How to Enhance Safety Standards with PTFE?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Safety Enhancement Background and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has been a revolutionary material in various industries since its accidental discovery in 1938. Its unique properties, including chemical inertness, low friction coefficient, and high temperature resistance, have made it indispensable in numerous applications. However, as with any advanced material, ensuring safety in its production, handling, and use has become increasingly crucial.

The evolution of PTFE safety standards has been closely tied to the material's expanding applications and growing understanding of its potential risks. Initially, PTFE was primarily used in industrial settings, with limited awareness of its long-term health and environmental impacts. As its use proliferated into consumer products, from cookware to clothing, the need for comprehensive safety standards became apparent.

In recent years, concerns have emerged regarding the potential health risks associated with PTFE, particularly when subjected to high temperatures or degradation. These concerns have prompted a renewed focus on enhancing safety standards across the entire PTFE lifecycle, from manufacturing to disposal.

The primary objective of enhancing PTFE safety standards is to mitigate risks while maximizing the material's benefits. This involves addressing several key areas: improving manufacturing processes to reduce harmful emissions, developing safer handling protocols for workers, ensuring product integrity to prevent degradation during use, and establishing proper disposal and recycling methods to minimize environmental impact.

Another critical goal is to increase transparency and public awareness about PTFE's properties, benefits, and potential risks. This includes clear labeling of PTFE-containing products and providing comprehensive safety information to consumers and industrial users alike.

Technological advancements play a crucial role in achieving these objectives. Innovations in production techniques aim to reduce the use of perfluorooctanoic acid (PFOA) and other potentially harmful substances in PTFE manufacturing. Additionally, the development of more sensitive detection methods enables better monitoring of PTFE degradation and potential release of harmful substances.

Regulatory bodies worldwide are actively involved in setting and updating PTFE safety standards. These efforts are driven by ongoing research into the long-term effects of PTFE exposure and the material's environmental persistence. The goal is to establish globally harmonized standards that ensure consistent safety measures across different regions and industries.

As we look to the future, the enhancement of PTFE safety standards is expected to focus on sustainable production methods, improved product design for longevity and safety, and advanced end-of-life management strategies. These efforts will not only address current safety concerns but also anticipate future challenges as PTFE continues to find new applications in emerging technologies.

The evolution of PTFE safety standards has been closely tied to the material's expanding applications and growing understanding of its potential risks. Initially, PTFE was primarily used in industrial settings, with limited awareness of its long-term health and environmental impacts. As its use proliferated into consumer products, from cookware to clothing, the need for comprehensive safety standards became apparent.

In recent years, concerns have emerged regarding the potential health risks associated with PTFE, particularly when subjected to high temperatures or degradation. These concerns have prompted a renewed focus on enhancing safety standards across the entire PTFE lifecycle, from manufacturing to disposal.

The primary objective of enhancing PTFE safety standards is to mitigate risks while maximizing the material's benefits. This involves addressing several key areas: improving manufacturing processes to reduce harmful emissions, developing safer handling protocols for workers, ensuring product integrity to prevent degradation during use, and establishing proper disposal and recycling methods to minimize environmental impact.

Another critical goal is to increase transparency and public awareness about PTFE's properties, benefits, and potential risks. This includes clear labeling of PTFE-containing products and providing comprehensive safety information to consumers and industrial users alike.

Technological advancements play a crucial role in achieving these objectives. Innovations in production techniques aim to reduce the use of perfluorooctanoic acid (PFOA) and other potentially harmful substances in PTFE manufacturing. Additionally, the development of more sensitive detection methods enables better monitoring of PTFE degradation and potential release of harmful substances.

Regulatory bodies worldwide are actively involved in setting and updating PTFE safety standards. These efforts are driven by ongoing research into the long-term effects of PTFE exposure and the material's environmental persistence. The goal is to establish globally harmonized standards that ensure consistent safety measures across different regions and industries.

As we look to the future, the enhancement of PTFE safety standards is expected to focus on sustainable production methods, improved product design for longevity and safety, and advanced end-of-life management strategies. These efforts will not only address current safety concerns but also anticipate future challenges as PTFE continues to find new applications in emerging technologies.

Market Demand for PTFE Safety Solutions

The market demand for PTFE safety solutions has been steadily increasing in recent years, driven by growing awareness of workplace safety and stringent regulatory requirements across various industries. PTFE, known for its exceptional chemical resistance, low friction, and high-temperature stability, has become a crucial material in enhancing safety standards across multiple sectors.

