How to Innovate Advanced PTFE Seal Technologies?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Seal Evolution

PTFE (Polytetrafluoroethylene) seal technology has undergone significant evolution since its inception in the 1930s. The journey of PTFE seals began with the accidental discovery of PTFE by Roy Plunkett at DuPont in 1938. Initially, the material's unique properties, such as chemical inertness and low friction, were not fully understood or utilized in sealing applications.

The 1950s marked the beginning of PTFE's use in sealing technology, primarily in static applications. During this period, engineers recognized PTFE's potential for creating effective seals in challenging environments where traditional elastomers failed. The material's resistance to chemicals and extreme temperatures made it particularly valuable in aerospace and chemical processing industries.

The 1960s and 1970s saw rapid advancements in PTFE seal design and manufacturing techniques. Researchers developed methods to modify PTFE's mechanical properties, enhancing its wear resistance and reducing cold flow issues. This period also witnessed the introduction of filled PTFE compounds, where additives like glass fibers, carbon, and bronze were incorporated to improve specific performance characteristics.

In the 1980s and 1990s, PTFE seal technology expanded into dynamic sealing applications. Engineers developed innovative designs such as spring-energized PTFE seals, which combined the material's low friction properties with the resilience of metal springs. This innovation allowed PTFE seals to be used in rotating and reciprocating equipment, significantly broadening their application scope.

The turn of the millennium brought about a focus on nanotechnology in PTFE seal development. Researchers began exploring ways to manipulate PTFE at the molecular level, creating nanocomposites with enhanced properties. These advancements led to PTFE seals with improved wear resistance, reduced permeability, and better overall performance in extreme conditions.

Recent years have seen a shift towards sustainability and efficiency in PTFE seal technology. Manufacturers are developing eco-friendly production methods and exploring bio-based alternatives to traditional PTFE. Additionally, there's a growing emphasis on predictive maintenance and smart sealing solutions, incorporating sensors and IoT technology to monitor seal performance in real-time.

The evolution of PTFE seal technology continues to be driven by the demands of emerging industries and the need for seals that can withstand increasingly challenging operating conditions. As we look to the future, the focus is on developing PTFE seals with enhanced durability, reduced friction, and improved sealing efficiency across a broader range of applications.

The 1950s marked the beginning of PTFE's use in sealing technology, primarily in static applications. During this period, engineers recognized PTFE's potential for creating effective seals in challenging environments where traditional elastomers failed. The material's resistance to chemicals and extreme temperatures made it particularly valuable in aerospace and chemical processing industries.

The 1960s and 1970s saw rapid advancements in PTFE seal design and manufacturing techniques. Researchers developed methods to modify PTFE's mechanical properties, enhancing its wear resistance and reducing cold flow issues. This period also witnessed the introduction of filled PTFE compounds, where additives like glass fibers, carbon, and bronze were incorporated to improve specific performance characteristics.

In the 1980s and 1990s, PTFE seal technology expanded into dynamic sealing applications. Engineers developed innovative designs such as spring-energized PTFE seals, which combined the material's low friction properties with the resilience of metal springs. This innovation allowed PTFE seals to be used in rotating and reciprocating equipment, significantly broadening their application scope.

The turn of the millennium brought about a focus on nanotechnology in PTFE seal development. Researchers began exploring ways to manipulate PTFE at the molecular level, creating nanocomposites with enhanced properties. These advancements led to PTFE seals with improved wear resistance, reduced permeability, and better overall performance in extreme conditions.

Recent years have seen a shift towards sustainability and efficiency in PTFE seal technology. Manufacturers are developing eco-friendly production methods and exploring bio-based alternatives to traditional PTFE. Additionally, there's a growing emphasis on predictive maintenance and smart sealing solutions, incorporating sensors and IoT technology to monitor seal performance in real-time.

The evolution of PTFE seal technology continues to be driven by the demands of emerging industries and the need for seals that can withstand increasingly challenging operating conditions. As we look to the future, the focus is on developing PTFE seals with enhanced durability, reduced friction, and improved sealing efficiency across a broader range of applications.

