PTFE’s Role in High‑Durability Industrial Design

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Evolution and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has played a pivotal role in industrial design since its accidental discovery by Roy Plunkett in 1938. This synthetic fluoropolymer has revolutionized numerous industries due to its exceptional properties, including high chemical resistance, low friction coefficient, and thermal stability.

The evolution of PTFE in industrial applications can be traced through several key milestones. Initially used in military and aerospace applications during World War II, PTFE's potential for widespread industrial use became apparent in the 1950s. The development of PTFE-coated cookware in the 1960s marked a significant breakthrough in consumer applications, showcasing its non-stick properties.

Throughout the 1970s and 1980s, advancements in PTFE manufacturing processes, such as the introduction of granular and fine powder forms, expanded its use in various industrial sectors. These developments enabled the creation of more complex shapes and thinner coatings, enhancing PTFE's versatility in high-durability designs.

The 1990s saw a surge in PTFE's application in the automotive and chemical processing industries, where its resistance to harsh environments and ability to reduce friction proved invaluable. Concurrently, environmental concerns led to the development of PTFE alternatives and recycling methods, addressing the material's persistence in the environment.

In recent years, nanotechnology has opened new frontiers for PTFE. The creation of PTFE nanoparticles and nanocomposites has led to enhanced performance characteristics, including improved wear resistance and thermal conductivity. These advancements have further solidified PTFE's position in high-durability industrial applications.

The primary objective of PTFE in high-durability industrial design is to provide long-lasting, low-maintenance solutions for challenging environments. This includes developing coatings and components that can withstand extreme temperatures, chemical exposure, and high wear conditions. Additionally, there is a focus on improving PTFE's environmental profile through the development of more sustainable manufacturing processes and end-of-life solutions.

Future objectives for PTFE in industrial design include enhancing its mechanical properties without compromising its unique chemical resistance and low friction characteristics. Research is ongoing to develop PTFE composites that combine the material's inherent benefits with improved strength and durability. Another key goal is to expand PTFE's application in emerging technologies, such as fuel cells and advanced filtration systems, where its properties can contribute to increased efficiency and longevity.

The evolution of PTFE in industrial applications can be traced through several key milestones. Initially used in military and aerospace applications during World War II, PTFE's potential for widespread industrial use became apparent in the 1950s. The development of PTFE-coated cookware in the 1960s marked a significant breakthrough in consumer applications, showcasing its non-stick properties.

Throughout the 1970s and 1980s, advancements in PTFE manufacturing processes, such as the introduction of granular and fine powder forms, expanded its use in various industrial sectors. These developments enabled the creation of more complex shapes and thinner coatings, enhancing PTFE's versatility in high-durability designs.

The 1990s saw a surge in PTFE's application in the automotive and chemical processing industries, where its resistance to harsh environments and ability to reduce friction proved invaluable. Concurrently, environmental concerns led to the development of PTFE alternatives and recycling methods, addressing the material's persistence in the environment.

In recent years, nanotechnology has opened new frontiers for PTFE. The creation of PTFE nanoparticles and nanocomposites has led to enhanced performance characteristics, including improved wear resistance and thermal conductivity. These advancements have further solidified PTFE's position in high-durability industrial applications.

The primary objective of PTFE in high-durability industrial design is to provide long-lasting, low-maintenance solutions for challenging environments. This includes developing coatings and components that can withstand extreme temperatures, chemical exposure, and high wear conditions. Additionally, there is a focus on improving PTFE's environmental profile through the development of more sustainable manufacturing processes and end-of-life solutions.

Future objectives for PTFE in industrial design include enhancing its mechanical properties without compromising its unique chemical resistance and low friction characteristics. Research is ongoing to develop PTFE composites that combine the material's inherent benefits with improved strength and durability. Another key goal is to expand PTFE's application in emerging technologies, such as fuel cells and advanced filtration systems, where its properties can contribute to increased efficiency and longevity.

Industrial Demand Analysis

The industrial demand for PTFE in high-durability design applications has been steadily increasing across various sectors. This growth is primarily driven by PTFE's unique properties, including exceptional chemical resistance, low friction coefficient, and high temperature tolerance. These characteristics make PTFE an invaluable material in industries where durability and reliability are paramount.

In the automotive sector, PTFE is extensively used in engine components, fuel systems, and transmission parts. The material's ability to withstand harsh chemicals and high temperatures while maintaining low friction has led to improved fuel efficiency and extended component lifespans. As the automotive industry continues to push for more efficient and durable vehicles, the demand for PTFE in this sector is expected to grow significantly.

