PTFE: Pioneering Improvements in Water Purification

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE in Water Purification: Background and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has emerged as a groundbreaking material in water purification technologies. Since its accidental discovery by Roy Plunkett in 1938, PTFE has revolutionized various industries, with its application in water treatment gaining significant traction in recent decades.

The evolution of PTFE in water purification can be traced back to the 1960s when researchers began exploring its potential in membrane filtration. The material's unique properties, including its hydrophobicity, chemical inertness, and thermal stability, made it an ideal candidate for developing advanced filtration systems. As global water scarcity and contamination issues intensified, the demand for more efficient and cost-effective purification methods grew, propelling PTFE-based technologies to the forefront of water treatment solutions.

In the context of water purification, PTFE has primarily been utilized in the fabrication of membranes for various filtration processes, including microfiltration, ultrafiltration, and reverse osmosis. These membranes have demonstrated exceptional performance in removing contaminants such as suspended solids, bacteria, viruses, and dissolved salts from water sources. The non-stick nature of PTFE also contributes to reduced fouling and easier cleaning of filtration systems, enhancing their longevity and operational efficiency.

The technological trajectory of PTFE in water purification has been marked by continuous improvements in membrane design, pore size control, and surface modification techniques. Recent advancements have focused on enhancing the material's selectivity, permeability, and antifouling properties, addressing key challenges in membrane-based water treatment. Researchers are also exploring novel PTFE composites and hybrid materials to further improve filtration performance and expand the range of treatable contaminants.

The primary objectives of ongoing PTFE research in water purification are multifaceted. These include developing membranes with higher flux rates and improved selectivity, reducing energy consumption in filtration processes, and extending membrane lifespan. Additionally, there is a growing emphasis on creating more sustainable and environmentally friendly PTFE-based solutions, addressing concerns about the material's persistence in the environment.

As water quality standards become increasingly stringent worldwide, the role of PTFE in water purification is expected to expand. Future developments aim to leverage the material's unique properties to tackle emerging contaminants, such as microplastics and pharmaceutical residues, while also focusing on scalable and cost-effective solutions for both industrial and municipal water treatment applications.

The evolution of PTFE in water purification can be traced back to the 1960s when researchers began exploring its potential in membrane filtration. The material's unique properties, including its hydrophobicity, chemical inertness, and thermal stability, made it an ideal candidate for developing advanced filtration systems. As global water scarcity and contamination issues intensified, the demand for more efficient and cost-effective purification methods grew, propelling PTFE-based technologies to the forefront of water treatment solutions.

In the context of water purification, PTFE has primarily been utilized in the fabrication of membranes for various filtration processes, including microfiltration, ultrafiltration, and reverse osmosis. These membranes have demonstrated exceptional performance in removing contaminants such as suspended solids, bacteria, viruses, and dissolved salts from water sources. The non-stick nature of PTFE also contributes to reduced fouling and easier cleaning of filtration systems, enhancing their longevity and operational efficiency.

The technological trajectory of PTFE in water purification has been marked by continuous improvements in membrane design, pore size control, and surface modification techniques. Recent advancements have focused on enhancing the material's selectivity, permeability, and antifouling properties, addressing key challenges in membrane-based water treatment. Researchers are also exploring novel PTFE composites and hybrid materials to further improve filtration performance and expand the range of treatable contaminants.

The primary objectives of ongoing PTFE research in water purification are multifaceted. These include developing membranes with higher flux rates and improved selectivity, reducing energy consumption in filtration processes, and extending membrane lifespan. Additionally, there is a growing emphasis on creating more sustainable and environmentally friendly PTFE-based solutions, addressing concerns about the material's persistence in the environment.

As water quality standards become increasingly stringent worldwide, the role of PTFE in water purification is expected to expand. Future developments aim to leverage the material's unique properties to tackle emerging contaminants, such as microplastics and pharmaceutical residues, while also focusing on scalable and cost-effective solutions for both industrial and municipal water treatment applications.

