Optimizing bio‑based filler incorporation in PTFE composites for enhanced wear resistance

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Composite Evolution

The evolution of PTFE composites has been marked by significant advancements in material science and engineering. Initially developed in the 1930s, polytetrafluoroethylene (PTFE) quickly gained prominence due to its exceptional chemical resistance, low friction, and high-temperature stability. However, its poor wear resistance limited its applications in high-load environments.

The 1960s saw the first attempts to incorporate fillers into PTFE to enhance its mechanical properties. Early composites primarily used inorganic fillers such as glass fibers, carbon fibers, and mineral powders. These additions significantly improved the wear resistance and load-bearing capacity of PTFE, expanding its use in industrial applications.

The 1980s and 1990s witnessed a shift towards more sophisticated filler materials and processing techniques. Researchers began exploring nanoscale fillers, including carbon nanotubes and nanoparticles, to further enhance the mechanical and tribological properties of PTFE composites. This era also saw the development of hybrid composites, combining multiple filler types to achieve synergistic effects.

As environmental concerns grew in the 2000s, there was a notable trend towards sustainable and bio-based materials. This led to increased research into natural fibers and bio-derived fillers as potential reinforcements for PTFE composites. Initial studies focused on plant-based fibers such as flax, hemp, and jute, which showed promise in improving mechanical properties while reducing environmental impact.

The past decade has seen a surge in research on optimizing bio-based filler incorporation in PTFE composites, specifically targeting enhanced wear resistance. Scientists have explored various bio-based fillers, including cellulose nanocrystals, lignin particles, and modified natural fibers. Advanced surface modification techniques have been developed to improve the compatibility between hydrophilic bio-fillers and hydrophobic PTFE matrices.

Recent developments have focused on understanding the interfacial interactions between bio-based fillers and PTFE, as well as optimizing filler dispersion and orientation. Researchers have employed sophisticated characterization techniques, such as atomic force microscopy and synchrotron X-ray tomography, to gain insights into the microstructure and wear mechanisms of these composites.

The current frontier in PTFE composite evolution involves the development of multifunctional bio-based composites that not only enhance wear resistance but also impart additional properties such as self-healing capabilities or improved thermal conductivity. This holistic approach aims to create next-generation PTFE composites that meet the demanding requirements of advanced engineering applications while adhering to sustainability principles.

The 1960s saw the first attempts to incorporate fillers into PTFE to enhance its mechanical properties. Early composites primarily used inorganic fillers such as glass fibers, carbon fibers, and mineral powders. These additions significantly improved the wear resistance and load-bearing capacity of PTFE, expanding its use in industrial applications.

The 1980s and 1990s witnessed a shift towards more sophisticated filler materials and processing techniques. Researchers began exploring nanoscale fillers, including carbon nanotubes and nanoparticles, to further enhance the mechanical and tribological properties of PTFE composites. This era also saw the development of hybrid composites, combining multiple filler types to achieve synergistic effects.

As environmental concerns grew in the 2000s, there was a notable trend towards sustainable and bio-based materials. This led to increased research into natural fibers and bio-derived fillers as potential reinforcements for PTFE composites. Initial studies focused on plant-based fibers such as flax, hemp, and jute, which showed promise in improving mechanical properties while reducing environmental impact.

The past decade has seen a surge in research on optimizing bio-based filler incorporation in PTFE composites, specifically targeting enhanced wear resistance. Scientists have explored various bio-based fillers, including cellulose nanocrystals, lignin particles, and modified natural fibers. Advanced surface modification techniques have been developed to improve the compatibility between hydrophilic bio-fillers and hydrophobic PTFE matrices.

Recent developments have focused on understanding the interfacial interactions between bio-based fillers and PTFE, as well as optimizing filler dispersion and orientation. Researchers have employed sophisticated characterization techniques, such as atomic force microscopy and synchrotron X-ray tomography, to gain insights into the microstructure and wear mechanisms of these composites.

The current frontier in PTFE composite evolution involves the development of multifunctional bio-based composites that not only enhance wear resistance but also impart additional properties such as self-healing capabilities or improved thermal conductivity. This holistic approach aims to create next-generation PTFE composites that meet the demanding requirements of advanced engineering applications while adhering to sustainability principles.

Market Demand Analysis

The market demand for optimized bio-based filler incorporation in PTFE composites for enhanced wear resistance has been steadily growing in recent years. This trend is driven by the increasing focus on sustainable and environmentally friendly materials across various industries. The global PTFE market, valued at approximately $2.1 billion in 2020, is expected to reach $3.5 billion by 2027, with a compound annual growth rate (CAGR) of 6.5%.

