Strategic Pathways in PTFE Innovations

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Evolution and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has been a revolutionary material since its accidental discovery by Roy Plunkett in 1938. This synthetic fluoropolymer has evolved significantly over the past eight decades, transforming various industries with its unique properties. The evolution of PTFE technology has been driven by the continuous pursuit of enhanced performance, sustainability, and cost-effectiveness.

Initially, PTFE was primarily valued for its non-stick properties and chemical resistance. However, as research progressed, its potential in diverse applications became apparent. The material's evolution has seen improvements in mechanical strength, thermal stability, and processability. These advancements have expanded PTFE's use from cookware to aerospace, electronics, and medical industries.

The objectives of PTFE innovation have shifted over time, reflecting changing market demands and environmental concerns. Early goals focused on improving the material's basic properties and manufacturing processes. Today, the objectives are more nuanced, addressing challenges such as reducing environmental impact, enhancing durability, and developing specialized grades for emerging technologies.

One key trend in PTFE evolution is the development of modified PTFE materials. These innovations aim to overcome some of the limitations of standard PTFE, such as poor wear resistance and difficulties in processing. Modified PTFE grades offer improved mechanical properties while maintaining the essential characteristics that make PTFE valuable.

Another significant objective in PTFE innovation is the pursuit of more sustainable production methods. This includes efforts to reduce the use of perfluorooctanoic acid (PFOA) in manufacturing, as well as developing recycling techniques for PTFE products. The industry is also exploring bio-based alternatives and ways to minimize the carbon footprint of PTFE production.

The miniaturization trend in electronics has driven the development of ultra-thin PTFE films and coatings. These innovations enable the use of PTFE in compact electronic devices, providing crucial insulation and protection. Similarly, in the medical field, there's a growing focus on creating biocompatible PTFE formulations for implants and drug delivery systems.

Looking ahead, the objectives for PTFE innovation include enhancing its performance in extreme conditions, such as space applications and deep-sea exploration. There's also a push towards smart PTFE materials that can respond to environmental stimuli, opening up new possibilities in sensors and adaptive technologies.

Initially, PTFE was primarily valued for its non-stick properties and chemical resistance. However, as research progressed, its potential in diverse applications became apparent. The material's evolution has seen improvements in mechanical strength, thermal stability, and processability. These advancements have expanded PTFE's use from cookware to aerospace, electronics, and medical industries.

The objectives of PTFE innovation have shifted over time, reflecting changing market demands and environmental concerns. Early goals focused on improving the material's basic properties and manufacturing processes. Today, the objectives are more nuanced, addressing challenges such as reducing environmental impact, enhancing durability, and developing specialized grades for emerging technologies.

One key trend in PTFE evolution is the development of modified PTFE materials. These innovations aim to overcome some of the limitations of standard PTFE, such as poor wear resistance and difficulties in processing. Modified PTFE grades offer improved mechanical properties while maintaining the essential characteristics that make PTFE valuable.

Another significant objective in PTFE innovation is the pursuit of more sustainable production methods. This includes efforts to reduce the use of perfluorooctanoic acid (PFOA) in manufacturing, as well as developing recycling techniques for PTFE products. The industry is also exploring bio-based alternatives and ways to minimize the carbon footprint of PTFE production.

The miniaturization trend in electronics has driven the development of ultra-thin PTFE films and coatings. These innovations enable the use of PTFE in compact electronic devices, providing crucial insulation and protection. Similarly, in the medical field, there's a growing focus on creating biocompatible PTFE formulations for implants and drug delivery systems.

Looking ahead, the objectives for PTFE innovation include enhancing its performance in extreme conditions, such as space applications and deep-sea exploration. There's also a push towards smart PTFE materials that can respond to environmental stimuli, opening up new possibilities in sensors and adaptive technologies.

