PTFE in Space Exploration: Opportunities and Challenges

JUN 27, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Space Applications

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has become an indispensable material in space exploration due to its unique properties. In the harsh environment of space, PTFE's exceptional chemical resistance, low friction coefficient, and wide temperature range make it an ideal choice for various applications.

One of the primary uses of PTFE in space is in satellite and spacecraft components. The material's low outgassing characteristics prevent contamination of sensitive optical equipment and other instruments. PTFE is used in seals, gaskets, and O-rings to maintain pressure integrity in spacecraft and space stations. Its ability to withstand extreme temperatures, ranging from -200°C to +260°C, makes it suitable for both cryogenic and high-temperature applications in space vehicles.

In space suits, PTFE plays a crucial role in ensuring astronaut safety and comfort. The material is used in the outer layer of spacesuits to provide thermal insulation and protection against micrometeorites. PTFE-coated fabrics are also used in the inner layers to manage moisture and maintain a stable environment for the astronaut.

PTFE's low friction properties make it an excellent choice for moving parts in space mechanisms. It is used in bearings, bushings, and sliding surfaces to reduce wear and extend the lifespan of critical components. This is particularly important in space applications where maintenance and replacement are not feasible.

In space-based scientific instruments, PTFE is used for insulation of wires and cables. Its excellent dielectric properties and resistance to radiation damage ensure reliable electrical performance in the harsh space environment. PTFE-based materials are also used in antenna systems and radar equipment on satellites and space probes.

The material's non-stick properties find applications in space-based manufacturing experiments. PTFE-coated surfaces are used in microgravity crystal growth and materials processing experiments to prevent unwanted adhesion and contamination.

Despite its numerous advantages, the use of PTFE in space applications also presents some challenges. The material's tendency to cold flow under stress can lead to dimensional changes over time, which must be accounted for in design. Additionally, PTFE's poor radiation resistance compared to some other polymers requires careful consideration in applications exposed to high radiation levels.

One of the primary uses of PTFE in space is in satellite and spacecraft components. The material's low outgassing characteristics prevent contamination of sensitive optical equipment and other instruments. PTFE is used in seals, gaskets, and O-rings to maintain pressure integrity in spacecraft and space stations. Its ability to withstand extreme temperatures, ranging from -200°C to +260°C, makes it suitable for both cryogenic and high-temperature applications in space vehicles.

In space suits, PTFE plays a crucial role in ensuring astronaut safety and comfort. The material is used in the outer layer of spacesuits to provide thermal insulation and protection against micrometeorites. PTFE-coated fabrics are also used in the inner layers to manage moisture and maintain a stable environment for the astronaut.

PTFE's low friction properties make it an excellent choice for moving parts in space mechanisms. It is used in bearings, bushings, and sliding surfaces to reduce wear and extend the lifespan of critical components. This is particularly important in space applications where maintenance and replacement are not feasible.

In space-based scientific instruments, PTFE is used for insulation of wires and cables. Its excellent dielectric properties and resistance to radiation damage ensure reliable electrical performance in the harsh space environment. PTFE-based materials are also used in antenna systems and radar equipment on satellites and space probes.

The material's non-stick properties find applications in space-based manufacturing experiments. PTFE-coated surfaces are used in microgravity crystal growth and materials processing experiments to prevent unwanted adhesion and contamination.

Despite its numerous advantages, the use of PTFE in space applications also presents some challenges. The material's tendency to cold flow under stress can lead to dimensional changes over time, which must be accounted for in design. Additionally, PTFE's poor radiation resistance compared to some other polymers requires careful consideration in applications exposed to high radiation levels.

Space Industry Demand

The space industry has witnessed a significant surge in demand for advanced materials that can withstand the harsh conditions of space exploration. PTFE (Polytetrafluoroethylene), commonly known as Teflon, has emerged as a crucial material in this sector due to its unique properties. The space industry's demand for PTFE is driven by several factors, including the material's exceptional thermal stability, chemical inertness, and low friction coefficient.

In spacecraft and satellite manufacturing, PTFE is extensively used for insulation purposes. Its ability to maintain its properties across a wide temperature range, from cryogenic levels to extreme heat, makes it ideal for protecting sensitive components from the temperature fluctuations encountered in space. This demand is further amplified by the increasing number of satellite launches, particularly in the growing small satellite market.