Market Analysis for PTFE-based Water Purification Solutions

The global market for PTFE-based water purification solutions has experienced significant growth in recent years, driven by increasing concerns over water quality and the need for efficient purification technologies. The market is characterized by a diverse range of applications, including municipal water treatment, industrial wastewater management, and residential water filtration systems.

PTFE's unique properties, such as chemical inertness, high temperature resistance, and low friction, make it an ideal material for water purification applications. The market for PTFE membranes in water treatment is particularly robust, with a compound annual growth rate (CAGR) projected to exceed 7% over the next five years. This growth is primarily attributed to the rising demand for clean water in both developed and developing countries.

The industrial sector represents a substantial portion of the PTFE-based water purification market, with applications in chemical processing, pharmaceuticals, and food and beverage industries. These industries require high-performance filtration systems to meet stringent regulatory standards and ensure product quality. The municipal water treatment segment is also a significant contributor to market growth, as governments worldwide invest in upgrading water infrastructure to address water scarcity and quality issues.

Geographically, North America and Europe currently dominate the PTFE-based water purification market, owing to stringent environmental regulations and high adoption rates of advanced water treatment technologies. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, urbanization, and increasing awareness of water quality issues in countries like China and India.

The residential water filtration segment is emerging as a promising market for PTFE-based solutions, particularly in regions with unreliable municipal water supplies. Point-of-use and point-of-entry filtration systems incorporating PTFE membranes are gaining popularity among consumers seeking to improve their drinking water quality.

Key market trends include the development of nanostructured PTFE membranes with enhanced filtration efficiency and fouling resistance. These advanced materials are expected to expand the application scope of PTFE in water purification, particularly in challenging environments such as desalination and wastewater reuse.

The competitive landscape of the PTFE-based water purification market is characterized by the presence of both large multinational corporations and specialized membrane manufacturers. Major players are investing heavily in research and development to improve membrane performance and reduce production costs, aiming to gain a competitive edge in this growing market.

PTFE's unique properties, such as chemical inertness, high temperature resistance, and low friction, make it an ideal material for water purification applications. The market for PTFE membranes in water treatment is particularly robust, with a compound annual growth rate (CAGR) projected to exceed 7% over the next five years. This growth is primarily attributed to the rising demand for clean water in both developed and developing countries.

The industrial sector represents a substantial portion of the PTFE-based water purification market, with applications in chemical processing, pharmaceuticals, and food and beverage industries. These industries require high-performance filtration systems to meet stringent regulatory standards and ensure product quality. The municipal water treatment segment is also a significant contributor to market growth, as governments worldwide invest in upgrading water infrastructure to address water scarcity and quality issues.

Geographically, North America and Europe currently dominate the PTFE-based water purification market, owing to stringent environmental regulations and high adoption rates of advanced water treatment technologies. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, urbanization, and increasing awareness of water quality issues in countries like China and India.

The residential water filtration segment is emerging as a promising market for PTFE-based solutions, particularly in regions with unreliable municipal water supplies. Point-of-use and point-of-entry filtration systems incorporating PTFE membranes are gaining popularity among consumers seeking to improve their drinking water quality.

Key market trends include the development of nanostructured PTFE membranes with enhanced filtration efficiency and fouling resistance. These advanced materials are expected to expand the application scope of PTFE in water purification, particularly in challenging environments such as desalination and wastewater reuse.

The competitive landscape of the PTFE-based water purification market is characterized by the presence of both large multinational corporations and specialized membrane manufacturers. Major players are investing heavily in research and development to improve membrane performance and reduce production costs, aiming to gain a competitive edge in this growing market.

Current PTFE Technology and Challenges in Water Treatment

Polytetrafluoroethylene (PTFE) has emerged as a crucial material in water purification technologies, offering unique properties that enhance filtration efficiency and durability. The current state of PTFE technology in water treatment showcases significant advancements, yet also presents notable challenges that require innovative solutions.