Market Demand Analysis

The market demand for advanced PTFE seal technologies has been steadily increasing across various industries due to their exceptional chemical resistance, low friction properties, and wide temperature range capabilities. In the automotive sector, the growing emphasis on fuel efficiency and emission reduction has led to a surge in demand for high-performance seals that can withstand extreme conditions in engines and powertrains. PTFE seals play a crucial role in enhancing the overall performance and longevity of automotive components.

The aerospace industry represents another significant market for advanced PTFE seal technologies. With the continuous push for lighter and more efficient aircraft, there is a growing need for seals that can maintain their integrity under high-pressure and high-temperature environments. PTFE seals offer excellent resistance to jet fuels and hydraulic fluids, making them indispensable in critical aerospace applications.

In the oil and gas sector, the exploration of deeper reserves and harsh offshore environments has intensified the demand for robust sealing solutions. Advanced PTFE seals are increasingly sought after for their ability to withstand corrosive chemicals, high pressures, and extreme temperatures encountered in drilling and production operations. The industry's focus on preventing leaks and ensuring environmental safety further drives the adoption of these advanced sealing technologies.

The semiconductor manufacturing industry is another key market for PTFE seals. As chip production processes become more sophisticated, the need for ultra-clean and chemically resistant seals has grown significantly. PTFE's exceptional purity and resistance to aggressive chemicals make it an ideal material for seals used in semiconductor fabrication equipment.

The healthcare and pharmaceutical sectors also contribute to the rising demand for advanced PTFE seal technologies. In medical devices and drug manufacturing equipment, PTFE seals are preferred for their biocompatibility, sterilization resistance, and ability to maintain purity in critical processes. The growing emphasis on personalized medicine and stringent regulatory requirements further propel the need for high-performance sealing solutions in these industries.

Market analysts project a compound annual growth rate (CAGR) for the PTFE seals market in the range of 5-7% over the next five years. This growth is attributed to the expanding applications in emerging technologies such as electric vehicles, renewable energy systems, and advanced manufacturing processes. The increasing focus on sustainability and energy efficiency across industries is expected to further boost the demand for innovative PTFE seal technologies that can enhance equipment performance and reduce maintenance requirements.

The aerospace industry represents another significant market for advanced PTFE seal technologies. With the continuous push for lighter and more efficient aircraft, there is a growing need for seals that can maintain their integrity under high-pressure and high-temperature environments. PTFE seals offer excellent resistance to jet fuels and hydraulic fluids, making them indispensable in critical aerospace applications.

In the oil and gas sector, the exploration of deeper reserves and harsh offshore environments has intensified the demand for robust sealing solutions. Advanced PTFE seals are increasingly sought after for their ability to withstand corrosive chemicals, high pressures, and extreme temperatures encountered in drilling and production operations. The industry's focus on preventing leaks and ensuring environmental safety further drives the adoption of these advanced sealing technologies.

The semiconductor manufacturing industry is another key market for PTFE seals. As chip production processes become more sophisticated, the need for ultra-clean and chemically resistant seals has grown significantly. PTFE's exceptional purity and resistance to aggressive chemicals make it an ideal material for seals used in semiconductor fabrication equipment.

The healthcare and pharmaceutical sectors also contribute to the rising demand for advanced PTFE seal technologies. In medical devices and drug manufacturing equipment, PTFE seals are preferred for their biocompatibility, sterilization resistance, and ability to maintain purity in critical processes. The growing emphasis on personalized medicine and stringent regulatory requirements further propel the need for high-performance sealing solutions in these industries.

Market analysts project a compound annual growth rate (CAGR) for the PTFE seals market in the range of 5-7% over the next five years. This growth is attributed to the expanding applications in emerging technologies such as electric vehicles, renewable energy systems, and advanced manufacturing processes. The increasing focus on sustainability and energy efficiency across industries is expected to further boost the demand for innovative PTFE seal technologies that can enhance equipment performance and reduce maintenance requirements.

Technical Challenges

The development of advanced PTFE seal technologies faces several significant challenges that require innovative solutions. One of the primary obstacles is improving the wear resistance of PTFE seals without compromising their inherent low friction properties. PTFE's soft nature, while beneficial for sealing, leads to rapid wear under high-pressure and high-temperature conditions, limiting its longevity in demanding applications.