In the industrial sector, there is a significant demand for PTFE-based safety solutions in chemical processing plants, oil refineries, and manufacturing facilities. These environments often involve exposure to corrosive chemicals, extreme temperatures, and high-pressure conditions, making PTFE an ideal material for protective equipment, seals, and linings. The market for PTFE-coated personal protective equipment (PPE) such as gloves, aprons, and face shields has seen substantial growth, as these products offer superior protection against chemical splashes and thermal hazards.

The automotive industry has also contributed to the rising demand for PTFE safety solutions. With the increasing focus on vehicle safety and performance, PTFE is being utilized in brake systems, fuel lines, and engine components to enhance reliability and reduce the risk of failure. The material's low friction properties make it particularly valuable in improving brake performance and reducing wear, thereby extending the lifespan of critical safety components.

In the aerospace sector, the demand for PTFE-based safety solutions is driven by the need for lightweight, durable materials that can withstand extreme conditions. PTFE is used in aircraft wiring insulation, fuel systems, and hydraulic seals, where its resistance to high temperatures and chemicals is crucial for maintaining safety standards in flight operations.

The healthcare industry represents another significant market for PTFE safety solutions. The material's biocompatibility and non-stick properties make it ideal for medical devices, implants, and surgical instruments. There is a growing demand for PTFE-coated medical equipment that reduces the risk of infections and improves patient safety during procedures.

Environmental concerns and sustainability initiatives have also influenced the market demand for PTFE safety solutions. Industries are seeking eco-friendly alternatives to traditional materials, and PTFE's long lifespan and recyclability make it an attractive option. This has led to increased adoption in waste management systems, water treatment facilities, and renewable energy installations, where PTFE components contribute to safer and more efficient operations.

The construction industry has shown a rising interest in PTFE-based safety solutions, particularly in the development of fire-resistant building materials. PTFE's high melting point and low flammability make it valuable for improving the fire safety of structures, leading to increased demand for PTFE-infused insulation, coatings, and sealants.

As global safety standards continue to evolve and become more stringent, the market for PTFE safety solutions is expected to expand further. Industries are increasingly recognizing the long-term cost benefits of investing in high-quality, PTFE-based safety equipment and materials, driving innovation and product development in this sector.

In the industrial sector, there is a significant demand for PTFE-based safety solutions in chemical processing plants, oil refineries, and manufacturing facilities. These environments often involve exposure to corrosive chemicals, extreme temperatures, and high-pressure conditions, making PTFE an ideal material for protective equipment, seals, and linings. The market for PTFE-coated personal protective equipment (PPE) such as gloves, aprons, and face shields has seen substantial growth, as these products offer superior protection against chemical splashes and thermal hazards.

The automotive industry has also contributed to the rising demand for PTFE safety solutions. With the increasing focus on vehicle safety and performance, PTFE is being utilized in brake systems, fuel lines, and engine components to enhance reliability and reduce the risk of failure. The material's low friction properties make it particularly valuable in improving brake performance and reducing wear, thereby extending the lifespan of critical safety components.

In the aerospace sector, the demand for PTFE-based safety solutions is driven by the need for lightweight, durable materials that can withstand extreme conditions. PTFE is used in aircraft wiring insulation, fuel systems, and hydraulic seals, where its resistance to high temperatures and chemicals is crucial for maintaining safety standards in flight operations.

The healthcare industry represents another significant market for PTFE safety solutions. The material's biocompatibility and non-stick properties make it ideal for medical devices, implants, and surgical instruments. There is a growing demand for PTFE-coated medical equipment that reduces the risk of infections and improves patient safety during procedures.

Environmental concerns and sustainability initiatives have also influenced the market demand for PTFE safety solutions. Industries are seeking eco-friendly alternatives to traditional materials, and PTFE's long lifespan and recyclability make it an attractive option. This has led to increased adoption in waste management systems, water treatment facilities, and renewable energy installations, where PTFE components contribute to safer and more efficient operations.

The construction industry has shown a rising interest in PTFE-based safety solutions, particularly in the development of fire-resistant building materials. PTFE's high melting point and low flammability make it valuable for improving the fire safety of structures, leading to increased demand for PTFE-infused insulation, coatings, and sealants.