PTFE membranes are widely utilized in various water treatment processes, including reverse osmosis, ultrafiltration, and nanofiltration. These membranes exhibit exceptional chemical resistance, low surface energy, and high thermal stability, making them ideal for separating contaminants from water. The hydrophobic nature of PTFE allows for effective removal of oils, organic compounds, and suspended solids, while its non-stick properties minimize fouling and extend membrane lifespan.

Recent developments in PTFE technology have focused on enhancing membrane performance through surface modifications and composite structures. Researchers have explored techniques such as plasma treatment, grafting, and nanoparticle incorporation to improve hydrophilicity, antifouling properties, and selectivity. These advancements have led to increased water flux and improved rejection rates for specific contaminants.

Despite these achievements, several challenges persist in the application of PTFE in water treatment. One primary concern is the inherent hydrophobicity of PTFE, which can limit water permeability and lead to decreased flux rates. This characteristic necessitates the development of strategies to balance hydrophobicity with water permeability without compromising the material's other beneficial properties.

Another significant challenge lies in the fabrication of PTFE membranes with precise pore sizes and distributions. Controlling these parameters is crucial for achieving optimal filtration performance across different water treatment applications. Current manufacturing processes often struggle to produce consistent, high-quality PTFE membranes at scale, impacting both cost-effectiveness and widespread adoption.

The long-term stability of modified PTFE membranes in harsh operating conditions remains a concern. While surface modifications can enhance performance, their durability under prolonged exposure to various water chemistries, temperatures, and pressures requires further investigation and improvement.

Environmental considerations also pose challenges for PTFE technology in water treatment. The production and disposal of PTFE materials raise sustainability concerns, prompting research into more eco-friendly alternatives or recycling methods. Additionally, the potential release of microplastics from PTFE membranes during operation is an emerging area of study that demands attention.

As the demand for clean water continues to grow globally, addressing these challenges becomes increasingly critical. Future research directions in PTFE technology for water purification are likely to focus on developing novel composite materials, optimizing membrane structures at the nanoscale, and exploring bio-inspired designs to overcome current limitations.

PTFE membranes are widely utilized in various water treatment processes, including reverse osmosis, ultrafiltration, and nanofiltration. These membranes exhibit exceptional chemical resistance, low surface energy, and high thermal stability, making them ideal for separating contaminants from water. The hydrophobic nature of PTFE allows for effective removal of oils, organic compounds, and suspended solids, while its non-stick properties minimize fouling and extend membrane lifespan.

Recent developments in PTFE technology have focused on enhancing membrane performance through surface modifications and composite structures. Researchers have explored techniques such as plasma treatment, grafting, and nanoparticle incorporation to improve hydrophilicity, antifouling properties, and selectivity. These advancements have led to increased water flux and improved rejection rates for specific contaminants.

Despite these achievements, several challenges persist in the application of PTFE in water treatment. One primary concern is the inherent hydrophobicity of PTFE, which can limit water permeability and lead to decreased flux rates. This characteristic necessitates the development of strategies to balance hydrophobicity with water permeability without compromising the material's other beneficial properties.

Another significant challenge lies in the fabrication of PTFE membranes with precise pore sizes and distributions. Controlling these parameters is crucial for achieving optimal filtration performance across different water treatment applications. Current manufacturing processes often struggle to produce consistent, high-quality PTFE membranes at scale, impacting both cost-effectiveness and widespread adoption.

The long-term stability of modified PTFE membranes in harsh operating conditions remains a concern. While surface modifications can enhance performance, their durability under prolonged exposure to various water chemistries, temperatures, and pressures requires further investigation and improvement.

Environmental considerations also pose challenges for PTFE technology in water treatment. The production and disposal of PTFE materials raise sustainability concerns, prompting research into more eco-friendly alternatives or recycling methods. Additionally, the potential release of microplastics from PTFE membranes during operation is an emerging area of study that demands attention.

