PTFE in the Modern Market: Trends and Insights

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Evolution and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has undergone significant evolution since its accidental discovery by Roy Plunkett in 1938. Initially developed as a refrigerant, PTFE's unique properties quickly led to its application in various industries. The material's journey from a laboratory curiosity to a ubiquitous industrial and consumer product exemplifies the transformative power of scientific innovation.

In the early stages, PTFE's development was primarily driven by its exceptional non-stick and heat-resistant properties. These characteristics made it invaluable in cookware and industrial applications where friction reduction was crucial. As manufacturing techniques improved, PTFE's use expanded into aerospace, automotive, and electronics industries, showcasing its versatility and durability under extreme conditions.

The modern PTFE market has evolved to address growing environmental concerns and sustainability requirements. Current research focuses on developing eco-friendly production methods and exploring biodegradable alternatives. Additionally, there is a push towards enhancing PTFE's performance in specialized applications, such as medical implants and advanced filtration systems.

One of the key objectives in PTFE's ongoing evolution is to improve its mechanical properties without compromising its chemical resistance. Researchers are exploring nanocomposite formulations and surface modification techniques to enhance PTFE's wear resistance and load-bearing capacity. These advancements aim to extend PTFE's lifespan in high-stress applications, reducing the need for frequent replacements and thereby improving cost-effectiveness.

Another significant trend is the development of PTFE-based materials with enhanced electrical properties. As the demand for high-performance insulators in the electronics industry grows, there is a concerted effort to create PTFE variants with improved dielectric strength and lower signal loss at high frequencies. This research is particularly relevant for the advancement of 5G and future telecommunications technologies.

In the medical field, PTFE continues to be a material of interest due to its biocompatibility. Current objectives include developing PTFE-based scaffolds for tissue engineering and improving the material's integration with biological systems. These advancements could lead to breakthroughs in regenerative medicine and long-term implantable devices.

The future of PTFE technology is likely to be shaped by the growing emphasis on sustainability and circular economy principles. Research is underway to develop recycling methods for PTFE products, aiming to reduce waste and environmental impact. Additionally, there is a focus on creating PTFE alternatives that maintain similar performance characteristics while being more environmentally friendly throughout their lifecycle.

In the early stages, PTFE's development was primarily driven by its exceptional non-stick and heat-resistant properties. These characteristics made it invaluable in cookware and industrial applications where friction reduction was crucial. As manufacturing techniques improved, PTFE's use expanded into aerospace, automotive, and electronics industries, showcasing its versatility and durability under extreme conditions.

The modern PTFE market has evolved to address growing environmental concerns and sustainability requirements. Current research focuses on developing eco-friendly production methods and exploring biodegradable alternatives. Additionally, there is a push towards enhancing PTFE's performance in specialized applications, such as medical implants and advanced filtration systems.

One of the key objectives in PTFE's ongoing evolution is to improve its mechanical properties without compromising its chemical resistance. Researchers are exploring nanocomposite formulations and surface modification techniques to enhance PTFE's wear resistance and load-bearing capacity. These advancements aim to extend PTFE's lifespan in high-stress applications, reducing the need for frequent replacements and thereby improving cost-effectiveness.

Another significant trend is the development of PTFE-based materials with enhanced electrical properties. As the demand for high-performance insulators in the electronics industry grows, there is a concerted effort to create PTFE variants with improved dielectric strength and lower signal loss at high frequencies. This research is particularly relevant for the advancement of 5G and future telecommunications technologies.

In the medical field, PTFE continues to be a material of interest due to its biocompatibility. Current objectives include developing PTFE-based scaffolds for tissue engineering and improving the material's integration with biological systems. These advancements could lead to breakthroughs in regenerative medicine and long-term implantable devices.

The future of PTFE technology is likely to be shaped by the growing emphasis on sustainability and circular economy principles. Research is underway to develop recycling methods for PTFE products, aiming to reduce waste and environmental impact. Additionally, there is a focus on creating PTFE alternatives that maintain similar performance characteristics while being more environmentally friendly throughout their lifecycle.

PTFE Market Demand Analysis

The global PTFE (Polytetrafluoroethylene) market has been experiencing steady growth, driven by its unique properties and diverse applications across various industries. The demand for PTFE is primarily fueled by its exceptional chemical resistance, low friction coefficient, and high-temperature stability, making it indispensable in numerous sectors.