PTFE Market Demand Analysis

The global PTFE (Polytetrafluoroethylene) market has been experiencing steady growth, driven by increasing demand across various industries. The unique properties of PTFE, including its high chemical resistance, low friction coefficient, and excellent thermal stability, have made it a sought-after material in numerous applications.

In the automotive sector, PTFE is widely used in gaskets, seals, and bearings due to its ability to withstand high temperatures and harsh chemical environments. The growing automotive industry, particularly in emerging economies, is expected to fuel the demand for PTFE in the coming years.

The electronics industry represents another significant market for PTFE. With the rapid advancement of technology and the increasing miniaturization of electronic devices, PTFE's excellent dielectric properties and thermal stability make it an ideal material for insulation and circuit board manufacturing.

The healthcare industry has also emerged as a key consumer of PTFE. Its biocompatibility and non-stick properties make it suitable for medical implants, surgical instruments, and pharmaceutical processing equipment. The aging population and increasing healthcare expenditure worldwide are likely to drive the demand for PTFE in this sector.

In the chemical processing industry, PTFE's exceptional chemical resistance makes it invaluable for lining pipes, valves, and tanks that handle corrosive substances. As industrial activities expand globally, the demand for PTFE in this sector is expected to grow significantly.

The construction industry utilizes PTFE in architectural membranes, coatings, and sealants due to its weather resistance and durability. The increasing focus on sustainable and energy-efficient buildings is likely to boost the adoption of PTFE-based materials in construction applications.

Market analysts project a compound annual growth rate (CAGR) for the global PTFE market in the range of 5-6% over the next five years. This growth is attributed to the material's expanding applications and the overall industrial development across regions.

However, the PTFE market faces challenges, including environmental concerns related to the production process and the high cost of raw materials. These factors have spurred research into more sustainable production methods and the development of PTFE alternatives, which could impact market dynamics in the long term.

Despite these challenges, the versatility and unique properties of PTFE continue to drive its demand across industries. Innovations in PTFE technology, such as the development of micro-powders and modified PTFE grades, are opening up new application areas and market opportunities. As industries continue to evolve and demand high-performance materials, PTFE is expected to maintain its significant role in various sectors, driving ongoing market growth and technological advancements.

In the automotive sector, PTFE is widely used in gaskets, seals, and bearings due to its ability to withstand high temperatures and harsh chemical environments. The growing automotive industry, particularly in emerging economies, is expected to fuel the demand for PTFE in the coming years.

The electronics industry represents another significant market for PTFE. With the rapid advancement of technology and the increasing miniaturization of electronic devices, PTFE's excellent dielectric properties and thermal stability make it an ideal material for insulation and circuit board manufacturing.

The healthcare industry has also emerged as a key consumer of PTFE. Its biocompatibility and non-stick properties make it suitable for medical implants, surgical instruments, and pharmaceutical processing equipment. The aging population and increasing healthcare expenditure worldwide are likely to drive the demand for PTFE in this sector.

In the chemical processing industry, PTFE's exceptional chemical resistance makes it invaluable for lining pipes, valves, and tanks that handle corrosive substances. As industrial activities expand globally, the demand for PTFE in this sector is expected to grow significantly.

The construction industry utilizes PTFE in architectural membranes, coatings, and sealants due to its weather resistance and durability. The increasing focus on sustainable and energy-efficient buildings is likely to boost the adoption of PTFE-based materials in construction applications.

Market analysts project a compound annual growth rate (CAGR) for the global PTFE market in the range of 5-6% over the next five years. This growth is attributed to the material's expanding applications and the overall industrial development across regions.

However, the PTFE market faces challenges, including environmental concerns related to the production process and the high cost of raw materials. These factors have spurred research into more sustainable production methods and the development of PTFE alternatives, which could impact market dynamics in the long term.

Despite these challenges, the versatility and unique properties of PTFE continue to drive its demand across industries. Innovations in PTFE technology, such as the development of micro-powders and modified PTFE grades, are opening up new application areas and market opportunities. As industries continue to evolve and demand high-performance materials, PTFE is expected to maintain its significant role in various sectors, driving ongoing market growth and technological advancements.

