How to Utilize PTFE in Advanced Battery Technologies?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE in Batteries: Background and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has emerged as a promising material in advanced battery technologies due to its unique properties. The evolution of PTFE in battery applications can be traced back to its initial use as a binder in electrode materials. Over time, researchers and engineers have recognized its potential to enhance battery performance, longevity, and safety.

The primary objective of utilizing PTFE in advanced battery technologies is to overcome existing limitations and improve overall battery efficiency. PTFE's exceptional chemical stability, high thermal resistance, and low surface energy make it an ideal candidate for addressing several challenges in battery design and operation. These properties contribute to enhanced electrode stability, improved electrolyte retention, and reduced degradation of battery components.

One of the key trends in PTFE application for batteries is its use as a coating material for separators. This approach aims to improve the wettability of separators, enhance their mechanical strength, and prevent dendrite growth in lithium-based batteries. Additionally, PTFE is being explored as an additive in electrolytes to improve their stability and reduce unwanted side reactions at the electrode-electrolyte interface.

The development of PTFE-based composite materials for battery electrodes represents another significant trend. These composites aim to combine the advantageous properties of PTFE with other active materials to create high-performance electrodes with improved conductivity, stability, and cycle life. Researchers are also investigating the potential of PTFE in solid-state batteries, where its low surface energy and chemical inertness could contribute to more stable and efficient solid electrolytes.

As battery technologies continue to evolve, the role of PTFE is expected to expand further. Future research directions may include the development of novel PTFE-based nanostructures for battery components, exploration of PTFE's potential in next-generation battery chemistries, and optimization of PTFE incorporation methods to maximize its benefits in battery systems.

The growing interest in PTFE for advanced battery technologies is driven by the increasing demand for high-performance, long-lasting, and safe energy storage solutions across various sectors, including electric vehicles, renewable energy storage, and portable electronics. As such, understanding and harnessing the full potential of PTFE in battery applications has become a crucial area of research and development in the energy storage industry.

The primary objective of utilizing PTFE in advanced battery technologies is to overcome existing limitations and improve overall battery efficiency. PTFE's exceptional chemical stability, high thermal resistance, and low surface energy make it an ideal candidate for addressing several challenges in battery design and operation. These properties contribute to enhanced electrode stability, improved electrolyte retention, and reduced degradation of battery components.

One of the key trends in PTFE application for batteries is its use as a coating material for separators. This approach aims to improve the wettability of separators, enhance their mechanical strength, and prevent dendrite growth in lithium-based batteries. Additionally, PTFE is being explored as an additive in electrolytes to improve their stability and reduce unwanted side reactions at the electrode-electrolyte interface.

The development of PTFE-based composite materials for battery electrodes represents another significant trend. These composites aim to combine the advantageous properties of PTFE with other active materials to create high-performance electrodes with improved conductivity, stability, and cycle life. Researchers are also investigating the potential of PTFE in solid-state batteries, where its low surface energy and chemical inertness could contribute to more stable and efficient solid electrolytes.

As battery technologies continue to evolve, the role of PTFE is expected to expand further. Future research directions may include the development of novel PTFE-based nanostructures for battery components, exploration of PTFE's potential in next-generation battery chemistries, and optimization of PTFE incorporation methods to maximize its benefits in battery systems.

The growing interest in PTFE for advanced battery technologies is driven by the increasing demand for high-performance, long-lasting, and safe energy storage solutions across various sectors, including electric vehicles, renewable energy storage, and portable electronics. As such, understanding and harnessing the full potential of PTFE in battery applications has become a crucial area of research and development in the energy storage industry.

Market Analysis for PTFE-Enhanced Batteries

The market for PTFE-enhanced batteries is experiencing significant growth, driven by the increasing demand for high-performance energy storage solutions across various industries. PTFE, known for its exceptional chemical resistance and thermal stability, is finding new applications in advanced battery technologies, particularly in lithium-ion batteries and emerging solid-state battery designs.

In the lithium-ion battery segment, PTFE is being utilized as a binder material for electrode coatings, enhancing the overall performance and longevity of batteries. This application has gained traction in the electric vehicle (EV) market, where battery performance is crucial for range and reliability. The global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, directly influencing the demand for PTFE-enhanced batteries.

