How to Drive Efficiency in Wear Protection Using PTFE?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Wear Protection Background and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has been a revolutionary material in wear protection since its accidental discovery by Roy Plunkett in 1938. This synthetic fluoropolymer has evolved from a niche material to a ubiquitous solution in various industries due to its exceptional properties, including low friction, chemical inertness, and high temperature resistance.

The development of PTFE for wear protection applications has been driven by the increasing demand for materials that can withstand harsh operating conditions while maintaining their performance characteristics. Over the years, researchers and engineers have focused on enhancing PTFE's wear resistance and expanding its applicability across diverse sectors such as automotive, aerospace, and industrial manufacturing.

The primary objective in driving efficiency in wear protection using PTFE is to maximize its inherent properties while addressing its limitations. This involves improving its wear resistance, load-bearing capacity, and longevity in high-stress environments. Researchers aim to develop advanced PTFE composites and coatings that can outperform traditional materials in terms of durability and performance under extreme conditions.

Another crucial goal is to optimize the manufacturing processes for PTFE-based wear protection solutions. This includes developing more efficient methods for applying PTFE coatings, creating innovative PTFE-based composites, and exploring novel fabrication techniques that can enhance the material's wear-resistant properties while maintaining cost-effectiveness.

The evolution of PTFE in wear protection is closely tied to advancements in nanotechnology and materials science. Current research focuses on incorporating nanoparticles and other reinforcing agents into PTFE matrices to create hybrid materials with superior wear resistance and mechanical properties. These efforts aim to expand the application range of PTFE in high-performance environments where traditional materials fall short.

Environmental considerations have also become a significant factor in PTFE wear protection research. As sustainability gains importance across industries, there is a growing emphasis on developing eco-friendly PTFE formulations and recycling methods. This aligns with the broader objective of creating wear protection solutions that are not only efficient but also environmentally responsible.

In the context of Industry 4.0 and smart manufacturing, integrating PTFE-based wear protection solutions with sensor technologies and predictive maintenance systems represents an emerging trend. This convergence aims to create intelligent wear protection systems that can adapt to changing conditions and provide real-time performance data, further enhancing efficiency and reliability in critical applications.

The development of PTFE for wear protection applications has been driven by the increasing demand for materials that can withstand harsh operating conditions while maintaining their performance characteristics. Over the years, researchers and engineers have focused on enhancing PTFE's wear resistance and expanding its applicability across diverse sectors such as automotive, aerospace, and industrial manufacturing.

The primary objective in driving efficiency in wear protection using PTFE is to maximize its inherent properties while addressing its limitations. This involves improving its wear resistance, load-bearing capacity, and longevity in high-stress environments. Researchers aim to develop advanced PTFE composites and coatings that can outperform traditional materials in terms of durability and performance under extreme conditions.

Another crucial goal is to optimize the manufacturing processes for PTFE-based wear protection solutions. This includes developing more efficient methods for applying PTFE coatings, creating innovative PTFE-based composites, and exploring novel fabrication techniques that can enhance the material's wear-resistant properties while maintaining cost-effectiveness.

The evolution of PTFE in wear protection is closely tied to advancements in nanotechnology and materials science. Current research focuses on incorporating nanoparticles and other reinforcing agents into PTFE matrices to create hybrid materials with superior wear resistance and mechanical properties. These efforts aim to expand the application range of PTFE in high-performance environments where traditional materials fall short.

Environmental considerations have also become a significant factor in PTFE wear protection research. As sustainability gains importance across industries, there is a growing emphasis on developing eco-friendly PTFE formulations and recycling methods. This aligns with the broader objective of creating wear protection solutions that are not only efficient but also environmentally responsible.

In the context of Industry 4.0 and smart manufacturing, integrating PTFE-based wear protection solutions with sensor technologies and predictive maintenance systems represents an emerging trend. This convergence aims to create intelligent wear protection systems that can adapt to changing conditions and provide real-time performance data, further enhancing efficiency and reliability in critical applications.

