Exploratory Paths for PTFE in Robotics & AI

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE in Robotics & AI: Background and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has been a revolutionary material in various industries since its accidental discovery in 1938. Its unique properties, including low friction, chemical inertness, and high temperature resistance, have made it invaluable in numerous applications. In recent years, the potential of PTFE in robotics and artificial intelligence (AI) has garnered significant attention from researchers and industry professionals alike.

The evolution of robotics and AI has been marked by continuous advancements in materials science, with a growing emphasis on developing components that can enhance performance, durability, and efficiency. PTFE, with its exceptional characteristics, has emerged as a promising candidate for addressing several challenges in these fields. The integration of PTFE in robotics and AI systems aims to improve mechanical performance, reduce wear and tear, and enhance overall system reliability.

The primary objective of exploring PTFE in robotics and AI is to leverage its unique properties to overcome existing limitations and push the boundaries of what is currently achievable. By incorporating PTFE into various components of robotic systems, researchers aim to develop more efficient and durable machines capable of operating in diverse environments. In the realm of AI, PTFE's potential lies in its ability to enhance the performance of sensors, actuators, and other critical components that form the interface between digital intelligence and the physical world.

One of the key areas of focus is the development of PTFE-based coatings and composites that can be applied to robotic joints, gears, and other moving parts. These applications aim to reduce friction, minimize energy loss, and extend the operational lifespan of robotic systems. Additionally, researchers are exploring the use of PTFE in the creation of flexible and adaptive structures that can mimic biological systems, potentially leading to more versatile and responsive robots.

In the field of AI, PTFE is being investigated for its potential in improving the performance of sensors and data collection devices. Its chemical inertness and resistance to environmental factors make it an ideal material for protecting sensitive electronic components in AI systems deployed in harsh conditions. Furthermore, the exploration of PTFE in AI extends to the development of novel computing architectures, where its unique electrical properties could potentially be harnessed for creating more efficient and robust processing units.

As we delve deeper into the exploration of PTFE in robotics and AI, it is crucial to consider the interdisciplinary nature of this research. The convergence of materials science, mechanical engineering, computer science, and artificial intelligence presents both challenges and opportunities. By fostering collaboration across these fields, we can unlock the full potential of PTFE and pave the way for groundbreaking innovations in robotics and AI technologies.

The evolution of robotics and AI has been marked by continuous advancements in materials science, with a growing emphasis on developing components that can enhance performance, durability, and efficiency. PTFE, with its exceptional characteristics, has emerged as a promising candidate for addressing several challenges in these fields. The integration of PTFE in robotics and AI systems aims to improve mechanical performance, reduce wear and tear, and enhance overall system reliability.

The primary objective of exploring PTFE in robotics and AI is to leverage its unique properties to overcome existing limitations and push the boundaries of what is currently achievable. By incorporating PTFE into various components of robotic systems, researchers aim to develop more efficient and durable machines capable of operating in diverse environments. In the realm of AI, PTFE's potential lies in its ability to enhance the performance of sensors, actuators, and other critical components that form the interface between digital intelligence and the physical world.

One of the key areas of focus is the development of PTFE-based coatings and composites that can be applied to robotic joints, gears, and other moving parts. These applications aim to reduce friction, minimize energy loss, and extend the operational lifespan of robotic systems. Additionally, researchers are exploring the use of PTFE in the creation of flexible and adaptive structures that can mimic biological systems, potentially leading to more versatile and responsive robots.

In the field of AI, PTFE is being investigated for its potential in improving the performance of sensors and data collection devices. Its chemical inertness and resistance to environmental factors make it an ideal material for protecting sensitive electronic components in AI systems deployed in harsh conditions. Furthermore, the exploration of PTFE in AI extends to the development of novel computing architectures, where its unique electrical properties could potentially be harnessed for creating more efficient and robust processing units.

As we delve deeper into the exploration of PTFE in robotics and AI, it is crucial to consider the interdisciplinary nature of this research. The convergence of materials science, mechanical engineering, computer science, and artificial intelligence presents both challenges and opportunities. By fostering collaboration across these fields, we can unlock the full potential of PTFE and pave the way for groundbreaking innovations in robotics and AI technologies.