In the automotive industry, PTFE is increasingly used in gaskets, seals, and bearings, contributing to improved fuel efficiency and reduced emissions. The aerospace sector relies on PTFE for its lightweight and heat-resistant properties, utilizing it in aircraft components and space exploration equipment. The chemical processing industry values PTFE for its corrosion resistance, employing it in pipes, valves, and linings for handling aggressive chemicals.

The electronics and semiconductor industries have witnessed a surge in PTFE demand, particularly in the production of high-frequency circuit boards and cable insulation. As 5G technology continues to roll out globally, the need for PTFE in telecommunications infrastructure is expected to rise significantly.

In the healthcare sector, PTFE's biocompatibility and non-stick properties have led to its increased use in medical devices, surgical instruments, and pharmaceutical processing equipment. The growing emphasis on advanced medical technologies and minimally invasive procedures is likely to further boost PTFE demand in this sector.

The construction industry has also embraced PTFE, particularly in architectural membranes for large-scale structures due to its durability and weather resistance. Additionally, the material's hydrophobic nature has found applications in water-repellent coatings and fabrics, catering to the growing demand for high-performance textiles.

Emerging economies, particularly in Asia-Pacific, are expected to be key drivers of PTFE market growth. Rapid industrialization, infrastructure development, and increasing consumer goods production in countries like China and India are creating substantial opportunities for PTFE manufacturers.

However, the PTFE market faces challenges related to environmental concerns and regulatory pressures. The persistence of fluoropolymers in the environment has led to increased scrutiny and potential restrictions in some regions. This has spurred research into more sustainable production methods and eco-friendly alternatives, which may shape the future landscape of the PTFE market.

Despite these challenges, the overall outlook for PTFE remains positive. Innovations in PTFE processing techniques, such as the development of micro-powders and modified PTFE grades, are opening up new application areas and enhancing the material's performance characteristics. These advancements are expected to sustain market growth and drive demand across various end-use industries in the coming years.

In the automotive industry, PTFE is increasingly used in gaskets, seals, and bearings, contributing to improved fuel efficiency and reduced emissions. The aerospace sector relies on PTFE for its lightweight and heat-resistant properties, utilizing it in aircraft components and space exploration equipment. The chemical processing industry values PTFE for its corrosion resistance, employing it in pipes, valves, and linings for handling aggressive chemicals.

The electronics and semiconductor industries have witnessed a surge in PTFE demand, particularly in the production of high-frequency circuit boards and cable insulation. As 5G technology continues to roll out globally, the need for PTFE in telecommunications infrastructure is expected to rise significantly.

In the healthcare sector, PTFE's biocompatibility and non-stick properties have led to its increased use in medical devices, surgical instruments, and pharmaceutical processing equipment. The growing emphasis on advanced medical technologies and minimally invasive procedures is likely to further boost PTFE demand in this sector.

The construction industry has also embraced PTFE, particularly in architectural membranes for large-scale structures due to its durability and weather resistance. Additionally, the material's hydrophobic nature has found applications in water-repellent coatings and fabrics, catering to the growing demand for high-performance textiles.

Emerging economies, particularly in Asia-Pacific, are expected to be key drivers of PTFE market growth. Rapid industrialization, infrastructure development, and increasing consumer goods production in countries like China and India are creating substantial opportunities for PTFE manufacturers.

However, the PTFE market faces challenges related to environmental concerns and regulatory pressures. The persistence of fluoropolymers in the environment has led to increased scrutiny and potential restrictions in some regions. This has spurred research into more sustainable production methods and eco-friendly alternatives, which may shape the future landscape of the PTFE market.

Despite these challenges, the overall outlook for PTFE remains positive. Innovations in PTFE processing techniques, such as the development of micro-powders and modified PTFE grades, are opening up new application areas and enhancing the material's performance characteristics. These advancements are expected to sustain market growth and drive demand across various end-use industries in the coming years.

PTFE Technical Challenges

Polytetrafluoroethylene (PTFE) faces several technical challenges in the modern market, despite its widespread use and unique properties. One of the primary issues is its poor wear resistance, which limits its application in high-friction environments. This characteristic often results in the need for frequent replacements or maintenance, increasing overall costs for industries relying on PTFE components.

