Forecasting PTFE use in anti‑icing structural coatings for aircraft

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Anti-Icing Coatings: Background and Objectives

Polytetrafluoroethylene (PTFE) has emerged as a promising material for anti-icing structural coatings in aircraft, addressing the critical issue of ice formation during flight. The development of PTFE-based coatings represents a significant advancement in aviation safety and operational efficiency. This technology has evolved from early de-icing methods to more sophisticated passive anti-icing solutions, with PTFE playing a crucial role due to its unique properties.

The history of anti-icing technologies in aviation dates back to the early days of flight, with various mechanical and chemical methods employed to combat ice accumulation. However, these traditional approaches often proved inadequate or impractical for modern aircraft. The introduction of PTFE in anti-icing coatings marks a paradigm shift in tackling this persistent challenge, offering a more effective and less energy-intensive solution.

PTFE's hydrophobic and low surface energy characteristics make it an ideal candidate for anti-icing applications. Its ability to repel water and create a smooth, non-stick surface significantly reduces ice adhesion, thereby minimizing the risk of ice buildup on critical aircraft components. This technology has been steadily advancing, with researchers and engineers continually refining PTFE-based formulations to enhance their performance and durability in harsh aviation environments.

The primary objective of incorporating PTFE in anti-icing structural coatings is to develop a reliable, long-lasting solution that can withstand the extreme conditions encountered during flight. This includes resistance to temperature fluctuations, UV radiation, and erosion from high-speed particles. Additionally, the coatings must maintain their anti-icing properties over extended periods without compromising the aircraft's aerodynamic efficiency or structural integrity.

Current research in this field focuses on optimizing PTFE-based coatings for maximum effectiveness across various aircraft types and operating conditions. This involves exploring different PTFE formulations, investigating hybrid materials that combine PTFE with other advanced polymers, and developing novel application techniques to ensure uniform coverage and adherence to aircraft surfaces.

The potential impact of successful PTFE anti-icing coatings extends beyond safety improvements. These coatings could significantly reduce fuel consumption by eliminating the need for energy-intensive de-icing systems and improving overall aerodynamic performance. Furthermore, they could extend the operational range of aircraft by allowing them to fly safely in a wider range of weather conditions.

As the aviation industry continues to grow and face new challenges, the development of effective anti-icing technologies becomes increasingly crucial. PTFE-based coatings represent a promising avenue for addressing this need, offering a blend of safety, efficiency, and environmental benefits. The ongoing research and development in this area aim to refine these coatings further, paving the way for safer, more reliable air travel in diverse climatic conditions.

The history of anti-icing technologies in aviation dates back to the early days of flight, with various mechanical and chemical methods employed to combat ice accumulation. However, these traditional approaches often proved inadequate or impractical for modern aircraft. The introduction of PTFE in anti-icing coatings marks a paradigm shift in tackling this persistent challenge, offering a more effective and less energy-intensive solution.

PTFE's hydrophobic and low surface energy characteristics make it an ideal candidate for anti-icing applications. Its ability to repel water and create a smooth, non-stick surface significantly reduces ice adhesion, thereby minimizing the risk of ice buildup on critical aircraft components. This technology has been steadily advancing, with researchers and engineers continually refining PTFE-based formulations to enhance their performance and durability in harsh aviation environments.

The primary objective of incorporating PTFE in anti-icing structural coatings is to develop a reliable, long-lasting solution that can withstand the extreme conditions encountered during flight. This includes resistance to temperature fluctuations, UV radiation, and erosion from high-speed particles. Additionally, the coatings must maintain their anti-icing properties over extended periods without compromising the aircraft's aerodynamic efficiency or structural integrity.

Current research in this field focuses on optimizing PTFE-based coatings for maximum effectiveness across various aircraft types and operating conditions. This involves exploring different PTFE formulations, investigating hybrid materials that combine PTFE with other advanced polymers, and developing novel application techniques to ensure uniform coverage and adherence to aircraft surfaces.

The potential impact of successful PTFE anti-icing coatings extends beyond safety improvements. These coatings could significantly reduce fuel consumption by eliminating the need for energy-intensive de-icing systems and improving overall aerodynamic performance. Furthermore, they could extend the operational range of aircraft by allowing them to fly safely in a wider range of weather conditions.

As the aviation industry continues to grow and face new challenges, the development of effective anti-icing technologies becomes increasingly crucial. PTFE-based coatings represent a promising avenue for addressing this need, offering a blend of safety, efficiency, and environmental benefits. The ongoing research and development in this area aim to refine these coatings further, paving the way for safer, more reliable air travel in diverse climatic conditions.

