Exploring PTFE–ceramic interfaces for high‑temperature wear protection

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE-ceramic interface background and objectives

Polytetrafluoroethylene (PTFE) and ceramic materials have long been recognized for their unique properties and potential applications in high-temperature wear protection. The exploration of PTFE-ceramic interfaces represents a critical area of research aimed at developing advanced materials with enhanced performance characteristics.

PTFE, a synthetic fluoropolymer, is renowned for its low friction coefficient, chemical inertness, and thermal stability. However, its poor wear resistance and mechanical properties at elevated temperatures have limited its use in certain high-performance applications. Ceramics, on the other hand, offer excellent hardness, wear resistance, and thermal stability, but often lack the self-lubricating properties of PTFE.

The combination of PTFE and ceramic materials at their interface presents an opportunity to synergize their respective strengths while mitigating their individual weaknesses. This approach has the potential to create composite materials that exhibit superior wear protection under high-temperature conditions, addressing a significant challenge in various industrial sectors.

The historical development of PTFE-ceramic interfaces can be traced back to the mid-20th century when researchers began exploring ways to enhance the tribological properties of materials. Initial attempts focused on simple mechanical mixtures or coatings, but these often failed to achieve the desired level of integration and performance.

As material science and nanotechnology advanced, more sophisticated methods for creating PTFE-ceramic interfaces emerged. These include techniques such as plasma spraying, chemical vapor deposition, and sol-gel processes, which allow for better control over the interface structure and properties.

The primary objective of exploring PTFE-ceramic interfaces for high-temperature wear protection is to develop materials that maintain low friction and high wear resistance at elevated temperatures. This goal encompasses several key aspects:

1. Understanding the fundamental mechanisms of interaction between PTFE and ceramic surfaces at high temperatures.

2. Optimizing the interface structure to maximize adhesion and minimize delamination under thermal and mechanical stress.

3. Developing novel fabrication techniques that enable precise control over the interface composition and morphology.

4. Investigating the effects of different ceramic materials and their surface characteristics on the performance of the PTFE-ceramic interface.

5. Exploring methods to enhance the thermal stability of PTFE within the composite structure.

By addressing these objectives, researchers aim to create a new generation of materials capable of withstanding extreme conditions in applications such as aerospace components, industrial machinery, and advanced manufacturing processes. The successful development of high-performance PTFE-ceramic interfaces could lead to significant improvements in energy efficiency, equipment longevity, and operational safety across various industries.

PTFE, a synthetic fluoropolymer, is renowned for its low friction coefficient, chemical inertness, and thermal stability. However, its poor wear resistance and mechanical properties at elevated temperatures have limited its use in certain high-performance applications. Ceramics, on the other hand, offer excellent hardness, wear resistance, and thermal stability, but often lack the self-lubricating properties of PTFE.

The combination of PTFE and ceramic materials at their interface presents an opportunity to synergize their respective strengths while mitigating their individual weaknesses. This approach has the potential to create composite materials that exhibit superior wear protection under high-temperature conditions, addressing a significant challenge in various industrial sectors.

The historical development of PTFE-ceramic interfaces can be traced back to the mid-20th century when researchers began exploring ways to enhance the tribological properties of materials. Initial attempts focused on simple mechanical mixtures or coatings, but these often failed to achieve the desired level of integration and performance.

As material science and nanotechnology advanced, more sophisticated methods for creating PTFE-ceramic interfaces emerged. These include techniques such as plasma spraying, chemical vapor deposition, and sol-gel processes, which allow for better control over the interface structure and properties.

The primary objective of exploring PTFE-ceramic interfaces for high-temperature wear protection is to develop materials that maintain low friction and high wear resistance at elevated temperatures. This goal encompasses several key aspects:

1. Understanding the fundamental mechanisms of interaction between PTFE and ceramic surfaces at high temperatures.

2. Optimizing the interface structure to maximize adhesion and minimize delamination under thermal and mechanical stress.