Another significant challenge is PTFE's inherent non-stick properties, which, while beneficial in many applications, can pose difficulties in bonding and adhesion. This limitation complicates the integration of PTFE with other materials in composite structures or multi-layer systems, potentially restricting its use in certain advanced applications.

The processing of PTFE also presents technical hurdles. Its high melting point and high melt viscosity make conventional thermoplastic processing methods ineffective. This necessitates specialized sintering techniques, which can be energy-intensive and time-consuming, potentially limiting production efficiency and scalability.

PTFE's thermal expansion characteristics pose challenges in applications where dimensional stability is crucial. The material's relatively high coefficient of thermal expansion can lead to issues in precision engineering and in environments with significant temperature fluctuations.

Environmental concerns also present a growing challenge for PTFE. The production process traditionally involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. While efforts have been made to phase out PFOA, finding equally effective and environmentally friendly alternatives remains an ongoing challenge for the industry.

The recycling of PTFE is another area of technical difficulty. Unlike many other plastics, PTFE cannot be easily melted and reformed, making traditional recycling methods ineffective. This characteristic contributes to waste management issues and conflicts with growing sustainability demands in various industries.

Lastly, while PTFE exhibits excellent chemical resistance, it can be susceptible to degradation under certain extreme conditions, such as exposure to highly energetic radiation or certain reactive metals at high temperatures. Addressing these limitations to expand PTFE's applicability in harsh environments remains an ongoing challenge for materials scientists and engineers.

Another significant challenge is PTFE's inherent non-stick properties, which, while beneficial in many applications, can pose difficulties in bonding and adhesion. This limitation complicates the integration of PTFE with other materials in composite structures or multi-layer systems, potentially restricting its use in certain advanced applications.

The processing of PTFE also presents technical hurdles. Its high melting point and high melt viscosity make conventional thermoplastic processing methods ineffective. This necessitates specialized sintering techniques, which can be energy-intensive and time-consuming, potentially limiting production efficiency and scalability.

PTFE's thermal expansion characteristics pose challenges in applications where dimensional stability is crucial. The material's relatively high coefficient of thermal expansion can lead to issues in precision engineering and in environments with significant temperature fluctuations.

Environmental concerns also present a growing challenge for PTFE. The production process traditionally involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. While efforts have been made to phase out PFOA, finding equally effective and environmentally friendly alternatives remains an ongoing challenge for the industry.

The recycling of PTFE is another area of technical difficulty. Unlike many other plastics, PTFE cannot be easily melted and reformed, making traditional recycling methods ineffective. This characteristic contributes to waste management issues and conflicts with growing sustainability demands in various industries.

Lastly, while PTFE exhibits excellent chemical resistance, it can be susceptible to degradation under certain extreme conditions, such as exposure to highly energetic radiation or certain reactive metals at high temperatures. Addressing these limitations to expand PTFE's applicability in harsh environments remains an ongoing challenge for materials scientists and engineers.

Current PTFE Applications

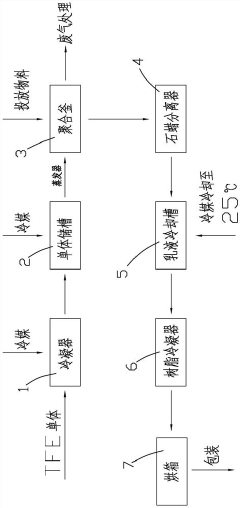

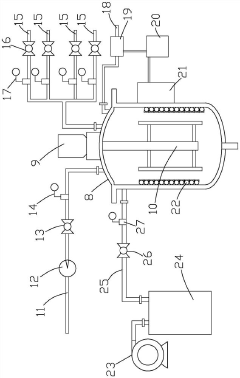

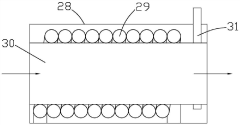

01 PTFE manufacturing processes

Various methods for producing PTFE are described, including polymerization techniques, extrusion processes, and molding methods. These processes aim to improve the quality, efficiency, and properties of the resulting PTFE materials.- PTFE manufacturing processes: Various methods for producing PTFE are described, including polymerization techniques, extrusion processes, and molding procedures. These processes aim to improve the quality, consistency, and properties of PTFE products for different applications.