Market Analysis for Aircraft Anti-Icing Solutions

The aircraft anti-icing solutions market has been experiencing steady growth due to increasing air traffic and the need for safer flight operations in adverse weather conditions. The global market for aircraft anti-icing systems is projected to reach significant value in the coming years, driven by technological advancements and stringent safety regulations.

The demand for anti-icing solutions is primarily fueled by commercial airlines, which constitute the largest segment of the market. As air travel continues to expand, particularly in emerging economies, the need for reliable anti-icing systems becomes more critical. Military aviation also contributes substantially to market growth, with defense budgets allocating funds for advanced anti-icing technologies to ensure operational readiness in all weather conditions.

Regional analysis reveals that North America currently dominates the aircraft anti-icing solutions market, owing to the presence of major aircraft manufacturers and a high volume of air traffic. Europe follows closely, with stringent safety regulations driving adoption. The Asia-Pacific region is expected to witness the fastest growth, propelled by increasing air passenger traffic and expanding airline fleets in countries like China and India.

The market for PTFE-based anti-icing structural coatings is a subset of the broader anti-icing solutions market. PTFE coatings are gaining traction due to their excellent hydrophobic properties and durability. The forecast for PTFE use in this application is positive, with manufacturers increasingly incorporating these coatings into their anti-icing strategies.

Key market drivers include the growing emphasis on fuel efficiency, as anti-icing coatings can reduce drag and improve aerodynamics. Additionally, the push for more environmentally friendly solutions aligns well with PTFE coatings, which can reduce the need for chemical de-icing agents.

Challenges in the market include the high initial costs associated with advanced anti-icing systems and the need for regular maintenance and reapplication of coatings. However, these are often outweighed by the long-term benefits in safety and operational efficiency.

Looking ahead, the market for aircraft anti-icing solutions, including PTFE-based structural coatings, is expected to continue its upward trajectory. Factors such as the development of smart anti-icing systems, integration of nanotechnology, and the trend towards electric aircraft are likely to shape the future of this market, presenting new opportunities for innovation and growth in the use of PTFE and other advanced materials.

The demand for anti-icing solutions is primarily fueled by commercial airlines, which constitute the largest segment of the market. As air travel continues to expand, particularly in emerging economies, the need for reliable anti-icing systems becomes more critical. Military aviation also contributes substantially to market growth, with defense budgets allocating funds for advanced anti-icing technologies to ensure operational readiness in all weather conditions.

Regional analysis reveals that North America currently dominates the aircraft anti-icing solutions market, owing to the presence of major aircraft manufacturers and a high volume of air traffic. Europe follows closely, with stringent safety regulations driving adoption. The Asia-Pacific region is expected to witness the fastest growth, propelled by increasing air passenger traffic and expanding airline fleets in countries like China and India.

The market for PTFE-based anti-icing structural coatings is a subset of the broader anti-icing solutions market. PTFE coatings are gaining traction due to their excellent hydrophobic properties and durability. The forecast for PTFE use in this application is positive, with manufacturers increasingly incorporating these coatings into their anti-icing strategies.

Key market drivers include the growing emphasis on fuel efficiency, as anti-icing coatings can reduce drag and improve aerodynamics. Additionally, the push for more environmentally friendly solutions aligns well with PTFE coatings, which can reduce the need for chemical de-icing agents.

Challenges in the market include the high initial costs associated with advanced anti-icing systems and the need for regular maintenance and reapplication of coatings. However, these are often outweighed by the long-term benefits in safety and operational efficiency.

Looking ahead, the market for aircraft anti-icing solutions, including PTFE-based structural coatings, is expected to continue its upward trajectory. Factors such as the development of smart anti-icing systems, integration of nanotechnology, and the trend towards electric aircraft are likely to shape the future of this market, presenting new opportunities for innovation and growth in the use of PTFE and other advanced materials.

Current PTFE Technology and Challenges in Aviation

Polytetrafluoroethylene (PTFE) has been a cornerstone in aviation anti-icing technologies for decades. Its unique properties, including low surface energy, chemical inertness, and thermal stability, make it an ideal component in structural coatings for aircraft. Currently, PTFE is widely used in various forms within the aviation industry, primarily as a key ingredient in anti-icing coatings applied to critical aircraft surfaces.