PTFE Technical Challenges

Polytetrafluoroethylene (PTFE) has been a revolutionary material since its accidental discovery in 1938. However, as with any mature technology, PTFE faces several technical challenges that hinder its further development and application expansion. These challenges primarily stem from its unique properties and the limitations of current manufacturing processes.

One of the most significant challenges is improving PTFE's wear resistance without compromising its low friction properties. While PTFE exhibits excellent lubricity, it tends to wear quickly under high loads or in abrasive environments. This limitation restricts its use in certain high-performance applications where longevity is crucial.

Another major hurdle is enhancing PTFE's adhesion to other materials. The very property that makes PTFE non-stick – its low surface energy – also makes it difficult to bond with other substances. This challenge is particularly relevant in composite materials and coatings, where strong interfacial bonding is essential for structural integrity and performance.

The processing of PTFE presents its own set of challenges. Unlike most thermoplastics, PTFE cannot be melt-processed due to its extremely high melting point and melt viscosity. This necessitates specialized sintering techniques, which can be energy-intensive and time-consuming. Developing more efficient processing methods that maintain or improve the material's properties is an ongoing challenge.

Environmental concerns also pose challenges for PTFE production and use. The traditional manufacturing process involves the use of perfluorooctanoic acid (PFOA), a persistent environmental pollutant. While many manufacturers have phased out PFOA, finding equally effective and environmentally friendly alternatives remains a challenge.

Recycling PTFE is another significant technical hurdle. The material's chemical inertness and high melting point make conventional recycling methods ineffective. Developing economically viable and environmentally sound recycling processes for PTFE waste is crucial for sustainable use of this material.

In the realm of PTFE modifications, achieving a balance between improved mechanical properties and retained chemical inertness presents a complex challenge. Efforts to enhance strength or hardness often come at the cost of reduced chemical resistance or increased friction, necessitating careful material design and processing strategies.

Lastly, the development of PTFE alternatives that maintain its beneficial properties while addressing its limitations is an ongoing challenge. This includes research into other fluoropolymers and novel materials that could potentially outperform PTFE in specific applications.

One of the most significant challenges is improving PTFE's wear resistance without compromising its low friction properties. While PTFE exhibits excellent lubricity, it tends to wear quickly under high loads or in abrasive environments. This limitation restricts its use in certain high-performance applications where longevity is crucial.

Another major hurdle is enhancing PTFE's adhesion to other materials. The very property that makes PTFE non-stick – its low surface energy – also makes it difficult to bond with other substances. This challenge is particularly relevant in composite materials and coatings, where strong interfacial bonding is essential for structural integrity and performance.

The processing of PTFE presents its own set of challenges. Unlike most thermoplastics, PTFE cannot be melt-processed due to its extremely high melting point and melt viscosity. This necessitates specialized sintering techniques, which can be energy-intensive and time-consuming. Developing more efficient processing methods that maintain or improve the material's properties is an ongoing challenge.

Environmental concerns also pose challenges for PTFE production and use. The traditional manufacturing process involves the use of perfluorooctanoic acid (PFOA), a persistent environmental pollutant. While many manufacturers have phased out PFOA, finding equally effective and environmentally friendly alternatives remains a challenge.

Recycling PTFE is another significant technical hurdle. The material's chemical inertness and high melting point make conventional recycling methods ineffective. Developing economically viable and environmentally sound recycling processes for PTFE waste is crucial for sustainable use of this material.

In the realm of PTFE modifications, achieving a balance between improved mechanical properties and retained chemical inertness presents a complex challenge. Efforts to enhance strength or hardness often come at the cost of reduced chemical resistance or increased friction, necessitating careful material design and processing strategies.

