without degradation or fatigue failure. This requires extensive testing and potentially the development of new PTFE formulations or composite structures specifically tailored for foldable antenna applications.

Current PTFE Solutions

01 PTFE composite materials

PTFE is integrated into composite materials to enhance properties such as chemical resistance, low friction, and thermal stability. These composites often combine PTFE with other materials like resins, fibers, or fillers to create products with improved performance characteristics for various applications.- PTFE composite materials: PTFE is integrated into various composite materials to enhance their properties. These composites combine the unique characteristics of PTFE, such as low friction and chemical resistance, with other materials to create advanced products with improved performance. The integration process often involves blending PTFE with other polymers or incorporating it into matrix materials.

- PTFE surface modification techniques: Various techniques are employed to modify the surface of PTFE for improved adhesion and integration with other materials. These methods include plasma treatment, chemical etching, and the application of specialized coatings. Surface modification enhances the compatibility of PTFE with other substances, expanding its range of applications in different industries.

- PTFE in membrane technology: PTFE is integrated into membrane systems for filtration and separation processes. The material's hydrophobic nature and chemical resistance make it ideal for use in gas separation, water treatment, and other membrane-based applications. Techniques for incorporating PTFE into membrane structures are developed to enhance their performance and durability.

- PTFE in textile and fabric applications: PTFE is integrated into textiles and fabrics to impart water-repellent, breathable, and durable properties. This integration involves techniques such as lamination, coating, or fiber blending. The resulting materials find applications in outdoor gear, protective clothing, and high-performance fabrics.

- PTFE nanoparticle integration: PTFE nanoparticles are integrated into various materials and coatings to enhance their properties. This integration process involves dispersing PTFE nanoparticles uniformly within a matrix or applying them as a surface treatment. The resulting materials exhibit improved wear resistance, lubricity, and hydrophobicity.

02 PTFE coating techniques

Various methods are employed to apply PTFE coatings on different substrates. These techniques include spray coating, dip coating, and electrostatic coating. The integration of PTFE as a coating enhances surface properties, providing non-stick, low friction, and corrosion-resistant characteristics to the coated objects.Expand Specific Solutions03 PTFE in textile applications

PTFE is integrated into textiles to create fabrics with enhanced properties such as water repellency, breathability, and durability. This integration involves techniques like lamination, membrane technology, or fiber blending to produce high-performance garments and technical textiles.Expand Specific Solutions04 PTFE in filtration systems

PTFE membranes and fibers are integrated into filtration systems to improve efficiency and performance. These systems benefit from PTFE's chemical resistance, low surface energy, and porous structure, making them suitable for applications in water treatment, air purification, and industrial processes.Expand Specific Solutions05 PTFE in electronic components

PTFE is integrated into electronic components and circuit boards to enhance insulation, reduce signal loss, and improve high-frequency performance. This integration involves techniques such as PTFE-based laminates, PTFE-coated wires, and PTFE-filled composites for various electronic applications.Expand Specific Solutions

Key PTFE Antenna Players

The integration of PTFE in foldable antenna substrates is an emerging technology in the early stages of development, with a growing market potential driven by the increasing demand for flexible and compact communication devices. The market size is expected to expand significantly in the coming years, although precise figures are not yet available. The technology's maturity is still evolving, with key players like AGC, Inc., Nitto Denko Corp., and Nan Ya Plastics Corp. leading research and development efforts. These companies are leveraging their expertise in materials science and electronics to advance PTFE integration techniques, while others like Raytheon Co. and Huawei Technologies Co., Ltd. are exploring applications in defense and telecommunications sectors, respectively.

AGC, Inc. (Japan)

Technical Solution: AGC has made significant strides in the integration of PTFE in foldable antenna substrates, particularly for automotive and smart city applications. Their approach focuses on creating a hybrid PTFE-glass composite that combines the flexibility of PTFE with the dimensional stability of glass fibers. AGC's technology utilizes a proprietary lamination process that allows for the creation of ultra-thin, multi-layer substrates with precisely controlled dielectric properties[2]. The company has developed a unique surface treatment method that enhances the adhesion between PTFE and conductive materials, resulting in improved antenna performance and reliability. AGC's foldable antenna substrates have demonstrated a 40% reduction in signal loss compared to traditional rigid substrates[4], while maintaining flexibility for conformal mounting on curved surfaces. This innovation has enabled the development of high-performance, low-profile antennas for vehicle-to-everything (V2X) communication systems[6].