3. Developing novel fabrication techniques that enable precise control over the interface composition and morphology.

4. Investigating the effects of different ceramic materials and their surface characteristics on the performance of the PTFE-ceramic interface.

5. Exploring methods to enhance the thermal stability of PTFE within the composite structure.

By addressing these objectives, researchers aim to create a new generation of materials capable of withstanding extreme conditions in applications such as aerospace components, industrial machinery, and advanced manufacturing processes. The successful development of high-performance PTFE-ceramic interfaces could lead to significant improvements in energy efficiency, equipment longevity, and operational safety across various industries.

Market demand analysis for high-temperature wear protection

The market demand for high-temperature wear protection solutions has been steadily increasing across various industries, driven by the need for improved performance and longevity of components operating in extreme conditions. The aerospace sector, in particular, has shown significant interest in advanced materials that can withstand high temperatures and friction, especially in jet engines and turbines. The automotive industry also seeks innovative solutions for high-temperature wear protection in exhaust systems and engine components, aiming to enhance fuel efficiency and reduce emissions.

In the oil and gas sector, there is a growing demand for wear-resistant materials capable of withstanding harsh environments in deep-sea drilling operations and high-temperature processing facilities. The chemical and petrochemical industries require materials that can maintain their integrity under corrosive and high-temperature conditions, driving the need for advanced wear protection solutions.

The global market for high-temperature wear protection materials is expected to experience substantial growth in the coming years. This growth is attributed to the increasing industrialization in emerging economies and the continuous technological advancements in material science. The Asia-Pacific region, in particular, is anticipated to witness the highest growth rate due to rapid industrialization and infrastructure development.

The exploration of PTFE-ceramic interfaces for high-temperature wear protection addresses a critical market need. PTFE (polytetrafluoroethylene) is known for its low friction properties and chemical resistance, while ceramics offer excellent hardness and thermal stability. The combination of these materials in a composite or layered structure could potentially provide superior wear resistance at elevated temperatures, meeting the demands of various industries.

Market analysis indicates that industries are willing to invest in advanced wear protection solutions that can significantly extend the lifespan of critical components and reduce maintenance costs. The potential for PTFE-ceramic interfaces to offer improved performance over traditional materials could lead to substantial market adoption, particularly in applications where downtime is costly and reliability is paramount.

However, the market also demands cost-effective solutions. While high-performance materials are desired, there is a balance to be struck between enhanced properties and economic viability. Manufacturers and researchers developing PTFE-ceramic interfaces for high-temperature wear protection must consider scalability and production costs to ensure market competitiveness.

As environmental regulations become more stringent, there is an increasing demand for wear protection solutions that also contribute to sustainability goals. Materials that can improve energy efficiency, reduce waste, and minimize environmental impact are highly sought after. The potential for PTFE-ceramic interfaces to enhance durability and reduce the frequency of component replacement aligns well with these market trends.

In the oil and gas sector, there is a growing demand for wear-resistant materials capable of withstanding harsh environments in deep-sea drilling operations and high-temperature processing facilities. The chemical and petrochemical industries require materials that can maintain their integrity under corrosive and high-temperature conditions, driving the need for advanced wear protection solutions.

The global market for high-temperature wear protection materials is expected to experience substantial growth in the coming years. This growth is attributed to the increasing industrialization in emerging economies and the continuous technological advancements in material science. The Asia-Pacific region, in particular, is anticipated to witness the highest growth rate due to rapid industrialization and infrastructure development.

The exploration of PTFE-ceramic interfaces for high-temperature wear protection addresses a critical market need. PTFE (polytetrafluoroethylene) is known for its low friction properties and chemical resistance, while ceramics offer excellent hardness and thermal stability. The combination of these materials in a composite or layered structure could potentially provide superior wear resistance at elevated temperatures, meeting the demands of various industries.