Lastly, the development of PTFE alternatives that maintain its beneficial properties while addressing its limitations is an ongoing challenge. This includes research into other fluoropolymers and novel materials that could potentially outperform PTFE in specific applications.

Current PTFE Solutions

01 PTFE manufacturing processes

Various methods for producing PTFE are described, including polymerization techniques, extrusion processes, and molding methods. These processes aim to improve the quality, efficiency, and properties of the resulting PTFE materials.- PTFE manufacturing processes: Various methods for producing PTFE are described, including polymerization techniques, extrusion processes, and molding methods. These processes aim to improve the quality, efficiency, and properties of the resulting PTFE materials.

- PTFE composite materials: PTFE is often combined with other materials to create composite structures with enhanced properties. These composites may include fillers, reinforcing agents, or other polymers to improve mechanical strength, thermal stability, or specific functional characteristics.

- Surface modification of PTFE: Techniques for modifying the surface of PTFE materials are explored to enhance properties such as adhesion, wettability, or biocompatibility. These modifications may involve chemical treatments, plasma processing, or the application of coatings.

- PTFE in membrane technology: PTFE is utilized in the development of various membrane technologies, including filtration systems, gas separation membranes, and water treatment applications. The unique properties of PTFE, such as its hydrophobicity and chemical resistance, make it valuable in these applications.

- PTFE in electronic and electrical applications: The use of PTFE in electronic and electrical components is explored, including its application in insulation, printed circuit boards, and high-frequency applications. PTFE's low dielectric constant and excellent insulating properties make it suitable for these uses.

02 PTFE composites and blends

The development of PTFE composites and blends with other materials to enhance specific properties such as wear resistance, thermal conductivity, or mechanical strength. These combinations aim to create materials with improved performance for various applications.Expand Specific Solutions03 Surface modification of PTFE

Techniques for modifying the surface of PTFE to improve its adhesion, wettability, or compatibility with other materials. These modifications can include chemical treatments, plasma treatments, or the application of coatings to enhance PTFE's functionality in specific applications.Expand Specific Solutions04 PTFE in membrane technology

The use of PTFE in the development of advanced membrane technologies for applications such as water treatment, gas separation, or fuel cells. These membranes leverage PTFE's unique properties to achieve high performance in filtration and separation processes.Expand Specific Solutions05 PTFE in medical and biomedical applications

The application of PTFE in medical devices, implants, and biomedical engineering. This includes the development of PTFE-based materials with enhanced biocompatibility, reduced friction, or improved wear resistance for use in various medical procedures and devices.Expand Specific Solutions

Key PTFE Industry Players

The strategic pathways in PTFE innovations are characterized by a mature market with steady growth, driven by established players and emerging technologies. The global PTFE market, valued at several billion dollars, is in a consolidation phase with key players like DAIKIN INDUSTRIES Ltd., W. L. Gore & Associates, and 3M Innovative Properties Co. leading innovation efforts. These companies are focusing on developing advanced PTFE applications in sectors such as electronics, automotive, and medical devices. The technology's maturity is evident in the diverse product offerings, ranging from high-performance coatings to specialized membranes. However, new entrants like Shandong Dongyue Polymer Material Co. Ltd. and research institutions such as Zhejiang University are pushing boundaries in PTFE modifications and applications, indicating potential for disruptive innovations in this well-established field.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has developed innovative PTFE processing techniques, including a unique stretching process that creates expanded PTFE (ePTFE) with enhanced properties. Their method involves biaxial stretching of PTFE at controlled temperatures, resulting in a microporous structure with improved strength and flexibility[1]. They have also pioneered a surface modification technique for PTFE, enhancing its adhesion properties without compromising its chemical resistance. This involves plasma treatment followed by the application of a proprietary coupling agent, enabling better bonding with other materials[3]. Additionally, DAIKIN has made strides in PTFE nanocomposite development, incorporating nanoparticles to enhance wear resistance and thermal conductivity[5].

