How to Use PTFE for Improved Heat Resistance?

JUN 27, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Heat Resistance Background and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has been a revolutionary material in various industries since its accidental discovery by Roy Plunkett in 1938. This synthetic fluoropolymer has gained significant attention due to its exceptional heat resistance properties, making it a crucial component in numerous high-temperature applications.

The development of PTFE for improved heat resistance has been driven by the increasing demand for materials that can withstand extreme thermal conditions in industries such as aerospace, automotive, and chemical processing. As technology advances and operational environments become more challenging, the need for materials with superior heat resistance capabilities continues to grow.

PTFE's unique molecular structure, consisting of a carbon backbone with fluorine atoms strongly bonded to it, contributes to its remarkable thermal stability. This structure allows PTFE to maintain its properties at temperatures up to 260°C (500°F) continuously, and even higher for short periods. The material's low coefficient of friction, chemical inertness, and electrical insulation properties further enhance its value in high-temperature applications.

Over the years, researchers and engineers have focused on improving PTFE's heat resistance through various methods, including the development of PTFE composites, surface modifications, and the exploration of new synthesis techniques. These efforts aim to push the boundaries of PTFE's thermal performance while maintaining its other desirable characteristics.

The primary objective of enhancing PTFE's heat resistance is to expand its applicability in extreme environments where conventional materials fail. This includes developing PTFE-based components for jet engines, rocket propulsion systems, and industrial furnaces. Additionally, improving PTFE's heat resistance can lead to increased durability and longevity of products, reducing maintenance costs and improving overall system efficiency.

Another crucial goal is to understand the fundamental mechanisms of PTFE's heat resistance at the molecular level. This knowledge can guide the development of new PTFE formulations or processing techniques that further enhance its thermal properties. Researchers are also exploring ways to combine PTFE with other materials to create hybrid solutions that offer the best of both worlds – PTFE's heat resistance and the complementary properties of other materials.

As we delve deeper into the realm of PTFE heat resistance, it is essential to consider the environmental impact and sustainability aspects of these developments. The challenge lies in improving PTFE's performance while minimizing its environmental footprint, aligning with global efforts towards more sustainable material solutions.

The development of PTFE for improved heat resistance has been driven by the increasing demand for materials that can withstand extreme thermal conditions in industries such as aerospace, automotive, and chemical processing. As technology advances and operational environments become more challenging, the need for materials with superior heat resistance capabilities continues to grow.

PTFE's unique molecular structure, consisting of a carbon backbone with fluorine atoms strongly bonded to it, contributes to its remarkable thermal stability. This structure allows PTFE to maintain its properties at temperatures up to 260°C (500°F) continuously, and even higher for short periods. The material's low coefficient of friction, chemical inertness, and electrical insulation properties further enhance its value in high-temperature applications.

Over the years, researchers and engineers have focused on improving PTFE's heat resistance through various methods, including the development of PTFE composites, surface modifications, and the exploration of new synthesis techniques. These efforts aim to push the boundaries of PTFE's thermal performance while maintaining its other desirable characteristics.

The primary objective of enhancing PTFE's heat resistance is to expand its applicability in extreme environments where conventional materials fail. This includes developing PTFE-based components for jet engines, rocket propulsion systems, and industrial furnaces. Additionally, improving PTFE's heat resistance can lead to increased durability and longevity of products, reducing maintenance costs and improving overall system efficiency.

Another crucial goal is to understand the fundamental mechanisms of PTFE's heat resistance at the molecular level. This knowledge can guide the development of new PTFE formulations or processing techniques that further enhance its thermal properties. Researchers are also exploring ways to combine PTFE with other materials to create hybrid solutions that offer the best of both worlds – PTFE's heat resistance and the complementary properties of other materials.

As we delve deeper into the realm of PTFE heat resistance, it is essential to consider the environmental impact and sustainability aspects of these developments. The challenge lies in improving PTFE's performance while minimizing its environmental footprint, aligning with global efforts towards more sustainable material solutions.

Market Analysis for High-Temperature Applications

The market for high-temperature applications utilizing PTFE (Polytetrafluoroethylene) has been experiencing significant growth due to the material's exceptional heat resistance properties. PTFE's ability to maintain its structural integrity and chemical inertness at elevated temperatures has made it a preferred choice across various industries.