The aerospace sector also relies heavily on PTFE for various applications. In rocket propulsion systems, PTFE-based seals and gaskets are essential for preventing fuel leaks and ensuring the integrity of critical components. The material's resistance to corrosive chemicals and its self-lubricating properties make it invaluable in these high-stress environments.

Space suits and life support systems represent another significant area of demand for PTFE. The material's biocompatibility and resistance to bodily fluids make it suitable for use in various components of life support systems. Additionally, PTFE-based fabrics are used in space suit construction, providing durability and protection against extreme temperatures and radiation.

The growing interest in long-duration space missions, including potential Mars expeditions, has further increased the demand for PTFE. These missions require materials that can maintain their integrity over extended periods without degradation, a characteristic that PTFE excels in. The material's low outgassing properties also make it suitable for use in sensitive optical and electronic equipment used in space exploration.

As space agencies and private companies continue to push the boundaries of space exploration, the demand for PTFE is expected to grow. The material's role in enabling new technologies and improving the reliability of space systems ensures its continued importance in the industry. However, this increasing demand also highlights the need for ongoing research and development to enhance PTFE's properties and explore potential alternatives that can meet the evolving challenges of space exploration.

In spacecraft and satellite manufacturing, PTFE is extensively used for insulation purposes. Its ability to maintain its properties across a wide temperature range, from cryogenic levels to extreme heat, makes it ideal for protecting sensitive components from the temperature fluctuations encountered in space. This demand is further amplified by the increasing number of satellite launches, particularly in the growing small satellite market.

The aerospace sector also relies heavily on PTFE for various applications. In rocket propulsion systems, PTFE-based seals and gaskets are essential for preventing fuel leaks and ensuring the integrity of critical components. The material's resistance to corrosive chemicals and its self-lubricating properties make it invaluable in these high-stress environments.

Space suits and life support systems represent another significant area of demand for PTFE. The material's biocompatibility and resistance to bodily fluids make it suitable for use in various components of life support systems. Additionally, PTFE-based fabrics are used in space suit construction, providing durability and protection against extreme temperatures and radiation.

The growing interest in long-duration space missions, including potential Mars expeditions, has further increased the demand for PTFE. These missions require materials that can maintain their integrity over extended periods without degradation, a characteristic that PTFE excels in. The material's low outgassing properties also make it suitable for use in sensitive optical and electronic equipment used in space exploration.

As space agencies and private companies continue to push the boundaries of space exploration, the demand for PTFE is expected to grow. The material's role in enabling new technologies and improving the reliability of space systems ensures its continued importance in the industry. However, this increasing demand also highlights the need for ongoing research and development to enhance PTFE's properties and explore potential alternatives that can meet the evolving challenges of space exploration.

PTFE Limitations

Despite its numerous advantages, PTFE faces several limitations in space exploration applications. One of the primary challenges is its poor resistance to atomic oxygen, a highly reactive form of oxygen prevalent in low Earth orbit. Atomic oxygen can cause significant erosion and degradation of PTFE surfaces, leading to potential material failure and compromised performance of spacecraft components.

Another limitation of PTFE in space environments is its susceptibility to cold flow or creep under sustained loads. In the extreme temperature fluctuations of space, this property can result in dimensional instability and potential loss of sealing effectiveness in critical applications such as O-rings and gaskets.

PTFE also exhibits relatively poor radiation resistance compared to some other polymers. Prolonged exposure to high-energy cosmic radiation can cause chain scission and cross-linking in the polymer structure, potentially altering its mechanical and chemical properties over time. This degradation can impact the long-term reliability of PTFE-based components in spacecraft and satellites.

The material's low thermal conductivity, while beneficial in some applications, can be a drawback in situations where heat dissipation is crucial. This limitation may necessitate additional thermal management strategies in space systems utilizing PTFE components.

Furthermore, PTFE's high coefficient of thermal expansion can lead to challenges in maintaining precise dimensional tolerances across the wide temperature ranges encountered in space. This property can complicate the design of components that require tight fits or precise alignments.