Market analysis indicates that industries are willing to invest in advanced wear protection solutions that can significantly extend the lifespan of critical components and reduce maintenance costs. The potential for PTFE-ceramic interfaces to offer improved performance over traditional materials could lead to substantial market adoption, particularly in applications where downtime is costly and reliability is paramount.

However, the market also demands cost-effective solutions. While high-performance materials are desired, there is a balance to be struck between enhanced properties and economic viability. Manufacturers and researchers developing PTFE-ceramic interfaces for high-temperature wear protection must consider scalability and production costs to ensure market competitiveness.

As environmental regulations become more stringent, there is an increasing demand for wear protection solutions that also contribute to sustainability goals. Materials that can improve energy efficiency, reduce waste, and minimize environmental impact are highly sought after. The potential for PTFE-ceramic interfaces to enhance durability and reduce the frequency of component replacement aligns well with these market trends.

Current challenges in PTFE-ceramic interface technology

The development of PTFE-ceramic interfaces for high-temperature wear protection faces several significant challenges. One of the primary issues is the inherent incompatibility between the hydrophobic nature of PTFE and the typically hydrophilic surface of ceramics. This mismatch in surface properties leads to poor adhesion and bonding at the interface, compromising the overall performance and durability of the composite system.

Another major challenge lies in maintaining the stability of the PTFE-ceramic interface at elevated temperatures. PTFE, while known for its excellent chemical resistance and low friction properties, begins to degrade at temperatures above 260°C. This thermal limitation restricts the application of PTFE-ceramic composites in extreme high-temperature environments, where wear protection is often most critical.

The difference in thermal expansion coefficients between PTFE and ceramic materials presents an additional hurdle. As temperature fluctuates, the disparate expansion rates can induce thermal stresses at the interface, potentially leading to delamination, cracking, or failure of the protective coating. This issue is particularly pronounced in applications involving rapid temperature changes or thermal cycling.

Furthermore, the low surface energy of PTFE makes it difficult to achieve strong mechanical interlocking with ceramic substrates. Traditional surface modification techniques used to enhance adhesion, such as chemical etching or plasma treatment, may not be as effective for PTFE due to its chemical inertness. This limitation necessitates the development of novel surface modification approaches specifically tailored for PTFE-ceramic systems.

The optimization of PTFE content in the composite is another challenge. While a higher PTFE content can improve lubricity and wear resistance, it may also reduce the overall strength and thermal conductivity of the composite. Striking the right balance to achieve optimal performance across various parameters remains a complex task for researchers and engineers.

Lastly, the long-term stability and wear resistance of PTFE-ceramic interfaces under harsh operating conditions, such as high loads, abrasive environments, or corrosive media, continue to be areas of concern. The gradual degradation of PTFE and potential weakening of the interface over time can lead to premature failure of the protective coating, necessitating frequent replacements and increased maintenance costs.

Another major challenge lies in maintaining the stability of the PTFE-ceramic interface at elevated temperatures. PTFE, while known for its excellent chemical resistance and low friction properties, begins to degrade at temperatures above 260°C. This thermal limitation restricts the application of PTFE-ceramic composites in extreme high-temperature environments, where wear protection is often most critical.

The difference in thermal expansion coefficients between PTFE and ceramic materials presents an additional hurdle. As temperature fluctuates, the disparate expansion rates can induce thermal stresses at the interface, potentially leading to delamination, cracking, or failure of the protective coating. This issue is particularly pronounced in applications involving rapid temperature changes or thermal cycling.

Furthermore, the low surface energy of PTFE makes it difficult to achieve strong mechanical interlocking with ceramic substrates. Traditional surface modification techniques used to enhance adhesion, such as chemical etching or plasma treatment, may not be as effective for PTFE due to its chemical inertness. This limitation necessitates the development of novel surface modification approaches specifically tailored for PTFE-ceramic systems.

The optimization of PTFE content in the composite is another challenge. While a higher PTFE content can improve lubricity and wear resistance, it may also reduce the overall strength and thermal conductivity of the composite. Striking the right balance to achieve optimal performance across various parameters remains a complex task for researchers and engineers.