- PTFE composite materials: PTFE is combined with other materials to create composite structures with enhanced properties. These composites may include reinforcing fibers, nanoparticles, or other polymers to improve mechanical strength, thermal stability, or electrical properties.

- Surface modification of PTFE: Techniques for modifying the surface properties of PTFE are explored, including chemical treatments, plasma treatments, and coating applications. These modifications aim to improve adhesion, wettability, or other surface characteristics for specific applications.

- PTFE in membrane technology: PTFE is utilized in the development of advanced membrane technologies for various applications, including filtration, separation, and gas diffusion. The unique properties of PTFE, such as its hydrophobicity and chemical resistance, make it suitable for these applications.

- PTFE in coating applications: PTFE is used in various coating formulations to impart non-stick, low friction, and corrosion-resistant properties to surfaces. These coatings find applications in cookware, industrial equipment, and automotive components.

02 PTFE composite materials

PTFE is combined with other materials to create composite structures with enhanced properties. These composites may include fillers, reinforcing agents, or other polymers to improve mechanical strength, thermal stability, or specific functional characteristics.Expand Specific Solutions03 Surface modification of PTFE

Techniques for modifying the surface properties of PTFE are explored, including chemical treatments, plasma treatments, and coating applications. These modifications aim to enhance adhesion, wettability, or other surface-dependent properties of PTFE materials.Expand Specific Solutions04 PTFE in membrane technology

PTFE is utilized in the development of various membrane technologies, including filtration membranes, gas separation membranes, and water treatment applications. The unique properties of PTFE, such as chemical resistance and hydrophobicity, are leveraged in these membrane systems.Expand Specific Solutions05 PTFE in coating applications

PTFE is incorporated into coating formulations to impart non-stick, low friction, and chemical resistance properties. These coatings find applications in cookware, industrial equipment, and various other fields where such properties are desirable.Expand Specific Solutions

Key PTFE Industry Players

The PTFE market is in a mature stage, characterized by steady growth and widespread adoption across various industries. The global market size for PTFE is substantial, estimated to be in the billions of dollars, with a compound annual growth rate projected in the mid-single digits. Technologically, PTFE is well-established, with ongoing innovations focused on enhancing performance and expanding applications. Key players like The Chemours Co., DuPont de Nemours, Inc., and 3M Innovative Properties Co. are driving advancements in PTFE technology. Japanese firms such as AGC, Inc. and DAIKIN INDUSTRIES Ltd. are also significant contributors, leveraging their expertise in fluoropolymers. The competitive landscape is diverse, with companies like Shamrock Technologies, Inc. and Guarniflon SpA offering specialized PTFE products, indicating a high level of technical maturity and market segmentation.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has developed advanced PTFE processing techniques, including their proprietary "fine powder" PTFE resin technology. This allows for the production of high-performance PTFE products with improved mechanical properties and chemical resistance[1]. They have also introduced eco-friendly PTFE alternatives, such as their ETFE (ethylene tetrafluoroethylene) products, which offer similar properties to PTFE but with enhanced recyclability and reduced environmental impact[2]. Daikin's research focuses on expanding PTFE applications in emerging markets, particularly in the automotive and aerospace industries, where their high-performance fluoropolymers provide critical solutions for extreme operating conditions[3].

Strengths: Strong R&D capabilities, diverse product portfolio, and eco-friendly innovations. Weaknesses: Potential higher costs associated with advanced technologies and eco-friendly alternatives.

The Chemours Co.

Technical Solution: Chemours has developed Teflon™ PTFE, a flagship product known for its exceptional non-stick and low friction properties. Their recent innovations include the development of micro-powders and aqueous PTFE dispersions, which expand the application range of PTFE in industries such as automotive, electronics, and industrial coatings[4]. Chemours has also focused on sustainability, introducing PTFE recycling programs and developing PFOA-free PTFE products to address environmental concerns[5]. Their research efforts are directed towards enhancing PTFE's thermal stability and chemical resistance for use in extreme environments, such as aerospace and semiconductor manufacturing[6].

Strengths: Strong brand recognition (Teflon™), extensive application knowledge, and commitment to sustainability. Weaknesses: Historical environmental concerns related to PFOA may affect public perception.