The non-stick nature of PTFE, while advantageous in many terrestrial applications, can pose difficulties in space environments where controlled adhesion is sometimes necessary. This limitation may restrict its use in certain bonding or coating applications within spacecraft.

Lastly, the manufacturing and processing of PTFE for space applications present their own set of challenges. The material's high melting point and viscosity make it difficult to process using conventional thermoplastic techniques, often requiring specialized and costly manufacturing methods. This can limit the complexity and scale of PTFE components that can be practically produced for space missions.

Another limitation of PTFE in space environments is its susceptibility to cold flow or creep under sustained loads. In the extreme temperature fluctuations of space, this property can result in dimensional instability and potential loss of sealing effectiveness in critical applications such as O-rings and gaskets.

PTFE also exhibits relatively poor radiation resistance compared to some other polymers. Prolonged exposure to high-energy cosmic radiation can cause chain scission and cross-linking in the polymer structure, potentially altering its mechanical and chemical properties over time. This degradation can impact the long-term reliability of PTFE-based components in spacecraft and satellites.

The material's low thermal conductivity, while beneficial in some applications, can be a drawback in situations where heat dissipation is crucial. This limitation may necessitate additional thermal management strategies in space systems utilizing PTFE components.

Furthermore, PTFE's high coefficient of thermal expansion can lead to challenges in maintaining precise dimensional tolerances across the wide temperature ranges encountered in space. This property can complicate the design of components that require tight fits or precise alignments.

The non-stick nature of PTFE, while advantageous in many terrestrial applications, can pose difficulties in space environments where controlled adhesion is sometimes necessary. This limitation may restrict its use in certain bonding or coating applications within spacecraft.

Lastly, the manufacturing and processing of PTFE for space applications present their own set of challenges. The material's high melting point and viscosity make it difficult to process using conventional thermoplastic techniques, often requiring specialized and costly manufacturing methods. This can limit the complexity and scale of PTFE components that can be practically produced for space missions.

Current PTFE Solutions

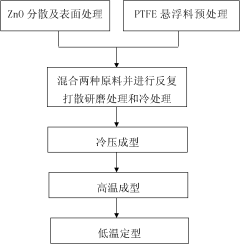

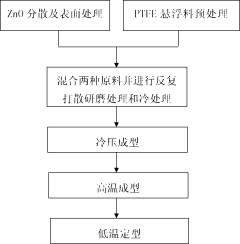

01 PTFE manufacturing and processing methods

Various techniques for manufacturing and processing PTFE, including molding, extrusion, and sintering. These methods are used to create different forms of PTFE products, such as sheets, films, and components with specific properties.- PTFE manufacturing processes: Various methods for producing PTFE are described, including polymerization techniques, extrusion processes, and molding methods. These processes aim to improve the quality, efficiency, and properties of the resulting PTFE materials.

- PTFE composite materials: PTFE is often combined with other materials to create composite structures with enhanced properties. These composites may include fillers, reinforcing agents, or other polymers to improve mechanical strength, thermal stability, or specific functional characteristics.

- Surface modification of PTFE: Techniques for modifying the surface of PTFE materials are explored to enhance properties such as adhesion, wettability, or biocompatibility. These modifications may involve chemical treatments, plasma processing, or the application of coatings.

- PTFE in membrane technology: PTFE is utilized in the development of advanced membrane technologies for various applications, including filtration, separation, and gas diffusion. These membranes leverage PTFE's unique properties such as chemical resistance and hydrophobicity.

- PTFE applications in specific industries: PTFE finds applications in diverse industries due to its exceptional properties. These include use in automotive components, electronics, medical devices, and industrial equipment. The material's low friction, high temperature resistance, and chemical inertness are key factors in its widespread adoption.