Market Analysis for PTFE in Advanced Technologies

The market for PTFE (Polytetrafluoroethylene) in advanced technologies, particularly in robotics and AI, is experiencing significant growth and transformation. This high-performance polymer's unique properties, including exceptional chemical resistance, low friction, and thermal stability, make it increasingly valuable in cutting-edge applications.

In the robotics sector, PTFE is finding extensive use in various components, enhancing the performance and durability of robotic systems. The material's low friction coefficient is crucial for reducing wear in moving parts, such as joints and actuators, leading to improved efficiency and longevity of robotic devices. As the robotics industry continues to expand, with projections indicating substantial growth in industrial, service, and collaborative robots, the demand for PTFE is expected to rise correspondingly.

The AI hardware market, particularly in data centers and high-performance computing systems, is another area where PTFE is gaining traction. Its excellent dielectric properties and heat resistance make it ideal for use in advanced circuit boards and thermal management systems. As AI applications become more prevalent and computationally intensive, the need for materials that can withstand high temperatures and maintain signal integrity becomes paramount.

The automotive industry, at the intersection of robotics and AI, represents a significant market for PTFE. With the increasing adoption of autonomous vehicles and advanced driver assistance systems (ADAS), PTFE is being utilized in sensors, connectors, and other critical components that require reliability under harsh conditions.

Market analysis indicates that the Asia-Pacific region, particularly China and Japan, is emerging as a key growth area for PTFE in advanced technologies. This is driven by the rapid expansion of their robotics and AI industries, coupled with significant investments in research and development.

However, the market faces challenges, including the high cost of PTFE production and environmental concerns related to its manufacturing process. These factors are spurring research into more sustainable production methods and alternative materials, which could impact the market dynamics in the coming years.

Despite these challenges, the overall outlook for PTFE in robotics and AI remains positive. The material's unique combination of properties continues to make it indispensable in many high-tech applications, with ongoing research exploring new potential uses. As these advanced technologies evolve and become more integrated into various industries, the market for PTFE is expected to expand, offering opportunities for innovation and growth in this specialized sector.

In the robotics sector, PTFE is finding extensive use in various components, enhancing the performance and durability of robotic systems. The material's low friction coefficient is crucial for reducing wear in moving parts, such as joints and actuators, leading to improved efficiency and longevity of robotic devices. As the robotics industry continues to expand, with projections indicating substantial growth in industrial, service, and collaborative robots, the demand for PTFE is expected to rise correspondingly.

The AI hardware market, particularly in data centers and high-performance computing systems, is another area where PTFE is gaining traction. Its excellent dielectric properties and heat resistance make it ideal for use in advanced circuit boards and thermal management systems. As AI applications become more prevalent and computationally intensive, the need for materials that can withstand high temperatures and maintain signal integrity becomes paramount.

The automotive industry, at the intersection of robotics and AI, represents a significant market for PTFE. With the increasing adoption of autonomous vehicles and advanced driver assistance systems (ADAS), PTFE is being utilized in sensors, connectors, and other critical components that require reliability under harsh conditions.

Market analysis indicates that the Asia-Pacific region, particularly China and Japan, is emerging as a key growth area for PTFE in advanced technologies. This is driven by the rapid expansion of their robotics and AI industries, coupled with significant investments in research and development.

However, the market faces challenges, including the high cost of PTFE production and environmental concerns related to its manufacturing process. These factors are spurring research into more sustainable production methods and alternative materials, which could impact the market dynamics in the coming years.

Despite these challenges, the overall outlook for PTFE in robotics and AI remains positive. The material's unique combination of properties continues to make it indispensable in many high-tech applications, with ongoing research exploring new potential uses. As these advanced technologies evolve and become more integrated into various industries, the market for PTFE is expected to expand, offering opportunities for innovation and growth in this specialized sector.

Current PTFE Applications and Challenges in Robotics

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has found significant applications in the field of robotics due to its unique properties. Its low friction coefficient, chemical inertness, and high temperature resistance make it an ideal material for various robotic components. In actuators and joints, PTFE coatings reduce friction and wear, enhancing the overall efficiency and lifespan of robotic systems. The material's self-lubricating properties are particularly valuable in environments where traditional lubricants may be ineffective or impractical.