Another critical challenge lies in enhancing the chemical resistance of PTFE seals. Although PTFE is known for its excellent chemical inertness, certain aggressive chemicals and extreme pH environments can still degrade its performance over time. Developing PTFE compounds that maintain their integrity in a broader range of chemical environments remains a key focus area for innovation.

Thermal expansion and creep are additional technical hurdles that need to be addressed. PTFE's high coefficient of thermal expansion can lead to seal failure in applications with significant temperature fluctuations. Moreover, its tendency to creep under load can result in reduced sealing effectiveness over time, particularly in static sealing applications.

The integration of PTFE seals with other materials and components presents another set of challenges. Achieving strong, durable bonds between PTFE and metals or other polymers is crucial for creating composite sealing solutions. However, PTFE's low surface energy makes adhesion difficult, necessitating the development of novel surface treatment techniques or intermediate bonding layers.

Manufacturability and cost-effectiveness pose ongoing challenges in PTFE seal innovation. Traditional manufacturing methods for PTFE seals, such as sintering and machining, can be time-consuming and costly. Developing more efficient production techniques, including advanced molding processes or additive manufacturing methods suitable for PTFE, is essential for reducing costs and expanding applications.

Environmental concerns also drive the need for innovation in PTFE seal technologies. While PTFE itself is inert and non-toxic, the production of its precursors, particularly fluoropolymers, has raised environmental issues. Finding more sustainable production methods or developing eco-friendly alternatives that maintain PTFE's desirable properties is a significant challenge facing the industry.

Lastly, the miniaturization trend in various industries demands the development of PTFE seals capable of performing reliably at increasingly smaller scales. This requires overcoming limitations in current manufacturing precision and developing new formulations that maintain PTFE's beneficial properties at micro and nano scales.

Another critical challenge lies in enhancing the chemical resistance of PTFE seals. Although PTFE is known for its excellent chemical inertness, certain aggressive chemicals and extreme pH environments can still degrade its performance over time. Developing PTFE compounds that maintain their integrity in a broader range of chemical environments remains a key focus area for innovation.

Thermal expansion and creep are additional technical hurdles that need to be addressed. PTFE's high coefficient of thermal expansion can lead to seal failure in applications with significant temperature fluctuations. Moreover, its tendency to creep under load can result in reduced sealing effectiveness over time, particularly in static sealing applications.

The integration of PTFE seals with other materials and components presents another set of challenges. Achieving strong, durable bonds between PTFE and metals or other polymers is crucial for creating composite sealing solutions. However, PTFE's low surface energy makes adhesion difficult, necessitating the development of novel surface treatment techniques or intermediate bonding layers.

Manufacturability and cost-effectiveness pose ongoing challenges in PTFE seal innovation. Traditional manufacturing methods for PTFE seals, such as sintering and machining, can be time-consuming and costly. Developing more efficient production techniques, including advanced molding processes or additive manufacturing methods suitable for PTFE, is essential for reducing costs and expanding applications.

Environmental concerns also drive the need for innovation in PTFE seal technologies. While PTFE itself is inert and non-toxic, the production of its precursors, particularly fluoropolymers, has raised environmental issues. Finding more sustainable production methods or developing eco-friendly alternatives that maintain PTFE's desirable properties is a significant challenge facing the industry.

Lastly, the miniaturization trend in various industries demands the development of PTFE seals capable of performing reliably at increasingly smaller scales. This requires overcoming limitations in current manufacturing precision and developing new formulations that maintain PTFE's beneficial properties at micro and nano scales.

Current PTFE Solutions

01 PTFE composite seals

Innovations in PTFE seals include the development of composite materials that combine PTFE with other substances to enhance performance. These composites can improve wear resistance, reduce friction, and increase the overall durability of the seal. The addition of fillers or reinforcing materials to PTFE can result in seals with superior mechanical properties and extended service life.- PTFE composite seals: Innovations in PTFE seals include the development of composite materials that combine PTFE with other substances to enhance performance. These composites can improve wear resistance, reduce friction, and increase the overall durability of the seal. The addition of fillers or reinforcing materials to PTFE can result in seals with superior mechanical properties and extended service life.