The aerospace industry represents another major market for PTFE in high-durability applications. Aircraft manufacturers utilize PTFE in various components, including hydraulic systems, seals, and electrical insulation. The material's resistance to extreme temperatures and its lightweight nature make it ideal for aerospace applications where reliability and weight reduction are critical factors.

In the chemical processing industry, PTFE's exceptional chemical resistance has made it indispensable for lining tanks, pipes, and valves. This sector's demand for PTFE is driven by the need for materials that can withstand corrosive environments while maintaining structural integrity over extended periods. As chemical processes become more complex and aggressive, the reliance on PTFE for equipment protection is likely to increase.

The electronics industry has also seen a surge in PTFE demand, particularly in high-frequency applications. PTFE's excellent dielectric properties and thermal stability make it an ideal material for insulating cables, connectors, and circuit boards in demanding environments. With the ongoing expansion of 5G networks and the increasing complexity of electronic devices, the demand for PTFE in this sector is projected to grow substantially.

In the medical field, PTFE's biocompatibility and non-stick properties have led to its widespread use in implants, surgical instruments, and drug delivery systems. The aging global population and advancements in medical technologies are driving factors for increased PTFE demand in this sector.

The oil and gas industry utilizes PTFE in various applications, including seals, gaskets, and linings for equipment exposed to harsh chemicals and extreme pressures. As exploration and extraction activities expand into more challenging environments, the demand for PTFE-based solutions is expected to rise.

Overall, the industrial demand for PTFE in high-durability design applications is robust and diverse. The material's unique combination of properties continues to make it an essential component in industries where performance, reliability, and longevity are critical. As technological advancements push the boundaries of material requirements, PTFE's role in industrial design is likely to expand further, driving innovation and opening new market opportunities.

In the automotive sector, PTFE is extensively used in engine components, fuel systems, and transmission parts. The material's ability to withstand harsh chemicals and high temperatures while maintaining low friction has led to improved fuel efficiency and extended component lifespans. As the automotive industry continues to push for more efficient and durable vehicles, the demand for PTFE in this sector is expected to grow significantly.

The aerospace industry represents another major market for PTFE in high-durability applications. Aircraft manufacturers utilize PTFE in various components, including hydraulic systems, seals, and electrical insulation. The material's resistance to extreme temperatures and its lightweight nature make it ideal for aerospace applications where reliability and weight reduction are critical factors.

In the chemical processing industry, PTFE's exceptional chemical resistance has made it indispensable for lining tanks, pipes, and valves. This sector's demand for PTFE is driven by the need for materials that can withstand corrosive environments while maintaining structural integrity over extended periods. As chemical processes become more complex and aggressive, the reliance on PTFE for equipment protection is likely to increase.

The electronics industry has also seen a surge in PTFE demand, particularly in high-frequency applications. PTFE's excellent dielectric properties and thermal stability make it an ideal material for insulating cables, connectors, and circuit boards in demanding environments. With the ongoing expansion of 5G networks and the increasing complexity of electronic devices, the demand for PTFE in this sector is projected to grow substantially.

In the medical field, PTFE's biocompatibility and non-stick properties have led to its widespread use in implants, surgical instruments, and drug delivery systems. The aging global population and advancements in medical technologies are driving factors for increased PTFE demand in this sector.

The oil and gas industry utilizes PTFE in various applications, including seals, gaskets, and linings for equipment exposed to harsh chemicals and extreme pressures. As exploration and extraction activities expand into more challenging environments, the demand for PTFE-based solutions is expected to rise.

Overall, the industrial demand for PTFE in high-durability design applications is robust and diverse. The material's unique combination of properties continues to make it an essential component in industries where performance, reliability, and longevity are critical. As technological advancements push the boundaries of material requirements, PTFE's role in industrial design is likely to expand further, driving innovation and opening new market opportunities.

PTFE Challenges in Design

While PTFE (Polytetrafluoroethylene) offers numerous advantages in high-durability industrial design, it also presents several challenges that designers and engineers must address. One of the primary difficulties lies in PTFE's inherent non-stick properties, which, while beneficial in many applications, can complicate bonding and adhesion processes. This characteristic makes it challenging to integrate PTFE components with other materials or to create multi-layer structures.