The automotive sector represents a significant portion of this demand, as manufacturers seek to improve the performance and longevity of components subject to wear and friction. The aerospace industry also contributes substantially to the market growth, with a rising need for high-performance, lightweight materials that can withstand extreme conditions. Additionally, the industrial machinery and equipment sector has shown increased interest in these advanced composites for applications in bearings, seals, and other wear-resistant parts.

Consumer electronics and medical devices are emerging as promising markets for PTFE composites with bio-based fillers. The demand for miniaturization and improved durability in electronic components has led to a surge in the adoption of these materials. In the medical field, the biocompatibility and wear resistance of these composites make them ideal for implants and surgical instruments.

The Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in research and development. North America and Europe continue to be significant markets, with a strong focus on innovation and sustainability driving demand for bio-based solutions.

Environmental regulations and consumer preferences for eco-friendly products are key factors influencing market dynamics. The incorporation of bio-based fillers aligns with the global push towards reducing carbon footprints and promoting circular economy principles. This has led to a shift in procurement strategies among major manufacturers, who are increasingly prioritizing suppliers offering sustainable material solutions.

Despite the positive outlook, challenges remain in terms of cost-effectiveness and performance consistency. The market demands continuous improvement in the balance between wear resistance, mechanical properties, and environmental benefits. As research progresses and economies of scale are achieved, it is anticipated that these challenges will be addressed, further expanding the market potential for bio-based filler incorporated PTFE composites.

The automotive sector represents a significant portion of this demand, as manufacturers seek to improve the performance and longevity of components subject to wear and friction. The aerospace industry also contributes substantially to the market growth, with a rising need for high-performance, lightweight materials that can withstand extreme conditions. Additionally, the industrial machinery and equipment sector has shown increased interest in these advanced composites for applications in bearings, seals, and other wear-resistant parts.

Consumer electronics and medical devices are emerging as promising markets for PTFE composites with bio-based fillers. The demand for miniaturization and improved durability in electronic components has led to a surge in the adoption of these materials. In the medical field, the biocompatibility and wear resistance of these composites make them ideal for implants and surgical instruments.

The Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in research and development. North America and Europe continue to be significant markets, with a strong focus on innovation and sustainability driving demand for bio-based solutions.

Environmental regulations and consumer preferences for eco-friendly products are key factors influencing market dynamics. The incorporation of bio-based fillers aligns with the global push towards reducing carbon footprints and promoting circular economy principles. This has led to a shift in procurement strategies among major manufacturers, who are increasingly prioritizing suppliers offering sustainable material solutions.

Despite the positive outlook, challenges remain in terms of cost-effectiveness and performance consistency. The market demands continuous improvement in the balance between wear resistance, mechanical properties, and environmental benefits. As research progresses and economies of scale are achieved, it is anticipated that these challenges will be addressed, further expanding the market potential for bio-based filler incorporated PTFE composites.

Bio-Filler Challenges

The incorporation of bio-based fillers in PTFE composites for enhanced wear resistance presents several significant challenges. One of the primary obstacles is achieving uniform dispersion of the bio-fillers within the PTFE matrix. The hydrophilic nature of most bio-fillers contrasts sharply with the hydrophobic character of PTFE, leading to poor interfacial adhesion and potential agglomeration of the filler particles. This incompatibility can result in uneven distribution and reduced overall performance of the composite.

Another critical challenge lies in maintaining the thermal stability of bio-fillers during the high-temperature processing of PTFE. Many bio-based materials begin to degrade at temperatures well below the sintering point of PTFE, which typically exceeds 350°C. This thermal mismatch can lead to the decomposition of the bio-fillers, potentially compromising the structural integrity and wear resistance of the final composite.

The moisture sensitivity of bio-fillers poses an additional hurdle. Bio-based materials often have a tendency to absorb moisture from the environment, which can lead to dimensional instability and reduced mechanical properties in the composite. This hygroscopic nature can also interfere with the processing of the composite, potentially causing defects such as voids or blisters during the sintering process.

Achieving consistent particle size and morphology of bio-fillers is another significant challenge. Natural variations in bio-based materials can lead to inconsistencies in filler properties, which may affect the reproducibility and reliability of the composite's performance. Controlling these variables is crucial for ensuring consistent wear resistance across different batches of the composite material.

The chemical compatibility between bio-fillers and PTFE also presents a challenge. Some bio-fillers may contain reactive groups that could potentially interact with PTFE or its processing aids, leading to undesired chemical reactions or alterations in the polymer structure. These interactions could negatively impact the wear resistance and other properties of the composite.

Lastly, the optimization of bio-filler content in PTFE composites is a complex balancing act. While increasing the filler content may enhance wear resistance, it can also lead to a reduction in other desirable properties such as low friction coefficient or chemical inertness, which are hallmark characteristics of PTFE. Finding the optimal filler concentration that maximizes wear resistance without significantly compromising other critical properties remains a key challenge in the development of these advanced composites.