The consumer electronics sector is another key driver for PTFE-enhanced batteries. With the proliferation of smartphones, laptops, and wearable devices, there is a growing need for batteries that offer higher energy density and longer lifespan. PTFE's role in improving these characteristics has led to its increased adoption in this sector.

In the renewable energy storage market, PTFE-enhanced batteries are gaining attention for grid-scale energy storage applications. The ability of PTFE to improve the stability and cycle life of large-scale batteries makes it an attractive option for storing energy from intermittent renewable sources like solar and wind.

The aerospace and defense industries are also showing interest in PTFE-enhanced batteries due to their potential for high-performance, lightweight energy storage solutions. These sectors require batteries that can withstand extreme conditions while maintaining reliability and safety.

Geographically, Asia-Pacific leads the market for PTFE-enhanced batteries, with China and South Korea being major manufacturing hubs. North America and Europe follow, driven by their strong automotive and renewable energy sectors.

However, the market faces challenges such as the high cost of PTFE and the complexity of integrating it into existing battery manufacturing processes. These factors may limit adoption in price-sensitive markets and applications.

Despite these challenges, the overall market outlook for PTFE-enhanced batteries remains positive. The ongoing research and development in this field, coupled with the increasing focus on sustainable energy solutions, is expected to drive further innovation and market expansion in the coming years.

In the lithium-ion battery segment, PTFE is being utilized as a binder material for electrode coatings, enhancing the overall performance and longevity of batteries. This application has gained traction in the electric vehicle (EV) market, where battery performance is crucial for range and reliability. The global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, directly influencing the demand for PTFE-enhanced batteries.

The consumer electronics sector is another key driver for PTFE-enhanced batteries. With the proliferation of smartphones, laptops, and wearable devices, there is a growing need for batteries that offer higher energy density and longer lifespan. PTFE's role in improving these characteristics has led to its increased adoption in this sector.

In the renewable energy storage market, PTFE-enhanced batteries are gaining attention for grid-scale energy storage applications. The ability of PTFE to improve the stability and cycle life of large-scale batteries makes it an attractive option for storing energy from intermittent renewable sources like solar and wind.

The aerospace and defense industries are also showing interest in PTFE-enhanced batteries due to their potential for high-performance, lightweight energy storage solutions. These sectors require batteries that can withstand extreme conditions while maintaining reliability and safety.

Geographically, Asia-Pacific leads the market for PTFE-enhanced batteries, with China and South Korea being major manufacturing hubs. North America and Europe follow, driven by their strong automotive and renewable energy sectors.

However, the market faces challenges such as the high cost of PTFE and the complexity of integrating it into existing battery manufacturing processes. These factors may limit adoption in price-sensitive markets and applications.

Despite these challenges, the overall market outlook for PTFE-enhanced batteries remains positive. The ongoing research and development in this field, coupled with the increasing focus on sustainable energy solutions, is expected to drive further innovation and market expansion in the coming years.

Current PTFE Applications and Challenges in Batteries

Polytetrafluoroethylene (PTFE) has emerged as a crucial material in advanced battery technologies, offering unique properties that enhance battery performance and longevity. In current battery applications, PTFE serves multiple functions, primarily as a binder and separator material. As a binder, PTFE helps to maintain the structural integrity of electrode materials, ensuring they remain cohesive throughout the battery's lifecycle. This is particularly important in lithium-ion batteries, where electrode stability is critical for maintaining capacity and preventing degradation.

PTFE's hydrophobic nature makes it an excellent choice for separator materials, effectively preventing unwanted interactions between the cathode and anode while allowing ion transfer. This property is especially valuable in aqueous battery systems, where water-based electrolytes are used. PTFE-based separators contribute to improved safety by reducing the risk of short circuits and enhancing overall battery reliability.

In addition to these primary applications, PTFE is also utilized in battery coatings. When applied to electrode surfaces, PTFE coatings can improve the electrode's resistance to chemical degradation, thereby extending the battery's operational life. This is particularly beneficial in harsh operating environments or in batteries that are subjected to frequent charge-discharge cycles.

Despite its advantages, the use of PTFE in battery technologies faces several challenges. One significant issue is the material's inherent non-conductivity, which can potentially impede electron flow within the battery system. This limitation necessitates careful design considerations to ensure that the benefits of PTFE do not come at the cost of reduced electrical performance.