Another significant challenge is PTFE's relatively low mechanical strength compared to other engineering plastics. This limitation can restrict its use in applications that require high load-bearing capabilities or resistance to impact. Designers must carefully consider these mechanical constraints when incorporating PTFE into structural components or high-stress environments.

PTFE's high thermal expansion coefficient poses additional design challenges, particularly in applications involving temperature fluctuations. The material's tendency to expand and contract more than surrounding materials can lead to issues with sealing, dimensional stability, and overall structural integrity. This necessitates careful consideration of thermal management and stress distribution in PTFE-based designs.

The material's low friction properties, while advantageous in many scenarios, can be problematic in certain design contexts. For instance, in applications where controlled friction is necessary, such as in some mechanical interfaces or load-bearing surfaces, PTFE's slippery nature may require additional engineering solutions or material modifications.

Processing and manufacturing PTFE components also present unique challenges. The material's high melting point and viscosity make traditional thermoplastic processing methods less effective. Specialized techniques like sintering are often required, which can increase production complexity and costs. Additionally, machining PTFE can be difficult due to its softness and tendency to deform under cutting forces.

PTFE's chemical inertness, while a key advantage in many applications, can pose challenges in surface modification and printing. This property makes it difficult to apply coatings, inks, or adhesives directly to PTFE surfaces, limiting design options for aesthetics or functional surface treatments.

Lastly, environmental concerns associated with PTFE production and disposal present challenges in sustainable design. The use of fluoropolymers has come under scrutiny due to their potential environmental impact, particularly regarding the persistence of perfluorinated compounds. Designers must navigate these environmental considerations while balancing the material's unique performance benefits.

Another significant challenge is PTFE's relatively low mechanical strength compared to other engineering plastics. This limitation can restrict its use in applications that require high load-bearing capabilities or resistance to impact. Designers must carefully consider these mechanical constraints when incorporating PTFE into structural components or high-stress environments.

PTFE's high thermal expansion coefficient poses additional design challenges, particularly in applications involving temperature fluctuations. The material's tendency to expand and contract more than surrounding materials can lead to issues with sealing, dimensional stability, and overall structural integrity. This necessitates careful consideration of thermal management and stress distribution in PTFE-based designs.

The material's low friction properties, while advantageous in many scenarios, can be problematic in certain design contexts. For instance, in applications where controlled friction is necessary, such as in some mechanical interfaces or load-bearing surfaces, PTFE's slippery nature may require additional engineering solutions or material modifications.

Processing and manufacturing PTFE components also present unique challenges. The material's high melting point and viscosity make traditional thermoplastic processing methods less effective. Specialized techniques like sintering are often required, which can increase production complexity and costs. Additionally, machining PTFE can be difficult due to its softness and tendency to deform under cutting forces.

PTFE's chemical inertness, while a key advantage in many applications, can pose challenges in surface modification and printing. This property makes it difficult to apply coatings, inks, or adhesives directly to PTFE surfaces, limiting design options for aesthetics or functional surface treatments.

Lastly, environmental concerns associated with PTFE production and disposal present challenges in sustainable design. The use of fluoropolymers has come under scrutiny due to their potential environmental impact, particularly regarding the persistence of perfluorinated compounds. Designers must navigate these environmental considerations while balancing the material's unique performance benefits.

Current PTFE Applications

01 Surface modification techniques for PTFE durability

Various surface modification techniques can be applied to enhance the durability of PTFE. These methods include plasma treatment, chemical etching, and the application of specialized coatings. Such modifications can improve adhesion, wear resistance, and overall longevity of PTFE components in various applications.- Enhanced PTFE durability through composite structures: Improving PTFE durability by creating composite structures with other materials. This approach combines PTFE with reinforcing agents or other polymers to enhance its mechanical properties, wear resistance, and overall longevity. These composites can maintain PTFE's beneficial properties while addressing its limitations in durability.

- Surface modification techniques for PTFE: Applying various surface modification techniques to enhance PTFE durability. These methods include plasma treatment, chemical etching, or coating with other materials to improve adhesion, wear resistance, and chemical resistance of PTFE surfaces. Such modifications can significantly extend the lifespan of PTFE components in demanding applications.

- Nanostructured PTFE for improved durability: Developing nanostructured PTFE materials to enhance durability. This approach involves manipulating the molecular structure of PTFE at the nanoscale to create materials with improved mechanical properties, wear resistance, and thermal stability. Nanostructured PTFE can offer superior durability compared to conventional PTFE.