02 PTFE composites and blends

Development of PTFE composites and blends with other materials to enhance specific properties such as wear resistance, thermal conductivity, or electrical properties. These composites find applications in various industries, including automotive and electronics.Expand Specific Solutions03 Surface modification of PTFE

Techniques for modifying the surface of PTFE to improve its adhesion, wettability, or compatibility with other materials. This includes chemical treatments, plasma treatments, and the application of coatings to enhance PTFE's functionality in specific applications.Expand Specific Solutions04 PTFE in membrane and filtration applications

Utilization of PTFE in the development of membranes and filtration systems due to its non-stick and chemical-resistant properties. These applications include water treatment, gas separation, and industrial filtration processes.Expand Specific Solutions05 PTFE in medical and biomedical applications

Integration of PTFE in medical devices, implants, and biomedical applications due to its biocompatibility and low friction properties. This includes the development of PTFE-based materials for cardiovascular devices, orthopedic implants, and drug delivery systems.Expand Specific Solutions

Space Industry Players

The PTFE in space exploration market is in a growth phase, driven by increasing space missions and demand for high-performance materials. The market size is expanding, with potential applications in spacecraft components, thermal insulation, and life support systems. Technologically, PTFE is mature but continues to evolve for space-specific requirements. Key players like W. L. Gore & Associates, DAIKIN INDUSTRIES, and AGC, Inc. are at the forefront, leveraging their expertise in fluoropolymers. Research institutions such as Zhejiang University and The Johns Hopkins University contribute to advancing PTFE applications in space, while companies like The Georgia Tech Research Corp. bridge academic research with industry needs, fostering innovation in this specialized field.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed advanced PTFE-based materials for space exploration applications. Their GORE® Space Cables and Assemblies utilize expanded PTFE (ePTFE) technology to create lightweight, high-performance cables that can withstand extreme temperatures and radiation in space environments[1]. The company has also engineered GORE® Microwave/RF Assemblies with PTFE dielectrics, offering low loss and phase stability for satellite communications[2]. Additionally, Gore has introduced GORE® SKYFLEX® Aerospace Materials, incorporating PTFE, for use in aircraft and spacecraft sealing applications, providing excellent resistance to chemicals, fuels, and extreme temperatures[3].

Strengths: Extensive experience in PTFE applications for aerospace, proven track record in space missions, and innovative ePTFE technology. Weaknesses: Potential high costs associated with specialized materials and limited public information on specific space exploration projects.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN INDUSTRIES has developed PTFE-based materials specifically tailored for space exploration. Their NEOFLON™ PTFE series offers exceptional thermal stability and chemical resistance, crucial for spacecraft components exposed to extreme conditions[1]. DAIKIN has also engineered OPTOOL™, a PTFE-based coating technology that provides low friction and non-stick properties, potentially useful for various space mechanisms and instruments[2]. The company's POLYFLON™ PTFE fine powder has been utilized in the production of thin-walled tubing and high-strength fibers, which could find applications in life support systems and space suits[3]. Furthermore, DAIKIN has developed PTFE-based fuel cell membranes that may contribute to power generation in future space missions[4].

Strengths: Diverse range of PTFE products applicable to space exploration, strong R&D capabilities in fluoropolymers. Weaknesses: Less publicly available information on direct involvement in space projects compared to some competitors.

PTFE Innovations

Functional composite material used for spacecraft and preparation method thereof

PatentInactiveCN102304258A

Innovation

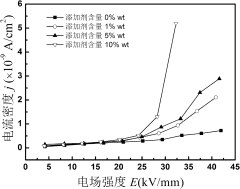

- A composite material of polytetrafluoroethylene PTFE matrix and micro-nano zinc oxide ZnO is prepared through steps such as ultrasonic vibration dispersion, surface treatment, repeated dispersion and grinding, cold treatment and high-temperature molding to form a functional composite material with nonlinear conductivity characteristics.

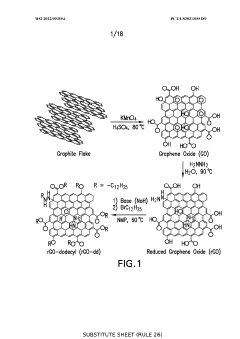

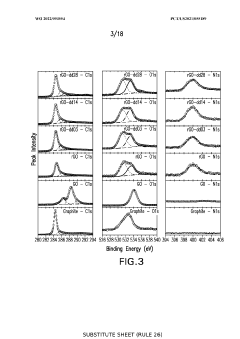

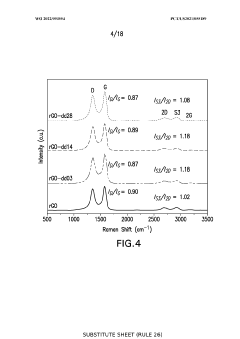

Chemically functionalized graphene oxide nanoparticle composites, coatings and methods of use thereof