Another critical challenge lies in maintaining the thermal stability of bio-fillers during the high-temperature processing of PTFE. Many bio-based materials begin to degrade at temperatures well below the sintering point of PTFE, which typically exceeds 350°C. This thermal mismatch can lead to the decomposition of the bio-fillers, potentially compromising the structural integrity and wear resistance of the final composite.

The moisture sensitivity of bio-fillers poses an additional hurdle. Bio-based materials often have a tendency to absorb moisture from the environment, which can lead to dimensional instability and reduced mechanical properties in the composite. This hygroscopic nature can also interfere with the processing of the composite, potentially causing defects such as voids or blisters during the sintering process.

Achieving consistent particle size and morphology of bio-fillers is another significant challenge. Natural variations in bio-based materials can lead to inconsistencies in filler properties, which may affect the reproducibility and reliability of the composite's performance. Controlling these variables is crucial for ensuring consistent wear resistance across different batches of the composite material.

The chemical compatibility between bio-fillers and PTFE also presents a challenge. Some bio-fillers may contain reactive groups that could potentially interact with PTFE or its processing aids, leading to undesired chemical reactions or alterations in the polymer structure. These interactions could negatively impact the wear resistance and other properties of the composite.

Lastly, the optimization of bio-filler content in PTFE composites is a complex balancing act. While increasing the filler content may enhance wear resistance, it can also lead to a reduction in other desirable properties such as low friction coefficient or chemical inertness, which are hallmark characteristics of PTFE. Finding the optimal filler concentration that maximizes wear resistance without significantly compromising other critical properties remains a key challenge in the development of these advanced composites.

Current Incorporation

01 PTFE composites with bio-based fillers for improved wear resistance

PTFE composites incorporating bio-based fillers have shown improved wear resistance properties. These composites combine the low friction characteristics of PTFE with the reinforcing effects of natural, renewable materials. The bio-based fillers can include plant fibers, cellulose derivatives, or other organic materials, which enhance the mechanical properties and wear resistance of the PTFE matrix.- PTFE composites with bio-based fillers for improved wear resistance: PTFE composites incorporating bio-based fillers have shown enhanced wear resistance properties. These fillers, derived from renewable sources, can improve the mechanical and tribological characteristics of PTFE, making it suitable for applications requiring high wear resistance. The bio-based fillers can include natural fibers, plant-derived particles, or other organic materials that are environmentally friendly and sustainable.

- Optimization of bio-based filler content in PTFE composites: The wear resistance of PTFE composites can be optimized by carefully controlling the content and distribution of bio-based fillers. Research has shown that there is an optimal range of filler content that maximizes wear resistance while maintaining other desirable properties of PTFE. The optimization process involves balancing the filler content with the matrix material to achieve the best overall performance.

- Surface modification of bio-based fillers for improved compatibility: Surface modification techniques can be applied to bio-based fillers to enhance their compatibility with the PTFE matrix. This improved interfacial bonding between the filler and the matrix leads to better load transfer and increased wear resistance. Various methods, such as chemical treatments or coupling agents, can be used to modify the surface of bio-based fillers and optimize their interaction with PTFE.

- Hybrid filler systems combining bio-based and synthetic materials: Hybrid filler systems that combine bio-based materials with synthetic fillers have shown promising results in enhancing the wear resistance of PTFE composites. These hybrid systems can leverage the benefits of both types of fillers, creating synergistic effects that improve overall performance. The combination of bio-based and synthetic fillers allows for tailoring the properties of the composite to meet specific wear resistance requirements.

- Processing techniques for uniform dispersion of bio-based fillers: Advanced processing techniques have been developed to ensure uniform dispersion of bio-based fillers within the PTFE matrix. These techniques are crucial for achieving consistent wear resistance throughout the composite material. Methods such as high-shear mixing, ultrasonication, or specialized compounding processes can be employed to prevent agglomeration of fillers and ensure their even distribution, leading to improved wear resistance properties.