PTFE Innovation Breakthroughs

Preparation process of PTFE resin with high compression ratio

PatentActiveCN112062891A

Innovation

- The preparation process of high compression ratio PTFE resin includes condensing tetrafluoroethylene monomer, adding stabilizer and modified monomer, forming a vortex through stirring and heating in the polymerization tank to accelerate the reaction, and using a paraffin separator to improve the purity. High quality agglomerates are formed by emulsion cooling and drying.

Process of making cellulosic fibers including PTFE

PatentInactiveHK1085518A

Innovation

- Incorporation of low micron or submicron PTFE particles into solution-spun fibers, resulting in improved properties such as decreased coefficient of friction and enhanced non-wetting characteristics.

- Uniform dispersion of PTFE particles throughout the body of the fiber, ensuring long-lasting enhanced properties resistant to surface wear and tear.

- Application of PTFE-enhanced fibers in various industrial and consumer products, including filtration materials, sportswear, and transportation textiles.

Environmental Impact of PTFE

The environmental impact of PTFE (Polytetrafluoroethylene) has become a significant concern in recent years, as the modern market increasingly prioritizes sustainability and eco-friendly practices. PTFE, widely known by its brand name Teflon, has been a staple in various industries due to its unique properties, including chemical resistance, low friction, and high-temperature stability. However, its production and disposal processes have raised environmental concerns that warrant careful examination.

The manufacturing of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that has been linked to various health and environmental issues. PFOA can contaminate water sources and persist in the environment for extended periods, potentially affecting wildlife and human health. In response to these concerns, many manufacturers have committed to phasing out PFOA in PTFE production, exploring alternative production methods that reduce environmental impact.

Despite efforts to improve production processes, the disposal of PTFE products remains a significant environmental challenge. PTFE is not biodegradable and can persist in landfills for hundreds of years. When incinerated, it can release harmful fluorine compounds into the atmosphere, contributing to air pollution and potentially affecting the ozone layer. This has led to increased focus on developing recycling technologies specifically tailored for PTFE products.

The carbon footprint associated with PTFE production and transportation is another area of environmental concern. The energy-intensive manufacturing process and the global distribution of PTFE products contribute to greenhouse gas emissions. As a result, there is growing interest in optimizing production efficiency and exploring localized manufacturing to reduce transportation-related emissions.

In response to these environmental challenges, the PTFE industry has been investing in research and development of more sustainable alternatives. This includes the exploration of bio-based fluoropolymers and the development of PTFE-like materials with reduced environmental impact. Additionally, there is an increasing focus on improving the recyclability of PTFE products, with some companies implementing take-back programs and developing innovative recycling technologies.

The regulatory landscape surrounding PTFE is also evolving, with stricter environmental regulations being implemented in various regions. These regulations aim to minimize the environmental impact of PTFE production and use, pushing manufacturers to adopt cleaner technologies and more sustainable practices. This regulatory pressure, combined with growing consumer awareness, is driving the industry towards more environmentally responsible approaches in PTFE production and application.

The manufacturing of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that has been linked to various health and environmental issues. PFOA can contaminate water sources and persist in the environment for extended periods, potentially affecting wildlife and human health. In response to these concerns, many manufacturers have committed to phasing out PFOA in PTFE production, exploring alternative production methods that reduce environmental impact.

Despite efforts to improve production processes, the disposal of PTFE products remains a significant environmental challenge. PTFE is not biodegradable and can persist in landfills for hundreds of years. When incinerated, it can release harmful fluorine compounds into the atmosphere, contributing to air pollution and potentially affecting the ozone layer. This has led to increased focus on developing recycling technologies specifically tailored for PTFE products.

The carbon footprint associated with PTFE production and transportation is another area of environmental concern. The energy-intensive manufacturing process and the global distribution of PTFE products contribute to greenhouse gas emissions. As a result, there is growing interest in optimizing production efficiency and exploring localized manufacturing to reduce transportation-related emissions.

In response to these environmental challenges, the PTFE industry has been investing in research and development of more sustainable alternatives. This includes the exploration of bio-based fluoropolymers and the development of PTFE-like materials with reduced environmental impact. Additionally, there is an increasing focus on improving the recyclability of PTFE products, with some companies implementing take-back programs and developing innovative recycling technologies.