In the realm of soft robotics, PTFE films and fabrics are utilized to create flexible, durable outer layers for robotic structures. These materials provide a balance between flexibility and strength, allowing for the development of robots that can interact safely with humans and navigate complex environments. PTFE's hydrophobic nature also makes it suitable for underwater robotics applications, where water resistance is crucial.

For robotic sensors and electronic components, PTFE serves as an excellent insulator and protective coating. Its dielectric properties and resistance to chemical degradation ensure the longevity and reliability of sensitive electronic systems in harsh operating conditions. In robotic end-effectors and grippers, PTFE coatings improve grip stability and reduce the risk of damage to handled objects, particularly in clean room environments or when dealing with delicate materials.

Despite these advantages, the integration of PTFE in robotics faces several challenges. One significant issue is the difficulty in bonding PTFE to other materials, which can complicate the manufacturing and assembly of robotic components. This limitation often requires specialized bonding techniques or the use of mechanical fastening methods, potentially increasing production costs and complexity.

Another challenge lies in the relatively high cost of high-quality PTFE materials, which can impact the overall cost-effectiveness of robotic systems, especially in large-scale production. Additionally, while PTFE's low friction properties are generally beneficial, they can sometimes be a drawback in applications where a certain level of friction is necessary for proper functionality.

The disposal and recycling of PTFE-containing robotic components also present environmental concerns. PTFE is not biodegradable and can persist in the environment for extended periods. As the robotics industry grows, developing sustainable practices for the use and disposal of PTFE materials becomes increasingly important.

In the context of AI-driven robotics, the integration of PTFE materials with smart sensors and adaptive control systems presents both opportunities and challenges. While PTFE can enhance the physical performance of robots, ensuring compatibility with advanced sensing and control technologies requires ongoing research and development efforts. This includes exploring ways to incorporate PTFE into flexible electronics and developing new composite materials that combine PTFE's beneficial properties with enhanced functionality for AI applications.

In the realm of soft robotics, PTFE films and fabrics are utilized to create flexible, durable outer layers for robotic structures. These materials provide a balance between flexibility and strength, allowing for the development of robots that can interact safely with humans and navigate complex environments. PTFE's hydrophobic nature also makes it suitable for underwater robotics applications, where water resistance is crucial.

For robotic sensors and electronic components, PTFE serves as an excellent insulator and protective coating. Its dielectric properties and resistance to chemical degradation ensure the longevity and reliability of sensitive electronic systems in harsh operating conditions. In robotic end-effectors and grippers, PTFE coatings improve grip stability and reduce the risk of damage to handled objects, particularly in clean room environments or when dealing with delicate materials.

Despite these advantages, the integration of PTFE in robotics faces several challenges. One significant issue is the difficulty in bonding PTFE to other materials, which can complicate the manufacturing and assembly of robotic components. This limitation often requires specialized bonding techniques or the use of mechanical fastening methods, potentially increasing production costs and complexity.

Another challenge lies in the relatively high cost of high-quality PTFE materials, which can impact the overall cost-effectiveness of robotic systems, especially in large-scale production. Additionally, while PTFE's low friction properties are generally beneficial, they can sometimes be a drawback in applications where a certain level of friction is necessary for proper functionality.

The disposal and recycling of PTFE-containing robotic components also present environmental concerns. PTFE is not biodegradable and can persist in the environment for extended periods. As the robotics industry grows, developing sustainable practices for the use and disposal of PTFE materials becomes increasingly important.

In the context of AI-driven robotics, the integration of PTFE materials with smart sensors and adaptive control systems presents both opportunities and challenges. While PTFE can enhance the physical performance of robots, ensuring compatibility with advanced sensing and control technologies requires ongoing research and development efforts. This includes exploring ways to incorporate PTFE into flexible electronics and developing new composite materials that combine PTFE's beneficial properties with enhanced functionality for AI applications.

Existing PTFE Solutions in AI and Robotics

01 PTFE manufacturing processes

Various methods for producing PTFE are described, including polymerization techniques, extrusion processes, and molding methods. These processes aim to improve the quality, consistency, and properties of PTFE products for different applications.- PTFE manufacturing processes: Various methods for producing PTFE are described, including polymerization techniques, extrusion processes, and molding methods. These processes aim to improve the quality, consistency, and properties of PTFE products for different applications.