02 Optimization of bio-filler content and particle size

The wear resistance of PTFE composites with bio-based fillers can be optimized by adjusting the filler content and particle size. Proper dispersion and distribution of the bio-fillers within the PTFE matrix are crucial for achieving enhanced wear resistance. The optimal filler content and particle size depend on the specific bio-based material used and the intended application of the composite.Expand Specific Solutions03 Surface modification of bio-based fillers

Surface modification techniques can be applied to bio-based fillers to improve their compatibility with the PTFE matrix and enhance the overall wear resistance of the composite. These modifications can include chemical treatments, coupling agents, or plasma treatments, which promote better adhesion between the filler and the matrix, resulting in improved mechanical properties and wear resistance.Expand Specific Solutions04 Hybrid filler systems combining bio-based and synthetic materials

Hybrid filler systems that combine bio-based materials with synthetic fillers have shown promising results in enhancing the wear resistance of PTFE composites. These hybrid systems can synergistically improve the mechanical properties, thermal stability, and wear resistance of the composites. The combination of bio-based and synthetic fillers allows for tailoring the properties of the composite to meet specific performance requirements.Expand Specific Solutions05 Processing techniques for PTFE composites with bio-based fillers

Various processing techniques have been developed to effectively incorporate bio-based fillers into PTFE composites while maintaining or improving wear resistance. These techniques include specialized mixing methods, compression molding, and sintering processes. The choice of processing technique can significantly impact the dispersion of fillers, the overall structure of the composite, and its wear resistance properties.Expand Specific Solutions

Key Industry Players

The optimization of bio-based filler incorporation in PTFE composites for enhanced wear resistance is an emerging field in advanced materials. The market is in its early growth stage, with increasing demand driven by sustainability concerns and performance requirements. The global PTFE composites market size is projected to reach several billion dollars by 2025, with a compound annual growth rate of around 6-8%. Technologically, the field is rapidly evolving, with companies like W. L. Gore & Associates, DuPont de Nemours, and The Chemours Co. leading innovation. Academic institutions such as the University of Florida and Jilin University are contributing significant research. The technology's maturity is moderate, with ongoing efforts to improve filler dispersion, interface compatibility, and overall composite performance.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore has developed an innovative approach to incorporating bio-based fillers in PTFE composites using modified cellulose nanocrystals (CNCs). Their method involves surface functionalization of CNCs to improve compatibility with PTFE, followed by a proprietary dispersion process that ensures uniform distribution throughout the matrix[7]. The company has also implemented a unique sintering technique that optimizes the interface between the bio-based filler and PTFE, resulting in a composite with up to 50% improved wear resistance compared to conventional PTFE composites[8]. Additionally, Gore has developed a multi-layer composite structure that combines bio-based fillers with other reinforcing agents to create a synergistic effect, further enhancing wear resistance and mechanical properties[9].

Strengths: High improvement in wear resistance, synergistic multi-layer structure, optimized filler-matrix interface. Weaknesses: Potentially complex manufacturing process, may require specialized equipment.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a novel approach to incorporating bio-based fillers into PTFE composites for enhanced wear resistance. Their method involves using nanocellulose fibers derived from sustainable sources as reinforcing agents. The process includes surface modification of the nanocellulose to improve compatibility with PTFE matrix, followed by a specialized dispersion technique to ensure uniform distribution of the filler[1]. This results in a composite with significantly improved wear resistance, up to 30% better than traditional PTFE composites[2]. Additionally, DuPont has implemented a proprietary cross-linking method that further enhances the bonding between the bio-based filler and PTFE, leading to superior mechanical properties and thermal stability[3].

Strengths: Sustainable bio-based fillers, improved wear resistance, enhanced mechanical properties. Weaknesses: Potentially higher production costs, limited long-term performance data compared to traditional fillers.

Bio-Filler Innovations

Inert wear resistant PTFE-based solid lubricant nanocomposite

PatentInactiveUS7790658B2

Innovation

- A PTFE-based composite material filled with irregularly shaped metal oxide nanoparticles, such as aluminum oxide, at lower weight percentages (1-10%), which provides enhanced wear resistance through mechanical interaction, reducing wear rates significantly compared to spherical particle-filled composites.