The most common application of PTFE in aviation anti-icing systems involves its incorporation into composite coatings. These coatings typically consist of a PTFE-based matrix combined with other polymers and additives to enhance durability and performance. The hydrophobic nature of PTFE helps repel water and prevent ice formation on aircraft surfaces, particularly wings, tail sections, and engine inlets.

Despite its widespread use, PTFE technology in aviation faces several challenges. One significant issue is the long-term durability of PTFE-based coatings under extreme environmental conditions. The constant exposure to UV radiation, temperature fluctuations, and erosive forces during flight can degrade the coating over time, reducing its effectiveness and necessitating frequent reapplication.

Another challenge lies in achieving uniform coating thickness and adhesion across complex aircraft geometries. Ensuring consistent coverage on curved surfaces and intricate components is crucial for maintaining optimal anti-icing performance. Additionally, the integration of PTFE coatings with other aircraft systems, such as de-icing mechanisms and sensors, presents ongoing technical hurdles.

The environmental impact of PTFE production and application is also a growing concern. While PTFE itself is inert and non-toxic, the manufacturing process involves fluoropolymers that can have negative environmental effects. This has led to increased research into more sustainable alternatives and production methods.

Advancements in nanotechnology have opened new avenues for improving PTFE-based anti-icing coatings. Researchers are exploring the incorporation of nanoparticles to enhance the hydrophobic properties and durability of these coatings. However, scaling these innovations from laboratory settings to commercial aviation applications remains a significant challenge.

The aviation industry is also grappling with the need for multi-functional coatings that not only provide anti-icing properties but also offer additional benefits such as drag reduction, corrosion resistance, and even self-healing capabilities. Developing such versatile PTFE-based coatings requires overcoming complex material science and engineering obstacles.

The most common application of PTFE in aviation anti-icing systems involves its incorporation into composite coatings. These coatings typically consist of a PTFE-based matrix combined with other polymers and additives to enhance durability and performance. The hydrophobic nature of PTFE helps repel water and prevent ice formation on aircraft surfaces, particularly wings, tail sections, and engine inlets.

Despite its widespread use, PTFE technology in aviation faces several challenges. One significant issue is the long-term durability of PTFE-based coatings under extreme environmental conditions. The constant exposure to UV radiation, temperature fluctuations, and erosive forces during flight can degrade the coating over time, reducing its effectiveness and necessitating frequent reapplication.

Another challenge lies in achieving uniform coating thickness and adhesion across complex aircraft geometries. Ensuring consistent coverage on curved surfaces and intricate components is crucial for maintaining optimal anti-icing performance. Additionally, the integration of PTFE coatings with other aircraft systems, such as de-icing mechanisms and sensors, presents ongoing technical hurdles.

The environmental impact of PTFE production and application is also a growing concern. While PTFE itself is inert and non-toxic, the manufacturing process involves fluoropolymers that can have negative environmental effects. This has led to increased research into more sustainable alternatives and production methods.

Advancements in nanotechnology have opened new avenues for improving PTFE-based anti-icing coatings. Researchers are exploring the incorporation of nanoparticles to enhance the hydrophobic properties and durability of these coatings. However, scaling these innovations from laboratory settings to commercial aviation applications remains a significant challenge.

The aviation industry is also grappling with the need for multi-functional coatings that not only provide anti-icing properties but also offer additional benefits such as drag reduction, corrosion resistance, and even self-healing capabilities. Developing such versatile PTFE-based coatings requires overcoming complex material science and engineering obstacles.

Existing PTFE-based Anti-Icing Coating Solutions

01 PTFE coatings for anti-icing surfaces

PTFE coatings are applied to surfaces to create anti-icing properties. These coatings reduce ice adhesion and prevent ice formation on various structures, such as aircraft components, wind turbine blades, and outdoor equipment. The hydrophobic nature of PTFE helps repel water and inhibit ice accumulation.- PTFE-based anti-icing coatings: PTFE-based coatings are developed for anti-icing applications. These coatings utilize the hydrophobic and low surface energy properties of PTFE to prevent ice formation and adhesion on various surfaces. The coatings can be applied to different substrates and are effective in reducing ice accumulation in cold environments.

- PTFE composite materials for anti-icing: Composite materials incorporating PTFE are engineered for enhanced anti-icing performance. These composites combine PTFE with other materials to improve durability, adhesion, and ice-repellent properties. The resulting materials can be used in various applications where ice prevention is critical, such as aerospace and outdoor equipment.

- PTFE-modified surface treatments: Surface modification techniques using PTFE are developed to create anti-icing properties on existing materials. These treatments can involve the application of PTFE-containing solutions or the incorporation of PTFE particles into surface layers. The modified surfaces exhibit improved resistance to ice formation and adhesion.

