How to Harness PTFE for Enhanced Microfluidic Devices?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE in Microfluidics: Background and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has emerged as a pivotal material in the realm of microfluidics. Its unique properties, including exceptional chemical resistance, low surface energy, and high thermal stability, have positioned PTFE as a game-changer in the development of advanced microfluidic devices. The journey of PTFE in microfluidics began in the late 20th century, with researchers recognizing its potential to overcome limitations posed by traditional materials such as glass and silicon.

The evolution of PTFE's role in microfluidics has been marked by significant milestones. Initially used primarily as a coating material, PTFE has gradually transitioned into a structural component in microfluidic chip fabrication. This shift has been driven by the increasing demand for chemically inert, biocompatible, and highly efficient microfluidic systems across various industries, including healthcare, environmental monitoring, and chemical synthesis.

As we delve into the current landscape, the integration of PTFE in microfluidic devices continues to address critical challenges in the field. These include enhancing fluid control, improving chemical compatibility, and increasing the overall robustness of microfluidic systems. The hydrophobic nature of PTFE has proven particularly valuable in creating droplet-based microfluidic platforms, enabling precise manipulation of discrete fluid volumes at the microscale.

Looking ahead, the objectives for harnessing PTFE in enhanced microfluidic devices are multifaceted. Researchers and engineers are focusing on developing novel fabrication techniques to create more complex and intricate PTFE-based microfluidic structures. This includes exploring methods for 3D printing PTFE microchannels and integrating PTFE with other materials to create hybrid systems with optimized performance characteristics.

Another key objective is to leverage PTFE's unique properties to expand the application scope of microfluidic devices. This involves designing PTFE-based microfluidic chips capable of handling aggressive chemicals, operating at extreme temperatures, and facilitating high-throughput screening processes. The goal is to push the boundaries of what's possible in fields such as drug discovery, point-of-care diagnostics, and advanced materials synthesis.

Furthermore, there is a growing emphasis on enhancing the surface modification techniques for PTFE in microfluidic contexts. By developing methods to selectively alter PTFE's surface properties, researchers aim to create microfluidic devices with programmable wettability, enabling unprecedented control over fluid behavior at the microscale. This has the potential to revolutionize applications ranging from droplet microfluidics to microfluidic cell culture systems.

The evolution of PTFE's role in microfluidics has been marked by significant milestones. Initially used primarily as a coating material, PTFE has gradually transitioned into a structural component in microfluidic chip fabrication. This shift has been driven by the increasing demand for chemically inert, biocompatible, and highly efficient microfluidic systems across various industries, including healthcare, environmental monitoring, and chemical synthesis.

As we delve into the current landscape, the integration of PTFE in microfluidic devices continues to address critical challenges in the field. These include enhancing fluid control, improving chemical compatibility, and increasing the overall robustness of microfluidic systems. The hydrophobic nature of PTFE has proven particularly valuable in creating droplet-based microfluidic platforms, enabling precise manipulation of discrete fluid volumes at the microscale.

Looking ahead, the objectives for harnessing PTFE in enhanced microfluidic devices are multifaceted. Researchers and engineers are focusing on developing novel fabrication techniques to create more complex and intricate PTFE-based microfluidic structures. This includes exploring methods for 3D printing PTFE microchannels and integrating PTFE with other materials to create hybrid systems with optimized performance characteristics.

Another key objective is to leverage PTFE's unique properties to expand the application scope of microfluidic devices. This involves designing PTFE-based microfluidic chips capable of handling aggressive chemicals, operating at extreme temperatures, and facilitating high-throughput screening processes. The goal is to push the boundaries of what's possible in fields such as drug discovery, point-of-care diagnostics, and advanced materials synthesis.

Furthermore, there is a growing emphasis on enhancing the surface modification techniques for PTFE in microfluidic contexts. By developing methods to selectively alter PTFE's surface properties, researchers aim to create microfluidic devices with programmable wettability, enabling unprecedented control over fluid behavior at the microscale. This has the potential to revolutionize applications ranging from droplet microfluidics to microfluidic cell culture systems.

