How to Maximize Safety with PTFE Coatings?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Coating Safety Background and Objectives

Polytetrafluoroethylene (PTFE) coatings have been widely used in various industries for decades due to their exceptional properties, including chemical resistance, low friction, and non-stick characteristics. The evolution of PTFE coating technology has been driven by the increasing demand for safer and more efficient industrial processes, particularly in sectors such as food processing, pharmaceuticals, and automotive manufacturing.

The primary objective of maximizing safety with PTFE coatings is to enhance the protection of both workers and end-users while maintaining the coating's functional properties. This goal encompasses several key aspects, including the reduction of potential health risks associated with PTFE exposure, improvement of coating durability to prevent degradation and particle release, and optimization of application methods to minimize environmental impact.

Throughout the development of PTFE coatings, safety concerns have been a significant focus. Early applications of PTFE faced challenges related to the release of harmful substances during high-temperature use. This led to extensive research and development efforts aimed at improving the stability and safety profile of PTFE coatings across a wide range of operating conditions.

Recent technological advancements have focused on enhancing the bonding strength between PTFE coatings and substrate materials, thereby reducing the risk of coating delamination and subsequent contamination. Additionally, innovations in PTFE formulations have aimed to lower the processing temperatures required for coating application, thus minimizing the potential for thermal degradation and the release of hazardous byproducts.

The current trend in PTFE coating safety is moving towards the development of more environmentally friendly and sustainable solutions. This includes the exploration of water-based PTFE coating systems that reduce the use of volatile organic compounds (VOCs) and the investigation of bio-based alternatives that maintain the desirable properties of traditional PTFE coatings while offering improved safety profiles.

As the industry continues to evolve, the objectives for maximizing safety with PTFE coatings are expanding to include not only the immediate safety concerns but also long-term environmental and health considerations. This holistic approach to safety encompasses the entire lifecycle of PTFE coatings, from raw material sourcing and manufacturing processes to application techniques and end-of-life disposal or recycling options.

The primary objective of maximizing safety with PTFE coatings is to enhance the protection of both workers and end-users while maintaining the coating's functional properties. This goal encompasses several key aspects, including the reduction of potential health risks associated with PTFE exposure, improvement of coating durability to prevent degradation and particle release, and optimization of application methods to minimize environmental impact.

Throughout the development of PTFE coatings, safety concerns have been a significant focus. Early applications of PTFE faced challenges related to the release of harmful substances during high-temperature use. This led to extensive research and development efforts aimed at improving the stability and safety profile of PTFE coatings across a wide range of operating conditions.

Recent technological advancements have focused on enhancing the bonding strength between PTFE coatings and substrate materials, thereby reducing the risk of coating delamination and subsequent contamination. Additionally, innovations in PTFE formulations have aimed to lower the processing temperatures required for coating application, thus minimizing the potential for thermal degradation and the release of hazardous byproducts.

The current trend in PTFE coating safety is moving towards the development of more environmentally friendly and sustainable solutions. This includes the exploration of water-based PTFE coating systems that reduce the use of volatile organic compounds (VOCs) and the investigation of bio-based alternatives that maintain the desirable properties of traditional PTFE coatings while offering improved safety profiles.

As the industry continues to evolve, the objectives for maximizing safety with PTFE coatings are expanding to include not only the immediate safety concerns but also long-term environmental and health considerations. This holistic approach to safety encompasses the entire lifecycle of PTFE coatings, from raw material sourcing and manufacturing processes to application techniques and end-of-life disposal or recycling options.

Market Demand for Safe PTFE Coatings

The market demand for safe PTFE coatings has been steadily increasing across various industries due to growing awareness of safety concerns and stringent regulatory requirements. PTFE (Polytetrafluoroethylene) coatings are widely recognized for their non-stick, low friction, and chemical resistance properties, making them essential in numerous applications where safety is paramount.

In the food processing industry, there is a significant demand for safe PTFE coatings on cookware, bakeware, and food processing equipment. Consumers and manufacturers alike are increasingly concerned about the potential health risks associated with traditional non-stick coatings. As a result, the market for PTFE-coated kitchenware that ensures food safety and prevents chemical leaching has expanded considerably.

The automotive sector has also witnessed a surge in demand for safe PTFE coatings. These coatings are used in various automotive components, including gaskets, seals, and fuel system parts, to enhance durability and reduce friction. With the automotive industry's focus on improving vehicle safety and performance, the adoption of PTFE coatings that can withstand extreme temperatures and harsh chemicals has become more prevalent.