In the automotive sector, PTFE is increasingly being used in engine components, gaskets, and seals that are exposed to high temperatures. The growing demand for more efficient and high-performance engines has driven the adoption of PTFE in this market segment. Similarly, the aerospace industry has been incorporating PTFE in aircraft engines, hydraulic systems, and other high-temperature applications to improve overall performance and reliability.

The industrial sector represents another major market for PTFE in high-temperature applications. Chemical processing plants, oil refineries, and power generation facilities rely on PTFE-based products for their heat-resistant properties in extreme environments. The material's resistance to corrosion and chemical attack further enhances its appeal in these industries.

The electronics industry has also been a significant consumer of PTFE for high-temperature applications. With the increasing miniaturization of electronic components and the need for better thermal management, PTFE is being used in printed circuit boards, insulation materials, and other heat-sensitive applications.

Market trends indicate a growing preference for PTFE-based composites that offer enhanced mechanical properties while maintaining excellent heat resistance. These advanced materials are finding applications in cutting-edge technologies such as 5G infrastructure, electric vehicles, and renewable energy systems.

The global market for PTFE in high-temperature applications is projected to continue its upward trajectory. Factors driving this growth include increasing industrialization in developing countries, stringent regulations promoting the use of high-performance materials, and ongoing technological advancements in manufacturing processes.

However, the market also faces challenges such as the high cost of PTFE compared to alternative materials and environmental concerns related to its production and disposal. These factors have spurred research into more sustainable and cost-effective alternatives, which could potentially impact the future market dynamics for PTFE in high-temperature applications.

In the automotive sector, PTFE is increasingly being used in engine components, gaskets, and seals that are exposed to high temperatures. The growing demand for more efficient and high-performance engines has driven the adoption of PTFE in this market segment. Similarly, the aerospace industry has been incorporating PTFE in aircraft engines, hydraulic systems, and other high-temperature applications to improve overall performance and reliability.

The industrial sector represents another major market for PTFE in high-temperature applications. Chemical processing plants, oil refineries, and power generation facilities rely on PTFE-based products for their heat-resistant properties in extreme environments. The material's resistance to corrosion and chemical attack further enhances its appeal in these industries.

The electronics industry has also been a significant consumer of PTFE for high-temperature applications. With the increasing miniaturization of electronic components and the need for better thermal management, PTFE is being used in printed circuit boards, insulation materials, and other heat-sensitive applications.

Market trends indicate a growing preference for PTFE-based composites that offer enhanced mechanical properties while maintaining excellent heat resistance. These advanced materials are finding applications in cutting-edge technologies such as 5G infrastructure, electric vehicles, and renewable energy systems.

The global market for PTFE in high-temperature applications is projected to continue its upward trajectory. Factors driving this growth include increasing industrialization in developing countries, stringent regulations promoting the use of high-performance materials, and ongoing technological advancements in manufacturing processes.

However, the market also faces challenges such as the high cost of PTFE compared to alternative materials and environmental concerns related to its production and disposal. These factors have spurred research into more sustainable and cost-effective alternatives, which could potentially impact the future market dynamics for PTFE in high-temperature applications.

Current PTFE Heat Resistance Limitations

Polytetrafluoroethylene (PTFE) is renowned for its exceptional heat resistance, making it a valuable material in various high-temperature applications. However, despite its impressive thermal properties, PTFE does have limitations when it comes to heat resistance. The current upper limit for continuous use of PTFE is approximately 260°C (500°F), with short-term exposure possible up to 300°C (572°F).

One of the primary limitations of PTFE's heat resistance is its tendency to degrade and decompose at temperatures above its continuous use limit. When exposed to temperatures exceeding 300°C, PTFE begins to break down, releasing potentially harmful fluorine-containing compounds. This decomposition not only compromises the material's structural integrity but also poses safety risks in certain applications.

Another limitation is the gradual loss of mechanical properties as temperatures approach the upper limit. While PTFE maintains its non-stick and low friction characteristics at elevated temperatures, its tensile strength and wear resistance may decrease, potentially leading to premature failure in high-stress environments.