Market Analysis for PTFE-based Microfluidic Devices

The market for PTFE-based microfluidic devices is experiencing significant growth, driven by the increasing demand for precise and efficient fluid handling systems across various industries. The global microfluidics market, which includes PTFE-based devices, is projected to reach $50 billion by 2025, with a compound annual growth rate (CAGR) of 18.5% from 2020 to 2025.

PTFE-based microfluidic devices are particularly attractive in the healthcare and life sciences sectors, where they find applications in drug discovery, diagnostics, and personalized medicine. The biomedical segment accounts for the largest share of the microfluidics market, with PTFE devices playing a crucial role due to their excellent chemical resistance and biocompatibility.

In the pharmaceutical industry, PTFE-based microfluidic devices are increasingly used for high-throughput screening and drug formulation studies. The ability of these devices to handle small sample volumes and provide precise control over fluid dynamics makes them invaluable in reducing drug development costs and accelerating time-to-market for new therapeutics.

The adoption of PTFE-based microfluidic devices in the field of point-of-care diagnostics is another significant market driver. The demand for rapid, portable, and accurate diagnostic tools has surged, especially in the wake of global health crises. PTFE's properties make it an ideal material for developing robust and reliable diagnostic platforms that can be used in resource-limited settings.

In the industrial sector, PTFE-based microfluidic devices are gaining traction in chemical synthesis and process optimization. The chemical industry is leveraging these devices for reaction screening, process intensification, and the development of more sustainable manufacturing processes. This trend is expected to contribute to market growth in the coming years.

Geographically, North America holds the largest market share for PTFE-based microfluidic devices, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing investments in healthcare infrastructure and research facilities.

Despite the positive market outlook, challenges such as high initial costs and the need for specialized expertise in device design and fabrication may hinder market growth. Additionally, the emergence of alternative materials and technologies could pose a threat to the PTFE-based microfluidic device market in the long term.

PTFE-based microfluidic devices are particularly attractive in the healthcare and life sciences sectors, where they find applications in drug discovery, diagnostics, and personalized medicine. The biomedical segment accounts for the largest share of the microfluidics market, with PTFE devices playing a crucial role due to their excellent chemical resistance and biocompatibility.

In the pharmaceutical industry, PTFE-based microfluidic devices are increasingly used for high-throughput screening and drug formulation studies. The ability of these devices to handle small sample volumes and provide precise control over fluid dynamics makes them invaluable in reducing drug development costs and accelerating time-to-market for new therapeutics.

The adoption of PTFE-based microfluidic devices in the field of point-of-care diagnostics is another significant market driver. The demand for rapid, portable, and accurate diagnostic tools has surged, especially in the wake of global health crises. PTFE's properties make it an ideal material for developing robust and reliable diagnostic platforms that can be used in resource-limited settings.

In the industrial sector, PTFE-based microfluidic devices are gaining traction in chemical synthesis and process optimization. The chemical industry is leveraging these devices for reaction screening, process intensification, and the development of more sustainable manufacturing processes. This trend is expected to contribute to market growth in the coming years.

Geographically, North America holds the largest market share for PTFE-based microfluidic devices, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing investments in healthcare infrastructure and research facilities.

Despite the positive market outlook, challenges such as high initial costs and the need for specialized expertise in device design and fabrication may hinder market growth. Additionally, the emergence of alternative materials and technologies could pose a threat to the PTFE-based microfluidic device market in the long term.

Current PTFE Applications and Challenges in Microfluidics

Polytetrafluoroethylene (PTFE) has emerged as a crucial material in the development of microfluidic devices due to its unique properties. Its hydrophobicity, chemical inertness, and thermal stability make it an ideal candidate for various applications in microfluidics. Currently, PTFE is widely used in the fabrication of microchannels, valves, and membranes within microfluidic systems.

In microfluidic channel fabrication, PTFE is employed to create non-wetting surfaces that facilitate the manipulation of droplets and prevent sample adhesion. This property is particularly valuable in droplet-based microfluidics, where precise control over fluid behavior is essential. PTFE-coated channels enable the generation and manipulation of monodisperse droplets, which is crucial for applications such as digital PCR and single-cell analysis.