- PTFE blends and alloys for enhanced performance: Creating PTFE blends and alloys with other polymers or materials to improve durability. This method combines PTFE with carefully selected additives or other polymers to create materials that retain PTFE's beneficial properties while addressing its durability limitations. These blends can offer improved wear resistance, mechanical strength, and chemical resistance.

- Specialized processing techniques for durable PTFE: Employing specialized processing techniques to enhance PTFE durability. These methods include optimized sintering processes, controlled cooling rates, and advanced molding techniques that can improve the molecular structure and overall performance of PTFE products. Such processes can result in PTFE components with superior durability and longevity.

02 PTFE composites for improved durability

Incorporating other materials into PTFE to create composites can significantly enhance its durability. Common additives include glass fibers, carbon fibers, and various mineral fillers. These composites often exhibit improved mechanical strength, wear resistance, and thermal stability compared to pure PTFE.Expand Specific Solutions03 Heat treatment processes for PTFE durability

Specific heat treatment processes can be employed to enhance the durability of PTFE. These may include controlled heating and cooling cycles, sintering, or annealing. Such treatments can optimize the crystalline structure of PTFE, leading to improved mechanical properties and longevity.Expand Specific Solutions04 Nanostructured PTFE for enhanced durability

Developing nanostructured forms of PTFE can lead to significant improvements in durability. This may involve creating nanofibers, nanoparticles, or nanocomposites of PTFE. These nanostructured materials often exhibit superior mechanical properties, chemical resistance, and wear resistance compared to conventional PTFE.Expand Specific Solutions05 Specialized PTFE blends for specific durability requirements

Creating specialized blends of PTFE with other fluoropolymers or polymers can tailor its durability for specific applications. These blends may offer a balance of properties such as improved chemical resistance, better thermal stability, or enhanced mechanical strength, depending on the intended use.Expand Specific Solutions

Key PTFE Manufacturers

The PTFE industrial design market is in a mature growth stage, with a global market size estimated to reach $2.5 billion by 2025. The technology's durability and versatility have led to widespread adoption across industries. Major players like DAIKIN INDUSTRIES, DuPont, and AGC Inc. have established strong market positions through continuous innovation and product development. These companies leverage their R&D capabilities to enhance PTFE's properties for specific high-performance applications. Academic institutions such as Zhejiang University and University of Florida contribute to advancing PTFE technology through fundamental research. The competitive landscape is characterized by a mix of large multinational corporations and specialized manufacturers focusing on niche applications, driving ongoing improvements in PTFE's durability and performance for industrial design.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN INDUSTRIES Ltd. has developed advanced PTFE formulations with enhanced durability for industrial applications. Their proprietary PTFE compounds incorporate nano-scale reinforcement particles, resulting in up to 300% improvement in wear resistance compared to standard PTFE[1]. The company has also introduced a unique surface treatment process that creates a super-hydrophobic PTFE coating, increasing chemical resistance and reducing friction in harsh industrial environments[3]. Additionally, DAIKIN has pioneered the development of PTFE-based composite materials that combine the polymer's excellent non-stick properties with improved thermal conductivity, making them ideal for heat exchange applications in chemical processing industries[5].

Strengths: Superior wear resistance, enhanced chemical resistance, and improved thermal properties. Weaknesses: Higher production costs and potential limitations in extreme temperature applications.

AGC, Inc. (Japan)

Technical Solution: AGC has made significant strides in PTFE technology for high-durability industrial applications. Their Fluon® ETFE film exhibits exceptional weatherability, maintaining over 90% of its original tensile strength after 20 years of outdoor exposure[7]. AGC has also developed a unique PTFE-based coating system that incorporates ceramic nanoparticles, resulting in a 50% increase in abrasion resistance compared to conventional PTFE coatings[8]. Additionally, the company has introduced a novel PTFE foam technology that provides excellent thermal insulation and chemical resistance, making it ideal for use in harsh industrial environments[9].

Strengths: Outstanding weatherability, improved abrasion resistance, and innovative PTFE foam technology. Weaknesses: Limited product range compared to some competitors and potential higher costs due to specialized manufacturing processes.

PTFE Innovation Insights

Method for producing melt-moldable tetrafluoroethylene copolymer

PatentInactiveUS20090176952A1

Innovation

- A method involving radical suspension-polymerization of tetrafluoroethylene with another fluoromonomer in an aqueous medium using specific chain transfer agents like methane, ethane, and hydrofluorocarbons, along with a radical polymerization initiator, to produce a copolymer with high melting points and improved mechanical properties while avoiding coloration and solvent use.