- PTFE seal design optimization: Advancements in seal design focus on optimizing the shape, profile, and structure of PTFE seals to improve their sealing effectiveness and longevity. This includes innovations in lip design, backup ring configurations, and spring-energized seals. These design improvements aim to enhance the seal's ability to maintain contact pressure and adapt to dynamic operating conditions.

- Surface treatment of PTFE seals: Innovative surface treatments for PTFE seals have been developed to modify their surface properties. These treatments can include plasma etching, chemical modification, or the application of specialized coatings. The goal is to improve the seal's compatibility with various fluids, enhance its adhesion properties, or reduce permeation rates, thereby extending the seal's performance range and applicability.

- PTFE seal manufacturing techniques: New manufacturing techniques for PTFE seals have been introduced to improve production efficiency and seal quality. These innovations include advanced molding processes, precision machining methods, and novel sintering techniques. Such manufacturing advancements allow for the production of more complex seal geometries, tighter tolerances, and improved consistency in seal performance.

- PTFE seal integration in specific applications: Innovations in PTFE seals also focus on their integration and optimization for specific industrial applications. This includes customized seal designs for automotive, aerospace, chemical processing, and medical industries. These application-specific innovations address unique challenges such as extreme temperatures, aggressive chemicals, or high-speed rotary applications, ensuring optimal sealing performance in diverse operating environments.

02 PTFE seal design optimization

Advancements in seal design focus on optimizing the shape, profile, and structure of PTFE seals to improve their sealing effectiveness and longevity. This includes innovations in lip design, backup ring configurations, and spring-energized seals. These design improvements aim to enhance the seal's ability to maintain contact pressure and adapt to dynamic operating conditions.Expand Specific Solutions03 Surface treatment of PTFE seals

Innovative surface treatments for PTFE seals have been developed to modify their surface properties. These treatments can include plasma etching, chemical modification, or the application of specialized coatings. The goal is to improve the seal's compatibility with various media, enhance its adhesion properties, or reduce permeation rates, thereby expanding the range of applications for PTFE seals.Expand Specific Solutions04 PTFE seal manufacturing techniques

New manufacturing processes for PTFE seals have been introduced to improve production efficiency and seal quality. These innovations include advanced molding techniques, precision machining methods, and novel sintering processes. Such manufacturing advancements allow for the production of more complex seal geometries and tighter tolerances, resulting in improved seal performance.Expand Specific Solutions05 PTFE seal integration and assembly

Innovations in the integration and assembly of PTFE seals into various systems and equipment have been developed. These advancements focus on improving the ease of installation, reducing assembly time, and ensuring proper seal positioning. Novel seal housing designs, installation tools, and assembly methods contribute to enhanced seal performance and reliability in diverse applications.Expand Specific Solutions

Key Industry Players

The advanced PTFE seal technologies market is in a mature growth stage, characterized by intense competition among established players and ongoing innovation. The global market size for PTFE seals is substantial, driven by demand across various industries such as automotive, aerospace, and chemical processing. Key players like W.L. Gore & Associates, Saint-Gobain Performance Plastics, and Daikin Industries lead the market with their advanced R&D capabilities and extensive product portfolios. The technology's maturity is evident in the diverse applications and specialized offerings from companies like Bal Seal Engineering and Federal-Mogul. However, there's still room for innovation, particularly in areas of enhanced durability, extreme temperature resistance, and eco-friendly formulations, as demonstrated by research efforts from institutions like Zhejiang University and Lanzhou Institute of Chemical Physics.

Carl Freudenberg KG

Technical Solution: Freudenberg has innovated in PTFE seal technologies through their Simmerring® seals with PTFE sealing lips. They have developed a proprietary process for bonding PTFE to elastomeric materials, creating hybrid seals that combine the chemical resistance of PTFE with the elasticity of rubber[10]. Freudenberg's innovation includes the use of specially formulated PTFE compounds that offer reduced friction and improved wear resistance in dynamic sealing applications. They have also implemented advanced surface texturing techniques on PTFE sealing lips to optimize lubrication and reduce break-away torque[11]. Freudenberg's latest developments include the use of conductive PTFE compounds for seals in electrical and electromagnetic shielding applications[12].