PTFE membranes are another significant application in microfluidic devices. These membranes serve as selective barriers, allowing the passage of certain molecules while blocking others. This feature is exploited in various separation and filtration processes within microfluidic systems, including gas-liquid separation and protein purification.

Despite its advantages, the use of PTFE in microfluidics faces several challenges. One of the primary obstacles is the difficulty in bonding PTFE to other materials commonly used in microfluidic device fabrication, such as glass or polydimethylsiloxane (PDMS). The inherent non-stick properties of PTFE that make it valuable for certain applications also complicate the creation of robust, leak-free seals in microfluidic devices.

Another challenge lies in the surface modification of PTFE. While its hydrophobicity is beneficial in many scenarios, there are instances where a more hydrophilic surface is desired. Modifying the surface properties of PTFE without compromising its bulk characteristics remains a significant research focus in the field of microfluidics.

The integration of PTFE components into complex microfluidic systems presents additional challenges. The material's relatively high cost and the specialized fabrication techniques required for PTFE processing can limit its widespread adoption in certain applications. Furthermore, the opacity of PTFE can hinder optical detection methods commonly employed in microfluidic devices, necessitating the development of alternative detection strategies or the use of transparent PTFE derivatives.

As the field of microfluidics continues to evolve, addressing these challenges associated with PTFE usage becomes increasingly important. Researchers and engineers are actively exploring novel fabrication techniques, surface modification methods, and hybrid material approaches to harness the full potential of PTFE in enhancing microfluidic devices. The ongoing efforts to overcome these obstacles promise to unlock new possibilities in the design and functionality of next-generation microfluidic systems.

In microfluidic channel fabrication, PTFE is employed to create non-wetting surfaces that facilitate the manipulation of droplets and prevent sample adhesion. This property is particularly valuable in droplet-based microfluidics, where precise control over fluid behavior is essential. PTFE-coated channels enable the generation and manipulation of monodisperse droplets, which is crucial for applications such as digital PCR and single-cell analysis.

PTFE membranes are another significant application in microfluidic devices. These membranes serve as selective barriers, allowing the passage of certain molecules while blocking others. This feature is exploited in various separation and filtration processes within microfluidic systems, including gas-liquid separation and protein purification.

Despite its advantages, the use of PTFE in microfluidics faces several challenges. One of the primary obstacles is the difficulty in bonding PTFE to other materials commonly used in microfluidic device fabrication, such as glass or polydimethylsiloxane (PDMS). The inherent non-stick properties of PTFE that make it valuable for certain applications also complicate the creation of robust, leak-free seals in microfluidic devices.

Another challenge lies in the surface modification of PTFE. While its hydrophobicity is beneficial in many scenarios, there are instances where a more hydrophilic surface is desired. Modifying the surface properties of PTFE without compromising its bulk characteristics remains a significant research focus in the field of microfluidics.

The integration of PTFE components into complex microfluidic systems presents additional challenges. The material's relatively high cost and the specialized fabrication techniques required for PTFE processing can limit its widespread adoption in certain applications. Furthermore, the opacity of PTFE can hinder optical detection methods commonly employed in microfluidic devices, necessitating the development of alternative detection strategies or the use of transparent PTFE derivatives.

As the field of microfluidics continues to evolve, addressing these challenges associated with PTFE usage becomes increasingly important. Researchers and engineers are actively exploring novel fabrication techniques, surface modification methods, and hybrid material approaches to harness the full potential of PTFE in enhancing microfluidic devices. The ongoing efforts to overcome these obstacles promise to unlock new possibilities in the design and functionality of next-generation microfluidic systems.

Existing PTFE Integration Methods for Microfluidics

01 PTFE modification techniques

Various methods are employed to enhance PTFE properties, including chemical modification, surface treatment, and blending with other materials. These techniques aim to improve characteristics such as adhesion, wear resistance, and thermal stability while maintaining PTFE's inherent properties like low friction and chemical inertness.- Surface modification of PTFE: Various techniques are employed to modify the surface of PTFE, enhancing its properties such as adhesion, wettability, and compatibility with other materials. These methods include plasma treatment, chemical etching, and grafting of functional groups onto the PTFE surface. Such modifications can improve the material's performance in applications like coatings, composites, and membranes.