Lastly, the long-term stability and wear resistance of PTFE-ceramic interfaces under harsh operating conditions, such as high loads, abrasive environments, or corrosive media, continue to be areas of concern. The gradual degradation of PTFE and potential weakening of the interface over time can lead to premature failure of the protective coating, necessitating frequent replacements and increased maintenance costs.

Existing PTFE-ceramic interface solutions

01 PTFE-ceramic composite coatings

Composite coatings combining PTFE and ceramic materials are used to enhance wear protection at interfaces. These coatings leverage the low friction properties of PTFE and the hardness of ceramics to create durable, wear-resistant surfaces. The combination can be applied to various substrates to improve their tribological performance in demanding environments.- PTFE-ceramic composite coatings: Composite coatings combining PTFE and ceramic materials are used to enhance wear protection at interfaces. These coatings leverage the low friction properties of PTFE and the hardness of ceramics to create a durable, wear-resistant surface. The composite nature of the coating allows for improved adhesion to substrates and better overall performance in high-wear applications.

- Nanostructured PTFE-ceramic interfaces: Nanostructured interfaces between PTFE and ceramic materials are developed to improve wear resistance. By controlling the interface at the nanoscale, researchers can enhance the bonding between the two materials and create a more uniform distribution of properties. This approach leads to improved wear protection and can be applied in various industrial applications where PTFE-ceramic interfaces are critical.

- Surface treatment techniques for PTFE-ceramic interfaces: Various surface treatment techniques are employed to enhance the wear protection of PTFE-ceramic interfaces. These may include plasma treatment, chemical etching, or physical modification of surfaces. Such treatments aim to improve the adhesion between PTFE and ceramic materials, increase surface roughness for better mechanical interlocking, or create functional groups that promote stronger bonding at the interface.

- Lubricant additives for PTFE-ceramic systems: Specialized lubricant additives are developed to enhance the wear protection of PTFE-ceramic interfaces. These additives can include nanoparticles, polymer blends, or other compounds that work synergistically with both PTFE and ceramic materials. The additives help to reduce friction, prevent wear, and maintain the integrity of the interface under high-stress conditions.

- PTFE-ceramic interface design for specific applications: Tailored PTFE-ceramic interface designs are created for specific applications such as bearings, seals, or high-temperature environments. These designs consider factors like thermal expansion, chemical resistance, and load-bearing capacity. By optimizing the interface for particular use cases, engineers can significantly improve wear protection and extend the lifespan of components in demanding industrial settings.

02 Nanostructured PTFE-ceramic interfaces

Nanostructured interfaces between PTFE and ceramic materials are developed to enhance wear protection. These interfaces utilize nanoscale features to improve adhesion, reduce friction, and increase wear resistance. The nanostructured approach can lead to superior performance compared to conventional macro-scale interfaces.Expand Specific Solutions03 PTFE-ceramic composites for high-temperature applications

Specialized PTFE-ceramic composites are formulated for use in high-temperature environments where wear protection is critical. These materials maintain their tribological properties at elevated temperatures, making them suitable for applications in industries such as aerospace, automotive, and manufacturing where heat resistance is essential.Expand Specific Solutions04 Surface modification techniques for PTFE-ceramic interfaces

Various surface modification techniques are employed to improve the wear protection of PTFE-ceramic interfaces. These may include plasma treatment, chemical etching, or the application of intermediate layers to enhance bonding and overall wear resistance. Such modifications can significantly extend the lifespan of components subject to wear.Expand Specific Solutions05 Self-lubricating PTFE-ceramic systems

Self-lubricating systems incorporating PTFE and ceramic materials are developed to provide continuous wear protection. These systems are designed to release lubricating particles or films during operation, maintaining low friction and high wear resistance over extended periods without the need for external lubrication.Expand Specific Solutions