Strengths: Advanced ePTFE production, improved adhesion properties, and enhanced nanocomposites. Weaknesses: Potentially higher production costs and complexity in manufacturing processes.

Shandong Dongyue Polymer Material Co. Ltd.

Technical Solution: Shandong Dongyue has made significant progress in PTFE production and modification technologies. They have developed a proprietary suspension polymerization process that allows for better control of PTFE particle size and morphology, resulting in improved processing characteristics[13]. The company has also introduced a novel thermal treatment method for PTFE that enhances its crystallinity and mechanical properties without compromising chemical resistance[15]. In addition, Shandong Dongyue has made strides in the development of PTFE micropowders with controlled particle size distributions, suitable for use as additives in various industries[17].

Strengths: Cost-effective PTFE production, advancements in PTFE modification, and growing market share. Weaknesses: Potential challenges in competing with more established global brands in high-end applications.

PTFE Patent Landscape

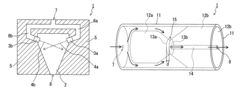

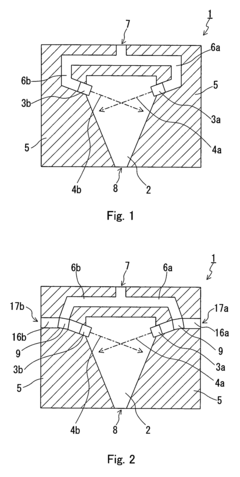

Method of manufacturing polytetrafluoroethylene particle aggregate and method of manufacturing polytetrafluoroethylene product

PatentInactiveUS8105515B2

Innovation

- A method involving the application of force to a dispersion of PTFE particles with water and a surfactant to aggregate the particles, allowing for the formation of a deformable PTFE particle aggregate that can be shaped and processed into various forms, including continuous production of PTFE products with improved mechanical properties.

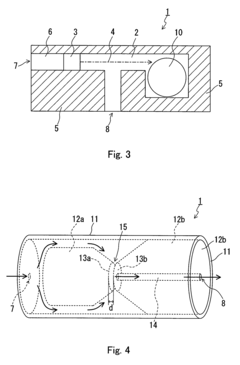

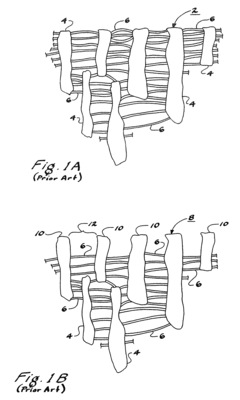

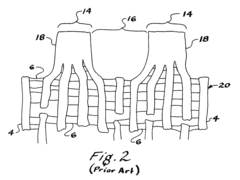

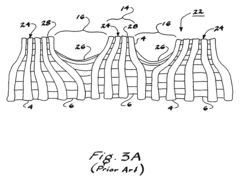

Surface modified expanded polytetrafluoroethylene devices and methods of producing the same

PatentInactiveUS7736576B2

Innovation

- A process using an unfocused laser beam to alter and remove selected PTFE fibrils and nodes, creating a ridge and valley texture with clustered nodes supported by shortened fibrils for porosity and stiffness, and gnarled nodes in valleys for enhanced roughness without compromising porosity.

Environmental Impact of PTFE

The environmental impact of PTFE (Polytetrafluoroethylene) is a critical consideration in the strategic pathways for PTFE innovations. This synthetic fluoropolymer, known for its exceptional chemical resistance and non-stick properties, has widespread applications across various industries. However, its production and disposal pose significant environmental challenges that must be addressed.

PTFE manufacturing processes involve the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant with potential health and environmental risks. PFOA has been detected in water sources, wildlife, and human blood samples globally, raising concerns about its long-term ecological effects. The bioaccumulation of PFOA in the food chain and its potential for long-range transport have led to increased scrutiny and regulatory pressure on PTFE production.