- PTFE nanocomposites: Incorporating nanoparticles or nanofibers into PTFE matrices creates nanocomposites with enhanced mechanical, thermal, and electrical properties. These nanocomposites can exhibit improved wear resistance, thermal conductivity, and dielectric strength compared to pure PTFE. Common nanofillers include carbon nanotubes, graphene, and metal oxide nanoparticles.

- PTFE processing techniques: Advanced processing techniques are developed to enhance the manufacturability and performance of PTFE products. These include improved sintering methods, extrusion processes, and molding techniques. Such advancements allow for the production of PTFE components with more complex geometries, better dimensional stability, and enhanced mechanical properties.

- PTFE blends and alloys: Blending PTFE with other polymers or creating alloys can result in materials with a combination of desirable properties. These blends can offer improved mechanical strength, chemical resistance, or processability while maintaining some of PTFE's unique characteristics like low friction and non-stick properties. Common blend partners include thermoplastics and other fluoropolymers.

- Functionalized PTFE: Chemical modification of PTFE to introduce functional groups can significantly alter its properties and expand its applications. Functionalization can improve the material's compatibility with other substances, enhance its reactivity, or introduce specific properties like antimicrobial activity. This approach enables the use of PTFE in new areas such as biomedical applications and advanced filtration systems.

02 PTFE composite materials

PTFE is combined with other materials to create composite structures with enhanced properties. These composites may incorporate fillers, reinforcing agents, or other polymers to improve mechanical strength, thermal conductivity, or electrical properties while retaining PTFE's beneficial characteristics.Expand Specific Solutions03 PTFE processing and manufacturing innovations

Advanced processing and manufacturing techniques are developed to enhance PTFE products. These may include novel extrusion methods, sintering processes, or molding techniques that improve the material's performance, consistency, or allow for the creation of complex shapes and structures.Expand Specific Solutions04 PTFE surface treatments

Various surface treatment methods are applied to PTFE to enhance its properties for specific applications. These treatments may include plasma treatment, chemical etching, or coating processes that modify the surface characteristics of PTFE, improving its adhesion, wettability, or compatibility with other materials.Expand Specific Solutions05 PTFE nanocomposites and nanotechnology applications

PTFE is incorporated into nanocomposite materials or modified at the nanoscale to achieve enhanced properties. This may involve the use of nanoparticles, nanofibers, or other nanostructures to improve the material's mechanical, thermal, or electrical properties while maintaining its desirable characteristics.Expand Specific Solutions

Key Players in PTFE Microfluidic Device Industry

The microfluidic device market utilizing PTFE is in a growth phase, driven by increasing demand in healthcare, biotechnology, and chemical industries. The global market size for microfluidic devices is projected to reach several billion dollars by 2025. While PTFE technology for microfluidics is relatively mature, ongoing research focuses on enhancing its performance and expanding applications. Key players like DuPont, W. L. Gore & Associates, and Daikin Industries are leading innovation in PTFE-based microfluidic solutions, with academic institutions such as Zhejiang University and Johns Hopkins University contributing to fundamental research. Companies like Medtronic and Boston Scientific are leveraging PTFE in medical microfluidic devices, indicating the technology's growing importance in healthcare applications.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced PTFE-based materials for microfluidic applications, focusing on enhancing surface properties and chemical resistance. Their Teflon AF fluoropolymer offers exceptional optical clarity and low refractive index, making it ideal for microfluidic devices requiring precise optical measurements[1]. DuPont's PTFE formulations incorporate nanoscale additives to improve wettability and reduce protein adsorption, crucial for biomedical microfluidics[2]. They have also introduced a plasma treatment process that modifies PTFE surface chemistry, allowing for better adhesion and bonding in multi-layer microfluidic devices[3]. DuPont's recent innovations include PTFE-based composites with enhanced thermal conductivity, addressing heat management issues in high-throughput microfluidic systems[4].