Strengths: Excellent combination of PTFE and elastomer properties, low friction, and suitability for high-speed applications. Weaknesses: Potential limitations in extreme temperature ranges compared to pure PTFE seals.

Bal Seal Engineering LLC

Technical Solution: Bal Seal has innovated in PTFE seal technologies through their Bal Spring® canted coil spring-energized PTFE seals. They have developed a unique seal design that incorporates a metallic spring element to maintain consistent sealing force over time, compensating for wear and thermal expansion[13]. Bal Seal's innovation includes the use of proprietary PTFE blends that offer enhanced lubricity and wear resistance. They have implemented advanced manufacturing techniques, such as precision machining and molding, to create complex seal geometries with tight tolerances[14]. Bal Seal has also developed a range of filled PTFE materials, including carbon fiber and glass fiber reinforced compounds, to meet specific performance requirements in various industries[15].

Strengths: Excellent long-term sealing performance, ability to handle misalignment, and customizable spring force. Weaknesses: More complex design may result in higher production costs compared to simple PTFE seals.

Core PTFE Technologies

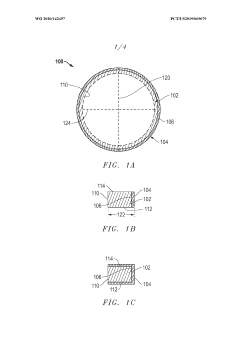

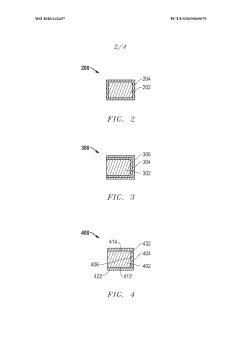

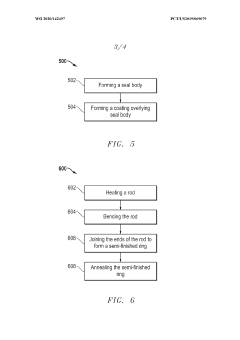

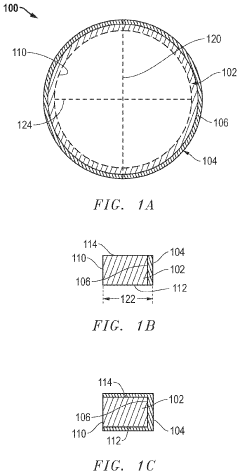

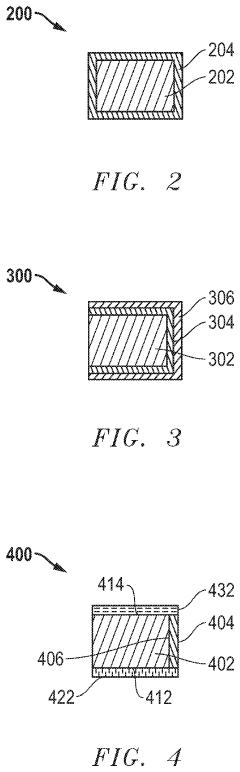

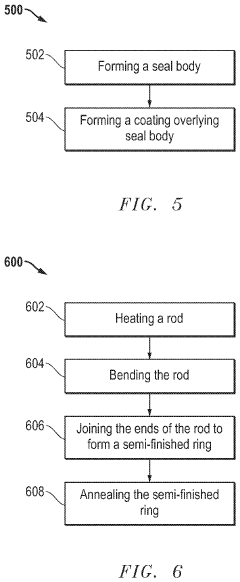

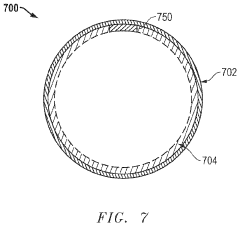

Seal including coating and method of forming

PatentWO2020142497A1

Innovation

- A seal comprising a high-performance polymer seal body with a fluoropolymer coating, where the coating is applied using techniques like plasma-enhanced chemical vapor deposition, enhancing mechanical and tribological properties such as tensile strength, elongation-at-break, and wear resistance.