As global safety standards continue to evolve and become more stringent, the market for PTFE safety solutions is expected to expand further. Industries are increasingly recognizing the long-term cost benefits of investing in high-quality, PTFE-based safety equipment and materials, driving innovation and product development in this sector.

Current PTFE Safety Challenges and Limitations

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has been widely used in various industries due to its unique properties. However, despite its numerous advantages, PTFE still faces several safety challenges and limitations that need to be addressed to enhance its overall safety standards.

One of the primary concerns with PTFE is its thermal stability at high temperatures. While PTFE is generally stable up to 260°C (500°F), it can begin to degrade and release toxic fumes when exposed to temperatures above this threshold. This poses significant risks in applications where PTFE-coated materials may be subjected to extreme heat, such as in certain industrial processes or firefighting equipment.

Another challenge lies in the potential for PTFE particles to become airborne during manufacturing, processing, or wear of PTFE-containing products. These particles, particularly when in the nanoscale range, can pose respiratory hazards if inhaled. The long-term health effects of exposure to PTFE nanoparticles are not yet fully understood, necessitating further research and improved safety measures in production environments.

The chemical resistance of PTFE, while generally an advantage, can also present challenges in certain scenarios. PTFE's inertness makes it difficult to bond with other materials, which can lead to potential failure points in composite structures or coatings. This limitation can compromise the integrity and safety of products in applications where strong adhesion is crucial.

PTFE's low friction properties, while beneficial in many applications, can sometimes lead to unexpected slips or falls when used in flooring or surface coatings. This presents a safety concern in workplace environments where slip resistance is critical. Developing PTFE formulations or surface treatments that maintain low friction while improving grip remains a challenge.

The disposal and recycling of PTFE products also pose environmental and safety concerns. PTFE is not biodegradable and can persist in the environment for extended periods. Incineration of PTFE waste can release harmful substances, including hydrofluoric acid and perfluoroisobutylene. Developing safe and efficient recycling methods for PTFE materials is an ongoing challenge that needs to be addressed to improve its overall environmental safety profile.

Lastly, the potential for PTFE to release perfluorooctanoic acid (PFOA) and other perfluorinated compounds during production or degradation has raised concerns about long-term environmental and health impacts. While many manufacturers have phased out the use of PFOA in PTFE production, ensuring the complete elimination of these persistent organic pollutants from the PTFE lifecycle remains a significant challenge.

Addressing these safety challenges and limitations requires a multifaceted approach, including ongoing research into PTFE alternatives, improved manufacturing processes, and the development of enhanced safety protocols. As industries continue to rely on PTFE for its unique properties, overcoming these hurdles is crucial for enhancing overall safety standards and ensuring the sustainable use of this versatile material.

One of the primary concerns with PTFE is its thermal stability at high temperatures. While PTFE is generally stable up to 260°C (500°F), it can begin to degrade and release toxic fumes when exposed to temperatures above this threshold. This poses significant risks in applications where PTFE-coated materials may be subjected to extreme heat, such as in certain industrial processes or firefighting equipment.

Another challenge lies in the potential for PTFE particles to become airborne during manufacturing, processing, or wear of PTFE-containing products. These particles, particularly when in the nanoscale range, can pose respiratory hazards if inhaled. The long-term health effects of exposure to PTFE nanoparticles are not yet fully understood, necessitating further research and improved safety measures in production environments.

The chemical resistance of PTFE, while generally an advantage, can also present challenges in certain scenarios. PTFE's inertness makes it difficult to bond with other materials, which can lead to potential failure points in composite structures or coatings. This limitation can compromise the integrity and safety of products in applications where strong adhesion is crucial.

PTFE's low friction properties, while beneficial in many applications, can sometimes lead to unexpected slips or falls when used in flooring or surface coatings. This presents a safety concern in workplace environments where slip resistance is critical. Developing PTFE formulations or surface treatments that maintain low friction while improving grip remains a challenge.

The disposal and recycling of PTFE products also pose environmental and safety concerns. PTFE is not biodegradable and can persist in the environment for extended periods. Incineration of PTFE waste can release harmful substances, including hydrofluoric acid and perfluoroisobutylene. Developing safe and efficient recycling methods for PTFE materials is an ongoing challenge that needs to be addressed to improve its overall environmental safety profile.