In the medical and pharmaceutical industries, the need for safe PTFE coatings has reached new heights. Medical devices, surgical instruments, and drug delivery systems often require coatings that are biocompatible, resistant to sterilization processes, and capable of reducing the risk of infections. The growing emphasis on patient safety has driven the demand for PTFE coatings that meet these stringent requirements.

The aerospace industry has also contributed to the increasing market demand for safe PTFE coatings. Aircraft components, such as hydraulic systems, fuel lines, and electrical wiring, benefit from PTFE coatings that provide excellent insulation, chemical resistance, and reduced friction. As safety remains a top priority in aviation, the demand for high-performance PTFE coatings continues to grow.

Furthermore, the construction and building materials sector has shown a rising interest in safe PTFE coatings. These coatings are used in architectural fabrics, roofing materials, and weather-resistant surfaces to enhance durability and safety. The demand for PTFE-coated materials that can withstand harsh environmental conditions while maintaining their protective properties has increased significantly.

As environmental concerns gain prominence, there is a growing market demand for eco-friendly and sustainable PTFE coating solutions. Manufacturers are investing in research and development to create safer formulations that minimize environmental impact without compromising performance. This trend is driven by both consumer preferences and regulatory pressures to adopt more sustainable practices across industries.

In the food processing industry, there is a significant demand for safe PTFE coatings on cookware, bakeware, and food processing equipment. Consumers and manufacturers alike are increasingly concerned about the potential health risks associated with traditional non-stick coatings. As a result, the market for PTFE-coated kitchenware that ensures food safety and prevents chemical leaching has expanded considerably.

The automotive sector has also witnessed a surge in demand for safe PTFE coatings. These coatings are used in various automotive components, including gaskets, seals, and fuel system parts, to enhance durability and reduce friction. With the automotive industry's focus on improving vehicle safety and performance, the adoption of PTFE coatings that can withstand extreme temperatures and harsh chemicals has become more prevalent.

In the medical and pharmaceutical industries, the need for safe PTFE coatings has reached new heights. Medical devices, surgical instruments, and drug delivery systems often require coatings that are biocompatible, resistant to sterilization processes, and capable of reducing the risk of infections. The growing emphasis on patient safety has driven the demand for PTFE coatings that meet these stringent requirements.

The aerospace industry has also contributed to the increasing market demand for safe PTFE coatings. Aircraft components, such as hydraulic systems, fuel lines, and electrical wiring, benefit from PTFE coatings that provide excellent insulation, chemical resistance, and reduced friction. As safety remains a top priority in aviation, the demand for high-performance PTFE coatings continues to grow.

Furthermore, the construction and building materials sector has shown a rising interest in safe PTFE coatings. These coatings are used in architectural fabrics, roofing materials, and weather-resistant surfaces to enhance durability and safety. The demand for PTFE-coated materials that can withstand harsh environmental conditions while maintaining their protective properties has increased significantly.

As environmental concerns gain prominence, there is a growing market demand for eco-friendly and sustainable PTFE coating solutions. Manufacturers are investing in research and development to create safer formulations that minimize environmental impact without compromising performance. This trend is driven by both consumer preferences and regulatory pressures to adopt more sustainable practices across industries.

Current Challenges in PTFE Coating Safety

Despite the widespread use and numerous benefits of PTFE coatings, several challenges persist in ensuring their optimal safety performance. One of the primary concerns is the potential for degradation under extreme conditions. When exposed to high temperatures or harsh chemical environments, PTFE coatings may break down, releasing potentially harmful substances. This degradation not only compromises the coating's protective properties but also poses health risks to workers and end-users.

Another significant challenge lies in achieving consistent coating thickness and uniformity across complex surfaces. Uneven application can lead to weak spots or areas of excessive buildup, both of which can compromise the coating's protective capabilities. This issue is particularly pronounced in industries requiring precise tolerances, such as aerospace and medical device manufacturing.

The adhesion of PTFE coatings to various substrates remains a persistent challenge. Poor adhesion can result in flaking or peeling, exposing the underlying material to corrosion or contamination. This is especially critical in applications where coating integrity is paramount, such as in food processing equipment or chemical storage tanks.