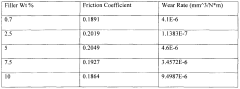

- PTFE composite materials: PTFE is often combined with other materials to create composite products with enhanced properties. These composites may include fillers, reinforcing agents, or other polymers to improve mechanical strength, wear resistance, or thermal conductivity.

- Surface modification of PTFE: Techniques for modifying the surface of PTFE materials are explored to enhance properties such as adhesion, wettability, or biocompatibility. These modifications may involve chemical treatments, plasma processing, or the application of coatings.

- PTFE in membrane technology: PTFE is widely used in membrane applications due to its chemical resistance and non-stick properties. Innovations in this area focus on creating porous PTFE membranes for filtration, separation, and other specialized applications.

- PTFE in electrical and electronic applications: The use of PTFE in electrical and electronic components is explored, leveraging its excellent dielectric properties and thermal stability. Applications include insulation materials, printed circuit boards, and high-frequency components.

02 PTFE composite materials

PTFE is combined with other materials to create composite structures with enhanced properties. These composites may include reinforcing fibers, nanoparticles, or other polymers to improve mechanical strength, thermal stability, or electrical properties.Expand Specific Solutions03 Surface modification of PTFE

Techniques for modifying the surface of PTFE to enhance its properties or compatibility with other materials are explored. These may include chemical treatments, plasma treatments, or the application of coatings to improve adhesion or other surface characteristics.Expand Specific Solutions04 PTFE in membrane technology

The use of PTFE in membrane applications is discussed, including its role in filtration, separation, and gas diffusion processes. PTFE membranes are developed with specific pore sizes and structures for various industrial and medical applications.Expand Specific Solutions05 PTFE in electronic and electrical applications

The development of PTFE-based materials for electronic and electrical applications is explored. This includes the use of PTFE in insulation, printed circuit boards, and high-frequency components due to its excellent dielectric properties and thermal stability.Expand Specific Solutions

Key Players in PTFE and Robotics Industries

The exploration of PTFE in robotics and AI is in its early stages, with the market still developing and showing potential for growth. The technology's maturity varies across applications, with established players like W. L. Gore & Associates and 3M Innovative Properties Co. leading in PTFE material development. Emerging companies such as OnRobot A/S are exploring PTFE's applications in robotic end-effectors. Academic institutions like the University of Florida and Soochow University are contributing to research, indicating a growing interest in PTFE's potential for advanced robotics and AI applications. The market size is expected to expand as more industries recognize PTFE's unique properties for enhancing robotic performance and AI-driven systems.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed advanced PTFE-based materials for robotics applications, focusing on improving flexibility and durability. Their ePTFE (expanded PTFE) technology offers enhanced properties such as increased porosity and strength-to-weight ratio[1]. For AI integration, Gore has explored the use of PTFE in flexible printed circuits and high-speed data transmission cables, crucial for robotic control systems. They have also developed PTFE-based sensor membranes that can withstand harsh environments while maintaining sensitivity, enabling more robust environmental sensing in robotics[2][3].

Strengths: Expertise in PTFE modifications, wide range of applications in robotics. Weaknesses: May face challenges in scaling production for mass robotic deployment.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has pioneered the development of fluoropolymer technologies, including advanced PTFE formulations for robotics. Their research focuses on creating PTFE compounds with improved wear resistance and lower friction coefficients, essential for robotic joint mechanisms and actuators. DAIKIN has also explored the integration of PTFE in soft robotics, developing materials that combine flexibility with chemical resistance[4]. In the AI domain, they have investigated PTFE-based dielectric materials for advanced sensors and actuators, potentially enhancing the sensory capabilities of robots[5].

Strengths: Strong R&D in fluoropolymers, diverse applications in robotics. Weaknesses: May need to strengthen partnerships with robotics manufacturers for wider adoption.

Innovative PTFE Applications in Smart Systems

Inert wear resistant fluoropolymer-based solid lubricants, methods of making, and methods of use

PatentWO2010057163A2

Innovation

- Development of fluoropolymer-based materials by admixing PTFE with a fluorine-reactive compound, such as nanoparticles or metal oxides, to create a composite that maintains inertness and reduces wear rates at lower filler loadings, enhancing wear resistance while maintaining low friction coefficients.