Lastly, the potential for PTFE to release perfluorooctanoic acid (PFOA) and other perfluorinated compounds during production or degradation has raised concerns about long-term environmental and health impacts. While many manufacturers have phased out the use of PFOA in PTFE production, ensuring the complete elimination of these persistent organic pollutants from the PTFE lifecycle remains a significant challenge.

Addressing these safety challenges and limitations requires a multifaceted approach, including ongoing research into PTFE alternatives, improved manufacturing processes, and the development of enhanced safety protocols. As industries continue to rely on PTFE for its unique properties, overcoming these hurdles is crucial for enhancing overall safety standards and ensuring the sustainable use of this versatile material.

Existing PTFE Safety Enhancement Methods

01 PTFE safety in medical devices

PTFE is widely used in medical devices due to its biocompatibility and non-stick properties. Safety standards for PTFE in medical applications focus on ensuring the material's purity, minimizing the risk of contamination, and evaluating its long-term performance in the human body. These standards often include testing for chemical stability, leaching, and potential adverse reactions.- PTFE safety in medical devices: PTFE is widely used in medical devices due to its biocompatibility and non-stick properties. Safety standards for PTFE in medical applications focus on ensuring the material's purity, stability, and resistance to degradation. Manufacturers must adhere to strict guidelines for processing and sterilization to prevent contamination and maintain the integrity of PTFE-coated devices.

- PTFE safety in industrial applications: Industrial use of PTFE requires adherence to safety standards related to chemical resistance, temperature tolerance, and wear resistance. These standards ensure that PTFE components maintain their integrity in harsh environments, preventing leaks or failures that could lead to safety hazards. Guidelines also cover proper handling and disposal of PTFE materials to minimize environmental impact.

- PTFE safety in food contact materials: Safety standards for PTFE in food contact materials focus on preventing migration of harmful substances into food. Regulations specify maximum allowable levels of certain compounds and require testing to ensure compliance. Manufacturers must use food-grade PTFE and follow specific processing guidelines to maintain the material's inertness and non-stick properties without compromising food safety.

- PTFE safety in personal protective equipment: PTFE is used in various personal protective equipment (PPE) due to its chemical resistance and breathability. Safety standards for PTFE in PPE focus on ensuring the material's effectiveness in protecting against hazardous substances while maintaining user comfort. Guidelines cover aspects such as permeation resistance, durability, and proper decontamination procedures.

- Environmental and disposal safety standards for PTFE: Safety standards for PTFE disposal and environmental impact address concerns about the material's persistence in the environment. Guidelines cover proper disposal methods, recycling procedures, and measures to prevent PTFE particles from entering ecosystems. Manufacturers are required to implement strategies to minimize waste and ensure responsible end-of-life management for PTFE products.

02 PTFE safety in cookware and food contact materials

Safety standards for PTFE used in cookware and food contact materials primarily address concerns about potential chemical migration into food. These standards typically involve testing for the release of perfluorooctanoic acid (PFOA) and other perfluorinated compounds, as well as evaluating the material's resistance to high temperatures and abrasion. Compliance with food safety regulations is crucial for PTFE-coated products in this category.Expand Specific Solutions03 PTFE safety in industrial applications

In industrial settings, PTFE safety standards focus on the material's performance under extreme conditions, such as high temperatures, pressures, and exposure to chemicals. These standards often include testing for thermal stability, chemical resistance, and mechanical properties. Additionally, safety measures for handling and processing PTFE in industrial environments are addressed to prevent the release of harmful fumes during heating or machining.Expand Specific Solutions04 Environmental and disposal considerations for PTFE

Safety standards related to the environmental impact and disposal of PTFE products are becoming increasingly important. These standards address concerns about the persistence of PTFE in the environment and its potential to break down into harmful substances. Guidelines for proper disposal, recycling, and incineration of PTFE-containing products are developed to minimize environmental risks and ensure compliance with waste management regulations.Expand Specific Solutions05 PTFE safety in personal protective equipment

PTFE is used in various personal protective equipment (PPE) due to its chemical resistance and low friction properties. Safety standards for PTFE in PPE focus on ensuring the material's effectiveness in protecting against specific hazards, such as chemical splashes or extreme temperatures. These standards often include testing for permeation resistance, durability, and compatibility with other materials used in PPE construction.Expand Specific Solutions