Strengths: Unparalleled expertise in fluoropolymer chemistry, extensive R&D capabilities, and a wide range of PTFE formulations tailored for specific microfluidic applications. Weaknesses: Higher cost compared to some alternative materials, and potential environmental concerns associated with fluoropolymer production.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has leveraged its expertise in expanded PTFE (ePTFE) to develop innovative solutions for microfluidic devices. Their ePTFE membranes offer unique properties such as high porosity, controlled pore size, and excellent chemical resistance[5]. Gore has introduced a line of ePTFE-based microfluidic components, including ultra-thin membranes for gas-liquid contactors and particle filtration in lab-on-a-chip devices[6]. They have also developed a proprietary surface modification technique that enhances the hydrophilicity of ePTFE, improving fluid flow and reducing bubble formation in microchannels[7]. Gore's recent advancements include the integration of ePTFE membranes with other materials to create hybrid microfluidic structures with tailored properties for specific applications, such as organ-on-a-chip platforms[8].

Strengths: Unique ePTFE technology offering high porosity and customizable properties, strong focus on microfluidic applications, and extensive experience in medical device industry. Weaknesses: Limited to ePTFE-based solutions, which may not be suitable for all microfluidic applications, and potentially higher production costs.

Innovative PTFE Surface Modification Techniques

Surface modified expanded polytetrafluoroethylene devices and methods of producing the same

PatentInactiveUS20090258960A1

Innovation

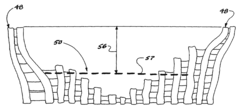

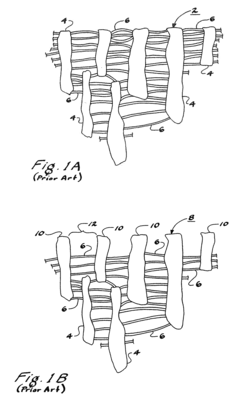

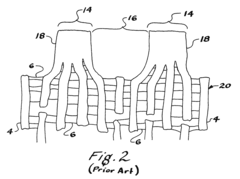

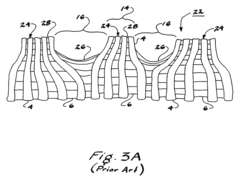

- A process using an unfocused laser beam to alter and remove selected PTFE fibrils and nodes, creating a ridge and valley texture with clustered nodes supported by shortened fibrils for porosity and stiffness, and gnarled nodes in valleys that contribute to surface roughness without compromising porosity.

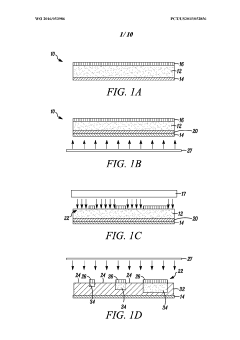

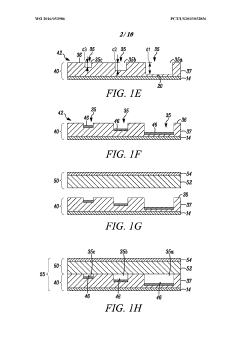

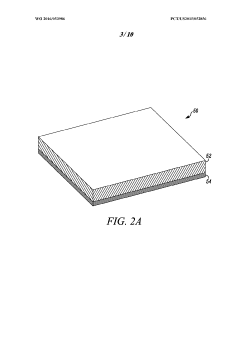

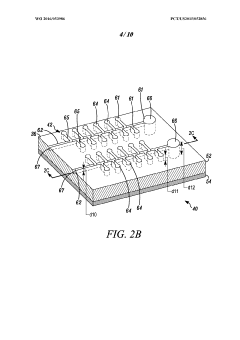

A microfluidic device and a method for preparing the microfluidic device from a photosensitive element

PatentWO2016053986A1

Innovation

- A method using a photosensitive element with a photopolymerizable composition that is imagewise exposed to actinic radiation to form microfluidic devices without the need for a mold, allowing for direct imaging and creation of microstructures with varying depths and widths, enabling high-volume production and degas-driven flow.