As the demand for clean water continues to grow globally, addressing these challenges becomes increasingly critical. Future research directions in PTFE technology for water purification are likely to focus on developing novel composite materials, optimizing membrane structures at the nanoscale, and exploring bio-inspired designs to overcome current limitations.

Existing PTFE-based Water Purification Methods

01 PTFE membrane filtration systems

PTFE membranes are used in water purification systems due to their excellent chemical resistance and non-stick properties. These membranes can effectively remove contaminants, including microorganisms and particles, from water. The hydrophobic nature of PTFE allows for efficient separation of water from other substances.- PTFE membrane filtration systems: PTFE membranes are used in water purification systems due to their excellent chemical resistance and non-stick properties. These membranes can effectively remove contaminants, including microorganisms and particulate matter, from water. The hydrophobic nature of PTFE allows for efficient separation of water from other substances, making it ideal for various filtration applications.

- PTFE-coated filter materials: Water purification systems utilize filter materials coated with PTFE to enhance their performance. The PTFE coating improves the filter's ability to repel water while allowing air to pass through, which is beneficial in certain filtration processes. This technology is applied to various filter media, including fabrics and porous substrates, to create more effective and durable water purification components.

- PTFE nanofiber-based filtration: Nanofibers made from PTFE are employed in advanced water purification systems. These nanofibers offer a high surface area-to-volume ratio, allowing for efficient filtration of contaminants at the nanoscale. The use of PTFE nanofibers in filtration membranes can significantly improve water purification efficiency and throughput compared to conventional filtration methods.

- PTFE-based composite membranes: Composite membranes incorporating PTFE are developed for enhanced water purification. These membranes combine the beneficial properties of PTFE with other materials to create synergistic effects. For example, PTFE may be combined with hydrophilic polymers or inorganic particles to improve water flux while maintaining excellent contaminant rejection capabilities.

- PTFE in water treatment equipment: PTFE is utilized in various components of water treatment equipment due to its chemical inertness and low friction properties. This includes the use of PTFE in seals, gaskets, and linings for pipes and tanks in water purification systems. The material's resistance to corrosion and fouling helps to maintain the efficiency and longevity of water treatment equipment.

02 PTFE-coated filtration materials

Various filtration materials, such as fibers, fabrics, and porous substrates, are coated with PTFE to enhance their water purification capabilities. The PTFE coating improves the material's hydrophobicity, durability, and resistance to fouling, making it more effective in removing contaminants from water.Expand Specific Solutions03 PTFE-based composite membranes

Composite membranes incorporating PTFE and other materials are developed for improved water purification performance. These composites combine the beneficial properties of PTFE with other materials to enhance filtration efficiency, mechanical strength, and overall membrane performance in water treatment applications.Expand Specific Solutions04 PTFE membrane modification techniques

Various modification techniques are applied to PTFE membranes to enhance their water purification properties. These include surface treatments, chemical modifications, and the incorporation of functional groups to improve hydrophilicity, anti-fouling properties, and contaminant removal efficiency.Expand Specific Solutions05 PTFE-based water purification devices

Specialized water purification devices and systems are designed incorporating PTFE components. These devices utilize the unique properties of PTFE to effectively remove contaminants from water in various applications, including household water purifiers, industrial water treatment systems, and portable water filtration units.Expand Specific Solutions