Key Players in PTFE Safety Industry

The market for enhancing safety standards with PTFE is in a growth phase, driven by increasing industrial safety regulations and demand for high-performance materials. The global PTFE market size is projected to reach $3.5 billion by 2025, with a CAGR of 6.2%. Technologically, PTFE applications are mature but continue to evolve, particularly in advanced coatings and composites. Key players like DAIKIN INDUSTRIES Ltd., Juhua Group Corp., and Nexans SA are investing in R&D to develop innovative PTFE formulations for safety-critical applications. Universities such as Zhejiang University and China University of Mining & Technology are collaborating with industry to advance PTFE technology, focusing on improved fire resistance, chemical inertness, and durability in extreme environments.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has developed advanced PTFE-based materials with enhanced safety features. Their NEOFLON™ PTFE series incorporates unique polymer structures that improve chemical resistance and thermal stability[1]. The company has also introduced a novel surface treatment technology that enhances the adhesion properties of PTFE, allowing for better integration in composite materials used in safety-critical applications[2]. DAIKIN's research focuses on optimizing the molecular weight distribution of PTFE to achieve a balance between processability and mechanical strength, resulting in materials that maintain their integrity under extreme conditions[3].

Strengths: Industry-leading expertise in fluoropolymers, extensive R&D capabilities, and a wide range of PTFE grades for various applications. Weaknesses: Higher cost compared to standard PTFE materials, which may limit adoption in price-sensitive markets.

Zhejiang University

Technical Solution: Zhejiang University has made significant strides in enhancing PTFE safety standards through innovative research. Their team has developed a novel PTFE nanocomposite that incorporates graphene oxide, resulting in improved flame retardancy and reduced smoke toxicity[4]. The university has also pioneered a surface modification technique for PTFE that enhances its compatibility with other materials, leading to stronger and more durable composites for safety-critical applications[5]. Additionally, their research into PTFE-based coatings has yielded materials with superior chemical resistance and anti-fouling properties, contributing to improved safety in industrial settings[6].

Strengths: Cutting-edge research in PTFE nanocomposites and surface modifications, strong academic partnerships for technology transfer. Weaknesses: Potential challenges in scaling up laboratory innovations to industrial production.

Core Innovations in PTFE Safety Standards

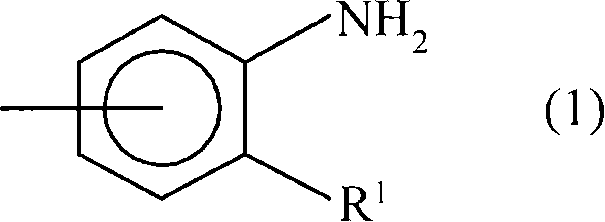

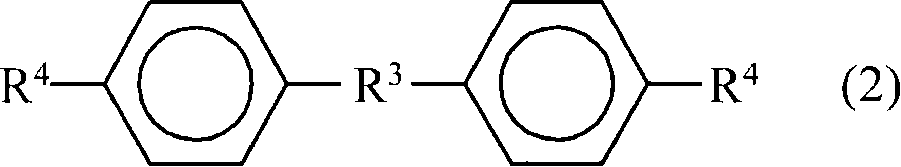

Crosslinkable polytetrafluoroethylene composition, cross-linked polytetrafluoroethylene powder, polytetrafluoro-ethylene moldings, resin blend compositions, and resin blend moldings

PatentInactiveCN101171296A

Innovation

- A cross-linked polytetrafluoroethylene composition containing polytetrafluoroethylene and a cross-linking agent is used to undergo a cross-linking reaction by heating to form a cyclic structure. The obtained cross-linked body can be manufactured by conventional methods such as compression molding and maintains Original strength and surface properties, avoiding anisotropy and inhomogeneity.

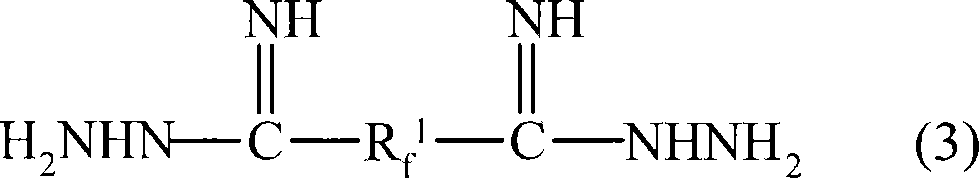

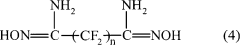

Resin composition with excellent compatibility as well as preparation method and application thereof