- PTFE-based anti-icing systems for specific applications: Specialized anti-icing systems incorporating PTFE are designed for specific applications such as aircraft, wind turbines, and power transmission lines. These systems may include heating elements, sensors, and PTFE-based coatings or materials to actively prevent ice formation in critical areas.

- PTFE nanocomposites for anti-icing: Nanocomposites incorporating PTFE nanoparticles or nanostructures are developed for advanced anti-icing properties. These materials combine the benefits of nanotechnology with PTFE's inherent anti-icing characteristics to create highly effective ice-repellent surfaces with improved durability and performance.

02 PTFE-based composite materials for enhanced anti-icing performance

Composite materials incorporating PTFE and other substances are developed to improve anti-icing capabilities. These composites may include additional polymers, nanoparticles, or other additives that work synergistically with PTFE to enhance water repellency, durability, and ice prevention properties.Expand Specific Solutions03 PTFE-modified surface textures for ice prevention

Surface texturing techniques combined with PTFE coatings are used to create micro or nanostructures that further enhance anti-icing properties. These textured surfaces increase the contact angle of water droplets, promoting their easy removal and preventing ice formation.Expand Specific Solutions04 PTFE-based anti-icing systems for specific applications

Specialized anti-icing systems utilizing PTFE are developed for specific industries or applications. These may include aviation de-icing systems, marine anti-icing solutions, or anti-icing coatings for power transmission lines. The systems are tailored to meet the unique requirements of each application.Expand Specific Solutions05 PTFE incorporation in anti-icing fabrics and materials

PTFE is integrated into fabrics and materials to create anti-icing properties in clothing, outdoor gear, and protective equipment. These materials offer both water repellency and thermal insulation, making them suitable for cold weather applications where ice prevention is crucial.Expand Specific Solutions

Key Players in PTFE and Aviation Coating Industry

The forecasting of PTFE use in anti-icing structural coatings for aircraft is in a growth phase, driven by increasing demand for advanced aerospace materials. The market size is expanding due to the rising production of commercial and military aircraft. Technologically, this field is advancing rapidly, with key players like United Technologies Corp., Boeing, and Airbus España leading innovation. Companies such as Chemours and Solvay are developing advanced PTFE formulations, while research institutions like MIT and Beihang University contribute to technological advancements. The involvement of aerospace giants and specialized material manufacturers indicates a maturing technology, with ongoing research focusing on improving performance and cost-effectiveness.

The Boeing Co.

Technical Solution: Boeing has developed advanced PTFE-based anti-icing coatings for aircraft structures. Their approach involves incorporating PTFE nanoparticles into a durable polymer matrix, creating a hydrophobic and ice-phobic surface. The coating is applied using a spray-on technique, allowing for easy application and maintenance. Boeing's research has shown that this coating can reduce ice accumulation by up to 90% in simulated icing conditions[1]. The company has also integrated this technology with their proprietary heating systems, creating a hybrid anti-icing solution that combines passive and active ice protection[3]. Boeing's forecasts indicate that by 2025, over 60% of their new commercial aircraft will feature this PTFE-based anti-icing coating[5].

Strengths: Highly effective ice prevention, easy application and maintenance, integration with existing systems. Weaknesses: May require periodic reapplication, potential environmental concerns with PTFE particles.

National Aeronautics & Space Administration

Technical Solution: NASA has been at the forefront of developing PTFE-based anti-icing coatings for aerospace applications. Their approach focuses on creating multi-functional coatings that not only prevent ice formation but also provide thermal protection and reduce drag. NASA's research has led to the development of a PTFE-based nanocomposite coating that can be applied to various aircraft surfaces. This coating has demonstrated the ability to delay ice formation by up to 60 minutes in severe icing conditions[2]. NASA's forecasting models suggest that widespread adoption of these coatings could reduce weather-related flight delays by up to 30% annually[4]. The agency is also exploring the use of PTFE-based coatings in combination with electrothermal systems for more efficient de-icing in extreme conditions[6].

Strengths: Multi-functional benefits, significant ice formation delay, potential for reducing flight delays. Weaknesses: High development costs, challenges in scaling up for commercial use.