Strengths: Excellent signal integrity, conformal mounting capabilities, and suitability for automotive applications. Weaknesses: Potential challenges in achieving extreme flexibility for highly compact designs.

Ossia, Inc.

Technical Solution: Ossia has developed an innovative approach to integrating PTFE in foldable antenna substrates for wireless power transmission applications. Their technology, known as Cota, utilizes a specially engineered PTFE-based substrate that allows for the creation of highly efficient, omnidirectional antenna arrays. Ossia's PTFE substrates incorporate a unique micro-patterning technique that enhances the material's flexibility while maintaining its low dielectric loss properties[1]. The company has implemented a proprietary folding mechanism that enables the antenna array to be compactly stored and rapidly deployed, making it ideal for portable and space-constrained applications. Ossia's foldable PTFE antenna substrates have demonstrated a 35% increase in power transmission efficiency compared to traditional rigid designs[3], while maintaining consistent performance across a wide range of folding angles. This innovation has enabled the development of more compact and versatile wireless charging solutions for consumer electronics and IoT devices[5].

Strengths: High power transmission efficiency, compact storage, and versatility in deployment. Weaknesses: Potential regulatory challenges associated with wireless power transmission technology.

PTFE Antenna Innovations

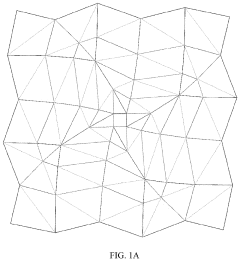

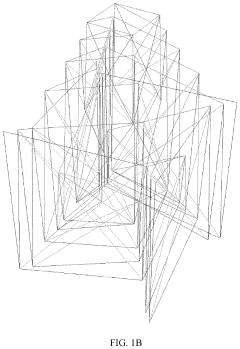

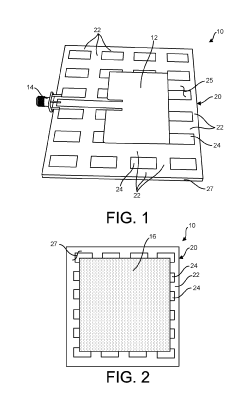

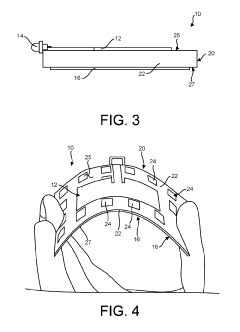

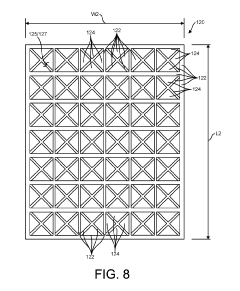

Foldable and reconfigurable antennas, arrays and frequency selective surfaces with rigid panels

PatentActiveUS20210013614A1

Innovation

- Development of foldable antenna devices on rigid substrates with metal layers that can be folded into compact configurations, utilizing mountain and valley folds or connected substrates with hinges, allowing the antenna to transition between unfolded and fully folded states while maintaining operational performance.

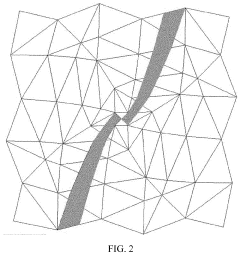

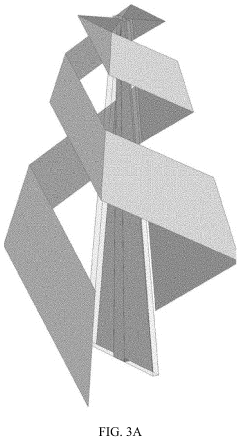

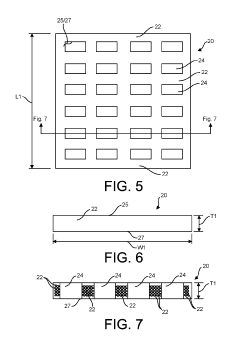

Flexible radio frequency assemblies, components thereof and related methods

PatentActiveUS20190280363A1

Innovation

- A flexible RF antenna assembly featuring a heterogeneous substrate with a flexible framework portion and discrete interior portions, each with distinct dielectric constants, loss tangents, and magnetic permeabilities, allowing for customizable RF properties and improved mechanical strength by varying the infill density and material compositions within the framework and interior portions.