Key Players in PTFE and Water Purification Industries

The water purification industry utilizing PTFE technology is in a mature growth phase, with a global market size expected to reach several billion dollars by 2025. The technology's maturity is evident from the involvement of major players across diverse sectors. Companies like DuPont de Nemours and W. L. Gore & Associates are at the forefront, leveraging their expertise in advanced materials. AGC, Inc. and Nitto Denko Corp. bring significant contributions from the Asian market, while specialized firms like Solvay Specialty Polymers Italy SpA focus on niche applications. Academic institutions such as Nanjing University and Tianjin University are driving research and innovation in this field, indicating ongoing efforts to improve and expand PTFE applications in water purification.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered the development of advanced PTFE membranes for water purification. Their innovative approach involves creating nanofibrous PTFE membranes with enhanced porosity and controlled pore size distribution. This technology allows for higher water flux while maintaining excellent contaminant rejection rates. DuPont's PTFE membranes are engineered to resist fouling and offer extended operational lifetimes in various water treatment applications. The company has also developed surface modification techniques to improve the hydrophilicity of PTFE membranes, addressing one of the material's inherent limitations[1][3]. These advancements have resulted in membranes that can effectively remove a wide range of pollutants, including microplastics, heavy metals, and organic compounds, while maintaining high water permeability.

Strengths: Superior chemical resistance, excellent filtration efficiency, and long-lasting performance. Weaknesses: Higher initial cost compared to some alternative materials, potential for membrane fouling in certain applications.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has made significant strides in PTFE membrane technology for water purification. Their approach focuses on creating expanded PTFE (ePTFE) membranes with a unique microstructure that enhances filtration performance. Gore's ePTFE membranes feature a network of interconnected pores that provide high water permeability while effectively capturing contaminants. The company has developed proprietary surface treatments to improve the membrane's hydrophilicity and reduce fouling potential. Gore's PTFE membranes are designed to withstand harsh chemical environments and high temperatures, making them suitable for industrial water treatment applications. Recent advancements include the integration of antimicrobial properties into the membrane structure, enhancing biofouling resistance and extending operational lifetimes[2][4].

Strengths: Exceptional durability, high chemical resistance, and versatility across various water treatment applications. Weaknesses: Relatively high production costs, potential for reduced efficiency in the presence of certain organic contaminants.

Innovative PTFE Technologies for Water Treatment

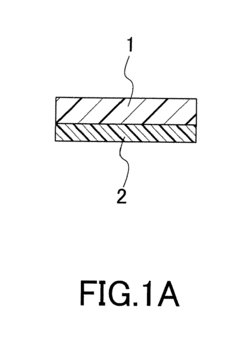

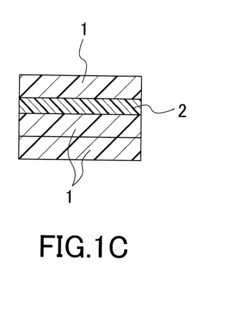

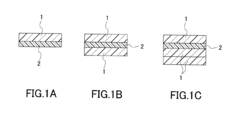

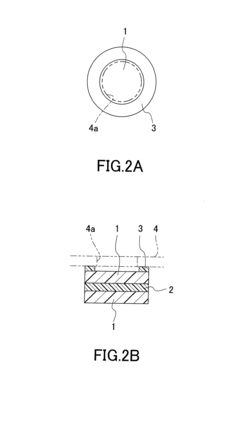

Porous polytetrafluoroethylene film, method for production thereof, and water-proof breathable filter

PatentActiveEP2223801A1

Innovation

- A method involving the lamination of two PTFE porous bodies, one stretched uniaxially and the other biaxially, with the integration of these layers at a temperature above the melting point of PTFE to achieve a porous PTFE membrane with enhanced thickness, air permeability, and water pressure resistance.

Aqueous polytetrafluoroethylene dispersion composition and process for its production

PatentInactiveUS7141620B2

Innovation

- Adding a specific nonionic surfactant and water to the PTFE polymer emulsion, followed by sedimentation and separation of the PTFE-rich phase, effectively transfers APFC to the aqueous phase, allowing for its concentration and recovery.

Environmental Impact of PTFE in Water Treatment

The environmental impact of PTFE in water treatment is a complex and multifaceted issue that requires careful consideration. PTFE, or polytetrafluoroethylene, has been widely used in water purification systems due to its exceptional chemical resistance and non-stick properties. However, its environmental implications have raised concerns among researchers and environmentalists.