Contamination during the application process poses another safety concern. Even minor impurities introduced during coating can significantly impact the final product's performance and safety profile. Ensuring a clean, controlled environment for PTFE application is crucial but often challenging in industrial settings.

The long-term durability of PTFE coatings under real-world conditions is an ongoing area of concern. While laboratory tests may demonstrate excellent performance, the cumulative effects of wear, chemical exposure, and thermal cycling in practical applications can lead to unexpected failures. This uncertainty necessitates frequent inspections and maintenance, which can be costly and time-consuming.

Environmental and health concerns related to the production and disposal of PTFE coatings also present challenges. The use of perfluorooctanoic acid (PFOA) in PTFE manufacturing has raised significant health and environmental concerns, leading to regulatory scrutiny and the need for alternative production methods.

Lastly, the challenge of balancing safety enhancements with cost-effectiveness remains a constant struggle. Implementing advanced safety features or using higher-grade materials can significantly increase production costs, potentially limiting the widespread adoption of safer PTFE coating technologies.

Another significant challenge lies in achieving consistent coating thickness and uniformity across complex surfaces. Uneven application can lead to weak spots or areas of excessive buildup, both of which can compromise the coating's protective capabilities. This issue is particularly pronounced in industries requiring precise tolerances, such as aerospace and medical device manufacturing.

The adhesion of PTFE coatings to various substrates remains a persistent challenge. Poor adhesion can result in flaking or peeling, exposing the underlying material to corrosion or contamination. This is especially critical in applications where coating integrity is paramount, such as in food processing equipment or chemical storage tanks.

Contamination during the application process poses another safety concern. Even minor impurities introduced during coating can significantly impact the final product's performance and safety profile. Ensuring a clean, controlled environment for PTFE application is crucial but often challenging in industrial settings.

The long-term durability of PTFE coatings under real-world conditions is an ongoing area of concern. While laboratory tests may demonstrate excellent performance, the cumulative effects of wear, chemical exposure, and thermal cycling in practical applications can lead to unexpected failures. This uncertainty necessitates frequent inspections and maintenance, which can be costly and time-consuming.

Environmental and health concerns related to the production and disposal of PTFE coatings also present challenges. The use of perfluorooctanoic acid (PFOA) in PTFE manufacturing has raised significant health and environmental concerns, leading to regulatory scrutiny and the need for alternative production methods.

Lastly, the challenge of balancing safety enhancements with cost-effectiveness remains a constant struggle. Implementing advanced safety features or using higher-grade materials can significantly increase production costs, potentially limiting the widespread adoption of safer PTFE coating technologies.

Existing PTFE Safety Enhancement Methods

01 Non-stick properties and chemical inertness

PTFE coatings are known for their non-stick properties and chemical inertness, making them safe for use in various applications. These properties contribute to their resistance to corrosion, chemicals, and high temperatures, enhancing the safety and longevity of coated products.- Non-stick properties and chemical inertness: PTFE coatings are known for their non-stick properties and chemical inertness, making them safe for use in various applications. These properties contribute to their resistance to corrosion, chemicals, and high temperatures, enhancing the safety and longevity of coated products.

- Low friction and wear resistance: PTFE coatings provide low friction surfaces and excellent wear resistance, reducing the risk of mechanical failures and improving the safety of moving parts in various applications. This characteristic makes them suitable for use in machinery, automotive components, and industrial equipment.

- Food-safe and non-toxic properties: PTFE coatings are generally considered food-safe and non-toxic when used within recommended temperature ranges. This makes them suitable for use in cookware, food processing equipment, and other applications where contact with food is possible, ensuring consumer safety.

- Environmental and health considerations: While PTFE itself is considered safe, concerns have been raised about the production process and potential breakdown products at very high temperatures. Manufacturers are developing safer production methods and alternative formulations to address these concerns and improve overall safety.

- Application techniques and quality control: Proper application techniques and quality control measures are crucial for ensuring the safety and effectiveness of PTFE coatings. This includes surface preparation, controlled application processes, and post-application testing to verify coating integrity and adherence to safety standards.