In response to these environmental concerns, the PTFE industry has been exploring alternative production methods and materials. One promising approach is the development of PFOA-free PTFE manufacturing processes, which utilize shorter-chain fluorinated compounds or entirely different chemistries. These innovations aim to maintain the desirable properties of PTFE while significantly reducing its environmental footprint.

The disposal of PTFE products presents another environmental challenge. PTFE is not biodegradable and can persist in the environment for extended periods. Incineration of PTFE waste can release harmful fluorinated compounds, including hydrogen fluoride and perfluoroisobutylene, which are toxic and contribute to air pollution. Consequently, there is a growing focus on developing effective recycling and upcycling strategies for PTFE materials.

Innovative recycling technologies are emerging as a key area of research in PTFE sustainability. Advanced mechanical and chemical recycling processes are being explored to break down PTFE into its constituent monomers or convert it into other useful materials. These recycling methods not only reduce waste but also offer the potential to create a circular economy for PTFE products.

The environmental impact of PTFE extends beyond its production and disposal. The exceptional durability and chemical resistance of PTFE contribute to the longevity of products, potentially reducing the need for frequent replacements and associated resource consumption. However, this durability also means that PTFE products may persist in the environment for extended periods if not properly managed at the end of their lifecycle.

As environmental regulations become more stringent, PTFE manufacturers are increasingly investing in green chemistry principles and sustainable production practices. This includes efforts to reduce energy consumption, minimize waste generation, and implement closed-loop manufacturing systems. The development of bio-based alternatives to PTFE is also an area of active research, aiming to create materials with similar properties but derived from renewable resources.

PTFE manufacturing processes involve the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant with potential health and environmental risks. PFOA has been detected in water sources, wildlife, and human blood samples globally, raising concerns about its long-term ecological effects. The bioaccumulation of PFOA in the food chain and its potential for long-range transport have led to increased scrutiny and regulatory pressure on PTFE production.

In response to these environmental concerns, the PTFE industry has been exploring alternative production methods and materials. One promising approach is the development of PFOA-free PTFE manufacturing processes, which utilize shorter-chain fluorinated compounds or entirely different chemistries. These innovations aim to maintain the desirable properties of PTFE while significantly reducing its environmental footprint.

The disposal of PTFE products presents another environmental challenge. PTFE is not biodegradable and can persist in the environment for extended periods. Incineration of PTFE waste can release harmful fluorinated compounds, including hydrogen fluoride and perfluoroisobutylene, which are toxic and contribute to air pollution. Consequently, there is a growing focus on developing effective recycling and upcycling strategies for PTFE materials.

Innovative recycling technologies are emerging as a key area of research in PTFE sustainability. Advanced mechanical and chemical recycling processes are being explored to break down PTFE into its constituent monomers or convert it into other useful materials. These recycling methods not only reduce waste but also offer the potential to create a circular economy for PTFE products.

The environmental impact of PTFE extends beyond its production and disposal. The exceptional durability and chemical resistance of PTFE contribute to the longevity of products, potentially reducing the need for frequent replacements and associated resource consumption. However, this durability also means that PTFE products may persist in the environment for extended periods if not properly managed at the end of their lifecycle.

As environmental regulations become more stringent, PTFE manufacturers are increasingly investing in green chemistry principles and sustainable production practices. This includes efforts to reduce energy consumption, minimize waste generation, and implement closed-loop manufacturing systems. The development of bio-based alternatives to PTFE is also an area of active research, aiming to create materials with similar properties but derived from renewable resources.

PTFE Regulatory Framework

The regulatory framework surrounding PTFE (Polytetrafluoroethylene) plays a crucial role in shaping the strategic pathways for innovation in this field. As a highly versatile and widely used synthetic fluoropolymer, PTFE is subject to various regulations across different industries and regions.