PatentActiveCN116656111A

Innovation

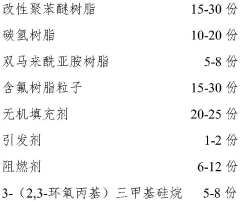

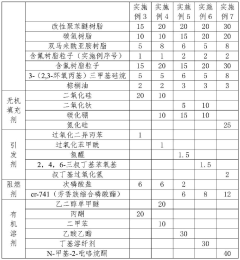

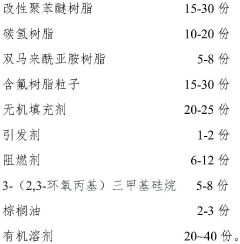

- Using modified polyphenylene ether, hydrocarbon resin and bismaleimide combined with modified fluorine-containing resin particles, PTFE is modified through sodium naphthalene solution chemical treatment to increase its surface energy, and the modified PTFE particles are polymerized with The compounding of matrix polymer improves compatibility and processing performance.

Environmental Impact of PTFE Safety Measures

The implementation of PTFE (Polytetrafluoroethylene) safety measures has significant environmental implications that must be carefully considered. While PTFE itself is chemically inert and non-toxic under normal conditions, its production and disposal processes can pose environmental challenges.

The manufacturing of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. Although many manufacturers have phased out PFOA, alternative chemicals used may still have environmental impacts. Efforts to enhance safety standards with PTFE must address the potential release of these substances during production, which can contaminate water sources and affect ecosystems.

PTFE's durability, while beneficial for safety applications, presents challenges in terms of waste management. The material's resistance to degradation means it persists in the environment for extended periods. Improper disposal of PTFE-containing products can lead to microplastic pollution in marine and terrestrial ecosystems. To mitigate this, safety standards should incorporate end-of-life considerations, promoting recycling and proper disposal methods for PTFE-based safety equipment.

The use of PTFE in safety measures can indirectly contribute to reduced environmental impact in certain scenarios. For instance, PTFE coatings on safety equipment can extend product lifespans, reducing the frequency of replacements and associated waste. Additionally, PTFE's non-stick properties can minimize the use of harsh cleaning chemicals in industrial settings, potentially decreasing water pollution from cleaning processes.

However, the incineration of PTFE waste at inadequate temperatures can release harmful substances, including hydrogen fluoride and perfluoroisobutylene. Stringent regulations on PTFE waste management are crucial to prevent these emissions. Safety standards should encompass not only the use of PTFE but also its entire lifecycle, from production to disposal.

Advancements in green chemistry offer promising avenues for reducing the environmental footprint of PTFE safety measures. Research into bio-based alternatives and environmentally friendly production methods could lead to more sustainable PTFE products. Safety standards should encourage the adoption of these innovations, balancing performance requirements with environmental considerations.

In conclusion, enhancing safety standards with PTFE necessitates a holistic approach that considers its full environmental impact. While PTFE offers valuable safety benefits, its implementation must be accompanied by responsible production practices, efficient use, and proper disposal methods to minimize negative environmental consequences.

The manufacturing of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. Although many manufacturers have phased out PFOA, alternative chemicals used may still have environmental impacts. Efforts to enhance safety standards with PTFE must address the potential release of these substances during production, which can contaminate water sources and affect ecosystems.

PTFE's durability, while beneficial for safety applications, presents challenges in terms of waste management. The material's resistance to degradation means it persists in the environment for extended periods. Improper disposal of PTFE-containing products can lead to microplastic pollution in marine and terrestrial ecosystems. To mitigate this, safety standards should incorporate end-of-life considerations, promoting recycling and proper disposal methods for PTFE-based safety equipment.

The use of PTFE in safety measures can indirectly contribute to reduced environmental impact in certain scenarios. For instance, PTFE coatings on safety equipment can extend product lifespans, reducing the frequency of replacements and associated waste. Additionally, PTFE's non-stick properties can minimize the use of harsh cleaning chemicals in industrial settings, potentially decreasing water pollution from cleaning processes.

However, the incineration of PTFE waste at inadequate temperatures can release harmful substances, including hydrogen fluoride and perfluoroisobutylene. Stringent regulations on PTFE waste management are crucial to prevent these emissions. Safety standards should encompass not only the use of PTFE but also its entire lifecycle, from production to disposal.