Environmental Impact of PTFE in Microfluidic Devices

The environmental impact of PTFE in microfluidic devices is a critical consideration as the technology continues to advance. PTFE, or polytetrafluoroethylene, is widely used in microfluidic applications due to its excellent chemical resistance, low surface energy, and non-stick properties. However, its production and disposal pose significant environmental challenges.

The manufacturing process of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. Although efforts have been made to phase out PFOA, concerns remain about the environmental persistence of PTFE and its potential to release microplastics. In microfluidic devices, the small scale of PTFE components exacerbates these issues, as they are more likely to degrade and release particles into the environment.

When PTFE-based microfluidic devices reach the end of their lifecycle, proper disposal becomes crucial. The material's resistance to degradation means it can persist in landfills for extended periods. Incineration of PTFE can release harmful fluorine compounds, contributing to air pollution and potentially affecting the ozone layer. Recycling PTFE from microfluidic devices presents challenges due to contamination and the small quantities involved.

Despite these concerns, the use of PTFE in microfluidic devices offers environmental benefits. The material's durability extends the lifespan of devices, reducing the frequency of replacement and associated waste. Additionally, the precision and efficiency of PTFE-enhanced microfluidic devices can lead to reduced reagent consumption and waste generation in various applications, from medical diagnostics to environmental monitoring.

Researchers are exploring alternatives to mitigate the environmental impact of PTFE in microfluidics. Bio-based fluoropolymers and surface modification techniques are being developed to reduce reliance on traditional PTFE. These innovations aim to maintain the beneficial properties of PTFE while minimizing its environmental footprint.

The scientific community is also focusing on improving end-of-life management for PTFE-containing microfluidic devices. Advanced recycling technologies and design-for-disassembly approaches are being investigated to facilitate the recovery and reuse of PTFE components. Furthermore, life cycle assessments are increasingly being conducted to quantify the environmental impact of PTFE in microfluidic applications, guiding more sustainable design and material choices.

As the field of microfluidics continues to evolve, balancing the performance benefits of PTFE with its environmental implications remains a key challenge. Future developments in this area will likely focus on creating more sustainable alternatives and improving the overall environmental profile of microfluidic technologies.

The manufacturing process of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. Although efforts have been made to phase out PFOA, concerns remain about the environmental persistence of PTFE and its potential to release microplastics. In microfluidic devices, the small scale of PTFE components exacerbates these issues, as they are more likely to degrade and release particles into the environment.

When PTFE-based microfluidic devices reach the end of their lifecycle, proper disposal becomes crucial. The material's resistance to degradation means it can persist in landfills for extended periods. Incineration of PTFE can release harmful fluorine compounds, contributing to air pollution and potentially affecting the ozone layer. Recycling PTFE from microfluidic devices presents challenges due to contamination and the small quantities involved.

Despite these concerns, the use of PTFE in microfluidic devices offers environmental benefits. The material's durability extends the lifespan of devices, reducing the frequency of replacement and associated waste. Additionally, the precision and efficiency of PTFE-enhanced microfluidic devices can lead to reduced reagent consumption and waste generation in various applications, from medical diagnostics to environmental monitoring.

Researchers are exploring alternatives to mitigate the environmental impact of PTFE in microfluidics. Bio-based fluoropolymers and surface modification techniques are being developed to reduce reliance on traditional PTFE. These innovations aim to maintain the beneficial properties of PTFE while minimizing its environmental footprint.

The scientific community is also focusing on improving end-of-life management for PTFE-containing microfluidic devices. Advanced recycling technologies and design-for-disassembly approaches are being investigated to facilitate the recovery and reuse of PTFE components. Furthermore, life cycle assessments are increasingly being conducted to quantify the environmental impact of PTFE in microfluidic applications, guiding more sustainable design and material choices.