PTFE's thermal expansion characteristics also present challenges in high-temperature applications. The material has a relatively high coefficient of thermal expansion, which can cause dimensional instability and potential sealing issues in precision components or gaskets subjected to significant temperature fluctuations.

Furthermore, PTFE's heat resistance can be compromised by the presence of certain chemicals or contaminants. Exposure to strong oxidizing agents or metal particles at elevated temperatures can accelerate degradation and reduce the material's overall heat resistance.

It's important to note that while pure PTFE has these limitations, various modified forms and composites have been developed to address some of these issues. For instance, filled PTFE grades incorporating materials like glass fibers, carbon, or bronze can offer improved mechanical properties and slightly higher temperature resistance, albeit at the cost of some of PTFE's inherent properties like chemical inertness.

The electrical properties of PTFE, while generally excellent, can also be affected at high temperatures. As the material approaches its upper temperature limit, its dielectric strength and volume resistivity may decrease, potentially impacting its performance in electrical insulation applications.

In conclusion, while PTFE offers exceptional heat resistance for a polymer, its current limitations necessitate careful consideration in extreme temperature environments. These constraints drive ongoing research and development efforts to enhance PTFE's thermal performance and expand its applicability in high-temperature scenarios.

One of the primary limitations of PTFE's heat resistance is its tendency to degrade and decompose at temperatures above its continuous use limit. When exposed to temperatures exceeding 300°C, PTFE begins to break down, releasing potentially harmful fluorine-containing compounds. This decomposition not only compromises the material's structural integrity but also poses safety risks in certain applications.

Another limitation is the gradual loss of mechanical properties as temperatures approach the upper limit. While PTFE maintains its non-stick and low friction characteristics at elevated temperatures, its tensile strength and wear resistance may decrease, potentially leading to premature failure in high-stress environments.

PTFE's thermal expansion characteristics also present challenges in high-temperature applications. The material has a relatively high coefficient of thermal expansion, which can cause dimensional instability and potential sealing issues in precision components or gaskets subjected to significant temperature fluctuations.

Furthermore, PTFE's heat resistance can be compromised by the presence of certain chemicals or contaminants. Exposure to strong oxidizing agents or metal particles at elevated temperatures can accelerate degradation and reduce the material's overall heat resistance.

It's important to note that while pure PTFE has these limitations, various modified forms and composites have been developed to address some of these issues. For instance, filled PTFE grades incorporating materials like glass fibers, carbon, or bronze can offer improved mechanical properties and slightly higher temperature resistance, albeit at the cost of some of PTFE's inherent properties like chemical inertness.

The electrical properties of PTFE, while generally excellent, can also be affected at high temperatures. As the material approaches its upper temperature limit, its dielectric strength and volume resistivity may decrease, potentially impacting its performance in electrical insulation applications.

In conclusion, while PTFE offers exceptional heat resistance for a polymer, its current limitations necessitate careful consideration in extreme temperature environments. These constraints drive ongoing research and development efforts to enhance PTFE's thermal performance and expand its applicability in high-temperature scenarios.

Existing PTFE Heat Enhancement Techniques

01 PTFE composites for enhanced heat resistance

Incorporating additives or fillers into PTFE to create composites that improve heat resistance. These composites can withstand higher temperatures while maintaining PTFE's desirable properties, making them suitable for various high-temperature applications.- PTFE composites for enhanced heat resistance: Incorporating additives or fillers into PTFE to create composites that improve heat resistance. These composites can withstand higher temperatures while maintaining PTFE's desirable properties, making them suitable for various high-temperature applications.

- Surface modification techniques for PTFE: Applying surface treatments or coatings to PTFE to enhance its heat resistance. These modifications can include plasma treatment, chemical etching, or the application of specialized coatings that improve the material's ability to withstand high temperatures.

- PTFE blends with other heat-resistant polymers: Combining PTFE with other heat-resistant polymers to create blends that offer improved thermal stability. These blends can leverage the strengths of multiple materials to achieve better overall heat resistance than PTFE alone.

- Nanostructured PTFE for improved heat resistance: Developing nanostructured forms of PTFE, such as nanofibers or nanocomposites, to enhance heat resistance. The unique properties of nanomaterials can contribute to improved thermal stability and heat dissipation in PTFE-based products.