Key players in PTFE and ceramic coating industry

The exploration of PTFE-ceramic interfaces for high-temperature wear protection is in a developing stage, with significant potential for growth. The market is expanding due to increasing demand in industries such as aerospace, automotive, and manufacturing. While the technology is advancing, it is not yet fully mature, with ongoing research and development efforts. Key players in this field include ExxonMobil Technology & Engineering Co., W. L. Gore & Associates GK, and DuPont Safety & Construction, Inc., each contributing to technological advancements. Academic institutions like Central South University and Sichuan University are also actively involved in research, indicating a collaborative approach between industry and academia to drive innovation in this area.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced PTFE-ceramic composite materials for high-temperature wear protection in industrial applications. Their approach involves incorporating ceramic nanoparticles into a PTFE matrix, creating a synergistic blend that enhances both wear resistance and thermal stability. The company has optimized the interface between PTFE and ceramic particles through surface modification techniques, improving adhesion and load transfer. This results in a composite material that maintains low friction properties of PTFE while significantly increasing wear resistance at elevated temperatures[1][3]. ExxonMobil's research has shown that these composites can operate effectively in temperatures up to 300°C, making them suitable for demanding environments in oil and gas, chemical processing, and automotive industries[2].

Strengths: Excellent wear resistance at high temperatures, low friction, and improved thermal stability. Weaknesses: Potentially higher production costs and limited flexibility compared to pure PTFE.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has pioneered a novel approach to PTFE-ceramic interfaces for high-temperature wear protection. Their technology focuses on creating a gradient structure within the composite, where the concentration of ceramic particles varies across the material thickness. This gradient structure allows for optimized wear resistance at the surface while maintaining the bulk properties of PTFE. DAIKIN's process involves a proprietary sintering technique that ensures strong bonding between PTFE and ceramic particles without compromising the material's overall integrity. The company has reported success in developing composites that can withstand temperatures up to 260°C while maintaining excellent wear resistance and low friction characteristics[4]. DAIKIN's materials have found applications in aerospace, semiconductor manufacturing, and industrial sealing systems[5].

Strengths: Gradient structure offers tailored properties, good balance of wear resistance and low friction. Weaknesses: Complex manufacturing process may limit large-scale production.

Core innovations in PTFE-ceramic bonding techniques

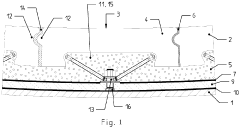

Temperature-gradient-optimized wear protection

PatentActiveEP3663086A1

Innovation

- A multi-layered wear protective lining comprising a ceramic outer layer with a polished surface, an adhesive layer, a pressure-relieving mineral layer, a nanoporous insulation layer based on pyrogenic silicic acid, and an inner mineral layer, designed to create a thermal conductivity gradient and provide mechanical stability, with fastening means for secure attachment.

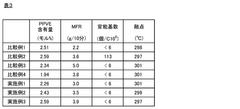

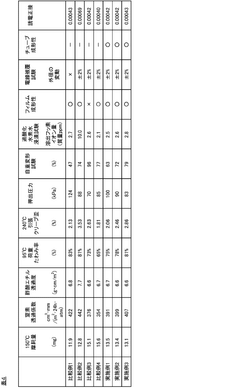

Copolymer, molded body, extruded body, extruded body, transfer molded body, and coated electrical wire

PatentWO2022181242A1

Innovation

- A copolymer composed of tetrafluoroethylene (TFE) and perfluoro(propyl vinyl ether) (PPVE) units with specific content ratios and melt flow rates, which provides excellent abrasion resistance, low nitrogen and chemical permeability, high temperature tensile creep properties, and resistance to fluorine ion elution, allowing for uniform thick coatings and improved moldability even in molten states.

Environmental impact of PTFE-ceramic coatings

The environmental impact of PTFE-ceramic coatings is a crucial consideration in their application for high-temperature wear protection. These composite coatings offer exceptional durability and performance, but their production, use, and disposal can have significant environmental implications.