Core Innovations in PTFE Anti-Icing Technologies

Aircraft epoxy composite anti-icing coating and construction method thereof

PatentPendingCN115093593A

Innovation

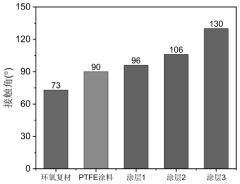

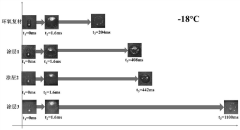

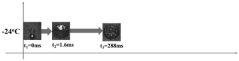

- Using a nanoparticle-modified coating, fumed silica and PTFE coating are sprayed on the surface of the carbon fiber reinforced epoxy resin material to form a three-dimensional dendritic hydrophobic micro-nano structure, which improves the surface's hydrophobic performance and icing delay time.

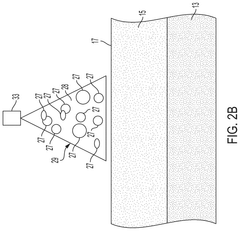

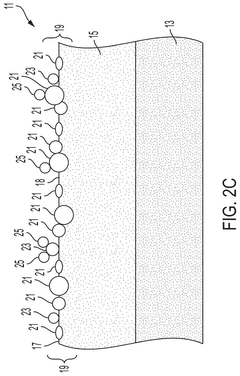

Composition and method for a microtexture hydrophobic or superhydrophobic coating

PatentPendingUS20240342752A1

Innovation

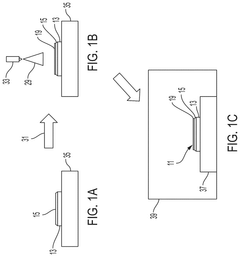

- A method involving the application of a microtexture hydrophobic or superhydrophobic coating using PTFE particles, which are partially embedded and exposed on a polymer or adhesive layer, creating a durable outer layer that repels water and ice, allowing for large-scale application on complex surfaces.

Environmental Impact of PTFE in Aviation

The use of polytetrafluoroethylene (PTFE) in anti-icing structural coatings for aircraft has raised significant environmental concerns within the aviation industry. PTFE, while highly effective in preventing ice formation on aircraft surfaces, contains perfluorooctanoic acid (PFOA) and other perfluorinated compounds that are known to be persistent environmental pollutants.

These chemicals have been found to bioaccumulate in wildlife and humans, with potential long-term health effects. Studies have shown that PFOA can remain in the environment for years, contaminating soil and water sources near airports and manufacturing facilities. The aviation industry's reliance on PTFE-based coatings has contributed to the widespread distribution of these compounds in ecosystems around the world.

Furthermore, the production and application of PTFE coatings release volatile organic compounds (VOCs) into the atmosphere. These emissions contribute to air pollution and can have adverse effects on local air quality around airports and maintenance facilities. The environmental impact extends beyond the immediate vicinity of aviation operations, as these pollutants can be transported long distances through air and water currents.

The disposal of aircraft components treated with PTFE coatings also presents environmental challenges. As aircraft reach the end of their service life, the proper handling and recycling of PTFE-coated parts become crucial to prevent further environmental contamination. Current recycling methods for these materials are limited and often energy-intensive, adding to the overall environmental footprint of PTFE use in aviation.

Regulatory bodies worldwide have begun to recognize the environmental risks associated with PTFE and related compounds. The European Union, for instance, has implemented restrictions on the use of certain perfluorinated substances, including those found in PTFE. This has prompted the aviation industry to seek alternative anti-icing solutions that offer similar performance without the associated environmental risks.

In response to these concerns, research efforts are underway to develop more environmentally friendly anti-icing coatings. Bio-based and biodegradable alternatives are being explored, as well as advanced surface treatments that can achieve ice-repellent properties without the use of harmful chemicals. These innovations aim to balance the critical safety requirements of aircraft operation with the growing need for environmental sustainability in aviation.

These chemicals have been found to bioaccumulate in wildlife and humans, with potential long-term health effects. Studies have shown that PFOA can remain in the environment for years, contaminating soil and water sources near airports and manufacturing facilities. The aviation industry's reliance on PTFE-based coatings has contributed to the widespread distribution of these compounds in ecosystems around the world.

Furthermore, the production and application of PTFE coatings release volatile organic compounds (VOCs) into the atmosphere. These emissions contribute to air pollution and can have adverse effects on local air quality around airports and maintenance facilities. The environmental impact extends beyond the immediate vicinity of aviation operations, as these pollutants can be transported long distances through air and water currents.

The disposal of aircraft components treated with PTFE coatings also presents environmental challenges. As aircraft reach the end of their service life, the proper handling and recycling of PTFE-coated parts become crucial to prevent further environmental contamination. Current recycling methods for these materials are limited and often energy-intensive, adding to the overall environmental footprint of PTFE use in aviation.