Another challenge lies in the processing of PTFE for battery applications. The material's high melting point and resistance to solvents make it difficult to process using conventional methods. This can lead to increased manufacturing complexity and costs, potentially limiting widespread adoption in certain battery types or applications.

Furthermore, as the battery industry moves towards more sustainable and environmentally friendly solutions, the non-biodegradable nature of PTFE presents a challenge. There is growing pressure to develop alternatives that offer similar performance characteristics but with improved end-of-life recyclability or biodegradability.

Researchers and manufacturers are actively working to address these challenges. Efforts are underway to develop composite materials that combine PTFE with conductive additives, aiming to mitigate its non-conductive properties while retaining its beneficial characteristics. Additionally, new processing techniques are being explored to simplify PTFE integration into battery components, potentially reducing manufacturing costs and expanding its applicability.

PTFE's hydrophobic nature makes it an excellent choice for separator materials, effectively preventing unwanted interactions between the cathode and anode while allowing ion transfer. This property is especially valuable in aqueous battery systems, where water-based electrolytes are used. PTFE-based separators contribute to improved safety by reducing the risk of short circuits and enhancing overall battery reliability.

In addition to these primary applications, PTFE is also utilized in battery coatings. When applied to electrode surfaces, PTFE coatings can improve the electrode's resistance to chemical degradation, thereby extending the battery's operational life. This is particularly beneficial in harsh operating environments or in batteries that are subjected to frequent charge-discharge cycles.

Despite its advantages, the use of PTFE in battery technologies faces several challenges. One significant issue is the material's inherent non-conductivity, which can potentially impede electron flow within the battery system. This limitation necessitates careful design considerations to ensure that the benefits of PTFE do not come at the cost of reduced electrical performance.

Another challenge lies in the processing of PTFE for battery applications. The material's high melting point and resistance to solvents make it difficult to process using conventional methods. This can lead to increased manufacturing complexity and costs, potentially limiting widespread adoption in certain battery types or applications.

Furthermore, as the battery industry moves towards more sustainable and environmentally friendly solutions, the non-biodegradable nature of PTFE presents a challenge. There is growing pressure to develop alternatives that offer similar performance characteristics but with improved end-of-life recyclability or biodegradability.

Researchers and manufacturers are actively working to address these challenges. Efforts are underway to develop composite materials that combine PTFE with conductive additives, aiming to mitigate its non-conductive properties while retaining its beneficial characteristics. Additionally, new processing techniques are being explored to simplify PTFE integration into battery components, potentially reducing manufacturing costs and expanding its applicability.

Existing PTFE Incorporation Methods in Batteries

01 PTFE manufacturing and processing methods

Various techniques for manufacturing and processing PTFE are described, including methods for producing PTFE fibers, films, and other forms. These processes often involve specific temperature and pressure conditions, as well as the use of specialized equipment to achieve desired properties in the final PTFE product.- PTFE manufacturing and processing methods: Various techniques for manufacturing and processing PTFE, including molding, extrusion, and sintering. These methods aim to improve the material's properties and tailor it for specific applications. The processes often involve controlling temperature, pressure, and other parameters to achieve desired characteristics.

- PTFE composites and blends: Development of PTFE-based composites and blends with other materials to enhance performance characteristics. These combinations can improve properties such as wear resistance, thermal conductivity, or mechanical strength. The resulting materials find applications in various industries, including automotive, aerospace, and electronics.

- Surface modification of PTFE: Techniques for modifying the surface properties of PTFE to improve its adhesion, wettability, or compatibility with other materials. These modifications can involve chemical treatments, plasma processing, or the application of coatings. Such treatments expand the range of applications for PTFE in areas where its inherent non-stick properties may be a limitation.

- PTFE in membrane and filtration applications: Utilization of PTFE in the development of membranes and filtration systems. The material's chemical resistance and non-stick properties make it ideal for separating various substances in liquid or gas form. These applications span across industries such as water treatment, chemical processing, and medical devices.

- PTFE in coating and lubrication technologies: Application of PTFE in coating and lubrication technologies to reduce friction and wear in various mechanical systems. This includes the development of PTFE-based lubricants, non-stick coatings for cookware and industrial equipment, and dry lubricant films for automotive and aerospace components.