Market Analysis for PTFE Wear Protection Solutions

The global market for PTFE wear protection solutions has been experiencing steady growth, driven by increasing demand across various industries such as automotive, aerospace, chemical processing, and industrial manufacturing. PTFE's unique properties, including low friction, chemical resistance, and high temperature tolerance, make it an ideal material for wear protection applications.

In recent years, the market has seen a shift towards more efficient and cost-effective wear protection solutions, with PTFE playing a crucial role. The automotive sector, in particular, has been a significant contributor to market growth, as manufacturers seek to improve fuel efficiency and reduce emissions through the use of lightweight materials and advanced coatings.

The aerospace industry has also been a key driver of demand for PTFE wear protection solutions, with applications in aircraft engines, landing gear, and other critical components. The need for materials that can withstand extreme temperatures and harsh environments has led to increased adoption of PTFE-based solutions in this sector.

In the industrial manufacturing sector, PTFE wear protection solutions are being increasingly utilized in machinery and equipment to extend operational life and reduce maintenance costs. This trend is particularly evident in industries dealing with abrasive materials or corrosive chemicals, where PTFE's resistance properties offer significant advantages.

The market for PTFE wear protection solutions is characterized by a mix of large multinational corporations and specialized niche players. Key market players have been focusing on research and development to improve the performance and durability of PTFE-based products, as well as exploring new application areas.

Geographically, North America and Europe have traditionally been the largest markets for PTFE wear protection solutions, owing to their well-established industrial bases and stringent regulatory standards. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by industrialization, infrastructure development, and increasing adoption of advanced manufacturing technologies in countries like China and India.

The market is also witnessing a trend towards customized solutions, as end-users seek wear protection products tailored to their specific applications and operating conditions. This has led to increased collaboration between material suppliers, coating specialists, and end-users to develop optimized solutions.

Looking ahead, the market for PTFE wear protection solutions is expected to continue its growth trajectory, fueled by ongoing technological advancements, expanding application areas, and increasing awareness of the benefits of PTFE in wear protection. The push for sustainability and energy efficiency across industries is likely to further boost demand for PTFE-based solutions that can contribute to reduced friction, improved performance, and extended equipment life.

In recent years, the market has seen a shift towards more efficient and cost-effective wear protection solutions, with PTFE playing a crucial role. The automotive sector, in particular, has been a significant contributor to market growth, as manufacturers seek to improve fuel efficiency and reduce emissions through the use of lightweight materials and advanced coatings.

The aerospace industry has also been a key driver of demand for PTFE wear protection solutions, with applications in aircraft engines, landing gear, and other critical components. The need for materials that can withstand extreme temperatures and harsh environments has led to increased adoption of PTFE-based solutions in this sector.

In the industrial manufacturing sector, PTFE wear protection solutions are being increasingly utilized in machinery and equipment to extend operational life and reduce maintenance costs. This trend is particularly evident in industries dealing with abrasive materials or corrosive chemicals, where PTFE's resistance properties offer significant advantages.

The market for PTFE wear protection solutions is characterized by a mix of large multinational corporations and specialized niche players. Key market players have been focusing on research and development to improve the performance and durability of PTFE-based products, as well as exploring new application areas.

Geographically, North America and Europe have traditionally been the largest markets for PTFE wear protection solutions, owing to their well-established industrial bases and stringent regulatory standards. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by industrialization, infrastructure development, and increasing adoption of advanced manufacturing technologies in countries like China and India.

The market is also witnessing a trend towards customized solutions, as end-users seek wear protection products tailored to their specific applications and operating conditions. This has led to increased collaboration between material suppliers, coating specialists, and end-users to develop optimized solutions.

Looking ahead, the market for PTFE wear protection solutions is expected to continue its growth trajectory, fueled by ongoing technological advancements, expanding application areas, and increasing awareness of the benefits of PTFE in wear protection. The push for sustainability and energy efficiency across industries is likely to further boost demand for PTFE-based solutions that can contribute to reduced friction, improved performance, and extended equipment life.