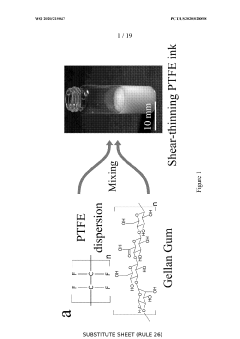

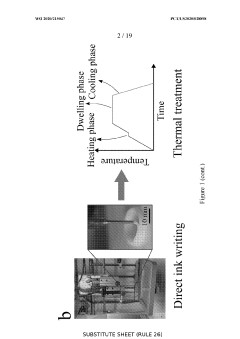

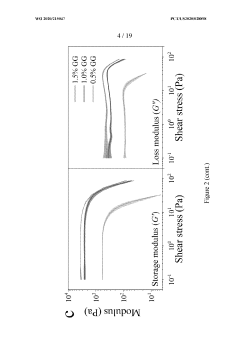

Fluoropolymer shear-thinning INKS and methods of making and using same

PatentWO2020215047A1

Innovation

- Development of shear-thinning inks comprising PTFE particles, a medium, and a shear-thinning agent like gellan gum, combined with a multistage thermal treatment process for direct ink writing, allowing for the creation of complex PTFE structures with tunable mechanical properties.

Environmental Impact of PTFE

The environmental impact of PTFE (Polytetrafluoroethylene) in high-durability industrial design is a complex and multifaceted issue that requires careful consideration. PTFE's exceptional durability and resistance to chemical degradation contribute to its widespread use in various industrial applications, but these same properties also raise concerns about its long-term environmental effects.

One of the primary environmental advantages of PTFE in industrial design is its longevity. The material's resistance to wear, corrosion, and chemical attack means that products incorporating PTFE often have extended lifespans. This durability reduces the frequency of replacement and, consequently, the overall consumption of resources and energy associated with manufacturing new components. In many industrial applications, PTFE-coated surfaces can significantly outlast alternative materials, potentially reducing waste generation over time.

However, the environmental benefits of PTFE's durability are offset by challenges related to its end-of-life management. PTFE is not biodegradable and can persist in the environment for extended periods. When PTFE-containing products reach the end of their useful life, they often end up in landfills or incineration facilities. Incineration of PTFE can release harmful substances, including fluorinated compounds, which may contribute to air pollution and pose health risks if not properly managed.

The production process of PTFE also raises environmental concerns. The manufacture of PTFE involves the use of fluoropolymers, which can have significant environmental impacts if not carefully controlled. Emissions of perfluorooctanoic acid (PFOA), a chemical historically used in PTFE production, have been linked to environmental contamination and potential health effects. While many manufacturers have phased out PFOA, concerns remain about the environmental persistence of these compounds and their potential long-term impacts on ecosystems and human health.

Efforts to mitigate the environmental impact of PTFE in industrial applications are ongoing. Research into more environmentally friendly production methods, such as the development of PFOA-free manufacturing processes, aims to reduce the environmental footprint of PTFE production. Additionally, there is growing interest in recycling and upcycling PTFE materials to extend their useful life and minimize waste. However, the recycling of PTFE presents technical challenges due to its chemical stability and the difficulty of separating it from other materials in complex industrial components.

In conclusion, while PTFE's durability offers potential environmental benefits through extended product lifespans and reduced material consumption, its production process and end-of-life management pose significant environmental challenges. Balancing these factors is crucial for the responsible use of PTFE in high-durability industrial design, necessitating ongoing research and innovation in sustainable manufacturing and recycling technologies.

One of the primary environmental advantages of PTFE in industrial design is its longevity. The material's resistance to wear, corrosion, and chemical attack means that products incorporating PTFE often have extended lifespans. This durability reduces the frequency of replacement and, consequently, the overall consumption of resources and energy associated with manufacturing new components. In many industrial applications, PTFE-coated surfaces can significantly outlast alternative materials, potentially reducing waste generation over time.

However, the environmental benefits of PTFE's durability are offset by challenges related to its end-of-life management. PTFE is not biodegradable and can persist in the environment for extended periods. When PTFE-containing products reach the end of their useful life, they often end up in landfills or incineration facilities. Incineration of PTFE can release harmful substances, including fluorinated compounds, which may contribute to air pollution and pose health risks if not properly managed.