One of the primary environmental concerns associated with PTFE in water treatment is its persistence in the environment. PTFE is a highly stable compound that does not readily degrade under natural conditions. This persistence can lead to long-term accumulation in ecosystems, potentially affecting wildlife and aquatic organisms. Studies have shown that PTFE particles can be found in various environmental matrices, including water bodies, sediments, and even in the tissues of marine animals.

The production process of PTFE also contributes to its environmental impact. The manufacturing of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that has been linked to various health and environmental issues. Although efforts have been made to phase out PFOA in PTFE production, concerns remain about the potential release of other fluorinated compounds during the manufacturing process.

In water treatment applications, the use of PTFE membranes and coatings can lead to the release of microplastics into the environment. As these membranes degrade over time, they may shed small particles that can enter water systems and potentially impact aquatic ecosystems. The long-term effects of these microplastics on marine life and human health are still being studied, but initial research suggests potential risks.

Despite these concerns, PTFE continues to play a crucial role in water purification technologies due to its unique properties. Its use in membrane filtration systems has significantly improved the efficiency and effectiveness of water treatment processes. PTFE-based membranes have demonstrated superior performance in removing contaminants, including bacteria, viruses, and various chemical pollutants.

To address the environmental challenges associated with PTFE in water treatment, researchers and industry professionals are exploring alternative materials and improved manufacturing processes. Efforts are being made to develop more environmentally friendly fluoropolymers that maintain the beneficial properties of PTFE while reducing its environmental footprint. Additionally, advancements in membrane technology are focusing on enhancing the durability and longevity of PTFE-based components to minimize particle shedding and extend their useful life.

The environmental impact of PTFE in water treatment remains an active area of research and debate. While its benefits in water purification are undeniable, the potential long-term consequences of its widespread use necessitate ongoing assessment and mitigation strategies. Balancing the need for effective water treatment technologies with environmental sustainability will be crucial in shaping the future of PTFE applications in this field.

One of the primary environmental concerns associated with PTFE in water treatment is its persistence in the environment. PTFE is a highly stable compound that does not readily degrade under natural conditions. This persistence can lead to long-term accumulation in ecosystems, potentially affecting wildlife and aquatic organisms. Studies have shown that PTFE particles can be found in various environmental matrices, including water bodies, sediments, and even in the tissues of marine animals.

The production process of PTFE also contributes to its environmental impact. The manufacturing of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that has been linked to various health and environmental issues. Although efforts have been made to phase out PFOA in PTFE production, concerns remain about the potential release of other fluorinated compounds during the manufacturing process.

In water treatment applications, the use of PTFE membranes and coatings can lead to the release of microplastics into the environment. As these membranes degrade over time, they may shed small particles that can enter water systems and potentially impact aquatic ecosystems. The long-term effects of these microplastics on marine life and human health are still being studied, but initial research suggests potential risks.

Despite these concerns, PTFE continues to play a crucial role in water purification technologies due to its unique properties. Its use in membrane filtration systems has significantly improved the efficiency and effectiveness of water treatment processes. PTFE-based membranes have demonstrated superior performance in removing contaminants, including bacteria, viruses, and various chemical pollutants.

To address the environmental challenges associated with PTFE in water treatment, researchers and industry professionals are exploring alternative materials and improved manufacturing processes. Efforts are being made to develop more environmentally friendly fluoropolymers that maintain the beneficial properties of PTFE while reducing its environmental footprint. Additionally, advancements in membrane technology are focusing on enhancing the durability and longevity of PTFE-based components to minimize particle shedding and extend their useful life.

The environmental impact of PTFE in water treatment remains an active area of research and debate. While its benefits in water purification are undeniable, the potential long-term consequences of its widespread use necessitate ongoing assessment and mitigation strategies. Balancing the need for effective water treatment technologies with environmental sustainability will be crucial in shaping the future of PTFE applications in this field.