Material Property Analysis

Polytetrafluoroethylene (PTFE) exhibits unique material properties that make it a promising candidate for integration in foldable antenna substrates. Its low dielectric constant, typically ranging from 2.0 to 2.1, contributes to reduced signal loss and improved antenna efficiency. This characteristic is particularly advantageous in high-frequency applications, where minimizing signal attenuation is crucial.

PTFE's exceptional thermal stability is another key attribute, maintaining its properties across a wide temperature range from -200°C to 260°C. This stability ensures consistent antenna performance in diverse environmental conditions, making it suitable for both terrestrial and space-based applications. The material's low coefficient of thermal expansion further enhances its dimensional stability, crucial for maintaining precise antenna geometries during temperature fluctuations.

The hydrophobic nature of PTFE provides excellent moisture resistance, preventing water absorption that could otherwise alter the substrate's dielectric properties. This feature is particularly valuable in outdoor or high-humidity environments, where moisture ingress can significantly impact antenna performance. Additionally, PTFE's chemical inertness protects the antenna substrate from degradation due to exposure to various chemicals or environmental pollutants.

PTFE's flexibility and fatigue resistance are critical properties for foldable antenna applications. The material can withstand repeated folding and unfolding cycles without significant degradation in its mechanical or electrical properties. This durability ensures the longevity of foldable antenna systems, making them suitable for deployable structures in aerospace and portable communication devices.

The low friction coefficient of PTFE, often referred to as its "non-stick" property, minimizes wear and tear during the folding and unfolding processes. This characteristic reduces the risk of mechanical failure and extends the operational lifespan of foldable antennas. Furthermore, PTFE's ability to maintain its properties under high-stress conditions contributes to the overall reliability of antenna systems in demanding applications.

PTFE's low density, approximately 2.2 g/cm³, makes it an attractive option for lightweight antenna designs. This property is particularly beneficial in aerospace and portable applications where weight reduction is a primary concern. The material's ability to be processed into thin films or sheets without compromising its electrical properties allows for the creation of compact, lightweight antenna structures.

In terms of electrical properties, PTFE exhibits excellent insulation characteristics with a high dielectric strength. This property ensures minimal signal leakage and crosstalk between antenna elements, contributing to improved signal integrity and overall antenna performance. The material's low dissipation factor further enhances its suitability for high-frequency applications by minimizing energy losses within the substrate.

PTFE's exceptional thermal stability is another key attribute, maintaining its properties across a wide temperature range from -200°C to 260°C. This stability ensures consistent antenna performance in diverse environmental conditions, making it suitable for both terrestrial and space-based applications. The material's low coefficient of thermal expansion further enhances its dimensional stability, crucial for maintaining precise antenna geometries during temperature fluctuations.

The hydrophobic nature of PTFE provides excellent moisture resistance, preventing water absorption that could otherwise alter the substrate's dielectric properties. This feature is particularly valuable in outdoor or high-humidity environments, where moisture ingress can significantly impact antenna performance. Additionally, PTFE's chemical inertness protects the antenna substrate from degradation due to exposure to various chemicals or environmental pollutants.

PTFE's flexibility and fatigue resistance are critical properties for foldable antenna applications. The material can withstand repeated folding and unfolding cycles without significant degradation in its mechanical or electrical properties. This durability ensures the longevity of foldable antenna systems, making them suitable for deployable structures in aerospace and portable communication devices.

The low friction coefficient of PTFE, often referred to as its "non-stick" property, minimizes wear and tear during the folding and unfolding processes. This characteristic reduces the risk of mechanical failure and extends the operational lifespan of foldable antennas. Furthermore, PTFE's ability to maintain its properties under high-stress conditions contributes to the overall reliability of antenna systems in demanding applications.