Advancements in green chemistry offer promising avenues for reducing the environmental footprint of PTFE safety measures. Research into bio-based alternatives and environmentally friendly production methods could lead to more sustainable PTFE products. Safety standards should encourage the adoption of these innovations, balancing performance requirements with environmental considerations.

In conclusion, enhancing safety standards with PTFE necessitates a holistic approach that considers its full environmental impact. While PTFE offers valuable safety benefits, its implementation must be accompanied by responsible production practices, efficient use, and proper disposal methods to minimize negative environmental consequences.

Regulatory Framework for PTFE Safety Standards

The regulatory framework for PTFE safety standards is a complex and evolving landscape that encompasses various national and international guidelines, regulations, and industry best practices. At the forefront of this framework is the United States Environmental Protection Agency (EPA), which has implemented stringent regulations under the Toxic Substances Control Act (TSCA) to govern the manufacture, use, and disposal of PTFE and related substances.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in ensuring the safe use of PTFE. REACH requires manufacturers and importers to register chemicals and provide detailed safety information, including potential risks and appropriate risk management measures.

The Occupational Safety and Health Administration (OSHA) in the United States has established specific standards for workplace exposure to PTFE and its byproducts. These standards set permissible exposure limits (PELs) and require employers to implement engineering controls, work practices, and personal protective equipment to minimize worker exposure.

International organizations such as the World Health Organization (WHO) and the International Agency for Research on Cancer (IARC) have also contributed to the regulatory framework by providing guidelines and classifications regarding the potential health effects of PTFE exposure.

Industry-specific standards, such as those developed by the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO), provide detailed specifications for PTFE materials and testing methods. These standards ensure consistency and quality in PTFE products across various applications.

The Food and Drug Administration (FDA) in the United States regulates the use of PTFE in food contact materials and medical devices, setting strict requirements for safety and biocompatibility. Similarly, the European Food Safety Authority (EFSA) provides guidelines for the use of PTFE in food contact materials within the EU.

As environmental concerns grow, regulations addressing the potential environmental impact of PTFE production and disposal have become increasingly important. The Stockholm Convention on Persistent Organic Pollutants (POPs) has implications for certain PTFE-related substances, driving the development of more environmentally friendly alternatives.

To enhance safety standards with PTFE, ongoing collaboration between regulatory bodies, industry stakeholders, and research institutions is essential. This collaboration facilitates the continuous updating of regulations based on the latest scientific findings and technological advancements. Additionally, harmonization efforts between different regulatory frameworks aim to create a more cohesive global approach to PTFE safety standards, reducing barriers to international trade while maintaining high levels of protection for human health and the environment.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in ensuring the safe use of PTFE. REACH requires manufacturers and importers to register chemicals and provide detailed safety information, including potential risks and appropriate risk management measures.

The Occupational Safety and Health Administration (OSHA) in the United States has established specific standards for workplace exposure to PTFE and its byproducts. These standards set permissible exposure limits (PELs) and require employers to implement engineering controls, work practices, and personal protective equipment to minimize worker exposure.

International organizations such as the World Health Organization (WHO) and the International Agency for Research on Cancer (IARC) have also contributed to the regulatory framework by providing guidelines and classifications regarding the potential health effects of PTFE exposure.

Industry-specific standards, such as those developed by the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO), provide detailed specifications for PTFE materials and testing methods. These standards ensure consistency and quality in PTFE products across various applications.

The Food and Drug Administration (FDA) in the United States regulates the use of PTFE in food contact materials and medical devices, setting strict requirements for safety and biocompatibility. Similarly, the European Food Safety Authority (EFSA) provides guidelines for the use of PTFE in food contact materials within the EU.

As environmental concerns grow, regulations addressing the potential environmental impact of PTFE production and disposal have become increasingly important. The Stockholm Convention on Persistent Organic Pollutants (POPs) has implications for certain PTFE-related substances, driving the development of more environmentally friendly alternatives.

To enhance safety standards with PTFE, ongoing collaboration between regulatory bodies, industry stakeholders, and research institutions is essential. This collaboration facilitates the continuous updating of regulations based on the latest scientific findings and technological advancements. Additionally, harmonization efforts between different regulatory frameworks aim to create a more cohesive global approach to PTFE safety standards, reducing barriers to international trade while maintaining high levels of protection for human health and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!