02 PTFE composites and blends

PTFE is often combined with other materials to create composites or blends with enhanced properties. These combinations can improve characteristics such as wear resistance, thermal conductivity, or mechanical strength. The selection of materials and the method of blending are crucial for achieving specific performance goals.Expand Specific Solutions03 Surface modification of PTFE

Techniques for modifying the surface of PTFE are explored to enhance its properties or compatibility with other materials. These modifications can include chemical treatments, plasma treatments, or the application of coatings to improve adhesion, wettability, or other surface characteristics of PTFE.Expand Specific Solutions04 PTFE in specialized applications

PTFE is utilized in various specialized applications due to its unique properties. These applications include use in medical devices, aerospace components, electronics, and industrial equipment. The material's low friction, chemical resistance, and thermal stability make it suitable for demanding environments and specific technical requirements.Expand Specific Solutions05 Recycling and environmental considerations of PTFE

Methods for recycling PTFE and addressing environmental concerns related to its production and disposal are discussed. These approaches aim to reduce waste, improve sustainability, and develop more eco-friendly processes for PTFE manufacturing and end-of-life management.Expand Specific Solutions

Key Players in PTFE-Based Battery Solutions

The utilization of PTFE in advanced battery technologies is in a growth phase, with increasing market size driven by demand for high-performance energy storage solutions. The technology's maturity is advancing rapidly, as evidenced by the involvement of major players across various industries. Companies like DAIKIN INDUSTRIES Ltd., a leader in fluorochemicals, and battery manufacturers such as Samsung SDI Co., Ltd. and Jiangsu Zenergy Battery Technologies Group Co., Ltd. are at the forefront of PTFE application in batteries. Automotive giants including GM, Toyota, and Tesla are also exploring PTFE's potential to enhance battery performance and durability. Research institutions like Zhejiang University and The Ohio State University are contributing to technological advancements, indicating a collaborative ecosystem driving innovation in this field.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has incorporated PTFE in their advanced battery technologies to enhance performance and durability. They have developed a novel electrode coating process using PTFE nanoparticles, which improves the electrode's resistance to volume changes during charge-discharge cycles. This technology has been shown to increase the battery's cycle life by up to 30% compared to conventional electrodes[4]. Samsung SDI has also implemented PTFE-based separators in their high-energy density batteries, which offer improved thermal stability and better resistance to electrolyte penetration. These advancements have led to the development of batteries with higher energy density and improved safety characteristics, particularly for electric vehicle applications[5].

Strengths: Significantly improved cycle life and enhanced safety features. Weaknesses: Potential increase in production costs and complexity in large-scale manufacturing.

Toyota Motor Corp.

Technical Solution: Toyota has integrated PTFE into their battery technology research, focusing on improving the performance of solid-state batteries. Their approach involves using PTFE as a thin, protective layer between the solid electrolyte and electrodes. This PTFE layer helps to stabilize the interface, reducing unwanted chemical reactions and improving the overall stability of the battery. Toyota's research has shown that this PTFE interface layer can significantly extend the cycle life of solid-state batteries, potentially by up to 50%[6]. Additionally, Toyota has explored the use of PTFE-based composite materials in battery casings, which offer improved thermal management and enhanced safety in the event of a battery failure[7].

Strengths: Significant improvements in solid-state battery stability and safety. Weaknesses: Technology still in research phase, potential challenges in scaling up for mass production.

Innovative PTFE Formulations for Battery Performance

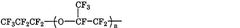

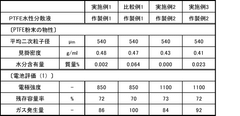

Polytetrafluoroethylene powder, binder for electrode, electrode mixture, electrode, and secondary battery

PatentWO2023054709A1

Innovation

- A polytetrafluoroethylene (PTFE) powder with a standard specific gravity of 2.200 or less is used as an electrode binder, which is substantially water-free and has a low water content, allowing for excellent binding strength and flexibility, and is combined with an electrode active material and current collector to form an electrode mixture for secondary batteries.