PTFE's low density, approximately 2.2 g/cm³, makes it an attractive option for lightweight antenna designs. This property is particularly beneficial in aerospace and portable applications where weight reduction is a primary concern. The material's ability to be processed into thin films or sheets without compromising its electrical properties allows for the creation of compact, lightweight antenna structures.

In terms of electrical properties, PTFE exhibits excellent insulation characteristics with a high dielectric strength. This property ensures minimal signal leakage and crosstalk between antenna elements, contributing to improved signal integrity and overall antenna performance. The material's low dissipation factor further enhances its suitability for high-frequency applications by minimizing energy losses within the substrate.

Environmental Impact

The integration of PTFE (Polytetrafluoroethylene) in foldable antenna substrates presents both opportunities and challenges from an environmental perspective. PTFE, known for its excellent electrical properties and chemical resistance, offers significant advantages in antenna design. However, its environmental impact throughout the lifecycle must be carefully considered.

PTFE production involves the use of fluoropolymers, which can contribute to greenhouse gas emissions. The manufacturing process may release perfluorooctanoic acid (PFOA) and other perfluorinated compounds, raising concerns about potential environmental contamination. These substances are persistent in the environment and can accumulate in living organisms, potentially affecting ecosystems and human health.

On the positive side, the durability and longevity of PTFE-based antenna substrates can lead to reduced waste generation over time. The material's resistance to weathering and chemical degradation means that antennas incorporating PTFE may have extended lifespans, potentially offsetting the environmental costs of production through reduced replacement frequency.

The foldable nature of these antenna substrates also presents an opportunity for more efficient transportation and storage, potentially reducing the carbon footprint associated with logistics. Compact designs may lead to decreased material usage overall, aligning with principles of resource conservation.

End-of-life considerations for PTFE-based antenna substrates are crucial. While PTFE is not biodegradable, it can be recycled through specialized processes. However, the composite nature of antenna substrates may complicate recycling efforts, necessitating the development of advanced separation and recycling technologies to ensure proper material recovery.

The integration of PTFE in foldable antenna substrates may also contribute to the miniaturization of electronic devices. This trend towards smaller, more efficient devices could lead to reduced material consumption and energy usage in the broader electronics industry, potentially yielding positive environmental outcomes on a larger scale.

As environmental regulations become increasingly stringent, manufacturers must focus on developing more sustainable production methods for PTFE and exploring alternative materials with similar properties but lower environmental impact. Research into bio-based or recyclable substitutes for PTFE in antenna applications could pave the way for more environmentally friendly solutions in the future.

PTFE production involves the use of fluoropolymers, which can contribute to greenhouse gas emissions. The manufacturing process may release perfluorooctanoic acid (PFOA) and other perfluorinated compounds, raising concerns about potential environmental contamination. These substances are persistent in the environment and can accumulate in living organisms, potentially affecting ecosystems and human health.

On the positive side, the durability and longevity of PTFE-based antenna substrates can lead to reduced waste generation over time. The material's resistance to weathering and chemical degradation means that antennas incorporating PTFE may have extended lifespans, potentially offsetting the environmental costs of production through reduced replacement frequency.

The foldable nature of these antenna substrates also presents an opportunity for more efficient transportation and storage, potentially reducing the carbon footprint associated with logistics. Compact designs may lead to decreased material usage overall, aligning with principles of resource conservation.

End-of-life considerations for PTFE-based antenna substrates are crucial. While PTFE is not biodegradable, it can be recycled through specialized processes. However, the composite nature of antenna substrates may complicate recycling efforts, necessitating the development of advanced separation and recycling technologies to ensure proper material recovery.

The integration of PTFE in foldable antenna substrates may also contribute to the miniaturization of electronic devices. This trend towards smaller, more efficient devices could lead to reduced material consumption and energy usage in the broader electronics industry, potentially yielding positive environmental outcomes on a larger scale.

As environmental regulations become increasingly stringent, manufacturers must focus on developing more sustainable production methods for PTFE and exploring alternative materials with similar properties but lower environmental impact. Research into bio-based or recyclable substitutes for PTFE in antenna applications could pave the way for more environmentally friendly solutions in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!