As the field of microfluidics continues to evolve, balancing the performance benefits of PTFE with its environmental implications remains a key challenge. Future developments in this area will likely focus on creating more sustainable alternatives and improving the overall environmental profile of microfluidic technologies.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for harnessing PTFE in enhanced microfluidic devices are crucial factors that significantly impact the widespread adoption and commercial viability of this technology. PTFE, known for its excellent chemical resistance and non-stick properties, presents unique challenges and opportunities in the manufacturing process of microfluidic devices.

One of the primary considerations is the development of efficient and cost-effective methods for patterning PTFE at the microscale. Traditional photolithography techniques used in microfluidic device fabrication are not directly applicable to PTFE due to its chemical inertness. However, recent advancements in laser ablation and plasma etching have shown promise in creating precise microstructures in PTFE substrates. These techniques offer the potential for scalable manufacturing processes, but further optimization is required to improve throughput and reduce production costs.

Another critical aspect is the integration of PTFE components with other materials commonly used in microfluidic devices, such as glass or silicon. Bonding PTFE to these materials presents challenges due to its low surface energy. Researchers have explored various approaches, including surface modification techniques and the use of intermediate adhesive layers, to achieve reliable and leak-free bonding. The development of standardized and reproducible bonding protocols is essential for scaling up production and ensuring consistent device performance.

The thermal properties of PTFE also play a significant role in manufacturing considerations. While its high melting point (327°C) provides stability in many applications, it can complicate thermal bonding processes commonly used in microfluidic device assembly. Alternative bonding methods, such as mechanical clamping or the use of specialized adhesives, need to be explored and optimized for large-scale production.

Addressing the challenge of feature resolution is crucial for advancing PTFE-based microfluidic devices. Current manufacturing techniques can achieve feature sizes down to tens of micrometers, but further improvements are needed to match the resolution capabilities of traditional materials like PDMS. Innovations in nanoimprint lithography and advanced etching techniques show potential for creating sub-micron features in PTFE, which could expand its applications in nanofluidic devices.

The recyclability and environmental impact of PTFE-based microfluidic devices must also be considered in the context of scalable manufacturing. While PTFE is highly durable and chemically resistant, these properties also make it challenging to recycle. Developing eco-friendly manufacturing processes and exploring potential recycling methods for PTFE microfluidic devices will be essential for sustainable large-scale production.

One of the primary considerations is the development of efficient and cost-effective methods for patterning PTFE at the microscale. Traditional photolithography techniques used in microfluidic device fabrication are not directly applicable to PTFE due to its chemical inertness. However, recent advancements in laser ablation and plasma etching have shown promise in creating precise microstructures in PTFE substrates. These techniques offer the potential for scalable manufacturing processes, but further optimization is required to improve throughput and reduce production costs.

Another critical aspect is the integration of PTFE components with other materials commonly used in microfluidic devices, such as glass or silicon. Bonding PTFE to these materials presents challenges due to its low surface energy. Researchers have explored various approaches, including surface modification techniques and the use of intermediate adhesive layers, to achieve reliable and leak-free bonding. The development of standardized and reproducible bonding protocols is essential for scaling up production and ensuring consistent device performance.

The thermal properties of PTFE also play a significant role in manufacturing considerations. While its high melting point (327°C) provides stability in many applications, it can complicate thermal bonding processes commonly used in microfluidic device assembly. Alternative bonding methods, such as mechanical clamping or the use of specialized adhesives, need to be explored and optimized for large-scale production.

Addressing the challenge of feature resolution is crucial for advancing PTFE-based microfluidic devices. Current manufacturing techniques can achieve feature sizes down to tens of micrometers, but further improvements are needed to match the resolution capabilities of traditional materials like PDMS. Innovations in nanoimprint lithography and advanced etching techniques show potential for creating sub-micron features in PTFE, which could expand its applications in nanofluidic devices.

The recyclability and environmental impact of PTFE-based microfluidic devices must also be considered in the context of scalable manufacturing. While PTFE is highly durable and chemically resistant, these properties also make it challenging to recycle. Developing eco-friendly manufacturing processes and exploring potential recycling methods for PTFE microfluidic devices will be essential for sustainable large-scale production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!