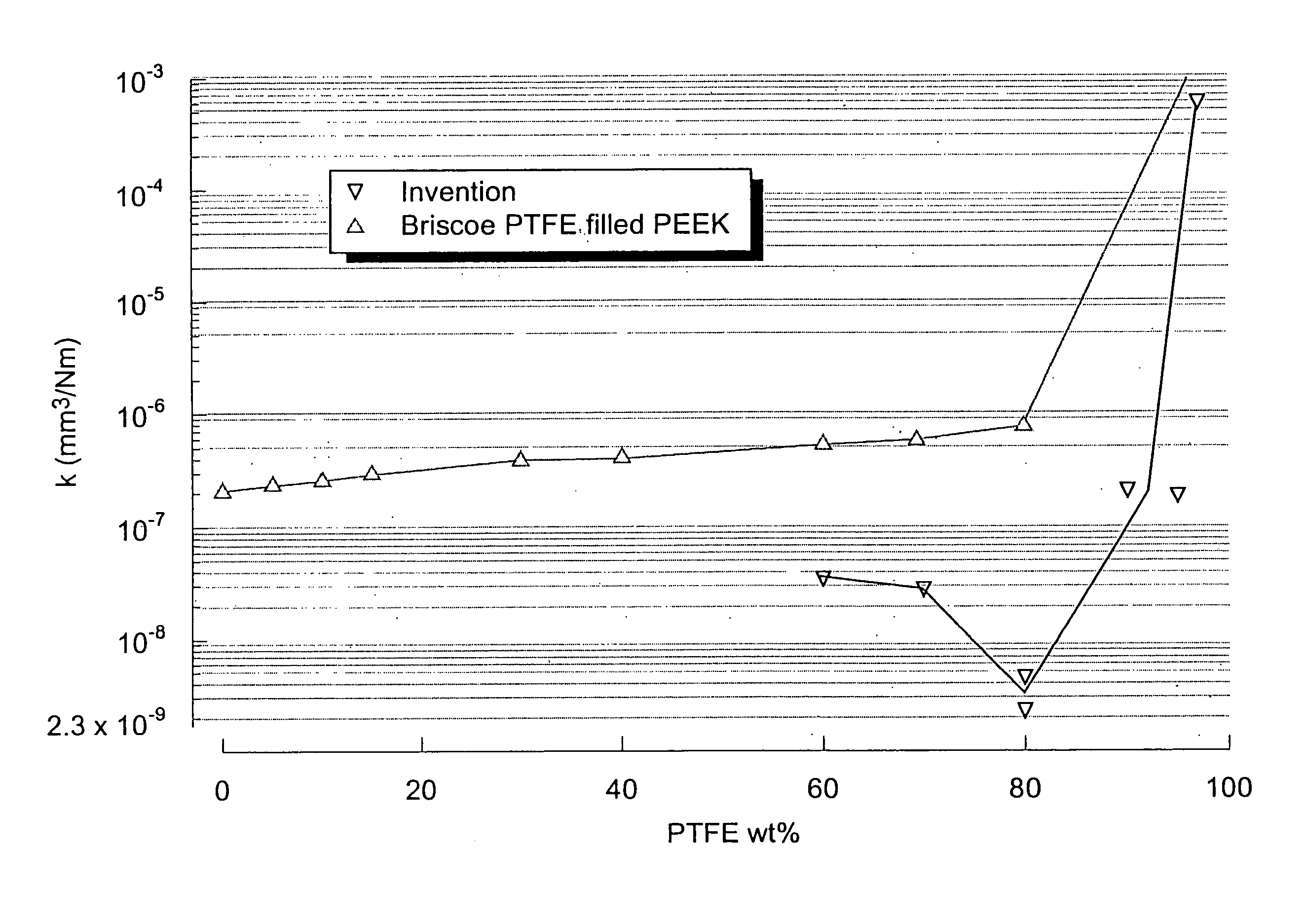

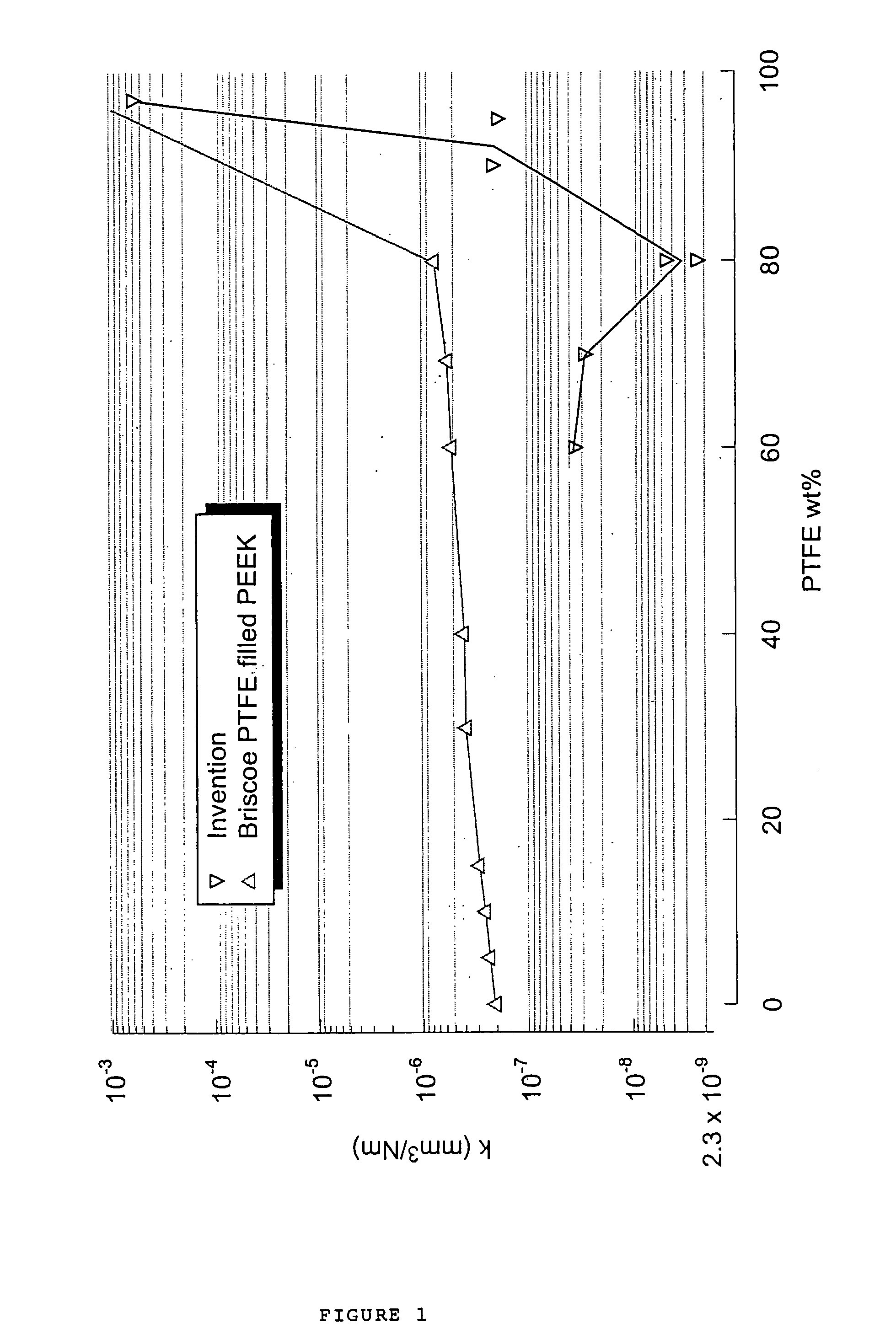

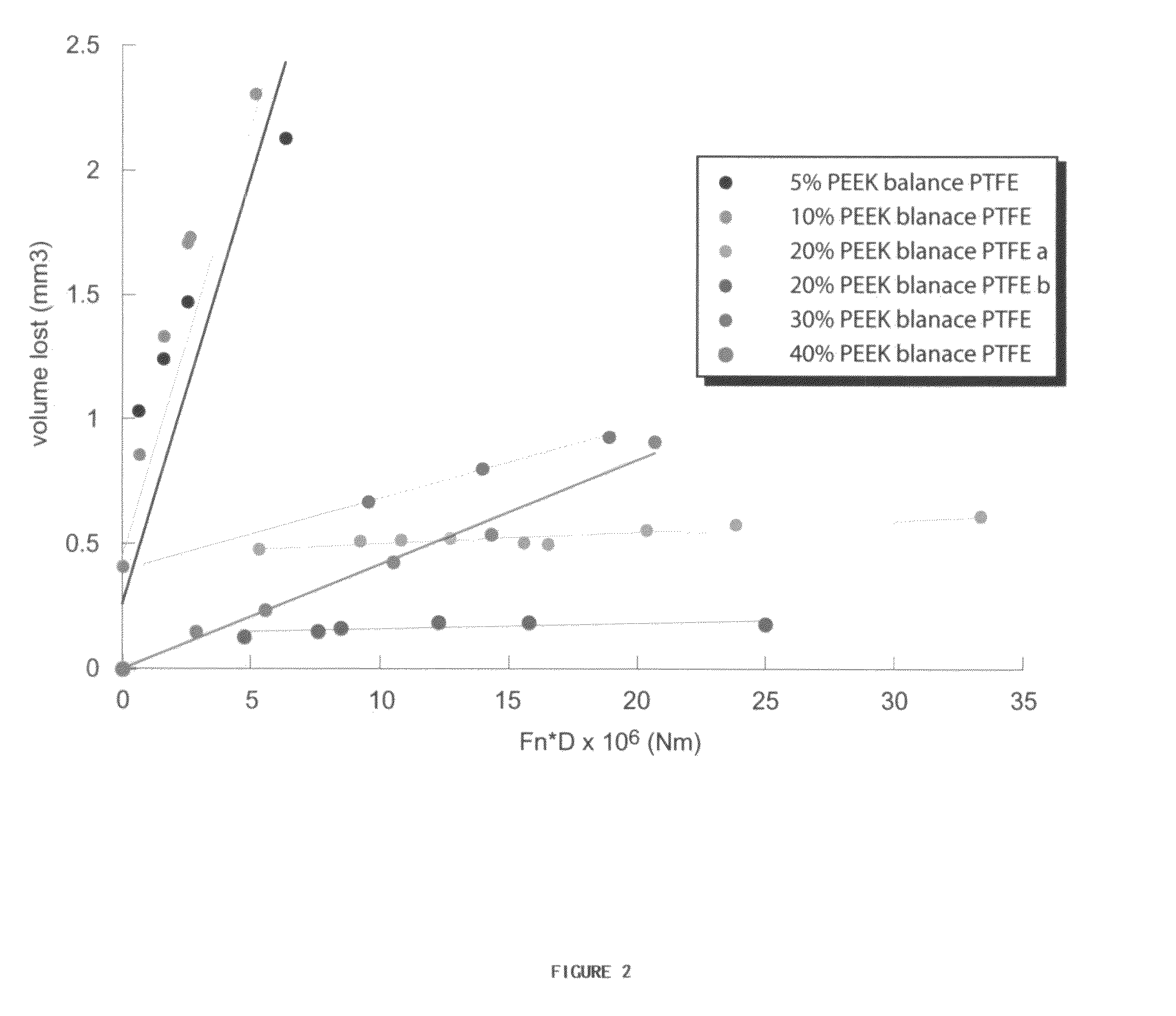

Low friction and low wear polymer/polymer composites

PatentInactiveUS7314646B2

Innovation

- A composite material comprising a transfer film forming polymer (at least 10 wt% PTFE) and a strengthening polymer (15-90 wt% PEEK or other strong polymers) forms an interconnected network structure, reducing wear rates to <10−7 mm3/Nm and friction coefficients to <0.10, with the polymers having softening points within 40°C of each other to facilitate interpenetrating networks and improved bonding.

Environmental Impact

The incorporation of bio-based fillers in PTFE composites for enhanced wear resistance presents significant environmental implications. This approach aligns with the growing global emphasis on sustainable materials and eco-friendly manufacturing processes. By utilizing bio-based fillers, the reliance on non-renewable resources traditionally used in PTFE composites can be reduced, contributing to the conservation of finite natural resources.

The production of bio-based fillers often requires less energy and generates fewer greenhouse gas emissions compared to the extraction and processing of conventional mineral fillers. This reduction in carbon footprint is particularly relevant in the context of increasing environmental regulations and the push for carbon-neutral industrial processes. Furthermore, the use of renewable, plant-derived materials as fillers can potentially lead to a more circular economy model, where waste from agricultural or forestry industries is repurposed into high-value composite materials.