The regulatory landscape surrounding PTFE is also evolving, with stricter environmental regulations being implemented in various regions. These regulations aim to minimize the environmental impact of PTFE production and use, pushing manufacturers to adopt cleaner technologies and more sustainable practices. This regulatory pressure, combined with growing consumer awareness, is driving the industry towards more environmentally responsible approaches in PTFE production and application.

PTFE Regulatory Landscape

The regulatory landscape for PTFE (Polytetrafluoroethylene) has evolved significantly in recent years, reflecting growing concerns about environmental and health impacts. Globally, regulatory bodies have implemented stricter controls on the production, use, and disposal of PTFE and related fluoropolymers.

In the United States, the Environmental Protection Agency (EPA) has taken a leading role in regulating PTFE and its precursors. Under the Toxic Substances Control Act (TSCA), the EPA has increased scrutiny of perfluoroalkyl and polyfluoroalkyl substances (PFAS), a group that includes PTFE. The agency has proposed new reporting and recordkeeping requirements for PFAS manufacturers and has initiated actions to address PFAS in drinking water.

The European Union has also tightened regulations on PTFE through its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) program. REACH requires manufacturers and importers to register chemicals and provide safety data. The European Chemicals Agency (ECHA) has placed several PFAS, including some PTFE precursors, on its Substances of Very High Concern (SVHC) list, potentially leading to further restrictions or bans.

In Asia, countries like Japan and South Korea have implemented their own chemical management systems, which include regulations on PTFE and related substances. China, a major producer of PTFE, has also begun to strengthen its environmental regulations, potentially impacting global supply chains.

The regulatory focus has largely been on the environmental persistence of PTFE and its potential to break down into harmful substances. Concerns about bioaccumulation and long-term health effects have driven much of the regulatory action. As a result, manufacturers are increasingly required to demonstrate the safety of their PTFE products and processes throughout the entire lifecycle.

These regulatory changes have significant implications for the PTFE market. Companies are investing in research and development to find more environmentally friendly alternatives or to improve PTFE production processes to meet stricter standards. The increased regulatory burden has also led to higher compliance costs, potentially affecting market dynamics and pricing structures.

Looking ahead, the regulatory landscape for PTFE is likely to continue evolving. There is a growing trend towards harmonization of international standards, which could lead to more consistent global regulations. Additionally, as scientific understanding of PFAS improves, regulations may become more targeted and nuanced, potentially differentiating between various types of fluoropolymers based on their specific properties and risks.

In the United States, the Environmental Protection Agency (EPA) has taken a leading role in regulating PTFE and its precursors. Under the Toxic Substances Control Act (TSCA), the EPA has increased scrutiny of perfluoroalkyl and polyfluoroalkyl substances (PFAS), a group that includes PTFE. The agency has proposed new reporting and recordkeeping requirements for PFAS manufacturers and has initiated actions to address PFAS in drinking water.

The European Union has also tightened regulations on PTFE through its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) program. REACH requires manufacturers and importers to register chemicals and provide safety data. The European Chemicals Agency (ECHA) has placed several PFAS, including some PTFE precursors, on its Substances of Very High Concern (SVHC) list, potentially leading to further restrictions or bans.

In Asia, countries like Japan and South Korea have implemented their own chemical management systems, which include regulations on PTFE and related substances. China, a major producer of PTFE, has also begun to strengthen its environmental regulations, potentially impacting global supply chains.

The regulatory focus has largely been on the environmental persistence of PTFE and its potential to break down into harmful substances. Concerns about bioaccumulation and long-term health effects have driven much of the regulatory action. As a result, manufacturers are increasingly required to demonstrate the safety of their PTFE products and processes throughout the entire lifecycle.

These regulatory changes have significant implications for the PTFE market. Companies are investing in research and development to find more environmentally friendly alternatives or to improve PTFE production processes to meet stricter standards. The increased regulatory burden has also led to higher compliance costs, potentially affecting market dynamics and pricing structures.

Looking ahead, the regulatory landscape for PTFE is likely to continue evolving. There is a growing trend towards harmonization of international standards, which could lead to more consistent global regulations. Additionally, as scientific understanding of PFAS improves, regulations may become more targeted and nuanced, potentially differentiating between various types of fluoropolymers based on their specific properties and risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!