Current PTFE Wear Protection Technologies and Challenges

Polytetrafluoroethylene (PTFE) has long been recognized as a superior material for wear protection due to its unique properties, including low friction, chemical inertness, and high temperature resistance. Current PTFE wear protection technologies leverage these properties to enhance the durability and efficiency of various mechanical systems and components.

One of the primary applications of PTFE in wear protection is as a coating material. PTFE coatings are applied to surfaces subject to friction and wear, creating a low-friction barrier that reduces material loss and extends component life. These coatings can be applied through various methods, including spray coating, dip coating, and electrostatic powder coating. Each method has its advantages and is selected based on the specific application requirements.

PTFE composites represent another significant advancement in wear protection technology. By incorporating PTFE into other materials, such as metals or ceramics, engineers have created composites that combine the low friction properties of PTFE with the strength and durability of the base material. These composites find applications in bearings, seals, and other high-wear components, offering improved performance over traditional materials.

Despite the advantages of PTFE in wear protection, several challenges persist. One of the primary issues is the relatively poor wear resistance of pure PTFE. While it offers excellent lubricity, PTFE can be prone to deformation and wear under high loads or prolonged use. This limitation has led to the development of modified PTFE formulations and composites aimed at enhancing wear resistance without sacrificing the material's beneficial properties.

Another challenge lies in the adhesion of PTFE coatings to substrate materials. The non-stick nature of PTFE, while beneficial in many applications, can make it difficult to achieve strong, durable bonds with other materials. This has necessitated the development of specialized surface preparation techniques and bonding agents to improve coating adhesion and longevity.

The thermal limitations of PTFE also present challenges in certain high-temperature applications. While PTFE performs well in a wide temperature range, it begins to degrade at temperatures above 260°C (500°F). This restricts its use in extreme temperature environments and has driven research into high-temperature PTFE variants and alternative materials for such applications.

Environmental concerns have also emerged as a challenge for PTFE wear protection technologies. The production of PTFE historically involved the use of perfluorooctanoic acid (PFOA), a persistent environmental pollutant. While many manufacturers have phased out PFOA, finding equally effective and environmentally friendly alternatives remains an ongoing challenge in the industry.

One of the primary applications of PTFE in wear protection is as a coating material. PTFE coatings are applied to surfaces subject to friction and wear, creating a low-friction barrier that reduces material loss and extends component life. These coatings can be applied through various methods, including spray coating, dip coating, and electrostatic powder coating. Each method has its advantages and is selected based on the specific application requirements.

PTFE composites represent another significant advancement in wear protection technology. By incorporating PTFE into other materials, such as metals or ceramics, engineers have created composites that combine the low friction properties of PTFE with the strength and durability of the base material. These composites find applications in bearings, seals, and other high-wear components, offering improved performance over traditional materials.

Despite the advantages of PTFE in wear protection, several challenges persist. One of the primary issues is the relatively poor wear resistance of pure PTFE. While it offers excellent lubricity, PTFE can be prone to deformation and wear under high loads or prolonged use. This limitation has led to the development of modified PTFE formulations and composites aimed at enhancing wear resistance without sacrificing the material's beneficial properties.

Another challenge lies in the adhesion of PTFE coatings to substrate materials. The non-stick nature of PTFE, while beneficial in many applications, can make it difficult to achieve strong, durable bonds with other materials. This has necessitated the development of specialized surface preparation techniques and bonding agents to improve coating adhesion and longevity.

The thermal limitations of PTFE also present challenges in certain high-temperature applications. While PTFE performs well in a wide temperature range, it begins to degrade at temperatures above 260°C (500°F). This restricts its use in extreme temperature environments and has driven research into high-temperature PTFE variants and alternative materials for such applications.

Environmental concerns have also emerged as a challenge for PTFE wear protection technologies. The production of PTFE historically involved the use of perfluorooctanoic acid (PFOA), a persistent environmental pollutant. While many manufacturers have phased out PFOA, finding equally effective and environmentally friendly alternatives remains an ongoing challenge in the industry.