Process for modifying the surface of polytetrafluorethylene, modified mouldings based on polytetrafluorethylene and use thereof

PatentWO1987000847A1

Innovation

- The process involves using volatile, easily hydrolyzable fluorides such as silicon, germanium, phosphorus, or arsenic compounds at elevated temperatures to create a pseudo-interpenetrating polymer network with silicic acid, which penetrates deeper into the PTFE structure, forming a hydrophilic surface that is mechanically resistant and adheres firmly.

Environmental Impact of PTFE in Tech Industry

The environmental impact of PTFE (Polytetrafluoroethylene) in the tech industry, particularly in robotics and AI applications, is a complex and multifaceted issue that requires careful consideration. PTFE, commonly known by its brand name Teflon, has unique properties that make it valuable in various technological applications, but its production and disposal can have significant environmental implications.

PTFE's non-stick and low friction properties make it an attractive material for use in robotic components, such as gears, bearings, and seals. In AI-driven systems, PTFE coatings can be used to protect sensitive electronic components from environmental factors. However, the production of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that can accumulate in the environment and living organisms.

The manufacturing process of PTFE releases greenhouse gases, including perfluorocarbons (PFCs) and hydrofluorocarbons (HFCs), which have high global warming potentials. These emissions contribute to climate change and can persist in the atmosphere for extended periods. Additionally, the disposal of PTFE-containing products at the end of their lifecycle poses challenges, as the material is not biodegradable and can release toxic compounds when incinerated.

In the context of robotics and AI, the use of PTFE can lead to improved performance and longevity of components, potentially reducing the need for frequent replacements and thereby minimizing waste. However, this benefit must be weighed against the environmental costs of production and disposal. As the demand for advanced robotics and AI systems grows, so does the potential environmental impact of PTFE usage in these technologies.

Efforts to mitigate the environmental impact of PTFE in the tech industry include research into alternative materials with similar properties but lower environmental footprints. Some companies are exploring bio-based polymers or developing PFOA-free PTFE production methods. Additionally, improved recycling technologies for PTFE-containing products are being investigated to reduce the amount of material ending up in landfills or incinerators.

The tech industry is also focusing on designing products with easier disassembly and material recovery in mind, which could facilitate more efficient recycling of PTFE components. Furthermore, advancements in nanotechnology may lead to the development of coatings that provide similar benefits to PTFE but with reduced environmental impact.

As the robotics and AI sectors continue to evolve, balancing the performance benefits of PTFE with its environmental consequences will be crucial. This may involve a combination of material innovation, improved manufacturing processes, and more effective end-of-life management strategies for PTFE-containing products in the tech industry.

PTFE's non-stick and low friction properties make it an attractive material for use in robotic components, such as gears, bearings, and seals. In AI-driven systems, PTFE coatings can be used to protect sensitive electronic components from environmental factors. However, the production of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that can accumulate in the environment and living organisms.

The manufacturing process of PTFE releases greenhouse gases, including perfluorocarbons (PFCs) and hydrofluorocarbons (HFCs), which have high global warming potentials. These emissions contribute to climate change and can persist in the atmosphere for extended periods. Additionally, the disposal of PTFE-containing products at the end of their lifecycle poses challenges, as the material is not biodegradable and can release toxic compounds when incinerated.

In the context of robotics and AI, the use of PTFE can lead to improved performance and longevity of components, potentially reducing the need for frequent replacements and thereby minimizing waste. However, this benefit must be weighed against the environmental costs of production and disposal. As the demand for advanced robotics and AI systems grows, so does the potential environmental impact of PTFE usage in these technologies.

Efforts to mitigate the environmental impact of PTFE in the tech industry include research into alternative materials with similar properties but lower environmental footprints. Some companies are exploring bio-based polymers or developing PFOA-free PTFE production methods. Additionally, improved recycling technologies for PTFE-containing products are being investigated to reduce the amount of material ending up in landfills or incinerators.

The tech industry is also focusing on designing products with easier disassembly and material recovery in mind, which could facilitate more efficient recycling of PTFE components. Furthermore, advancements in nanotechnology may lead to the development of coatings that provide similar benefits to PTFE but with reduced environmental impact.