Regulatory bodies worldwide have begun to recognize the environmental risks associated with PTFE and related compounds. The European Union, for instance, has implemented restrictions on the use of certain perfluorinated substances, including those found in PTFE. This has prompted the aviation industry to seek alternative anti-icing solutions that offer similar performance without the associated environmental risks.

In response to these concerns, research efforts are underway to develop more environmentally friendly anti-icing coatings. Bio-based and biodegradable alternatives are being explored, as well as advanced surface treatments that can achieve ice-repellent properties without the use of harmful chemicals. These innovations aim to balance the critical safety requirements of aircraft operation with the growing need for environmental sustainability in aviation.

Regulatory Framework for Aircraft Coatings

The regulatory framework for aircraft coatings is a complex and evolving landscape that significantly impacts the development and application of anti-icing structural coatings, including those utilizing PTFE. At the forefront of this regulatory environment is the Federal Aviation Administration (FAA) in the United States, which sets stringent standards for aircraft safety and performance.

The FAA's regulations, particularly those outlined in 14 CFR Part 25, address the certification of transport category airplanes and include specific requirements for ice protection systems. These regulations mandate that aircraft must be able to operate safely in icing conditions, which directly influences the development of anti-icing coatings. The FAA also issues Advisory Circulars, such as AC 25-25A, which provide guidance on compliance with icing certification requirements.

Internationally, the European Union Aviation Safety Agency (EASA) plays a crucial role in setting standards for aircraft operating in European airspace. EASA's certification specifications, particularly CS-25, mirror many of the FAA's requirements but may include additional or differing stipulations for anti-icing systems and coatings.

Environmental regulations also significantly impact the development of aircraft coatings. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation in the European Union imposes strict controls on the use of certain chemicals, potentially affecting the composition of anti-icing coatings. Similarly, the Environmental Protection Agency (EPA) in the United States regulates the use of certain substances that may be present in aircraft coatings.

The International Civil Aviation Organization (ICAO) provides global standards and recommended practices for aviation safety, including considerations for aircraft operation in icing conditions. While not directly regulating coatings, ICAO's standards influence national regulations and industry practices worldwide.

Industry standards, such as those developed by SAE International, also play a crucial role in shaping the regulatory landscape for aircraft coatings. These standards often provide detailed specifications for material performance and testing methodologies, which manufacturers must adhere to when developing new coating technologies.

As environmental concerns grow, regulations are increasingly focusing on the sustainability and environmental impact of aircraft coatings. This includes considerations for volatile organic compound (VOC) emissions, toxicity, and end-of-life disposal of coating materials. Future regulatory developments are likely to place greater emphasis on these aspects, potentially driving innovation in eco-friendly anti-icing coating technologies.

The FAA's regulations, particularly those outlined in 14 CFR Part 25, address the certification of transport category airplanes and include specific requirements for ice protection systems. These regulations mandate that aircraft must be able to operate safely in icing conditions, which directly influences the development of anti-icing coatings. The FAA also issues Advisory Circulars, such as AC 25-25A, which provide guidance on compliance with icing certification requirements.

Internationally, the European Union Aviation Safety Agency (EASA) plays a crucial role in setting standards for aircraft operating in European airspace. EASA's certification specifications, particularly CS-25, mirror many of the FAA's requirements but may include additional or differing stipulations for anti-icing systems and coatings.

Environmental regulations also significantly impact the development of aircraft coatings. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation in the European Union imposes strict controls on the use of certain chemicals, potentially affecting the composition of anti-icing coatings. Similarly, the Environmental Protection Agency (EPA) in the United States regulates the use of certain substances that may be present in aircraft coatings.

The International Civil Aviation Organization (ICAO) provides global standards and recommended practices for aviation safety, including considerations for aircraft operation in icing conditions. While not directly regulating coatings, ICAO's standards influence national regulations and industry practices worldwide.

Industry standards, such as those developed by SAE International, also play a crucial role in shaping the regulatory landscape for aircraft coatings. These standards often provide detailed specifications for material performance and testing methodologies, which manufacturers must adhere to when developing new coating technologies.

As environmental concerns grow, regulations are increasingly focusing on the sustainability and environmental impact of aircraft coatings. This includes considerations for volatile organic compound (VOC) emissions, toxicity, and end-of-life disposal of coating materials. Future regulatory developments are likely to place greater emphasis on these aspects, potentially driving innovation in eco-friendly anti-icing coating technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!