Existing PTFE Wear Protection Efficiency Solutions

01 PTFE membrane efficiency in filtration

PTFE membranes are highly efficient in filtration processes due to their unique properties. These membranes offer excellent chemical resistance, high temperature tolerance, and low surface energy, making them ideal for various filtration applications. The porous structure of PTFE membranes allows for high flow rates while maintaining excellent particle retention, enhancing overall filtration efficiency.- PTFE membrane efficiency in filtration: PTFE membranes are highly efficient in filtration processes due to their unique properties. These membranes offer excellent chemical resistance, high temperature tolerance, and low surface energy, making them ideal for various filtration applications. The porous structure of PTFE membranes allows for high flow rates while maintaining excellent particle retention, enhancing overall filtration efficiency.

- PTFE coatings for improved surface properties: PTFE coatings are utilized to enhance surface properties of various materials. These coatings provide non-stick, low friction, and hydrophobic characteristics, improving the efficiency of components in diverse applications. The durability and chemical inertness of PTFE coatings contribute to extended product life and reduced maintenance requirements.

- PTFE in energy-efficient applications: PTFE is employed in energy-efficient applications due to its excellent insulating properties and low dielectric constant. It is used in the production of high-performance wires, cables, and electronic components, contributing to reduced energy losses and improved overall system efficiency. PTFE's thermal stability also makes it suitable for heat management in various energy-related applications.

- PTFE composites for enhanced performance: PTFE composites are developed by incorporating various fillers or reinforcing materials to enhance specific properties. These composites offer improved mechanical strength, wear resistance, and thermal conductivity while maintaining PTFE's inherent benefits. The resulting materials demonstrate higher efficiency in applications such as bearings, seals, and gaskets, where traditional PTFE may have limitations.

- PTFE recycling and sustainability: Efforts are being made to improve the efficiency of PTFE recycling processes and enhance its sustainability. Advanced techniques are being developed to recover and reprocess PTFE waste, reducing environmental impact and improving resource utilization. These methods aim to maintain the high-performance characteristics of PTFE while promoting circular economy principles in its lifecycle.

02 PTFE coatings for improved surface properties

PTFE coatings are utilized to enhance surface properties of various materials. These coatings provide low friction, non-stick characteristics, and improved wear resistance. The efficiency of PTFE coatings is demonstrated in applications such as cookware, industrial equipment, and automotive components, where they significantly reduce friction and increase durability.Expand Specific Solutions03 PTFE in textile applications

PTFE is employed in textile applications to improve fabric performance. PTFE-based materials or coatings on textiles enhance water repellency, breathability, and durability. This technology is particularly efficient in outdoor and protective clothing, where it provides excellent weather resistance while maintaining comfort.Expand Specific Solutions04 PTFE in energy-efficient systems

PTFE components contribute to energy efficiency in various systems. Due to its low friction properties, PTFE is used in bearings, seals, and other mechanical parts to reduce energy loss from friction. This efficiency is particularly notable in automotive, aerospace, and industrial machinery applications, where it helps improve overall system performance and reduce energy consumption.Expand Specific Solutions05 PTFE in chemical processing efficiency

PTFE plays a crucial role in improving efficiency in chemical processing industries. Its exceptional chemical resistance and non-reactive nature make it ideal for use in reactors, pipelines, and storage tanks. PTFE linings and components enhance process efficiency by preventing corrosion, reducing contamination, and extending equipment lifespan in harsh chemical environments.Expand Specific Solutions

Key Players in PTFE Wear Protection Industry

The wear protection market using PTFE is in a mature stage, with a global market size estimated to exceed $1 billion. The technology's maturity is evident from the involvement of established players like W. L. Gore & Associates, DuPont, and Sefar AG, who have been developing PTFE-based solutions for decades. These companies, along with newer entrants like Shamrock Technologies, are continuously innovating to improve PTFE's efficiency in wear protection applications. The competitive landscape is characterized by a mix of large multinational corporations and specialized manufacturers, with research institutions like the University of Florida and Lanzhou Institute of Chemical Physics contributing to technological advancements in the field.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates, Inc. has developed advanced PTFE-based solutions for wear protection. Their approach involves creating expanded PTFE (ePTFE) materials with a unique microstructure that enhances durability and performance. The company's ePTFE technology allows for the creation of thin, lightweight, and highly wear-resistant coatings and fabrics[1]. These materials are engineered to have a high strength-to-weight ratio and excellent chemical resistance. Gore's PTFE solutions often incorporate nanostructured additives to further improve wear resistance and reduce friction[2]. The company has also developed specialized manufacturing processes to create PTFE composites that can be tailored for specific wear protection applications, such as in industrial machinery, automotive components, and aerospace systems[3].