However, the environmental benefits of bio-based fillers must be carefully evaluated through comprehensive life cycle assessments. These assessments should consider factors such as land use changes, water consumption, and potential competition with food crops. It is crucial to ensure that the sourcing and processing of bio-based fillers do not inadvertently lead to negative environmental impacts that could offset their benefits.

The biodegradability of bio-based fillers may also contribute to improved end-of-life scenarios for PTFE composites. While PTFE itself is not biodegradable, the incorporation of bio-based fillers could potentially enhance the recyclability or compostability of the composite material. This could lead to reduced waste accumulation and lower environmental impact at the product's end-of-life stage.

Additionally, the optimization of bio-based filler incorporation may result in PTFE composites with enhanced durability and wear resistance. This improvement in material performance could lead to longer-lasting products, reducing the need for frequent replacements and thereby decreasing overall material consumption and waste generation. The potential for creating more durable and environmentally friendly materials aligns well with the principles of sustainable design and green engineering.

It is important to note that the environmental impact of bio-based fillers in PTFE composites extends beyond the material itself. The manufacturing processes, transportation, and application of these composites should also be considered in the overall environmental assessment. Innovations in processing techniques that reduce energy consumption or enable the use of greener solvents and additives could further enhance the environmental profile of these advanced materials.

The production of bio-based fillers often requires less energy and generates fewer greenhouse gas emissions compared to the extraction and processing of conventional mineral fillers. This reduction in carbon footprint is particularly relevant in the context of increasing environmental regulations and the push for carbon-neutral industrial processes. Furthermore, the use of renewable, plant-derived materials as fillers can potentially lead to a more circular economy model, where waste from agricultural or forestry industries is repurposed into high-value composite materials.

However, the environmental benefits of bio-based fillers must be carefully evaluated through comprehensive life cycle assessments. These assessments should consider factors such as land use changes, water consumption, and potential competition with food crops. It is crucial to ensure that the sourcing and processing of bio-based fillers do not inadvertently lead to negative environmental impacts that could offset their benefits.

The biodegradability of bio-based fillers may also contribute to improved end-of-life scenarios for PTFE composites. While PTFE itself is not biodegradable, the incorporation of bio-based fillers could potentially enhance the recyclability or compostability of the composite material. This could lead to reduced waste accumulation and lower environmental impact at the product's end-of-life stage.