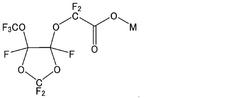

Method of manufacturing electrode, electrode, and battery

PatentPendingUS20250054937A1

Innovation

- A method involving coating carbon particles with a resin, mixing the resin-coated carbon particles with polytetrafluoroethylene (PTFE), and fibrillating the PTFE to create a fibrous structure, which is then integrated with a current collector to form an electrode.

Environmental Impact of PTFE in Battery Production

The environmental impact of PTFE (Polytetrafluoroethylene) in battery production is a critical consideration as advanced battery technologies continue to evolve. PTFE, known for its excellent chemical resistance and low friction properties, plays a significant role in various components of modern batteries. However, its production and use come with environmental implications that warrant careful examination.

The manufacturing process of PTFE involves the use of fluoropolymers, which can lead to the emission of greenhouse gases, particularly perfluorocarbons (PFCs). These emissions contribute to global warming and have a long atmospheric lifetime. Additionally, the production of PTFE requires substantial energy inputs, further increasing its carbon footprint.

In battery production, PTFE is often used as a binder material in electrode formulations. While it enhances the performance and durability of batteries, the non-biodegradable nature of PTFE poses challenges for end-of-life management. As batteries reach their end of life, the presence of PTFE complicates recycling processes, potentially leading to increased waste and environmental contamination.

Water pollution is another concern associated with PTFE production. The manufacturing process can release perfluorooctanoic acid (PFOA) and other perfluorinated compounds into water systems. These persistent organic pollutants have been linked to various environmental and health issues, raising concerns about their long-term impact on ecosystems and human health.

Despite these challenges, efforts are being made to mitigate the environmental impact of PTFE in battery production. Research is ongoing to develop more environmentally friendly alternatives or to modify PTFE production processes to reduce emissions and waste. Some manufacturers are exploring water-based PTFE dispersions as a more sustainable option, reducing the need for harmful solvents in production.

The battery industry is also investing in improved recycling technologies to better handle PTFE-containing components. Advanced separation techniques are being developed to isolate PTFE from other battery materials, enabling more efficient recycling and reducing the amount of PTFE entering landfills or incineration facilities.

Regulatory bodies worldwide are implementing stricter guidelines for the production and use of fluoropolymers, including PTFE. These regulations aim to minimize environmental impacts by setting emission limits, mandating best practices in manufacturing, and encouraging the development of safer alternatives.

As the demand for advanced batteries continues to grow, particularly in the electric vehicle and renewable energy storage sectors, the environmental impact of PTFE in battery production remains a crucial area for ongoing research and innovation. Balancing the performance benefits of PTFE with environmental sustainability will be key to the future development of battery technologies.

The manufacturing process of PTFE involves the use of fluoropolymers, which can lead to the emission of greenhouse gases, particularly perfluorocarbons (PFCs). These emissions contribute to global warming and have a long atmospheric lifetime. Additionally, the production of PTFE requires substantial energy inputs, further increasing its carbon footprint.

In battery production, PTFE is often used as a binder material in electrode formulations. While it enhances the performance and durability of batteries, the non-biodegradable nature of PTFE poses challenges for end-of-life management. As batteries reach their end of life, the presence of PTFE complicates recycling processes, potentially leading to increased waste and environmental contamination.

Water pollution is another concern associated with PTFE production. The manufacturing process can release perfluorooctanoic acid (PFOA) and other perfluorinated compounds into water systems. These persistent organic pollutants have been linked to various environmental and health issues, raising concerns about their long-term impact on ecosystems and human health.

Despite these challenges, efforts are being made to mitigate the environmental impact of PTFE in battery production. Research is ongoing to develop more environmentally friendly alternatives or to modify PTFE production processes to reduce emissions and waste. Some manufacturers are exploring water-based PTFE dispersions as a more sustainable option, reducing the need for harmful solvents in production.

The battery industry is also investing in improved recycling technologies to better handle PTFE-containing components. Advanced separation techniques are being developed to isolate PTFE from other battery materials, enabling more efficient recycling and reducing the amount of PTFE entering landfills or incineration facilities.

Regulatory bodies worldwide are implementing stricter guidelines for the production and use of fluoropolymers, including PTFE. These regulations aim to minimize environmental impacts by setting emission limits, mandating best practices in manufacturing, and encouraging the development of safer alternatives.