Strengths: Superior wear resistance, chemical inertness, and low friction properties. Highly customizable for specific applications. Weaknesses: Potentially higher cost compared to traditional materials, limited high-temperature performance in some formulations.

DuPont Safety & Construction, Inc.

Technical Solution: DuPont Safety & Construction, Inc. has pioneered innovative PTFE-based solutions for wear protection. Their approach focuses on developing advanced PTFE composites and coatings that offer exceptional durability and low friction properties. DuPont's PTFE formulations often incorporate proprietary additives and fillers to enhance wear resistance, thermal stability, and load-bearing capacity[4]. The company has developed specialized processing techniques to create PTFE materials with optimized molecular structures, resulting in improved mechanical properties and longer service life[5]. DuPont's wear protection solutions include PTFE-based fabrics, films, and coatings that can be applied to a wide range of substrates, offering versatility across various industries such as automotive, aerospace, and industrial manufacturing[6].

Strengths: Extensive research and development capabilities, wide range of PTFE formulations for different applications. Weaknesses: Some solutions may require specialized application processes, potentially limiting ease of use in certain scenarios.

Innovative PTFE Wear Protection Technologies

Low friction and low wear polymer/polymer composites

PatentWO2006020619A1

Innovation

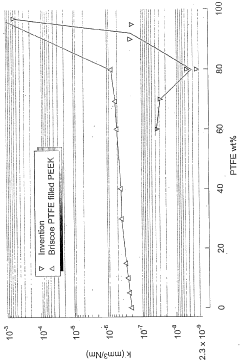

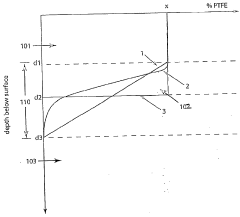

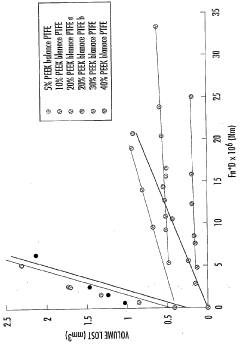

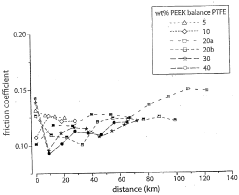

- A composite material comprising a transfer film forming polymer (at least 10 wt% PTFE) and a strengthening polymer (15-90 wt% PEEK) with a compositionally graded transition layer, providing a wear rate <10^-7 mm^3/Nm and a friction coefficient <0.10, formed through extrusion or molding above the softening points of the polymers, enhancing bonding and wear resistance.

Ultra-Low Wear Magnetic Polymer Composite

PatentPendingUS20230272184A1

Innovation

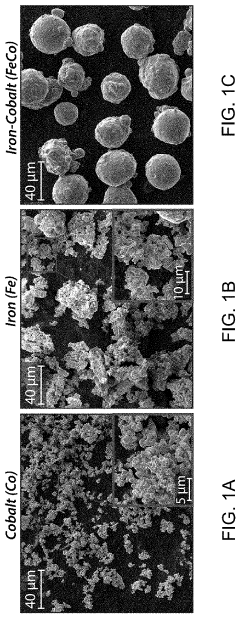

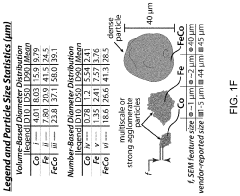

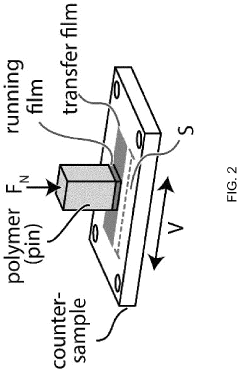

- A magnetic polymer composite is developed using iron-cobalt intermetallic alloy particles dispersed in a perfluoropolymer matrix, with particle sizes between 100 nm and 100 μm, and a composition that balances mechanical and magnetic properties to achieve low wear rates.