Regulatory Framework for PTFE in Water Purification Systems

The regulatory framework for PTFE in water purification systems is a complex and evolving landscape that plays a crucial role in ensuring the safety and efficacy of these technologies. At the forefront of this framework is the United States Environmental Protection Agency (EPA), which has established stringent guidelines for the use of PTFE in drinking water applications. The EPA's National Primary Drinking Water Regulations set maximum contaminant levels for various substances, including those that might be associated with PTFE manufacturing or usage.

In the European Union, the regulatory approach is guided by the European Chemicals Agency (ECHA) and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. These bodies oversee the safety assessment of PTFE and its related compounds, ensuring that any potential risks to human health or the environment are thoroughly evaluated and mitigated.

The World Health Organization (WHO) also provides global guidelines for drinking water quality, which many countries use as a basis for their national standards. While WHO does not specifically regulate PTFE, its guidelines influence the overall regulatory landscape for water purification technologies.

In recent years, there has been increased scrutiny of per- and polyfluoroalkyl substances (PFAS), a group of chemicals that includes some compounds used in PTFE production. This has led to more stringent regulations in many jurisdictions, with some countries implementing bans or restrictions on certain PFAS compounds. As a result, manufacturers of PTFE-based water purification systems must navigate an increasingly complex regulatory environment to ensure compliance.

The Food and Drug Administration (FDA) in the United States also plays a role in regulating PTFE in water purification systems, particularly when these systems are used in food processing or pharmaceutical applications. The FDA's regulations focus on ensuring that materials used in contact with food or drugs do not introduce harmful substances into the final product.

Internationally, various countries have their own regulatory bodies and standards for water purification technologies. For example, Japan's Ministry of Health, Labour and Welfare sets standards for water quality and treatment technologies, while China's Ministry of Ecology and Environment oversees environmental protection regulations that impact water purification systems.

As the understanding of PTFE's environmental and health impacts continues to evolve, regulatory frameworks are likely to adapt. This dynamic regulatory landscape necessitates ongoing vigilance and adaptability from manufacturers and researchers working with PTFE in water purification applications. Future regulations may focus on lifecycle assessments, sustainable production methods, and improved end-of-life management for PTFE-based products in water treatment systems.

In the European Union, the regulatory approach is guided by the European Chemicals Agency (ECHA) and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. These bodies oversee the safety assessment of PTFE and its related compounds, ensuring that any potential risks to human health or the environment are thoroughly evaluated and mitigated.

The World Health Organization (WHO) also provides global guidelines for drinking water quality, which many countries use as a basis for their national standards. While WHO does not specifically regulate PTFE, its guidelines influence the overall regulatory landscape for water purification technologies.

In recent years, there has been increased scrutiny of per- and polyfluoroalkyl substances (PFAS), a group of chemicals that includes some compounds used in PTFE production. This has led to more stringent regulations in many jurisdictions, with some countries implementing bans or restrictions on certain PFAS compounds. As a result, manufacturers of PTFE-based water purification systems must navigate an increasingly complex regulatory environment to ensure compliance.

The Food and Drug Administration (FDA) in the United States also plays a role in regulating PTFE in water purification systems, particularly when these systems are used in food processing or pharmaceutical applications. The FDA's regulations focus on ensuring that materials used in contact with food or drugs do not introduce harmful substances into the final product.

Internationally, various countries have their own regulatory bodies and standards for water purification technologies. For example, Japan's Ministry of Health, Labour and Welfare sets standards for water quality and treatment technologies, while China's Ministry of Ecology and Environment oversees environmental protection regulations that impact water purification systems.

As the understanding of PTFE's environmental and health impacts continues to evolve, regulatory frameworks are likely to adapt. This dynamic regulatory landscape necessitates ongoing vigilance and adaptability from manufacturers and researchers working with PTFE in water purification applications. Future regulations may focus on lifecycle assessments, sustainable production methods, and improved end-of-life management for PTFE-based products in water treatment systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!