02 Low friction and wear resistance

PTFE coatings provide low friction surfaces and excellent wear resistance, which can improve the safety and performance of coated components. This characteristic reduces the risk of mechanical failures and extends the lifespan of coated parts, particularly in industrial and automotive applications.Expand Specific Solutions03 Food contact safety

PTFE coatings are widely used in food processing equipment and cookware due to their non-stick properties and safety for food contact. When properly applied and maintained, these coatings do not leach harmful substances into food, making them suitable for use in food-related applications.Expand Specific Solutions04 Environmental and health considerations

While PTFE itself is generally considered safe, concerns have been raised about the environmental and health impacts of certain chemicals used in its production, such as perfluorooctanoic acid (PFOA). Efforts have been made to develop alternative production methods and safer formulations to address these concerns and improve the overall safety profile of PTFE coatings.Expand Specific Solutions05 Application methods and quality control

The safety of PTFE coatings is heavily dependent on proper application methods and quality control measures. Factors such as surface preparation, curing temperature, and coating thickness play crucial roles in ensuring the integrity and safety of the final coated product. Adherence to industry standards and best practices is essential for maximizing the safety benefits of PTFE coatings.Expand Specific Solutions

Key Players in PTFE Coating Industry

The market for PTFE coatings is in a mature stage, with a global market size estimated to reach $2.1 billion by 2026. The technology has evolved significantly, offering enhanced safety features across various industries. Key players like DuPont de Nemours, Inc. and Juhua Group Corp. have established strong market positions, leveraging their extensive R&D capabilities. Emerging companies such as Sida Fluorine Plastic Co., Ltd. and Nanjing Comptech Composites Corp. are introducing innovative PTFE formulations, focusing on improved safety characteristics. The competitive landscape is characterized by ongoing research into advanced PTFE composites, with collaborations between industry leaders and research institutions like Zhejiang University driving technological advancements in safety-oriented applications.

Shengyi Technology Co., Ltd.

Technical Solution: Shengyi Technology has developed high-performance PTFE-based laminates for printed circuit boards (PCBs) with enhanced safety features. Their PTFE composites offer excellent dielectric properties and thermal stability, crucial for high-frequency and high-speed applications[9]. The company's PTFE coatings for PCBs provide improved fire resistance, meeting UL 94 V-0 standards, and offer a low dielectric constant of 2.2-2.6, reducing signal loss in high-frequency circuits[10]. Shengyi has also introduced PTFE coatings with self-extinguishing properties, enhancing the overall safety of electronic devices[11].

Strengths: Strong presence in the electronics industry, specialized PTFE formulations for PCBs, focus on high-frequency applications. Weaknesses: Limited presence outside of Asia, narrower application range compared to global chemical conglomerates.

Sida Fluorine Plastic Co., Ltd.

Technical Solution: Sida Fluorine Plastic specializes in PTFE and other fluoropolymer products, with a focus on safety-enhancing coatings. They have developed a range of PTFE coatings with improved wear resistance, extending the lifespan of industrial components by up to 40% compared to standard PTFE coatings[12]. Their anti-corrosion PTFE coatings offer protection against a wide range of chemicals, including strong acids and bases, improving safety in harsh industrial environments[13]. Sida has also introduced PTFE coatings with antimicrobial properties, reducing bacterial growth by up to 99.9% on treated surfaces, which is particularly valuable in medical and food processing applications[14].

Strengths: Specialization in fluoropolymers, competitive pricing, strong presence in Asian markets. Weaknesses: Limited global reach compared to multinational corporations, smaller R&D budget than industry giants.

Innovations in PTFE Coating Safety

Pin joint

PatentWO2005098249A1

Innovation

- The implementation of a polytetrafluoroethylene (PTFE) coating in contact areas of the bellows seal with the pivot section and mating components reduces friction, enhances sealing functionality, and protects against environmental influences, allowing for relative movement and preventing material degradation.