Environmental Impact of PTFE Wear Protection

The environmental impact of PTFE wear protection is a critical consideration in its application and long-term sustainability. PTFE, or polytetrafluoroethylene, is widely used for its excellent wear resistance and low friction properties. However, its environmental footprint extends throughout its lifecycle, from production to disposal.

During the manufacturing process of PTFE, the emission of greenhouse gases, particularly perfluorocarbons (PFCs), is a significant concern. These emissions contribute to global warming and have a long atmospheric lifetime. Additionally, the production of PTFE requires the use of fluoropolymer precursors, which can lead to the release of potentially harmful substances into the environment if not properly managed.

In its application as a wear protection material, PTFE demonstrates positive environmental attributes. Its durability and low friction properties contribute to extended equipment life and reduced energy consumption in various industrial applications. This longevity translates to fewer replacements and less frequent maintenance, indirectly reducing the overall environmental impact associated with manufacturing and transportation of replacement parts.

However, the disposal of PTFE-coated products presents environmental challenges. PTFE is not biodegradable and can persist in the environment for extended periods. Incineration of PTFE-containing materials can release toxic substances, including hydrogen fluoride and perfluoroisobutylene, necessitating specialized disposal methods.

Recent research has focused on developing more environmentally friendly alternatives to traditional PTFE. These include water-based PTFE coatings that reduce the use of volatile organic compounds (VOCs) and the exploration of bio-based materials that mimic PTFE's wear protection properties. Additionally, efforts are being made to improve recycling techniques for PTFE-containing products, although this remains a complex and energy-intensive process.

The environmental impact of PTFE wear protection also extends to its potential for microplastic pollution. As PTFE coatings wear down over time, they can release microscopic particles into the environment, contributing to the growing concern of microplastic contamination in ecosystems.

In conclusion, while PTFE offers significant benefits in wear protection and efficiency, its environmental impact is multifaceted. Balancing its performance advantages with environmental considerations remains a key challenge for industries relying on this material. Future developments in PTFE technology and its alternatives will likely focus on minimizing environmental impacts while maintaining or improving wear protection efficiency.

During the manufacturing process of PTFE, the emission of greenhouse gases, particularly perfluorocarbons (PFCs), is a significant concern. These emissions contribute to global warming and have a long atmospheric lifetime. Additionally, the production of PTFE requires the use of fluoropolymer precursors, which can lead to the release of potentially harmful substances into the environment if not properly managed.

In its application as a wear protection material, PTFE demonstrates positive environmental attributes. Its durability and low friction properties contribute to extended equipment life and reduced energy consumption in various industrial applications. This longevity translates to fewer replacements and less frequent maintenance, indirectly reducing the overall environmental impact associated with manufacturing and transportation of replacement parts.

However, the disposal of PTFE-coated products presents environmental challenges. PTFE is not biodegradable and can persist in the environment for extended periods. Incineration of PTFE-containing materials can release toxic substances, including hydrogen fluoride and perfluoroisobutylene, necessitating specialized disposal methods.

Recent research has focused on developing more environmentally friendly alternatives to traditional PTFE. These include water-based PTFE coatings that reduce the use of volatile organic compounds (VOCs) and the exploration of bio-based materials that mimic PTFE's wear protection properties. Additionally, efforts are being made to improve recycling techniques for PTFE-containing products, although this remains a complex and energy-intensive process.

The environmental impact of PTFE wear protection also extends to its potential for microplastic pollution. As PTFE coatings wear down over time, they can release microscopic particles into the environment, contributing to the growing concern of microplastic contamination in ecosystems.