During the manufacturing process of PTFE-ceramic coatings, the production of PTFE involves the use of fluoropolymers, which can release harmful greenhouse gases such as perfluorocarbons (PFCs) and hydrofluorocarbons (HFCs). These emissions contribute to global warming and ozone depletion. Additionally, the ceramic component production may require energy-intensive processes, further increasing the carbon footprint.

The application of PTFE-ceramic coatings often involves spray techniques that can release volatile organic compounds (VOCs) and particulate matter into the atmosphere. While modern application methods have improved efficiency and reduced emissions, there is still potential for environmental contamination if proper controls are not in place.

In terms of product lifecycle, PTFE-ceramic coatings generally extend the lifespan of components, reducing the need for frequent replacements. This longevity can lead to reduced waste generation and resource consumption over time. However, the disposal of PTFE-ceramic coated materials at the end of their life cycle presents challenges due to the non-biodegradable nature of PTFE.

Recent research has focused on developing more environmentally friendly alternatives to traditional PTFE-ceramic coatings. Bio-based polymers and water-based coating systems are being explored as potential substitutes to reduce the environmental impact. Additionally, advancements in recycling technologies are being pursued to recover and reuse PTFE and ceramic materials from discarded coatings.

The use of PTFE-ceramic coatings in high-temperature applications can indirectly contribute to environmental benefits. By improving energy efficiency and reducing friction in industrial processes, these coatings can lead to lower energy consumption and decreased greenhouse gas emissions in various sectors, such as automotive and aerospace industries.

Regulatory bodies worldwide are implementing stricter environmental standards for coating materials. This has prompted manufacturers to invest in research and development of more sustainable PTFE-ceramic coating formulations and application methods. The industry is moving towards adopting life cycle assessment (LCA) approaches to comprehensively evaluate the environmental impact of these coatings from production to disposal.

During the manufacturing process of PTFE-ceramic coatings, the production of PTFE involves the use of fluoropolymers, which can release harmful greenhouse gases such as perfluorocarbons (PFCs) and hydrofluorocarbons (HFCs). These emissions contribute to global warming and ozone depletion. Additionally, the ceramic component production may require energy-intensive processes, further increasing the carbon footprint.

The application of PTFE-ceramic coatings often involves spray techniques that can release volatile organic compounds (VOCs) and particulate matter into the atmosphere. While modern application methods have improved efficiency and reduced emissions, there is still potential for environmental contamination if proper controls are not in place.

In terms of product lifecycle, PTFE-ceramic coatings generally extend the lifespan of components, reducing the need for frequent replacements. This longevity can lead to reduced waste generation and resource consumption over time. However, the disposal of PTFE-ceramic coated materials at the end of their life cycle presents challenges due to the non-biodegradable nature of PTFE.

Recent research has focused on developing more environmentally friendly alternatives to traditional PTFE-ceramic coatings. Bio-based polymers and water-based coating systems are being explored as potential substitutes to reduce the environmental impact. Additionally, advancements in recycling technologies are being pursued to recover and reuse PTFE and ceramic materials from discarded coatings.

The use of PTFE-ceramic coatings in high-temperature applications can indirectly contribute to environmental benefits. By improving energy efficiency and reducing friction in industrial processes, these coatings can lead to lower energy consumption and decreased greenhouse gas emissions in various sectors, such as automotive and aerospace industries.

Regulatory bodies worldwide are implementing stricter environmental standards for coating materials. This has prompted manufacturers to invest in research and development of more sustainable PTFE-ceramic coating formulations and application methods. The industry is moving towards adopting life cycle assessment (LCA) approaches to comprehensively evaluate the environmental impact of these coatings from production to disposal.

Standardization and testing protocols

Standardization and testing protocols play a crucial role in ensuring the reliability and reproducibility of research on PTFE-ceramic interfaces for high-temperature wear protection. These protocols are essential for comparing results across different studies and validating the performance of new materials and coatings.