- Heat-resistant PTFE for specific applications: Tailoring PTFE formulations for specific high-temperature applications, such as in automotive, aerospace, or industrial settings. These specialized formulations focus on optimizing heat resistance while maintaining other critical properties required for the intended use.

02 Surface modification techniques for PTFE

Applying surface treatments or modifications to PTFE to enhance its heat resistance. These techniques can include plasma treatment, chemical etching, or coating with heat-resistant materials, improving the material's performance in high-temperature environments.Expand Specific Solutions03 PTFE-based heat-resistant coatings

Developing PTFE-based coatings that provide excellent heat resistance for various substrates. These coatings can protect underlying materials from high temperatures while maintaining the non-stick and low friction properties of PTFE.Expand Specific Solutions04 Optimized PTFE processing for heat resistance

Improving PTFE heat resistance through optimized processing techniques. This can include specialized sintering processes, controlled cooling, or the addition of specific steps during manufacturing to enhance the material's thermal stability and performance at high temperatures.Expand Specific Solutions05 PTFE blends for high-temperature applications

Creating blends of PTFE with other heat-resistant polymers or materials to achieve superior thermal performance. These blends can combine the unique properties of PTFE with the heat resistance of other materials, resulting in a composite suitable for extreme temperature environments.Expand Specific Solutions

Key PTFE Manufacturers and Suppliers

The market for PTFE in heat resistance applications is in a mature growth stage, with a global market size estimated to be over $2 billion. The technology is well-established, with key players like DAIKIN INDUSTRIES, W. L. Gore & Associates, and DuPont de Nemours leading innovation. These companies have developed advanced PTFE formulations and manufacturing processes to enhance heat resistance properties. Emerging players such as Zhejiang Juhua and Nanjing Comptech Composites are also contributing to technological advancements, particularly in specialized applications. The competitive landscape is characterized by ongoing R&D efforts to improve PTFE's performance at extreme temperatures and expand its use in demanding industries like aerospace, automotive, and electronics.

DAIKIN INDUSTRIES Ltd.

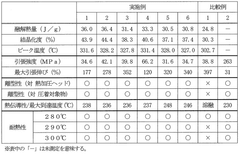

Technical Solution: Daikin has pioneered the development of modified PTFE resins with improved heat resistance. Their Polyflon™ PTFE series includes grades specifically engineered for high-temperature applications. Daikin's approach involves optimizing the molecular weight distribution and incorporating stabilizing additives to enhance thermal stability[4]. They have also developed a unique sintering process that results in a more uniform microstructure, reducing thermal expansion and improving heat resistance. Daikin's PTFE products can withstand continuous temperatures up to 280°C (536°F), with some grades capable of short-term exposure to 300°C (572°F)[5]. Additionally, Daikin has introduced PTFE-based coatings that provide excellent heat resistance and non-stick properties for industrial equipment operating in high-temperature environments[6].

Strengths: Strong focus on PTFE innovations, diverse product portfolio, and global manufacturing capabilities. Weaknesses: Relatively higher prices for specialized grades, potential regulatory challenges in some markets due to environmental concerns.

AGC, Inc. (Japan)

Technical Solution: AGC has developed innovative PTFE products with improved heat resistance under their Fluon® brand. Their approach focuses on optimizing the polymer structure and incorporating proprietary additives to enhance thermal stability. AGC's high-performance PTFE grades can withstand continuous temperatures up to 290°C (554°F), with some specialized formulations capable of short-term exposure to even higher temperatures[10]. They have also introduced PTFE-based composite materials that combine the polymer's heat resistance with other high-temperature resistant materials, such as ceramic fillers or specialized fibers. AGC's research has led to the development of PTFE products with reduced thermal expansion and improved creep resistance at elevated temperatures, making them suitable for demanding industrial applications[11]. Additionally, AGC has pioneered the use of nanotechnology to modify PTFE, resulting in materials with enhanced heat dissipation properties and improved overall thermal performance[12].

Strengths: Strong R&D capabilities in fluoropolymers, wide range of PTFE grades for various applications, and global manufacturing presence. Weaknesses: Potential environmental concerns associated with fluoropolymer production, competition from other major players in the industry.