In conclusion, while PTFE offers significant benefits in wear protection and efficiency, its environmental impact is multifaceted. Balancing its performance advantages with environmental considerations remains a key challenge for industries relying on this material. Future developments in PTFE technology and its alternatives will likely focus on minimizing environmental impacts while maintaining or improving wear protection efficiency.

Cost-Benefit Analysis of PTFE Wear Protection Solutions

The cost-benefit analysis of PTFE wear protection solutions reveals a compelling case for their implementation across various industries. Initial investment in PTFE-based wear protection systems may seem substantial, but the long-term benefits often outweigh the upfront costs significantly.

One of the primary advantages of PTFE wear protection is its exceptional durability. PTFE coatings and components can withstand harsh operating conditions, including extreme temperatures, chemical exposure, and abrasive environments. This longevity translates into reduced maintenance frequency and extended equipment lifespan, resulting in substantial cost savings over time.

The low friction properties of PTFE contribute to improved energy efficiency in mechanical systems. By reducing friction between moving parts, PTFE wear protection solutions minimize power consumption and heat generation. This not only leads to lower operational costs but also enhances overall system performance and reliability.

PTFE's non-stick characteristics offer additional benefits in terms of cleaning and maintenance. Equipment protected with PTFE coatings requires less frequent cleaning and is less susceptible to material buildup or contamination. This reduces downtime for maintenance procedures and lowers associated labor costs.

In industries where product purity is critical, such as food processing or pharmaceuticals, PTFE wear protection provides an added layer of safety. Its inert nature prevents contamination, potentially avoiding costly product recalls or regulatory non-compliance issues.

The environmental impact of PTFE wear protection solutions should also be considered. While the production of PTFE has some environmental concerns, its long-lasting nature and ability to improve equipment efficiency can lead to a net positive environmental impact over the lifecycle of the protected equipment.

When evaluating the cost-benefit ratio, it's essential to consider the specific application and operating conditions. High-wear environments or critical components may see a faster return on investment compared to less demanding applications. Additionally, the potential for increased productivity due to reduced downtime and improved performance should be factored into the analysis.

While the initial cost of PTFE wear protection solutions may be higher than traditional alternatives, the long-term savings in maintenance, energy consumption, and equipment longevity often result in a favorable return on investment. As with any technological implementation, a thorough assessment of the specific use case and operating conditions is crucial to determine the most cost-effective approach to wear protection using PTFE.

One of the primary advantages of PTFE wear protection is its exceptional durability. PTFE coatings and components can withstand harsh operating conditions, including extreme temperatures, chemical exposure, and abrasive environments. This longevity translates into reduced maintenance frequency and extended equipment lifespan, resulting in substantial cost savings over time.

The low friction properties of PTFE contribute to improved energy efficiency in mechanical systems. By reducing friction between moving parts, PTFE wear protection solutions minimize power consumption and heat generation. This not only leads to lower operational costs but also enhances overall system performance and reliability.

PTFE's non-stick characteristics offer additional benefits in terms of cleaning and maintenance. Equipment protected with PTFE coatings requires less frequent cleaning and is less susceptible to material buildup or contamination. This reduces downtime for maintenance procedures and lowers associated labor costs.

In industries where product purity is critical, such as food processing or pharmaceuticals, PTFE wear protection provides an added layer of safety. Its inert nature prevents contamination, potentially avoiding costly product recalls or regulatory non-compliance issues.

The environmental impact of PTFE wear protection solutions should also be considered. While the production of PTFE has some environmental concerns, its long-lasting nature and ability to improve equipment efficiency can lead to a net positive environmental impact over the lifecycle of the protected equipment.

When evaluating the cost-benefit ratio, it's essential to consider the specific application and operating conditions. High-wear environments or critical components may see a faster return on investment compared to less demanding applications. Additionally, the potential for increased productivity due to reduced downtime and improved performance should be factored into the analysis.

While the initial cost of PTFE wear protection solutions may be higher than traditional alternatives, the long-term savings in maintenance, energy consumption, and equipment longevity often result in a favorable return on investment. As with any technological implementation, a thorough assessment of the specific use case and operating conditions is crucial to determine the most cost-effective approach to wear protection using PTFE.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!