Seal including coating and method of forming

PatentActiveUS11808357B2

Innovation

- A seal comprising a high-performance polymer body with a fluoropolymer coating, where the coating is applied using techniques like plasma-enhanced chemical vapor deposition, enhancing the mechanical and tribological properties such as tensile strength, elongation-at-break, coefficient of friction, and wear resistance.

Environmental Impact

The environmental impact of advanced PTFE seal technologies is a critical consideration in their development and application. PTFE (Polytetrafluoroethylene) seals have traditionally been known for their durability and chemical resistance, but their environmental footprint has been a concern. Recent innovations in PTFE seal technologies have focused on addressing these environmental challenges while maintaining or improving performance.

One of the primary environmental concerns associated with PTFE seals is their production process. The manufacture of PTFE involves the use of fluoropolymers, which can release greenhouse gases and other pollutants. However, advancements in production techniques have led to significant reductions in emissions. Some manufacturers have implemented closed-loop systems that capture and recycle process gases, minimizing their release into the atmosphere.

The longevity of PTFE seals contributes positively to their environmental profile. Advanced PTFE seals are designed to last longer, reducing the frequency of replacement and, consequently, the overall material consumption and waste generation. This extended lifespan not only reduces the environmental impact but also provides economic benefits to end-users.

Innovations in PTFE seal technologies have also focused on improving their recyclability. Traditional PTFE seals were challenging to recycle due to their chemical stability. However, new formulations and manufacturing processes have made it possible to recycle PTFE seals more effectively. Some companies have developed methods to break down used PTFE seals and reprocess them into new products, creating a more circular economy for these materials.

The development of bio-based alternatives to traditional PTFE seals is another area of environmental innovation. Researchers are exploring the use of plant-based polymers that can mimic the properties of PTFE while being more biodegradable. Although these alternatives are still in the early stages of development, they show promise in reducing the long-term environmental impact of seal technologies.

Energy efficiency is another aspect where advanced PTFE seal technologies are making environmental strides. Improved seal designs reduce friction and energy loss in various applications, from industrial machinery to automotive engines. This increased efficiency translates to lower energy consumption and reduced carbon emissions over the lifecycle of the equipment.

As environmental regulations become more stringent globally, the push for eco-friendly PTFE seal technologies continues to grow. Manufacturers are investing in research and development to create seals that not only meet performance requirements but also align with sustainability goals. This includes exploring new materials, optimizing production processes, and developing end-of-life solutions that minimize environmental impact.

One of the primary environmental concerns associated with PTFE seals is their production process. The manufacture of PTFE involves the use of fluoropolymers, which can release greenhouse gases and other pollutants. However, advancements in production techniques have led to significant reductions in emissions. Some manufacturers have implemented closed-loop systems that capture and recycle process gases, minimizing their release into the atmosphere.

The longevity of PTFE seals contributes positively to their environmental profile. Advanced PTFE seals are designed to last longer, reducing the frequency of replacement and, consequently, the overall material consumption and waste generation. This extended lifespan not only reduces the environmental impact but also provides economic benefits to end-users.

Innovations in PTFE seal technologies have also focused on improving their recyclability. Traditional PTFE seals were challenging to recycle due to their chemical stability. However, new formulations and manufacturing processes have made it possible to recycle PTFE seals more effectively. Some companies have developed methods to break down used PTFE seals and reprocess them into new products, creating a more circular economy for these materials.

The development of bio-based alternatives to traditional PTFE seals is another area of environmental innovation. Researchers are exploring the use of plant-based polymers that can mimic the properties of PTFE while being more biodegradable. Although these alternatives are still in the early stages of development, they show promise in reducing the long-term environmental impact of seal technologies.

Energy efficiency is another aspect where advanced PTFE seal technologies are making environmental strides. Improved seal designs reduce friction and energy loss in various applications, from industrial machinery to automotive engines. This increased efficiency translates to lower energy consumption and reduced carbon emissions over the lifecycle of the equipment.