As the robotics and AI sectors continue to evolve, balancing the performance benefits of PTFE with its environmental consequences will be crucial. This may involve a combination of material innovation, improved manufacturing processes, and more effective end-of-life management strategies for PTFE-containing products in the tech industry.

Collaborative Research Opportunities

Collaborative research opportunities in the field of PTFE applications for robotics and AI present exciting prospects for interdisciplinary innovation. By fostering partnerships between academic institutions, research laboratories, and industry leaders, we can accelerate the development of novel PTFE-based solutions for advanced robotic systems and AI applications.

One promising avenue for collaboration is the integration of PTFE materials in soft robotics. Research teams from materials science, mechanical engineering, and robotics can work together to explore how PTFE's unique properties can enhance the flexibility, durability, and performance of soft robotic actuators and sensors. This could lead to breakthroughs in creating more adaptable and resilient robotic systems for various applications, from healthcare to industrial automation.

Another potential area for joint research is the development of PTFE-based coatings and surfaces for AI-enabled robotic systems. By combining expertise in surface chemistry, nanotechnology, and machine learning, researchers can investigate how PTFE-enhanced surfaces can improve the tactile sensing capabilities of robots. This could result in more sophisticated haptic feedback systems, enabling robots to interact more precisely with their environment and handle delicate objects with greater dexterity.

Collaborative efforts can also focus on exploring PTFE's potential in thermal management for AI hardware. As AI systems become more complex and computationally intensive, efficient heat dissipation becomes crucial. Interdisciplinary teams comprising materials scientists, thermal engineers, and AI hardware specialists can work together to develop innovative PTFE-based cooling solutions for high-performance AI chips and processors.

Furthermore, joint research initiatives can investigate the use of PTFE in advanced robotic joints and bearings. By combining knowledge from tribology, mechanical engineering, and robotics, researchers can develop novel PTFE-based components that offer improved wear resistance, reduced friction, and enhanced performance in robotic systems. This could lead to the creation of more efficient and longer-lasting robots for various applications, from manufacturing to space exploration.

Lastly, collaborative research can explore the potential of PTFE in developing self-cleaning and contamination-resistant surfaces for robots operating in challenging environments. By bringing together experts in materials science, environmental engineering, and robotics, we can investigate how PTFE's non-stick properties can be leveraged to create robots that maintain optimal performance in dusty, corrosive, or biologically active settings.

One promising avenue for collaboration is the integration of PTFE materials in soft robotics. Research teams from materials science, mechanical engineering, and robotics can work together to explore how PTFE's unique properties can enhance the flexibility, durability, and performance of soft robotic actuators and sensors. This could lead to breakthroughs in creating more adaptable and resilient robotic systems for various applications, from healthcare to industrial automation.

Another potential area for joint research is the development of PTFE-based coatings and surfaces for AI-enabled robotic systems. By combining expertise in surface chemistry, nanotechnology, and machine learning, researchers can investigate how PTFE-enhanced surfaces can improve the tactile sensing capabilities of robots. This could result in more sophisticated haptic feedback systems, enabling robots to interact more precisely with their environment and handle delicate objects with greater dexterity.

Collaborative efforts can also focus on exploring PTFE's potential in thermal management for AI hardware. As AI systems become more complex and computationally intensive, efficient heat dissipation becomes crucial. Interdisciplinary teams comprising materials scientists, thermal engineers, and AI hardware specialists can work together to develop innovative PTFE-based cooling solutions for high-performance AI chips and processors.

Furthermore, joint research initiatives can investigate the use of PTFE in advanced robotic joints and bearings. By combining knowledge from tribology, mechanical engineering, and robotics, researchers can develop novel PTFE-based components that offer improved wear resistance, reduced friction, and enhanced performance in robotic systems. This could lead to the creation of more efficient and longer-lasting robots for various applications, from manufacturing to space exploration.

Lastly, collaborative research can explore the potential of PTFE in developing self-cleaning and contamination-resistant surfaces for robots operating in challenging environments. By bringing together experts in materials science, environmental engineering, and robotics, we can investigate how PTFE's non-stick properties can be leveraged to create robots that maintain optimal performance in dusty, corrosive, or biologically active settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!