PatentWO2022093554A9

Innovation

- Development of chemically functionalized graphene oxide nanoparticle composites and coatings, where graphene oxide nanoparticles are alkylated and dispersed in a polymer matrix to enhance mechanical and electrical properties, and synthesized using methods like reacting graphite flakes with potassium permanganate and sulfuric acid, followed by hydrazine reduction and further functionalization in N-methyl-2-pyrrolidone with an alkyl halide.

Space Regulations

Space exploration activities are subject to a complex web of international and national regulations that govern the use of PTFE and other materials in space applications. The Outer Space Treaty of 1967 serves as the foundational framework for space law, emphasizing the peaceful use of outer space and the responsibility of nations for their space activities. This treaty, along with subsequent agreements, has implications for the use of PTFE in space, particularly regarding environmental protection and debris mitigation.

The United Nations Office for Outer Space Affairs (UNOOSA) plays a crucial role in promoting international cooperation and establishing guidelines for space activities. These guidelines often influence the selection and use of materials like PTFE in space missions. For instance, the Space Debris Mitigation Guidelines encourage the use of materials that minimize the generation of space debris, a consideration that impacts the application of PTFE in spacecraft design.

National space agencies, such as NASA and ESA, have developed their own regulations and standards for materials used in space missions. These often include rigorous testing procedures to ensure materials like PTFE can withstand the harsh space environment without degrading or releasing harmful substances. The NASA Technical Standard 6016, for example, provides detailed requirements for materials and processes used in spacecraft development.

Regulatory bodies also address the potential environmental impacts of space activities. The Committee on the Peaceful Uses of Outer Space (COPUOS) has discussed the need for sustainable space practices, which may influence future regulations on materials used in space, including PTFE. The growing concern over space debris has led to discussions about end-of-life disposal of satellites and other space objects, potentially affecting how PTFE-containing components are designed and used.

International standardization organizations, such as the International Organization for Standardization (ISO), have developed standards specific to space applications. ISO 24113, which focuses on space debris mitigation requirements, indirectly affects the use of PTFE by setting guidelines for spacecraft design and operation. Compliance with these standards is often mandatory for space agencies and commercial entities engaged in space activities.

As commercial space activities expand, regulatory frameworks are evolving to address new challenges. The U.S. Federal Aviation Administration (FAA) and other national bodies are developing regulations for commercial space operations, which may include specific provisions for materials used in spacecraft and launch vehicles. These regulations aim to ensure safety and environmental protection while fostering innovation in space technology.

The United Nations Office for Outer Space Affairs (UNOOSA) plays a crucial role in promoting international cooperation and establishing guidelines for space activities. These guidelines often influence the selection and use of materials like PTFE in space missions. For instance, the Space Debris Mitigation Guidelines encourage the use of materials that minimize the generation of space debris, a consideration that impacts the application of PTFE in spacecraft design.

National space agencies, such as NASA and ESA, have developed their own regulations and standards for materials used in space missions. These often include rigorous testing procedures to ensure materials like PTFE can withstand the harsh space environment without degrading or releasing harmful substances. The NASA Technical Standard 6016, for example, provides detailed requirements for materials and processes used in spacecraft development.

Regulatory bodies also address the potential environmental impacts of space activities. The Committee on the Peaceful Uses of Outer Space (COPUOS) has discussed the need for sustainable space practices, which may influence future regulations on materials used in space, including PTFE. The growing concern over space debris has led to discussions about end-of-life disposal of satellites and other space objects, potentially affecting how PTFE-containing components are designed and used.

International standardization organizations, such as the International Organization for Standardization (ISO), have developed standards specific to space applications. ISO 24113, which focuses on space debris mitigation requirements, indirectly affects the use of PTFE by setting guidelines for spacecraft design and operation. Compliance with these standards is often mandatory for space agencies and commercial entities engaged in space activities.