Additionally, the optimization of bio-based filler incorporation may result in PTFE composites with enhanced durability and wear resistance. This improvement in material performance could lead to longer-lasting products, reducing the need for frequent replacements and thereby decreasing overall material consumption and waste generation. The potential for creating more durable and environmentally friendly materials aligns well with the principles of sustainable design and green engineering.

It is important to note that the environmental impact of bio-based fillers in PTFE composites extends beyond the material itself. The manufacturing processes, transportation, and application of these composites should also be considered in the overall environmental assessment. Innovations in processing techniques that reduce energy consumption or enable the use of greener solvents and additives could further enhance the environmental profile of these advanced materials.

Regulatory Landscape

The regulatory landscape surrounding the optimization of bio-based filler incorporation in PTFE composites for enhanced wear resistance is complex and evolving. Environmental regulations play a significant role in shaping the development and adoption of these materials. Many countries and regions have implemented policies to promote the use of bio-based materials as part of their sustainability initiatives. For instance, the European Union's Circular Economy Action Plan encourages the use of renewable resources in manufacturing, which could potentially benefit bio-based PTFE composites.

In the United States, the Environmental Protection Agency (EPA) regulates the use of certain chemicals in manufacturing processes. The Toxic Substances Control Act (TSCA) requires manufacturers to report new chemical substances, which may include novel bio-based fillers used in PTFE composites. Additionally, the FDA's regulations on food contact materials could impact the use of these composites in applications such as non-stick cookware or food processing equipment.

Safety regulations also influence the development and application of bio-based PTFE composites. Occupational Safety and Health Administration (OSHA) standards in the US and similar agencies worldwide set guidelines for worker exposure to particulate matter during the manufacturing process. These regulations may affect the choice of bio-based fillers and the methods used to incorporate them into PTFE matrices.

The global push towards reducing greenhouse gas emissions and combating climate change has led to the implementation of carbon pricing mechanisms in various countries. This could potentially create economic incentives for manufacturers to adopt bio-based materials, including in PTFE composites, as they often have a lower carbon footprint compared to their synthetic counterparts.

Waste management regulations are another crucial aspect of the regulatory landscape. The end-of-life disposal or recycling of PTFE composites with bio-based fillers must comply with local and international waste management laws. The European Union's Waste Framework Directive, for example, sets targets for recycling and recovery of materials, which could influence the design and composition of these composites to ensure easier recyclability.

Standardization bodies such as ISO and ASTM International are developing standards for bio-based materials and their incorporation into polymers. These standards aim to ensure consistency in quality, performance, and environmental impact assessment across the industry. Compliance with these standards may become increasingly important for market acceptance and regulatory approval of bio-based PTFE composites.

As research in this field progresses, it is likely that regulatory frameworks will continue to evolve. Manufacturers and researchers must stay informed about changes in regulations and proactively engage with regulatory bodies to ensure compliance and to contribute to the development of appropriate standards for these innovative materials.

In the United States, the Environmental Protection Agency (EPA) regulates the use of certain chemicals in manufacturing processes. The Toxic Substances Control Act (TSCA) requires manufacturers to report new chemical substances, which may include novel bio-based fillers used in PTFE composites. Additionally, the FDA's regulations on food contact materials could impact the use of these composites in applications such as non-stick cookware or food processing equipment.

Safety regulations also influence the development and application of bio-based PTFE composites. Occupational Safety and Health Administration (OSHA) standards in the US and similar agencies worldwide set guidelines for worker exposure to particulate matter during the manufacturing process. These regulations may affect the choice of bio-based fillers and the methods used to incorporate them into PTFE matrices.

The global push towards reducing greenhouse gas emissions and combating climate change has led to the implementation of carbon pricing mechanisms in various countries. This could potentially create economic incentives for manufacturers to adopt bio-based materials, including in PTFE composites, as they often have a lower carbon footprint compared to their synthetic counterparts.

Waste management regulations are another crucial aspect of the regulatory landscape. The end-of-life disposal or recycling of PTFE composites with bio-based fillers must comply with local and international waste management laws. The European Union's Waste Framework Directive, for example, sets targets for recycling and recovery of materials, which could influence the design and composition of these composites to ensure easier recyclability.

Standardization bodies such as ISO and ASTM International are developing standards for bio-based materials and their incorporation into polymers. These standards aim to ensure consistency in quality, performance, and environmental impact assessment across the industry. Compliance with these standards may become increasingly important for market acceptance and regulatory approval of bio-based PTFE composites.

As research in this field progresses, it is likely that regulatory frameworks will continue to evolve. Manufacturers and researchers must stay informed about changes in regulations and proactively engage with regulatory bodies to ensure compliance and to contribute to the development of appropriate standards for these innovative materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!