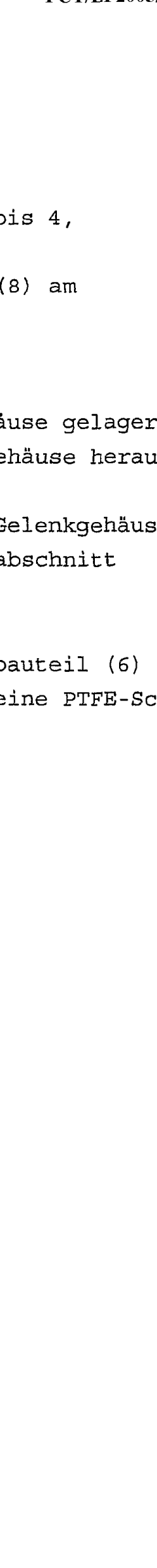

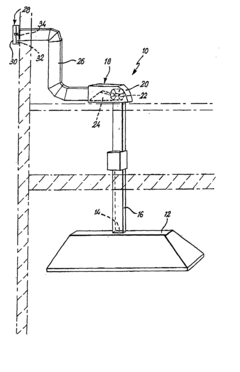

Extraction system and a component therefor

PatentInactiveUS20020088351A1

Innovation

- Coating the inner surfaces and elements of extraction system components, such as canopies, conduits, and impeller means, with a non-stick, heat-resistant, and flame-retardant material like polytetrafluoroethene (PTFE) to prevent matter from sticking and reduce fire risks.

Environmental Impact of PTFE Coatings

The environmental impact of PTFE coatings is a critical consideration in their application and use. These coatings, while offering numerous benefits in terms of safety and performance, also present potential environmental concerns that must be carefully evaluated and addressed.

PTFE coatings are known for their exceptional chemical resistance and non-stick properties, which contribute to their widespread use in various industries. However, the production and disposal of PTFE-coated products can have significant environmental implications. The manufacturing process of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that has been linked to environmental contamination and health risks.

Recent efforts have focused on developing PFOA-free PTFE coatings to mitigate these environmental concerns. Many manufacturers have transitioned to alternative production methods that eliminate or significantly reduce the use of PFOA. This shift has led to a decrease in the environmental impact associated with PTFE coating production, although ongoing research is necessary to fully understand the long-term effects of these alternative methods.

The durability of PTFE coatings contributes to their environmental profile in both positive and negative ways. On one hand, the long-lasting nature of these coatings reduces the need for frequent replacements, potentially decreasing overall material consumption and waste. Conversely, the persistence of PTFE in the environment raises concerns about its long-term accumulation and potential effects on ecosystems.

End-of-life considerations for PTFE-coated products are another crucial aspect of their environmental impact. While PTFE itself is not biodegradable, efforts are being made to develop recycling and recovery processes for PTFE-coated materials. These initiatives aim to reduce the amount of PTFE waste entering landfills and potentially contaminating soil and water resources.

The application of PTFE coatings can also have indirect environmental benefits. In industrial settings, the non-stick properties of PTFE can lead to reduced energy consumption and decreased use of cleaning chemicals, potentially lowering the overall environmental footprint of manufacturing processes. Additionally, the corrosion resistance provided by PTFE coatings can extend the lifespan of equipment and infrastructure, reducing the need for replacements and associated resource consumption.

As environmental regulations become more stringent, the PTFE coating industry is adapting to meet these challenges. Ongoing research and development efforts are focused on creating more environmentally friendly PTFE formulations and application techniques. These advancements aim to maintain the safety and performance benefits of PTFE coatings while minimizing their environmental impact throughout their lifecycle.

PTFE coatings are known for their exceptional chemical resistance and non-stick properties, which contribute to their widespread use in various industries. However, the production and disposal of PTFE-coated products can have significant environmental implications. The manufacturing process of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that has been linked to environmental contamination and health risks.

Recent efforts have focused on developing PFOA-free PTFE coatings to mitigate these environmental concerns. Many manufacturers have transitioned to alternative production methods that eliminate or significantly reduce the use of PFOA. This shift has led to a decrease in the environmental impact associated with PTFE coating production, although ongoing research is necessary to fully understand the long-term effects of these alternative methods.

The durability of PTFE coatings contributes to their environmental profile in both positive and negative ways. On one hand, the long-lasting nature of these coatings reduces the need for frequent replacements, potentially decreasing overall material consumption and waste. Conversely, the persistence of PTFE in the environment raises concerns about its long-term accumulation and potential effects on ecosystems.

End-of-life considerations for PTFE-coated products are another crucial aspect of their environmental impact. While PTFE itself is not biodegradable, efforts are being made to develop recycling and recovery processes for PTFE-coated materials. These initiatives aim to reduce the amount of PTFE waste entering landfills and potentially contaminating soil and water resources.

The application of PTFE coatings can also have indirect environmental benefits. In industrial settings, the non-stick properties of PTFE can lead to reduced energy consumption and decreased use of cleaning chemicals, potentially lowering the overall environmental footprint of manufacturing processes. Additionally, the corrosion resistance provided by PTFE coatings can extend the lifespan of equipment and infrastructure, reducing the need for replacements and associated resource consumption.