In the United States, the Environmental Protection Agency (EPA) regulates PTFE under the Toxic Substances Control Act (TSCA). The EPA has established specific guidelines for the manufacturing, processing, and disposal of PTFE-based products. These regulations aim to minimize environmental impact and ensure worker safety throughout the product lifecycle.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which apply to PTFE and its precursors. REACH requires manufacturers and importers to register chemicals and provide safety data, promoting transparency and responsible use of PTFE in various applications.

In the food industry, the U.S. Food and Drug Administration (FDA) has approved PTFE for use in food contact materials, subject to specific conditions and limitations. Similarly, the European Food Safety Authority (EFSA) has established guidelines for PTFE use in food packaging and processing equipment.

The medical device industry faces stringent regulations for PTFE applications. In the United States, the FDA oversees medical devices containing PTFE through its premarket approval (PMA) and 510(k) clearance processes. The European Union's Medical Device Regulation (MDR) imposes similar requirements for PTFE-based medical devices in the European market.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, address worker exposure to PTFE during manufacturing and processing. These regulations set permissible exposure limits and mandate appropriate safety measures in industrial settings.

Environmental regulations also impact PTFE innovation strategies. The Stockholm Convention on Persistent Organic Pollutants has led to increased scrutiny of perfluorooctanoic acid (PFOA), a chemical historically used in PTFE production. This has driven research into alternative production methods and safer PTFE formulations.

As sustainability becomes a global priority, regulations promoting circular economy principles are influencing PTFE innovation. The European Union's Circular Economy Action Plan, for instance, encourages the development of recyclable and reusable PTFE products, pushing manufacturers to explore novel recycling technologies and eco-friendly alternatives.

The regulatory landscape for PTFE is dynamic, with ongoing revisions and new regulations emerging in response to scientific advancements and environmental concerns. Innovators in the PTFE industry must navigate this complex regulatory framework, aligning their research and development efforts with current and anticipated regulatory requirements to ensure long-term success and market acceptance of their innovations.

In the United States, the Environmental Protection Agency (EPA) regulates PTFE under the Toxic Substances Control Act (TSCA). The EPA has established specific guidelines for the manufacturing, processing, and disposal of PTFE-based products. These regulations aim to minimize environmental impact and ensure worker safety throughout the product lifecycle.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which apply to PTFE and its precursors. REACH requires manufacturers and importers to register chemicals and provide safety data, promoting transparency and responsible use of PTFE in various applications.

In the food industry, the U.S. Food and Drug Administration (FDA) has approved PTFE for use in food contact materials, subject to specific conditions and limitations. Similarly, the European Food Safety Authority (EFSA) has established guidelines for PTFE use in food packaging and processing equipment.

The medical device industry faces stringent regulations for PTFE applications. In the United States, the FDA oversees medical devices containing PTFE through its premarket approval (PMA) and 510(k) clearance processes. The European Union's Medical Device Regulation (MDR) imposes similar requirements for PTFE-based medical devices in the European market.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, address worker exposure to PTFE during manufacturing and processing. These regulations set permissible exposure limits and mandate appropriate safety measures in industrial settings.

Environmental regulations also impact PTFE innovation strategies. The Stockholm Convention on Persistent Organic Pollutants has led to increased scrutiny of perfluorooctanoic acid (PFOA), a chemical historically used in PTFE production. This has driven research into alternative production methods and safer PTFE formulations.

As sustainability becomes a global priority, regulations promoting circular economy principles are influencing PTFE innovation. The European Union's Circular Economy Action Plan, for instance, encourages the development of recyclable and reusable PTFE products, pushing manufacturers to explore novel recycling technologies and eco-friendly alternatives.

The regulatory landscape for PTFE is dynamic, with ongoing revisions and new regulations emerging in response to scientific advancements and environmental concerns. Innovators in the PTFE industry must navigate this complex regulatory framework, aligning their research and development efforts with current and anticipated regulatory requirements to ensure long-term success and market acceptance of their innovations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!