The production process of PTFE also raises environmental concerns. The manufacture of PTFE involves the use of fluoropolymers, which can have significant environmental impacts if not carefully controlled. Emissions of perfluorooctanoic acid (PFOA), a chemical historically used in PTFE production, have been linked to environmental contamination and potential health effects. While many manufacturers have phased out PFOA, concerns remain about the environmental persistence of these compounds and their potential long-term impacts on ecosystems and human health.

Efforts to mitigate the environmental impact of PTFE in industrial applications are ongoing. Research into more environmentally friendly production methods, such as the development of PFOA-free manufacturing processes, aims to reduce the environmental footprint of PTFE production. Additionally, there is growing interest in recycling and upcycling PTFE materials to extend their useful life and minimize waste. However, the recycling of PTFE presents technical challenges due to its chemical stability and the difficulty of separating it from other materials in complex industrial components.

In conclusion, while PTFE's durability offers potential environmental benefits through extended product lifespans and reduced material consumption, its production process and end-of-life management pose significant environmental challenges. Balancing these factors is crucial for the responsible use of PTFE in high-durability industrial design, necessitating ongoing research and innovation in sustainable manufacturing and recycling technologies.

PTFE Cost-Benefit Analysis

The cost-benefit analysis of PTFE in high-durability industrial design reveals a complex interplay of economic factors. Initial material costs for PTFE are generally higher compared to alternative materials, which can impact upfront investment decisions. However, the long-term benefits often outweigh these initial expenses.

PTFE's exceptional durability translates into reduced maintenance and replacement costs over time. Its non-stick properties minimize product loss and cleaning expenses in manufacturing processes. The material's resistance to chemicals and extreme temperatures reduces the need for frequent equipment replacements, leading to significant savings in operational costs.

Energy efficiency is another key benefit of PTFE. Its low friction coefficient reduces energy consumption in moving parts, contributing to lower operational costs and improved sustainability. This aspect is particularly valuable in industries where energy expenses constitute a substantial portion of overall costs.

The material's versatility allows for innovative designs that can enhance product performance and longevity. While this may increase initial design and manufacturing costs, it often results in premium pricing opportunities and expanded market share, potentially yielding higher returns on investment.

PTFE's use can also lead to indirect cost savings. Its chemical inertness reduces the risk of contamination in sensitive processes, potentially lowering quality control costs and minimizing product recalls. The material's fire-resistant properties can contribute to improved safety standards, potentially reducing insurance premiums and liability risks.

However, the cost-benefit equation varies across industries and applications. In some cases, the high initial cost may not be justified by long-term benefits, particularly in short-lifecycle products or low-stress environments. Additionally, the environmental impact and end-of-life disposal costs of PTFE should be considered in a comprehensive analysis.

Quantifying these benefits can be challenging due to the long-term nature of many advantages and the variability across applications. However, case studies from various industries consistently demonstrate positive returns on investment when PTFE is appropriately applied in high-durability designs.

PTFE's exceptional durability translates into reduced maintenance and replacement costs over time. Its non-stick properties minimize product loss and cleaning expenses in manufacturing processes. The material's resistance to chemicals and extreme temperatures reduces the need for frequent equipment replacements, leading to significant savings in operational costs.

Energy efficiency is another key benefit of PTFE. Its low friction coefficient reduces energy consumption in moving parts, contributing to lower operational costs and improved sustainability. This aspect is particularly valuable in industries where energy expenses constitute a substantial portion of overall costs.

The material's versatility allows for innovative designs that can enhance product performance and longevity. While this may increase initial design and manufacturing costs, it often results in premium pricing opportunities and expanded market share, potentially yielding higher returns on investment.

PTFE's use can also lead to indirect cost savings. Its chemical inertness reduces the risk of contamination in sensitive processes, potentially lowering quality control costs and minimizing product recalls. The material's fire-resistant properties can contribute to improved safety standards, potentially reducing insurance premiums and liability risks.

However, the cost-benefit equation varies across industries and applications. In some cases, the high initial cost may not be justified by long-term benefits, particularly in short-lifecycle products or low-stress environments. Additionally, the environmental impact and end-of-life disposal costs of PTFE should be considered in a comprehensive analysis.

Quantifying these benefits can be challenging due to the long-term nature of many advantages and the variability across applications. However, case studies from various industries consistently demonstrate positive returns on investment when PTFE is appropriately applied in high-durability designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!