As environmental regulations become more stringent, the PTFE coating industry is adapting to meet these challenges. Ongoing research and development efforts are focused on creating more environmentally friendly PTFE formulations and application techniques. These advancements aim to maintain the safety and performance benefits of PTFE coatings while minimizing their environmental impact throughout their lifecycle.

Regulatory Framework for PTFE Coating Safety

The regulatory framework for PTFE coating safety encompasses a comprehensive set of guidelines, standards, and legal requirements designed to ensure the safe production, application, and use of PTFE coatings across various industries. At the forefront of this framework are international organizations such as the Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA), which have established stringent regulations for PTFE coatings in food contact applications.

In the United States, the FDA has approved PTFE for use in food contact materials under specific conditions, as outlined in 21 CFR 177.1550. This regulation stipulates the permissible types of PTFE resins, their composition, and the maximum use temperatures. Similarly, the European Union has implemented Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food, which includes provisions for PTFE coatings.

Occupational safety is another critical aspect of the regulatory framework. The Occupational Safety and Health Administration (OSHA) in the U.S. has established exposure limits for PTFE-related compounds, particularly when the material is heated to high temperatures. These regulations aim to protect workers from potential health hazards associated with PTFE fumes and particulates.

Environmental regulations also play a significant role in the PTFE coating industry. The Environmental Protection Agency (EPA) has implemented strict guidelines for the handling and disposal of PTFE-related materials, including the perfluorooctanoic acid (PFOA) formerly used in PTFE production. The Stockholm Convention on Persistent Organic Pollutants has further reinforced these environmental safeguards on a global scale.

Industry-specific standards complement these regulatory frameworks. For instance, the aerospace industry adheres to AS5942, a standard that outlines the requirements for the qualification and quality control of PTFE coatings used in aerospace applications. Similarly, the automotive industry follows specific standards for PTFE coatings used in vehicle components, ensuring durability and safety under various operating conditions.

To ensure compliance with these diverse regulations, manufacturers and users of PTFE coatings must implement rigorous quality control measures and documentation processes. This includes maintaining detailed records of raw materials, production processes, and testing results. Regular audits and certifications from accredited bodies are often required to demonstrate ongoing compliance with relevant standards and regulations.

As the understanding of PTFE's properties and potential impacts evolves, regulatory bodies continue to update and refine their guidelines. This dynamic regulatory landscape necessitates ongoing vigilance and adaptability from all stakeholders in the PTFE coating industry to maintain the highest standards of safety and performance.

In the United States, the FDA has approved PTFE for use in food contact materials under specific conditions, as outlined in 21 CFR 177.1550. This regulation stipulates the permissible types of PTFE resins, their composition, and the maximum use temperatures. Similarly, the European Union has implemented Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food, which includes provisions for PTFE coatings.

Occupational safety is another critical aspect of the regulatory framework. The Occupational Safety and Health Administration (OSHA) in the U.S. has established exposure limits for PTFE-related compounds, particularly when the material is heated to high temperatures. These regulations aim to protect workers from potential health hazards associated with PTFE fumes and particulates.

Environmental regulations also play a significant role in the PTFE coating industry. The Environmental Protection Agency (EPA) has implemented strict guidelines for the handling and disposal of PTFE-related materials, including the perfluorooctanoic acid (PFOA) formerly used in PTFE production. The Stockholm Convention on Persistent Organic Pollutants has further reinforced these environmental safeguards on a global scale.

Industry-specific standards complement these regulatory frameworks. For instance, the aerospace industry adheres to AS5942, a standard that outlines the requirements for the qualification and quality control of PTFE coatings used in aerospace applications. Similarly, the automotive industry follows specific standards for PTFE coatings used in vehicle components, ensuring durability and safety under various operating conditions.

To ensure compliance with these diverse regulations, manufacturers and users of PTFE coatings must implement rigorous quality control measures and documentation processes. This includes maintaining detailed records of raw materials, production processes, and testing results. Regular audits and certifications from accredited bodies are often required to demonstrate ongoing compliance with relevant standards and regulations.

As the understanding of PTFE's properties and potential impacts evolves, regulatory bodies continue to update and refine their guidelines. This dynamic regulatory landscape necessitates ongoing vigilance and adaptability from all stakeholders in the PTFE coating industry to maintain the highest standards of safety and performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!