As environmental regulations become more stringent globally, the push for eco-friendly PTFE seal technologies continues to grow. Manufacturers are investing in research and development to create seals that not only meet performance requirements but also align with sustainability goals. This includes exploring new materials, optimizing production processes, and developing end-of-life solutions that minimize environmental impact.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of advanced PTFE seal technologies. As these seals are often used in critical applications across various industries, adherence to stringent regulations is essential to ensure safety, reliability, and environmental protection.

In the United States, the Food and Drug Administration (FDA) regulates PTFE seals used in food processing and pharmaceutical applications. Manufacturers must comply with FDA guidelines for materials that come into contact with food or drugs, ensuring that the seals do not leach harmful substances or affect product quality. Similarly, the Environmental Protection Agency (EPA) sets standards for PTFE seals used in environmental applications, particularly focusing on their resistance to chemicals and potential environmental impact.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another significant consideration for PTFE seal manufacturers. This regulation aims to protect human health and the environment from the risks posed by chemicals. Manufacturers must register the substances used in their PTFE seals and provide safety information to ensure compliance with REACH requirements.

In the automotive industry, PTFE seals must meet specific standards set by organizations such as the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO). These standards cover aspects such as temperature resistance, chemical compatibility, and durability under various operating conditions.

For aerospace applications, PTFE seals are subject to rigorous regulations set by agencies like the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA). These regulations focus on the seals' ability to withstand extreme temperatures, pressures, and vibrations encountered during flight.

The oil and gas industry also imposes strict regulatory requirements on PTFE seals. Standards set by organizations such as the American Petroleum Institute (API) and NORSOK ensure that seals used in offshore drilling and production equipment can withstand harsh environments and prevent leaks that could lead to environmental disasters.

As PTFE seal technologies continue to advance, manufacturers must stay abreast of evolving regulations and standards. This includes participating in industry working groups, collaborating with regulatory bodies, and investing in research and development to ensure compliance with current and future requirements. Additionally, companies must implement robust quality control systems and documentation processes to demonstrate regulatory compliance throughout the product lifecycle.

Innovating advanced PTFE seal technologies while maintaining regulatory compliance requires a delicate balance between pushing the boundaries of performance and adhering to established safety and environmental standards. This challenge drives continuous improvement in seal design, material science, and manufacturing processes, ultimately leading to more reliable and sustainable sealing solutions across various industries.

In the United States, the Food and Drug Administration (FDA) regulates PTFE seals used in food processing and pharmaceutical applications. Manufacturers must comply with FDA guidelines for materials that come into contact with food or drugs, ensuring that the seals do not leach harmful substances or affect product quality. Similarly, the Environmental Protection Agency (EPA) sets standards for PTFE seals used in environmental applications, particularly focusing on their resistance to chemicals and potential environmental impact.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another significant consideration for PTFE seal manufacturers. This regulation aims to protect human health and the environment from the risks posed by chemicals. Manufacturers must register the substances used in their PTFE seals and provide safety information to ensure compliance with REACH requirements.

In the automotive industry, PTFE seals must meet specific standards set by organizations such as the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO). These standards cover aspects such as temperature resistance, chemical compatibility, and durability under various operating conditions.

For aerospace applications, PTFE seals are subject to rigorous regulations set by agencies like the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA). These regulations focus on the seals' ability to withstand extreme temperatures, pressures, and vibrations encountered during flight.

The oil and gas industry also imposes strict regulatory requirements on PTFE seals. Standards set by organizations such as the American Petroleum Institute (API) and NORSOK ensure that seals used in offshore drilling and production equipment can withstand harsh environments and prevent leaks that could lead to environmental disasters.

As PTFE seal technologies continue to advance, manufacturers must stay abreast of evolving regulations and standards. This includes participating in industry working groups, collaborating with regulatory bodies, and investing in research and development to ensure compliance with current and future requirements. Additionally, companies must implement robust quality control systems and documentation processes to demonstrate regulatory compliance throughout the product lifecycle.

Innovating advanced PTFE seal technologies while maintaining regulatory compliance requires a delicate balance between pushing the boundaries of performance and adhering to established safety and environmental standards. This challenge drives continuous improvement in seal design, material science, and manufacturing processes, ultimately leading to more reliable and sustainable sealing solutions across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!