One of the primary challenges in this field is the lack of universally accepted standards for testing PTFE-ceramic interfaces at high temperatures. To address this issue, several international organizations, such as ASTM International and ISO, have been working on developing standardized testing methods. These efforts aim to establish consistent procedures for evaluating wear resistance, friction coefficients, and thermal stability of PTFE-ceramic composites under extreme conditions.

A key aspect of standardization is the development of precise sample preparation techniques. This includes guidelines for surface roughness, cleaning procedures, and coating application methods. Standardized sample preparation ensures that test results are not influenced by variations in manufacturing processes or surface conditions.

Testing protocols for PTFE-ceramic interfaces typically involve a combination of tribological and thermal analyses. Tribological tests, such as pin-on-disk or ball-on-flat configurations, are used to assess wear rates and friction behavior. These tests are often conducted at elevated temperatures to simulate real-world operating conditions. Thermal analysis techniques, including thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC), are employed to evaluate the thermal stability and phase transitions of the materials.

To ensure the accuracy of high-temperature wear tests, specialized equipment and instrumentation are required. This includes high-temperature tribometers capable of maintaining stable temperatures up to 500°C or higher. The development of such equipment has been a focus of research, with several manufacturers now offering commercial solutions designed specifically for testing PTFE-ceramic interfaces at elevated temperatures.

Another critical aspect of standardization is the establishment of reporting guidelines. These guidelines specify the minimum set of data that should be included in research publications, such as test conditions, material compositions, and quantitative results. By adhering to these reporting standards, researchers can facilitate the comparison and meta-analysis of results across different studies.

Interlaboratory studies have been conducted to validate the reproducibility of testing protocols for PTFE-ceramic interfaces. These studies involve multiple laboratories performing the same tests on identical samples, allowing for the assessment of variability in results and the identification of potential sources of error. The outcomes of these studies contribute to the refinement of testing protocols and the establishment of acceptable tolerance ranges for key performance metrics.

One of the primary challenges in this field is the lack of universally accepted standards for testing PTFE-ceramic interfaces at high temperatures. To address this issue, several international organizations, such as ASTM International and ISO, have been working on developing standardized testing methods. These efforts aim to establish consistent procedures for evaluating wear resistance, friction coefficients, and thermal stability of PTFE-ceramic composites under extreme conditions.

A key aspect of standardization is the development of precise sample preparation techniques. This includes guidelines for surface roughness, cleaning procedures, and coating application methods. Standardized sample preparation ensures that test results are not influenced by variations in manufacturing processes or surface conditions.

Testing protocols for PTFE-ceramic interfaces typically involve a combination of tribological and thermal analyses. Tribological tests, such as pin-on-disk or ball-on-flat configurations, are used to assess wear rates and friction behavior. These tests are often conducted at elevated temperatures to simulate real-world operating conditions. Thermal analysis techniques, including thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC), are employed to evaluate the thermal stability and phase transitions of the materials.

To ensure the accuracy of high-temperature wear tests, specialized equipment and instrumentation are required. This includes high-temperature tribometers capable of maintaining stable temperatures up to 500°C or higher. The development of such equipment has been a focus of research, with several manufacturers now offering commercial solutions designed specifically for testing PTFE-ceramic interfaces at elevated temperatures.

Another critical aspect of standardization is the establishment of reporting guidelines. These guidelines specify the minimum set of data that should be included in research publications, such as test conditions, material compositions, and quantitative results. By adhering to these reporting standards, researchers can facilitate the comparison and meta-analysis of results across different studies.

Interlaboratory studies have been conducted to validate the reproducibility of testing protocols for PTFE-ceramic interfaces. These studies involve multiple laboratories performing the same tests on identical samples, allowing for the assessment of variability in results and the identification of potential sources of error. The outcomes of these studies contribute to the refinement of testing protocols and the establishment of acceptable tolerance ranges for key performance metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!