As the demand for advanced batteries continues to grow, particularly in the electric vehicle and renewable energy storage sectors, the environmental impact of PTFE in battery production remains a crucial area for ongoing research and innovation. Balancing the performance benefits of PTFE with environmental sustainability will be key to the future development of battery technologies.

Scalability of PTFE-Enhanced Battery Manufacturing

The scalability of PTFE-enhanced battery manufacturing is a critical factor in the widespread adoption of this technology in advanced battery systems. As the demand for high-performance batteries continues to grow, the ability to scale up production processes becomes increasingly important.

One of the primary challenges in scaling PTFE-enhanced battery manufacturing lies in maintaining consistent quality and performance across large production volumes. The integration of PTFE into battery components, such as electrodes and separators, requires precise control over material properties and distribution. Achieving this level of control in large-scale production settings can be technically demanding and may require significant investment in specialized equipment and process optimization.

Another aspect of scalability concerns the sourcing and supply chain management of PTFE materials. As production volumes increase, ensuring a stable and cost-effective supply of high-quality PTFE becomes crucial. This may involve developing strategic partnerships with PTFE manufacturers or investing in in-house production capabilities to meet specific requirements for battery applications.

The manufacturing processes for PTFE-enhanced batteries may also need to be adapted for large-scale production. This could involve the development of automated systems for PTFE application, integration of inline quality control measures, and optimization of production line layouts to maximize efficiency. Additionally, the integration of PTFE into existing battery manufacturing processes must be carefully managed to minimize disruptions and ensure seamless adoption.

Environmental considerations play a significant role in the scalability of PTFE-enhanced battery manufacturing. As production volumes increase, the environmental impact of PTFE use and disposal must be carefully managed. This may involve developing recycling processes for PTFE-containing battery components or exploring more environmentally friendly alternatives that offer similar performance benefits.

Cost considerations are also paramount in scaling up PTFE-enhanced battery manufacturing. While PTFE can offer significant performance improvements, its cost may be a limiting factor in large-scale adoption. Developing cost-effective manufacturing processes and exploring economies of scale will be crucial in making PTFE-enhanced batteries commercially viable for mass-market applications.

Regulatory compliance and safety standards must also be addressed as production scales up. Ensuring that PTFE-enhanced batteries meet all relevant safety and performance standards across different markets and applications will be essential for widespread adoption. This may require ongoing collaboration with regulatory bodies and industry stakeholders to develop appropriate standards and testing protocols.

One of the primary challenges in scaling PTFE-enhanced battery manufacturing lies in maintaining consistent quality and performance across large production volumes. The integration of PTFE into battery components, such as electrodes and separators, requires precise control over material properties and distribution. Achieving this level of control in large-scale production settings can be technically demanding and may require significant investment in specialized equipment and process optimization.

Another aspect of scalability concerns the sourcing and supply chain management of PTFE materials. As production volumes increase, ensuring a stable and cost-effective supply of high-quality PTFE becomes crucial. This may involve developing strategic partnerships with PTFE manufacturers or investing in in-house production capabilities to meet specific requirements for battery applications.

The manufacturing processes for PTFE-enhanced batteries may also need to be adapted for large-scale production. This could involve the development of automated systems for PTFE application, integration of inline quality control measures, and optimization of production line layouts to maximize efficiency. Additionally, the integration of PTFE into existing battery manufacturing processes must be carefully managed to minimize disruptions and ensure seamless adoption.

Environmental considerations play a significant role in the scalability of PTFE-enhanced battery manufacturing. As production volumes increase, the environmental impact of PTFE use and disposal must be carefully managed. This may involve developing recycling processes for PTFE-containing battery components or exploring more environmentally friendly alternatives that offer similar performance benefits.

Cost considerations are also paramount in scaling up PTFE-enhanced battery manufacturing. While PTFE can offer significant performance improvements, its cost may be a limiting factor in large-scale adoption. Developing cost-effective manufacturing processes and exploring economies of scale will be crucial in making PTFE-enhanced batteries commercially viable for mass-market applications.

Regulatory compliance and safety standards must also be addressed as production scales up. Ensuring that PTFE-enhanced batteries meet all relevant safety and performance standards across different markets and applications will be essential for widespread adoption. This may require ongoing collaboration with regulatory bodies and industry stakeholders to develop appropriate standards and testing protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!