Innovative PTFE Composite Technologies

Method for producing porous sheet, heat storage sheet, and chemical heat storage system

PatentWO2013157252A1

Innovation

- A porous sheet manufacturing method using polytetrafluoroethylene (PTFE) and chemical heat storage materials, where sheet-like moldings are prepared and stacked to create a laminated structure with self-adhesiveness, facilitating easy installation and improved heat conversion efficiency.

Heat-resistant release sheet and thermocompression bonding method

PatentWO2020071386A1

Innovation

- A heat-resistant release sheet made of polytetrafluoroethylene (PTFE) or modified PTFE with high heat resistance and thermal conductivity is used between the object to be crimped and the heat-pressing head, allowing for faster heat transfer and improved bonding efficiency.

Environmental Impact of PTFE Production

The production of Polytetrafluoroethylene (PTFE) has significant environmental implications that warrant careful consideration. The manufacturing process involves the use of fluoropolymers, which can lead to the release of perfluorooctanoic acid (PFOA) and other perfluorinated compounds into the environment. These substances are known for their persistence and potential to bioaccumulate, raising concerns about long-term ecological impacts.

During PTFE production, greenhouse gas emissions are a notable issue. The process generates fluorinated greenhouse gases, particularly hydrofluorocarbons (HFCs) and perfluorocarbons (PFCs), which have high global warming potentials. These emissions contribute to climate change and are subject to increasing regulatory scrutiny worldwide.

Water pollution is another environmental challenge associated with PTFE manufacturing. Wastewater from production facilities may contain fluorinated compounds and other chemical residues. If not properly treated, these contaminants can enter aquatic ecosystems, potentially affecting water quality and aquatic life. Implementing advanced water treatment technologies is crucial to mitigate this risk.

The disposal of PTFE products at the end of their lifecycle presents additional environmental concerns. While PTFE is chemically inert and does not biodegrade, it can break down into microplastics over time. These microplastics may accumulate in the environment, particularly in marine ecosystems, posing risks to wildlife and potentially entering the food chain.

Energy consumption in PTFE production is substantial, contributing to indirect environmental impacts through increased carbon emissions from power generation. The high temperatures required for polymerization and the energy-intensive nature of fluoropolymer synthesis contribute to this energy demand. Efforts to improve energy efficiency and transition to renewable energy sources in manufacturing can help mitigate these impacts.

Raw material extraction for PTFE production, particularly fluorite mining, can lead to habitat disruption and landscape alterations. Responsible mining practices and site rehabilitation are essential to minimize these environmental effects. Additionally, the transportation of raw materials and finished products contributes to the overall carbon footprint of PTFE manufacturing.

To address these environmental challenges, the PTFE industry is exploring more sustainable production methods. This includes developing alternative polymerization processes that reduce or eliminate the use of PFOA, implementing closed-loop systems to minimize waste and emissions, and investing in recycling technologies to improve the circularity of PTFE products. Regulatory bodies are also tightening controls on perfluorinated compounds, driving innovation in greener manufacturing techniques.

During PTFE production, greenhouse gas emissions are a notable issue. The process generates fluorinated greenhouse gases, particularly hydrofluorocarbons (HFCs) and perfluorocarbons (PFCs), which have high global warming potentials. These emissions contribute to climate change and are subject to increasing regulatory scrutiny worldwide.

Water pollution is another environmental challenge associated with PTFE manufacturing. Wastewater from production facilities may contain fluorinated compounds and other chemical residues. If not properly treated, these contaminants can enter aquatic ecosystems, potentially affecting water quality and aquatic life. Implementing advanced water treatment technologies is crucial to mitigate this risk.

The disposal of PTFE products at the end of their lifecycle presents additional environmental concerns. While PTFE is chemically inert and does not biodegrade, it can break down into microplastics over time. These microplastics may accumulate in the environment, particularly in marine ecosystems, posing risks to wildlife and potentially entering the food chain.

Energy consumption in PTFE production is substantial, contributing to indirect environmental impacts through increased carbon emissions from power generation. The high temperatures required for polymerization and the energy-intensive nature of fluoropolymer synthesis contribute to this energy demand. Efforts to improve energy efficiency and transition to renewable energy sources in manufacturing can help mitigate these impacts.