As commercial space activities expand, regulatory frameworks are evolving to address new challenges. The U.S. Federal Aviation Administration (FAA) and other national bodies are developing regulations for commercial space operations, which may include specific provisions for materials used in spacecraft and launch vehicles. These regulations aim to ensure safety and environmental protection while fostering innovation in space technology.

Environmental Impact

The use of PTFE (Polytetrafluoroethylene) in space exploration presents both opportunities and challenges in terms of environmental impact. While PTFE offers numerous advantages for space applications, its production and disposal raise concerns about potential environmental consequences.

PTFE's exceptional chemical resistance and stability make it an ideal material for space exploration, as it can withstand the harsh conditions of outer space without degrading. This durability contributes to the longevity of space equipment, reducing the need for frequent replacements and minimizing space debris. Additionally, PTFE's low friction properties help improve the efficiency of mechanical systems in spacecraft, potentially reducing fuel consumption and emissions during launch and operation.

However, the production of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that can accumulate in the environment and living organisms. Although efforts have been made to phase out PFOA in PTFE manufacturing, concerns remain about the environmental impact of alternative production methods and the long-term effects of PTFE particles in the environment.

In space applications, PTFE may undergo degradation due to exposure to atomic oxygen, UV radiation, and other space environment factors. This degradation can lead to the release of fluoropolymer particles, which may contribute to space debris and potentially impact the Earth's atmosphere upon re-entry. The long-term effects of these particles on the upper atmosphere and ozone layer are not yet fully understood and require further research.

The disposal of PTFE-containing space equipment at the end of its lifecycle also poses environmental challenges. While PTFE is not biodegradable, it can be recycled through specialized processes. However, the complex nature of space equipment and the potential contamination with other materials make recycling a challenging and energy-intensive process.

To address these environmental concerns, researchers and space agencies are exploring more sustainable alternatives to PTFE and developing improved recycling techniques for space materials. Additionally, efforts are being made to optimize the use of PTFE in space applications, minimizing waste and maximizing the material's benefits while reducing its potential environmental impact.

As space exploration continues to advance, balancing the unique properties of PTFE with environmental considerations will be crucial. Future developments in materials science and sustainable manufacturing processes may lead to more environmentally friendly alternatives that can match or exceed PTFE's performance in space applications, ensuring the continued progress of space exploration while minimizing its ecological footprint.

PTFE's exceptional chemical resistance and stability make it an ideal material for space exploration, as it can withstand the harsh conditions of outer space without degrading. This durability contributes to the longevity of space equipment, reducing the need for frequent replacements and minimizing space debris. Additionally, PTFE's low friction properties help improve the efficiency of mechanical systems in spacecraft, potentially reducing fuel consumption and emissions during launch and operation.

However, the production of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that can accumulate in the environment and living organisms. Although efforts have been made to phase out PFOA in PTFE manufacturing, concerns remain about the environmental impact of alternative production methods and the long-term effects of PTFE particles in the environment.

In space applications, PTFE may undergo degradation due to exposure to atomic oxygen, UV radiation, and other space environment factors. This degradation can lead to the release of fluoropolymer particles, which may contribute to space debris and potentially impact the Earth's atmosphere upon re-entry. The long-term effects of these particles on the upper atmosphere and ozone layer are not yet fully understood and require further research.

The disposal of PTFE-containing space equipment at the end of its lifecycle also poses environmental challenges. While PTFE is not biodegradable, it can be recycled through specialized processes. However, the complex nature of space equipment and the potential contamination with other materials make recycling a challenging and energy-intensive process.

To address these environmental concerns, researchers and space agencies are exploring more sustainable alternatives to PTFE and developing improved recycling techniques for space materials. Additionally, efforts are being made to optimize the use of PTFE in space applications, minimizing waste and maximizing the material's benefits while reducing its potential environmental impact.

As space exploration continues to advance, balancing the unique properties of PTFE with environmental considerations will be crucial. Future developments in materials science and sustainable manufacturing processes may lead to more environmentally friendly alternatives that can match or exceed PTFE's performance in space applications, ensuring the continued progress of space exploration while minimizing its ecological footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!