Raw material extraction for PTFE production, particularly fluorite mining, can lead to habitat disruption and landscape alterations. Responsible mining practices and site rehabilitation are essential to minimize these environmental effects. Additionally, the transportation of raw materials and finished products contributes to the overall carbon footprint of PTFE manufacturing.

To address these environmental challenges, the PTFE industry is exploring more sustainable production methods. This includes developing alternative polymerization processes that reduce or eliminate the use of PFOA, implementing closed-loop systems to minimize waste and emissions, and investing in recycling technologies to improve the circularity of PTFE products. Regulatory bodies are also tightening controls on perfluorinated compounds, driving innovation in greener manufacturing techniques.

PTFE Recycling and Sustainability Strategies

As the global focus on environmental sustainability intensifies, the recycling and sustainable management of PTFE (Polytetrafluoroethylene) have become crucial aspects of its lifecycle. PTFE, known for its exceptional heat resistance and chemical inertness, presents unique challenges in recycling due to its durability and resistance to degradation.

Traditional recycling methods for PTFE have been limited, often resulting in downcycling or incineration. However, recent advancements in recycling technologies have opened new avenues for more efficient and sustainable PTFE management. Mechanical recycling processes have been refined to preserve the material's properties, allowing for the production of high-quality recycled PTFE for various applications.

Chemical recycling techniques, such as pyrolysis and depolymerization, have shown promise in breaking down PTFE into its constituent monomers or other valuable chemical compounds. These processes not only reduce waste but also provide raw materials for new PTFE production, creating a more circular economy for fluoropolymers.

The development of bio-based alternatives to PTFE is another area of focus in sustainability strategies. Researchers are exploring the potential of plant-based polymers that mimic PTFE's properties while offering improved biodegradability. Although these alternatives are still in early stages, they represent a potential long-term solution for reducing the environmental impact of fluoropolymer production.

Industry collaborations and extended producer responsibility programs are emerging as key strategies for improving PTFE sustainability. Manufacturers are increasingly implementing take-back programs and closed-loop recycling systems to ensure proper end-of-life management of PTFE products. These initiatives not only reduce waste but also provide valuable insights into product design for recyclability.

Advancements in additive manufacturing technologies are also contributing to PTFE sustainability. 3D printing with PTFE and its composites allows for more precise material usage, reducing waste in production processes. This technology also enables the creation of complex geometries that can enhance product performance while minimizing material consumption.

As regulations around persistent organic pollutants tighten, the development of safe disposal methods for non-recyclable PTFE waste remains a priority. Research into controlled incineration techniques and the capture of fluorine compounds is ongoing, aiming to minimize environmental impact when recycling is not feasible.

Traditional recycling methods for PTFE have been limited, often resulting in downcycling or incineration. However, recent advancements in recycling technologies have opened new avenues for more efficient and sustainable PTFE management. Mechanical recycling processes have been refined to preserve the material's properties, allowing for the production of high-quality recycled PTFE for various applications.

Chemical recycling techniques, such as pyrolysis and depolymerization, have shown promise in breaking down PTFE into its constituent monomers or other valuable chemical compounds. These processes not only reduce waste but also provide raw materials for new PTFE production, creating a more circular economy for fluoropolymers.

The development of bio-based alternatives to PTFE is another area of focus in sustainability strategies. Researchers are exploring the potential of plant-based polymers that mimic PTFE's properties while offering improved biodegradability. Although these alternatives are still in early stages, they represent a potential long-term solution for reducing the environmental impact of fluoropolymer production.

Industry collaborations and extended producer responsibility programs are emerging as key strategies for improving PTFE sustainability. Manufacturers are increasingly implementing take-back programs and closed-loop recycling systems to ensure proper end-of-life management of PTFE products. These initiatives not only reduce waste but also provide valuable insights into product design for recyclability.

Advancements in additive manufacturing technologies are also contributing to PTFE sustainability. 3D printing with PTFE and its composites allows for more precise material usage, reducing waste in production processes. This technology also enables the creation of complex geometries that can enhance product performance while minimizing material consumption.

As regulations around persistent organic pollutants tighten, the development of safe disposal methods for non-recyclable PTFE waste remains a priority. Research into controlled incineration techniques and the capture of fluorine compounds is ongoing, aiming to minimize environmental impact when recycling is not feasible.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!